See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

API LAUNCHES RANGE OF PLASTIC-FREE HOLOGRAPHIC LAMINATES API Group has enhanced its range of Transmet™ products with the launch of new holographic designs. The range of 12 hologr...

January 15 2019

API LAUNCHES RANGE OF PLASTIC-FREE HOLOGRAPHIC LAMINATES

API Group has enhanced its range of Transmet™ products with the launch of new holographic designs. The range of 12 holographic patterns are available in API’s Transmet laminate, a plastic-free option for paperboard packaging, ensuring brand owners and designers have a sustainable packaging option without compromising on aesthetics.

Transmet has all the benefits of traditional metalised polyester cartonboard laminates, but without the film content, allowing it to be fully recycled through normal waste streams. The new Transmet holographic designs will allow brands to retain their stand-out shelf appeal, while also reducing their environmental impact.

Richard Burhouse, Marketing Director at API, said: “Over the last couple of years, we have experienced an uptake in demand for our Transmet plastic-free laminates as brands look for environmentally-friendly alternatives to create a fully recyclable end product.“It is more important than ever that we provide innovative solutions that consider both sustainability and shelf appeal. In an increasingly competitive retail environment, holographic and diffractive patterns can be used as an effective and eye-catching way for brands to strengthen their differentiation on shelf, delivering luxury effects that create a unique on-shelf identity. Our new holographic patterns will give brand owners and designers a wider variety of options to add visual impact to their product’s packaging and elevate brands to the next level.”

API Group has invested heavily in its Livingston plant in Scotland, consolidating its film, holographics and foil production under one roof to create a European technical centre of excellence.

Richard added: “As pioneers of Transmet, we like to push the boundaries and having brought together our films, foils and holographics expertise into one place, our customers are now able to enjoy the benefits of this effort. With unrivalled technology, industry experience and capacity, we are fully committed to continued development of packaging enhancement solutions that provide stand-out shelf appeal while being better for the environment.”

The designs will be available immediately and can be used across all approved board types.

Azon Matrix R Industrial Platform Now with Ricoh Gen5 Print Heads for More Productivity Azonprinter, a worldwide manufacturer of digital inkjet solutions takes a new direction with its...

January 15 2019

Azon Matrix R Industrial Platform Now with Ricoh Gen5 Print Heads for More Productivity

Azonprinter, a worldwide manufacturer of digital inkjet solutions takes a new direction with its Azon Matrix industrial solutions and welcomes new addition, Azon Matrix R platform based on Ricoh Gen5 print heads.

Azon Matrix R industrial series offers flat-bad UV-LED inkjet printing solutions with optional bed sizes of 800 mm x 1600 mm / 1600 mm x 2500/3200 mm. Azon Matrix R platform will be able to print on to substrates up to 25cm in height and is capable of handling heavy materials up to 100 kg for indoor, outdoor and industrial applications. Azon Matrix R series extends productivity and creativity by printing directly onto any type of material such as ABS, polycarbonate, TPU, PVC, wood, stone, glass, canvas, ceramic, aluminium and additionally covering ADA and Braille 3D printing and print on cylindrical objects. The latest version of the print head comes with 4 channels and 4 colours due to its 4-row construction choice with 1200 nozzles per colour and full greyscale which enables printing speeds up to 25,8 sqm/hr. Designed for 100 billion actuations per nozzle, the Gen5 is designed to last.

Along with new Gen5 print heads, full-featured Azon RIP software and flex, Phthalate free ink with EN 71-3 certificate ensures quality print and safe use on various applications coming from children furniture and toy industry and in overall the lowest running ink cost per 1sqm. The versatility of white ink as a base for high-density CMYK layer delivers unusual and creative textures on all materials. Azon Matrix R series supports sign makers, printing houses, commercial customers, gift stores, photographers and enters new business areas with a diversified approach for future market demands in home décor, interior design, graphics industry and in overall to all industrial applications.

Caldera Software Company announces a Management Change Caldera, an industry leader in the RIP software market, announces the departure of Joseph Mergui, founder and president.

January 15 2019

Caldera Software Company announces a Management Change

Caldera, an industry leader in the RIP software market, announces the departure of Joseph Mergui, founder and president.

After having grown Caldera into a very successful company and gained international recognition, Joseph Mergui has decided to entrust Dover Digital Printing with taking Caldera to new growth levels and transforming the company from a ‘family-owned’ operation to a multinational company.

As a market leader in digital inkjet software, Caldera will continue to invest in innovative technology, and meet the expectations of an expanding customer base.

Samin Sarkar will serve as General Manager of the company, supported by a dynamic and experienced management team.

“It has been a privilege to lead and grow Caldera for 28 years and a pleasure to have worked with an extremely strong, talented and dedicated team. I have no doubt on the fact that Caldera will continue growing and being a key player in the digital printing market. I personally have decided to move on to pursue new projects,” Joseph Mergui - Founder, Caldera.

CHROMALUXE EXTERIOR NOW AVAILABLE FROM GJS GJS today announced the availability of new, high-definition ChromaLuxe aluminium dye sublimation products that are suitable for exterior use...

January 15 2019

CHROMALUXE EXTERIOR NOW AVAILABLE FROM GJS

GJS today announced the availability of new, high-definition ChromaLuxe aluminium dye sublimation products that are suitable for exterior use. These new products give digital decorators and creators the ability to produce dye sublimation designs and products that can be used outdoors and in direct sunlight for the first time.

The new UV-resistant gloss finish provides the same dynamic image quality as traditional ChromaLuxe panels, is equally easy to clean and resistant to graffiti, scratches and chemicals.

“A previous limitation of dye sublimation was the inability to create and use designs outside and especially in direct sunlight,” said Greg Stone, Managing Director, GJS. “These new panels and products from ChromaLuxe solve this problem and have the potential to open up entire new markets for the dye sublimation market.

While photo reproduction is a favourite application, ChromaLuxe exterior products can also be used for branded logo work, directional and informational signage, wayfinding signs, menu boards, cabinetry, wall coverings and many more applications including:

Hotels

Printers can now create vibrant wall décor for hotels that is multi-functional, serving as an outdoor option or indoors into direct sunlight. Perfect for open lobbies and entryways, or outdoor restaurants and gathering spaces.

Corporate settings

ChromaLuxe exterior is perfect for corporate branding, works of art or inspiring photography inside and outside the office setting. Completely customisable, add logos to vibrant imagery or simply display high-quality wall décor anywhere in the office.

High-end retail

With a sleek and modern look, create stunning branded environments that can be displayed either outdoors or directly in windows and that match a brand’s luxury and exclusivity.

Directional/wayfinding

Thanks to its extreme durability, ChromaLuxe exterior products can be used for directional signage that will hold up to wind, weather and other elements. Thoroughly tested for fade, abrasion and impact resistance, the print surface stands up to the most exacting environmental conditions.

Display/POP

In addition to exceptional image quality, ChromaLuxe exterior is also a perfect fit for point-of-purchase and display messaging including outdoor restaurants, cafes and other businesses.

“We’ve already seen some incredible examples of the versatility of this product around the globe, so we’re excited to see what our customers will create with it,” Greg added.

ChromaLuxe exterior products are available now from GJS in a variety of sizes to serve the signage, display and outdoor photography markets.

Heidelberg Assistant celebrates first anniversary with over 700 users One year from its launch, the Heidelberg Assistant customer portal is now in operation at over 400 print shops wit...

January 15 2019

Heidelberg Assistant celebrates first anniversary with over 700 users

One year from its launch, the Heidelberg Assistant customer portal is now in operation at over 400 print shops with over 700 users – and has just won the 2019 Digital Edge 50 Award in the United States. The platform is currently being rolled out in Japan, Poland and Austria. The OEM’s new digital customer communication platform was launched as a pilot in Canada, the United States, Germany and Switzerland in January of 2018.

The Heidelberg Assistant digitisation solution paves the way for creating and ensuring the smooth operation of a company’s new digital business models. Customers benefit from a transparent process workflow together with smart and efficient print-shop operation. Each user has personal access to the customer portal and obtains an overview of his or her print shop’s service and maintenance status – including helpful data-driven ‘failure predictions.’ Users also benefit from “access to the sector’s largest knowledge database.” In addition, they can access big-data performance analyses that can also boosting productivity. Heidelberg is currently using the technology for further market scaling of its existing big-data applications, such as Predictive Monitoring and Performance Consulting.

“Digitisation is becoming increasingly important at a great many print shops, and our customers appreciate the digital service portfolio we offer them 24/7 with Heidelberg Assistant,” said Professor Ulrich Hermann, Member of the Management Board and Chief Digital Officer at Heidelberg. “Designed as an open digital platform, it’s used by customers of all sizes and from all segments with their own personal Heidelberg ID.” User feedback is equally positive. Jeff Taylor, Senior Vice President of Manufacturing at Hemlock Printers in Vancouver added: “This is exactly the data and information we need to manage production efficiently.”

To coincide with the first anniversary of its market launch, Heidelberg Assistant has won a 2019 Digital Edge 50 Award from the U.S.-based International Data Group (IDG), a world-leading supplier of technology media and data/marketing services. The award is a sought-after accolade that goes to 50 organisations each year for digital innovations that improve business success, modernise operations and enhance the customer experience. “Winning a 2019 Digital Edge 50 Award underlines that we have our finger on the pulse with the Heidelberg Assistant, and have assumed a leading industry role in digitising customer communications,” Hermann added.

Kornit Digital launches the Atlas, the super-industrial, next-generation direct-to-garment printing platform Kornit Digital, a global market leader in digital textile printing innovati...

January 15 2019

Kornit Digital launches the Atlas, the super-industrial, next-generation direct-to-garment printing platform

Kornit Digital, a global market leader in digital textile printing innovation, has announced the introduction of the Kornit Atlas. Following the success of Kornit’s Storm HD6 and Avalanche HD6 / HDK, the Atlas is the first instance of the company’s next-generation direct-to-garment printing platform, providing garment decorators and screen printers a unique tool for mastering the current and future challenges of the textile supply chain.

The Kornit Atlas is a heavy-duty system created for super-industrial garment decoration businesses. It was designed to deliver a typical annual production capacity of up to 350,000 impressions, optimising production efficiency and cost of ownership. The Kornit Atlas is aimed at highly productive garment decorators, mid to large size screen printers and innovative businesses looking to combine state-of-the art technology with lowest cost of ownership. The system is equipped with new recirculating print heads and comes with a newly developed ink, NeoPigment Eco-Rapid. The Kornit Atlas is equipped with a unique printing engine, featuring an enhanced version of Kornit’s HD technology, complemented by a professional RIP (raster image processing) software solution, and produces prints that meet the highest standards of retail quality and durability. The all-new Atlas comes ready for Kornit’s future releases of its cloud-based business intelligence, productivity analytics and optimisation software platforms, scheduled to be released in the second half of 2019. It will allow for easy future network connectivity required to support fleet management and optimisation of global multi-systems and multi-site enterprises.

Omer Kulka, Kornit’s VP of Marketing and Product Strategy, comments, “This is a huge leap forward, not only for Kornit, but also for the direct-to-garment industry as a whole. We have delivered the Atlas on the collective feedback of thousands of Kornit systems’ operators and on the experience collected from hundreds of millions of printed garments – simply put, the Atlas is the best and most cost-efficient direct-to-garment printing technology for high-quantity and high-quality production requirements. On top of that, the Atlas has been designed in a modular and future-ready way, driving quick and easy implementation of new developments in the future. At Kornit, we remain focused on constantly introducing technology that allows the industry's leading brands to better connect with their customers and to adapt to the rapid changes in consumer preferences, impacting the fashion and apparel industry and is driven by the talent in our global research and development division.”

The new NeoPigment Eco-Rapid ink is a main driver of the Atlas’ retail quality prints. It provides an industry-leading white ink opacity, matched to those of conventional screen inks, and meets highest durability standards on multiple fabric types. Its increased colour gamut and saturation allow for deep full tones and precise spot colour matching. The new ink has been developed with sustainability in mind, carries the Oeko-Tex Eco-Passport certification and is GOTS pre-approved. The new Eco-Rapid ink will be integrated with new Storm HD6 and Avalanche HD6/HDK systems and will also be retrofitted to existing Kornit HD systems. Kornit intends to switch all existing HD customers to NeoPigment Eco-Rapid during the year 2019.

The launch of the Atlas completes an extensive period of beta testing, with extremely positive feedback from early adopters. Deborah H. Merrill, President of the Delta Group, parent company of DTG2Go, comments, “Many of the Kornit Atlas’ innovative capabilities, including the wrinkle detection and pallet ergonomics, present clear productivity benefits. The new Eco-Rapid ink provides impressive brilliance and colour gamut, meeting all wash test standards with no discernible scent. We are glad we had the opportunity to beta-test the Kornit Atlas and are certain it will become a key component within DTG2Go’s production line.”

Jon Lunt, Co-Founder and Director at T Shirt & Sons, adds, “Using the Atlas, T Shirt and Sons achieved a significant boost in garment decoration production through the peak holiday season. In several weeks of rigorous testing in a high-volume production environment, the Kornit Atlas – with its new Eco-Rapid ink set – was a revelation, doubling our output with very high-quality prints and the reliability this high-pressure season demanded.”

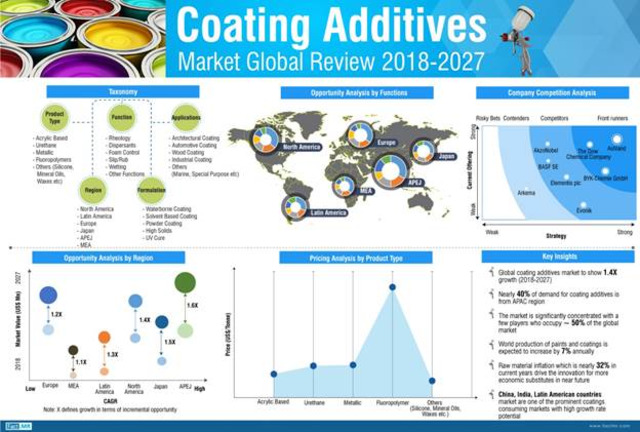

Skyrocketing demand from a multitude of industries, ranging from architecture to automotive, is a key factor fuelling coating additives sales. According to the study, growing focus on quality is dr...

January 15 2019

Skyrocketing demand from a multitude of industries, ranging from architecture to automotive, is a key factor fuelling coating additives sales. According to the study, growing focus on quality is driving demand for coating additives in manufacturing processes. These insights are according to a latest Fact.MR study that projects a bullish run for coating additives market. According to the study, demand for coating additives is likely to reach 1.37 Mn tons by 2019-end, up from 1.35 Mn tons in 2018.

Acrylic Based Coating Retains its Buoyancy Owing to Performance-driven Requirements

As per the report, acrylic based coating additives will remain the top-selling product type. The popularity of acrylic based coating additive can be accredited to its competency in enhancing product properties and optimising production processes. Urethane and fluoropolymer are the other top-selling additive types.

Demand for rheology coating additives is likely to reach 449,000 tons in 2018. With the rising demand for low-VOC or VOC-free waterborne coating systems, the rheological additives are witnessing revved up adoption. Dispersant additives trail the former as the second most preferred function type and offering prime opportunities for the market players to take into consideration.

The waterborne coating remains the highly sought-after formulation, followed by solvent based coating and powder coating. Waterborne coatings are being increasingly sought on the back of their competency to offer great resistance to heat as well as abrasion. Moreover, architectural coatings maintain their lead as the largest application segment and the booming number of infrastructure-related projects extrapolate the same.

“Robust demand for coatings is poised to be registered from the architectural and industrial applications over the upcoming years. This, in turn, will translate into a significant surge in demand for additives in terms of performance enhancement requirements”, says, research consultant Pratik Kumar from, Fact.MR

The thriving commercial and residential construction activities in Asia-Pacific have been spurring the sales of coating additives, making it the most remunerative region for the market stakeholders from an investment-making standpoint. The flourishing automotive sector in the region is also triggering the clamour for high-performance coating additives, finds the Fact.MR study.

Coating Additives Market Remains a Consolidated Landscape

The report also indicates that innovative products such as multifunctional additives, silicone based additives, and green coating additives are expected to witness a spike in demand, giving a major boost to the overall growth of coating additives market. According to the research study, product developments and technological innovations remain the key facets boosting the bottom lines of companies operating in the market space. Moreover, moderate pricing and diverse product portfolio are anticipated to be the major factors driving the industry over the foreseeable future.

The study envisages, the coating additives market remains a consolidated landscape and portrays the reign of leading players with strong product portfolios. The tier 1 players in the coating additives market have been identified to hold approximately 45-50% revenue share and remain highly focused on go-to market strategies aimed for reaching out to the customer segments in a much more efficient manner.

Tier 2 players are focused on development of unique and exclusive products and commercialisation of the same at competitive price points to gain substantial revenue benefits. The market players falling into the tier 3 category are shifting their focus toward strategic alliances and partnerships with leading industry giants for affluent expansion. In addition to that, long-term contracts with the domestic manufacturers or suppliers have also been identified to be a key differential move to tackle volatile pricing as well as uninterrupted supply.

As per the report, the coating additives market is poised to expand at a volume CAGR of more than 3.5% over the forecast period, 2018-2027.

The insights presented here are from a research study on www.factmr.com/report/2427/coating-additives-market

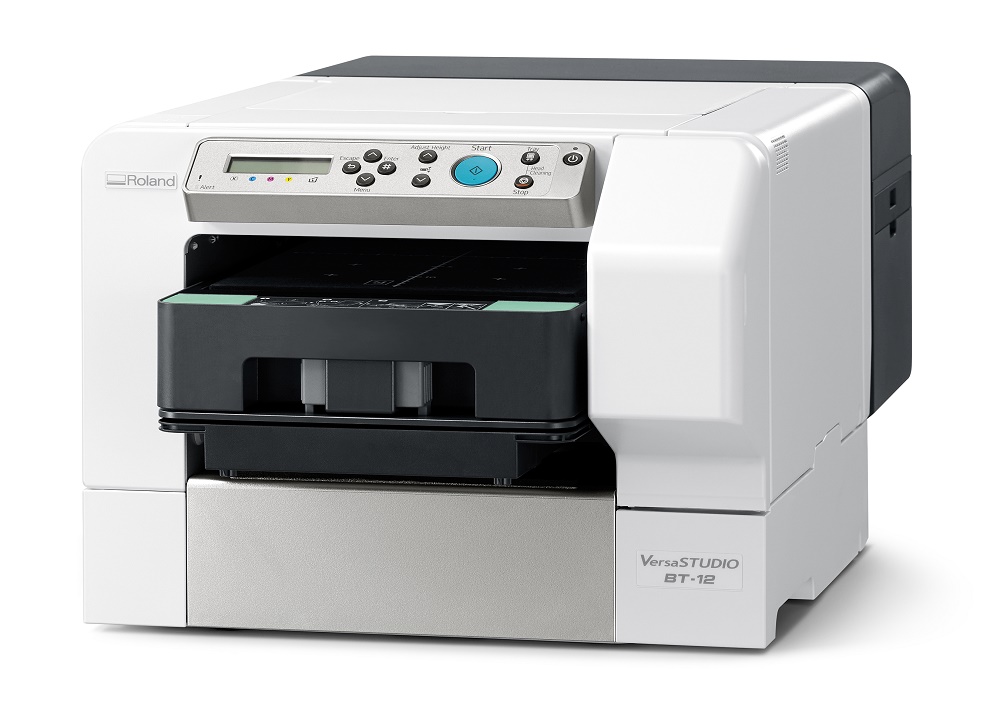

Roland DG Announces First Direct-To-Garment Printer for On-Demand Personalisation Roland DG Corporation, a leading manufacturer of wide format inkjet printers and 3D devices worldwide,...

January 15 2019

Roland DG Announces First Direct-To-Garment Printer for On-Demand Personalisation

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and 3D devices worldwide, today announced the launch of the VersaSTUDIO BT-12 desktop direct-to-garment printer for printing directly on cotton-based products. Built for on-demand personalisation, the BT-12 is ideal for businesses looking for new revenue opportunities by offering an engaging in-store experience for their customers.

According to Etsuo Harada, Division President of COTO Business Division for Roland DG, since the introduction of VersaCAMM SP-300 in 2003, Roland DG inkjet printers have increasingly been used in the production of custom apparel and fabric goods. “More recently,” Harada said, “in-store personalisation services for printing customer designs have grown rapidly. To meet this demand, the COTO Business Division developed the new DTG printer.”

The BT-12 is an easy-to-use A4 size printer that allows printing directly on cotton* substrates. You can print full colour graphics including photos, logos and text on a variety of products, such as t-shirts, tote bags and interior decoration items. Its compact size and affordable pricing allow businesses to offer personalisation services with a low initial investment and in locations where space is limited, including shopping malls, kiosks, apparel stores, hotel gift shops and tourist destinations, or even at events.

* Fabric must be 50~100% cotton.

When combined with cotodesign, an optional design and print management software that can be purchased separately, the BT-12 can become a complete design, order and print management solution to open new business opportunities and increase foot traffic at retail locations. cotodesign also supports* additional Roland DG devices, allowing businesses to use it for a wide variety of applications and events.

* cotodesign supports VersaSTUDIO BN-20, VersaUV LEF Series and LD-80 Laser Foil Decorator.

Harada said that the BT-12 is affordably priced, allowing businesses to explore new opportunities with very low initial investment. Capable of producing a product from start to finish in as little as 10 minutes, the BT-12 is designed for ultimate ease of use and can be operated by virtually anyone with minimal training. Cassettes are used for holding the items for printing and finishing, ensuring the safety of operators and customers.

With dimensions of 399mm (W) ×760mm (D), the printer unit requires very little space. The optional finishing equipment has been designed to be stacked with the printer unit. This dramatically reduces the installation space that is typically required for a traditional direct-to-garment printer and finishing unit combination so that businesses can install the BT-12 in small spaces at retail locations and event venues.

The BT-12 is bundled with easy-to-use Roland Design Software. With an intuitive user interface, anyone can create unique designs with minimal training. In addition to the BT-12, the optional cotodesign software also supports the VersaSTUDIO BN-20 Printer Cutter, the VersaUV LEF Series Printers, that are widely popular for the production of promotional and one-off personalised products, and the LD-80 Laser Foil Decorator. These solutions not only help to add value to merchandise, but also provide customers with a rewarding new shopping experience, that can help build store traffic as well as become a popular topic of conversation on social media.

“Consumer behaviour has been shifting from consumption to experience due to the diversification of consumer values,” Harada said. “As a result, businesses have an opportunity to offer high-value merchandise such as personalised products to meet customer needs and desires.”

“Our goal,” Harada continued, “is to provide our users with tools that help deliver a unique experience and quality time for their customers and to transform their imagination into reality.”

www.rolanddg.com.au/products/printers/versastudio-bt-12-direct-to-garment-printer

swissQprint has new roll to roll printer 'Karibu' coming Come May 2019, swissQprint will be presenting a dedicated roll to roll printer at Fespa in Munich. This promises to be an inter...

January 15 2019

swissQprint has new roll to roll printer 'Karibu' coming

Come May 2019, swissQprint will be presenting a dedicated roll to roll printer at Fespa in Munich. This promises to be an interesting addition to the high-end flatbed printers for which the Swiss manufacturer is already known.

"Another major milestone is on the horizon," says Reto Eicher, CEO of swissQprint, the developer and producer of large-format printers. swissQprint will present a dedicated roll to roll printer with unique features at Fespa 2019. "Our aim with this printer is to meet current trends and give users an efficient working tool," says Eicher.

Technical specifications for the new product will be announced when swissQprint unveils it at Fespa in May 2019. What is certain for now is that the UV roll to roll printer will bear the distinctive name "Karibu" and complement the existing swissQprint flatbed range. It will thus be in a position to round out the machinery pool at print service providers who strive for the optimum in order fulfilment.

swissQprint has been synonymous with high-quality flatbed printing for over eleven years. The market appreciates these Swiss products for their precision, reliability and durability, and also for the variety of applications they can handle. So, expect an impeccable pedigree for Karibu as well.

TECHKON, the innovation leader in high-precision colour measurement solutions for the global print and packaging communities – announces the launch of the New Generation SpectroPlate. The Tec...

January 15 2019

TECHKON, the innovation leader in high-precision colour measurement solutions for the global print and packaging communities – announces the launch of the New Generation SpectroPlate. The Techkon SpectroPlate is a high resolution digital microscope that measures dot percentage, screen angles, lines per inch/cm, dot gain and AM, FM or Hybrid Screens of traditional offset or process-less, chemistry-free printing plates.

The New Generation instrument boasts a unibody case that is precisely machined from a single block of aluminium to maximise durability and reliability in harsh production environments. It is also now equipped with a high-resolution anti-glare display and well as an improved user-interface.

The Techkon SpectroPlate has been a long-standing favourite among the top plate manufacturers due to its speed, accuracy, and reliability. The SpectroPlate is the latest Techkon instrument to be added to its New Generation line and now includes:

• Inductive charging

• New generation battery with up to 10X lifespan

• Micro USB port

• Charging on console and USB port

Techkon’s entire product line is recognised by leading industry organisations, and its products are positioned as the coluor quality tools of choice for printers around the world.

www.techkonusa.com

AstroNova GmbH is expanding its Product Identification portfolio with the new digital, toner-based colour QL-300 label printer with five colours, including QuickLabel's white. The QL-300 also print...

January 07 2019

AstroNova GmbH is expanding its Product Identification portfolio with the new digital, toner-based colour QL-300 label printer with five colours, including QuickLabel's white. The QL-300 also prints high-UV-resistant "no-label-look" labels.

According to the company, the introduction of the QL-300 proves AstroNova is prepared to meet changing market requirements. The QL-300 is the first 5-colour CMYKW tabletop printer for printing R2R (roll-to-roll processing), AstroNova says.

The printer's capability of printing five colours with 1200 dpi resolution, including white, is a game-changer. Printing in white allows direct printing on coloured materials, such as black polyester or silver paper. This feature also ensures excellent readability when printing bar codes, even on transparent materials. The high scratch resistance of the print result extends the use of the QL-300 in all areas that demand the highest requirements such as the the chemical, cosmetic and e-cigarette industries.

The electrophotography printing system of the toner-based label printer uses a printing process in which the print image is transferred directly from a computer to the QL-300 without the need of time-consuming preliminary work. The print's high resistance to oils, solvents, water and UV-rays on virtually all materials, makes the QL-300 a universal label printer perfect for all applications.

It can also print on various materials, from paper and metalised polyester to transparent materials. The transparent labels are more flexible and cost-effective compared to direct printing. Other effects for increasing customer motivation to buy a product are also possible such as bottle transparency.

The printer's high printing speed of up to 152 mm/s and printing widths of up to 126mm allow a wide variety of shapes and colour labels to be printed. The toner-based 5-coluor CMYKW printing system is also ideal for brand owners and packaging industry.

Durst, a manufacturer of advanced digital printing and production technologies, has entered into a 50/50 joint venture with printing press manufacturer Koenig & Bauer for the joint development ...

January 07 2019

Durst, a manufacturer of advanced digital printing and production technologies, has entered into a 50/50 joint venture with printing press manufacturer Koenig & Bauer for the joint development and marketing of single-pass digital printing systems for folding carton and cartonboard corrugated industry.

As technology leader in inkjet printing, Durst bundles this expertise with the market presence and excellent mechanical engineering of the Koenig & Bauer Group, which, with more than 5,700 employees, is one of the world's major suppliers of packaging and banknote printing.

In future, fully automated production lines will be developed in the joint venture and distributed worldwide. The digital transformation is also in the packaging industry, as the ever-changing requirements can no longer be met with conventional production technologies. Unlike in the graphics industry, an inkjet press alone is not enough, but there is a need to integrate different peripheral systems into a fully automatic production line. The new partner company will be based in Germany and will also manage the service and ink business in close cooperation with the global network of both companies.

“Durst and Koenig & Bauer is really a 'perfect match' because combining our strengths will drive digitalization in the packaging industry," said Christoph Gamper, CEO of Durst Group. "Both companies are similar in their culture and strategic direction, and both are technology leaders in their fields. With the partnership, we are even more strongly positioning ourselves as a high-end systems supplier to the industry."

Claus Bolza-Schünemann, CEO of Koenig & Bauer AG, said: "We look forward to the joint innovations and further development of future-oriented digital printing solutions for folding carton and corrugated board printing, which offer our customers added value. For folding carton printing, the modular concept of the VariJET enables the combination of digital inkjet printing with off-set printing and inline finishing options. Durst is the ideal partner for these goals because of its existing know-how and experience with inkjet and its high-quality solutions."

INX International Ink Co. has developed a solution for brand owners and food packaging providers looking for safe and sustainable alternatives with natural-based inks. INXhrc offers a number of adv...

January 07 2019

INX International Ink Co. has developed a solution for brand owners and food packaging providers looking for safe and sustainable alternatives with natural-based inks. INXhrc offers a number of advantages that reduce regulatory risk for brand owners and printers and improves production efficiencies for printers and converters.

INXhrc natural-based water, solvent and conventional offset inks have had a far-reaching impact on the food packaging marketplace since they use fewer chemicals compared to traditional inks. INXhrc contains no allergens, nanomaterials, flurochemicals, fanal pigments, heavy metals, latex or PTFE. By utilising clean, bio-renewable and sustainable ingredients, they have reduced CO2 emissions and annually replaced over two million pounds of petro-chemically derived resins, waxes and additives.

“INX International’s commitment to providing safe and sustainable product solutions can help printers and brand owners achieve sustainability goals, and consumers feel confident in their product choices,” says John Hrdlick, president of INX International. “We are keenly aware of the impact we can have on consumer safety, brand marketability and the environment throughout a product’s lifecycle. Our INXhrc inks provide a path to measurable, reportable CO2 savings and ultimately help brands tell a richer sustainability story.”

In addition to the sustainability advantages, the performance improvements of INXhrc has encouraged the adoption of this new technology in numerous pressrooms globally. When combined with high strength colour concentrates, INXhrc provides strong finished inks with excellent resolubility and transfer properties. Printers are seeing increased ink mileage and better production efficiency, leading to reduced resource consumption and waste generation.

HAVI presented an opportunity to align on the mutual recognition of the many benefits that could be derived from natural-based inks. Working together with INX, the company developed the right formula for the market with more sustainable packaging. Acknowledging a 25-to-30% lower CO2 footprint than conventional inks and reduced regulatory risk for brand owners and printers, the global, privately-owned company’s endorsement with INXhrc represents another aspect of the clean food movement and the principle of simplifying materials and chemistries for safer, more environmentally-friendly packaging.

“As a pioneer of clean packaging, HAVI is committed to not only improving the sustainability of food service packaging, but helping food service providers anticipate and stay ahead of consumer concerns about health and safety,” says Shane Bertsch, HAVI’s vice president, innovation. “Working with INX to bring natural-based inks to market has been a meaningful and insightful collaboration. Their expertise in ink formulation and printing have been critical to bringing this new product range to market. We look forward to further driving market innovation through our continued partnership.”

Nestlé has announced the creation of the Nestlé Institute of Packaging Sciences, dedicated to the discovery and development of functional, safe and environmentally friendly packaging ...

January 07 2019

Nestlé has announced the creation of the Nestlé Institute of Packaging Sciences, dedicated to the discovery and development of functional, safe and environmentally friendly packaging solutions. This is a step further to achieve the Company's commitment to make 100% of its packaging recyclable or reusable by 2025.

Nestlé CEO Mark Schneider said, "We want to be a leader in developing the most sustainable packaging solutions for our food and beverage products. To achieve this, we are enhancing our research capabilities to develop new packaging materials and solutions. Through this, we hope to address the growing packaging waste problem, in particular plastics. We aim to minimize our impact on the natural environment while safely delivering to our consumers healthier and tastier products."

The Nestlé Institute of Packaging Sciences, which is part of Nestlé's global research organization, will be located in Lausanne, Switzerland. It will employ around 50 people and include a state-of-the-art laboratory complex as well as facilities for rapid prototyping.

In close collaboration with the Company's global R&D network, academic partners, suppliers and start-ups, the institute will evaluate the safety and functionality of various sustainable packaging materials. Research focus areas will include recyclable, biodegradable or compostable polymers, functional paper, as well as new packaging concepts and technologies to increase the recyclability of plastic packaging. The new solutions will be tested in various product categories, before they are rolled out across Nestlé's global portfolio.

Nestlé Chief Technology Officer Stefan Palzer said, "Packaging plays a crucial role in helping us deliver safe and nutritious products to our consumers. The new Institute of Packaging Sciences will enable us to accelerate the redesign of our packaging solutions. Cutting-edge science as well as a close collaboration with globally leading academic institutions and industrial partners will deliver a pipeline of highly performing environmentally friendly packaging solutions."

Onyx Graphics, Inc., announced the global availability of ONYX 18.5 software, the latest version release of the company’s wide- and grand-format RIP software. ONYX 18.5 software ...

January 07 2019

Onyx Graphics, Inc., announced the global availability of ONYX 18.5 software, the latest version release of the company’s wide- and grand-format RIP software.

ONYX 18.5 software builds upon the award-winning ONYX 18 version, taking print production to the next level with the distinction of being the first wide-format RIP solution with Adobe PDF Print Engine 5.1 (APPE 5.1). With APPE 5.1, users benefit from the latest technological advancements for complete design-to-print workflows including high impact colour rendering, smoother edges for graphics, enhanced Unicode support; plus support for PDF 2.0 features such as black-point compensation, half-tone origin, special data for spot colours, and page-level output intent.

“ONYX 18.5 continues to lead the wide-format print industry with technological advancements that future-proof print service providers needing to differentiate themselves from their competition,” said Bryan Manwaring, Director of Product Marketing at Onyx Graphics.

“Helping our customers stay ahead of the curve as well as enabling them to take advantage of unrivalled RIP and production speeds are achievements that can greatly benefit their operations for years to come.”

ONYX 18.5 also introduces new Quick Set application library management for improved automation, enhanced iccMAX compatibility with support for third-party files and new spot colour tools for greater colour accuracy and vibrancy. Coupled with new ColorCheck reports,

ONYX 18.5 delivers industry-leading output that can literally be validated to print buyers.

Highlights of ONYX 18.5 include:

• APPE 5.1, the latest Adobe PDF Print Engine

• PDF 2.0 features including black-point compensation

• Unrivalled performance gains with 2X faster RIP speeds and 5X faster production speeds

• Added spot colour vibrancy with Relative Gamut Mapping chroma preservation

• QuickSet application library management to manage multiple QuickSets at the click of a button for securing data and getting to sellable prints faster

Availability

ONYX 18.5 software – covering the entire product portfolio of ONYX solutions including ONYX Thrive print workflow; and ONYX ProductionHouse, ONYX PosterShop, and ONYX RIPCentre RIP software – is now available to all ONYX Advantage customers by requesting a key update and to all other customers through a license purchase.

The ONYX Advantage subscription program gives ONYX software users a quick and easy way to keep their software current and secure their investment. Customers that are not ONYX Advantage subscribers should contact their local Authorised ONYX Reseller or visit onyxgfx.com for more information.

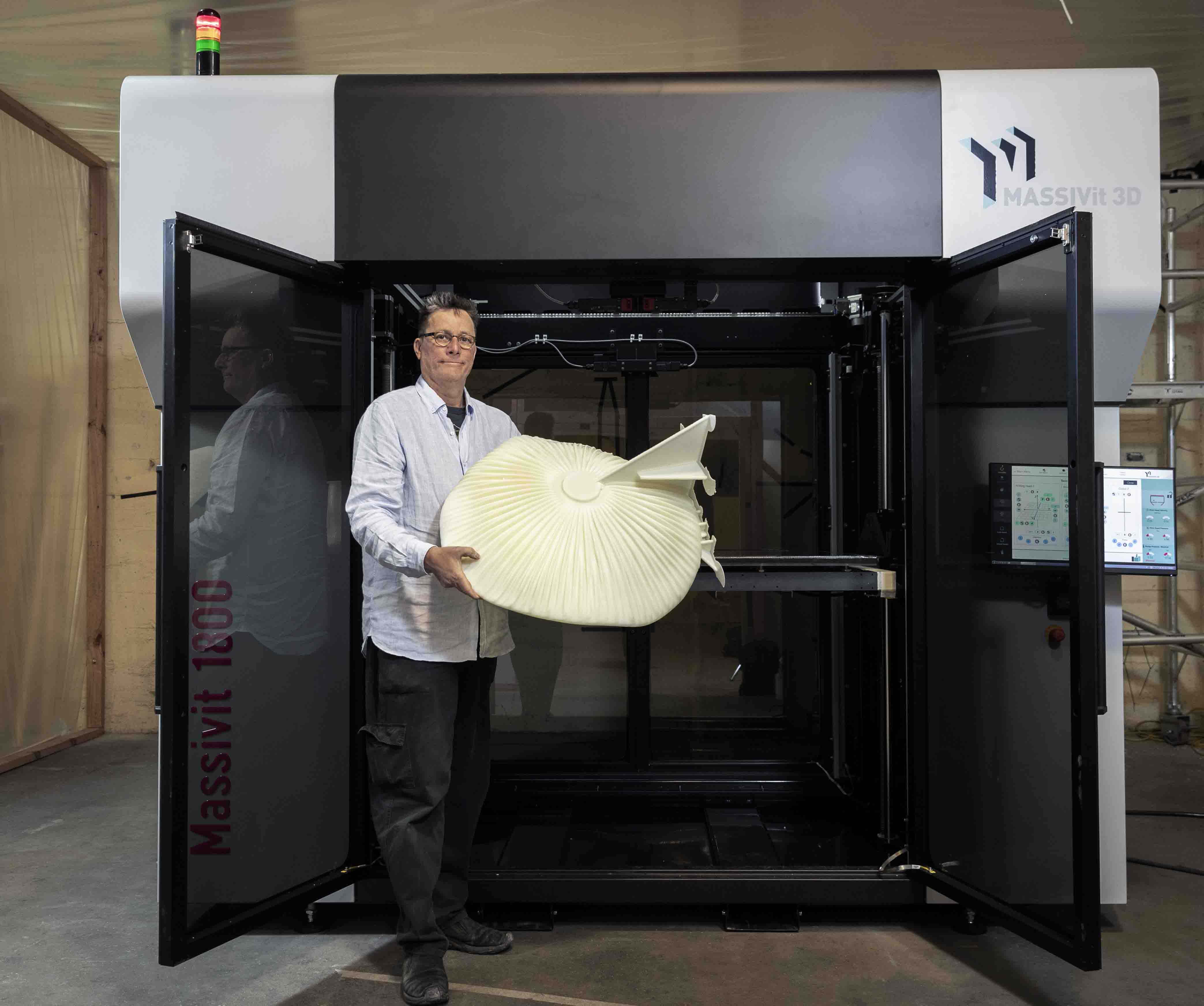

Massivit 3D has announced that Academy Award®-winning design studio and manufacturing facility, Weta Workshop, has installed a Massivit 1800 3D Printing Solution at its Wellington, New Zealand-...

January 07 2019

Massivit 3D has announced that Academy Award®-winning design studio and manufacturing facility, Weta Workshop, has installed a Massivit 1800 3D Printing Solution at its Wellington, New Zealand-based premises.

The company is recognised for its work on blockbuster films such as The Lord of the Rings and The Hobbit motion picture trilogies, Avatar, King Kong, Ghost in the Shell, and Blade Runner 2049. The installation of this Massivit 1800 was made possible by Massivit 3D’s local Australian and New Zealand distributor, Stick on Signs.

Richard Taylor, Weta Workshop Co-founder, CEO and Creative Director, says, “We manufacture super-sized, hyper-realistic human figures, creatures, vehicles, and other huge props for film and television and have always been on the search for technology that can produce large parts at a high speed.

“For 15 years, we have dreamed of a day when a printer would provide super large scale, speed, and build strength at low print costs, in equal measure. The Massivit 1800 has delivered this for us.”

Taylor adds, “With the Massivit 1800, our team has been able to redefine what is creatively possible for our large-scale manufacturing projects. It is a powerful and versatile machine that has transformed the way we work and has supercharged our output. It really is a dream come true.”

According to Pietro Marson, Workshop Operations Analyst at Weta Workshop, the company’s manufacturing teams have until now deployed a range of technologies for their fabrication processes, including CNC routers, industrial robots, and smaller 3D printers. Many of these technologies have presented limitations when it comes to manufacturing bigger props.

“We’re often required to create 8- or 9-meter-tall (26.2 or 29.5-foot) sculptures and mannequins, which means we need to print multiple parts and then manually fit them together,” he explains. “Needless to say, this is both time-consuming and expensive.

“The largest commercially available SLA 3D printer in the country has a maximum print volume of 60 x 60 x 40 centimeters, whereas the Massivit 1800 allows us to print up to 1.8-meter-high [5.9-foot] components,” he continues. “We can also print much more quickly and with far greater geometry freedom than with CNC machining.”

Weta Workshop expects to be able to save thousands of dollars by printing larger components. The Massivit 1800’s print volume has proven particularly useful for one of the company’s latest projects which requires the production of large-scale molds. Producing these molds with CNC technology would have been challenging due to their size and the inability of CNC routers to create complex, deep intrusions.

“The Massivit 1800 has surpassed our expectations insofar as the added capabilities and extra efficiency it delivers our operations,” says Richard Taylor. “Since its installation, it has stimulated a lot of creative thought and our teams are buzzing with what we will be able to achieve with it moving forward,” he concludes.

Classic metal effect films by ASLAN ASLAN, the German developer and manufacturer, renowned as a specialist in self-adhesive films, expands its portfolio of special effect films with th...

December 07 2018

Classic metal effect films by ASLAN

ASLAN, the German developer and manufacturer, renowned as a specialist in self-adhesive films, expands its portfolio of special effect films with the introduction of the MetalLux ASLAN SE 50 in Champagne and Platinum. These classic shades impress by their elegant appearance, are both trendy and timeless at the same time.

When applied to a smooth, compatible surface the silky matt shades come into full effect. While Champagne creates a warm ambience, Platinum brings a touch of cool elegance to every single interior space. These self-adhesive films can be used to cover complete surfaces or plotter cut to produce spectacular highlights to any graphic design or logo.

Due to their 50 μm thickness, both Champagne and Platinum are particularly easy to handle and to apply. ASLAN recommends a dry application but wet application is possible as well – as this reduces static charges and makes repositioning even easier. It is important to press the water out completely and carefully with the use of a squeegee. Any slight visible marks that may appear while using a squeegee, are easily removed with a microfiber cloth.

Both Champagne and Platinum are perfectly suited for shop fitting, exhibition stand design, visual merchandising and interior design. These self-adhesive metal effect films are specifically designed for the decoration of smooth surfaces. This makes them ideal for application to flat areas on furniture, ceilings and walls – whether applied to large areas for a complete surface design, or as an individually set highlight. Surfaces should always be cleaned thoroughly, to achieve that trendy and yet timeless classic effect.

MetalLux ASLAN SE 50 Champagne and Platinum have an outdoor durability of 2 years and are available in the dimensions 25 m x 1.25 m.

EFI introduces Reggiani BOLT 8000 sq.m hour textile printer The brand-new, next-generation, single-pass EFI Reggiani BOLT textile digital printer from Electronics For Imaging, Inc. mad...

December 07 2018

EFI introduces Reggiani BOLT 8000 sq.m hour textile printer

The brand-new, next-generation, single-pass EFI Reggiani BOLT textile digital printer from Electronics For Imaging, Inc. made its debut this week during an open house event at the EFI Reggiani facility in Bergamo, Italy.

The advanced, ultra-high-speed digital single-pass printer has the potential to revolutionise the textile printing market, providing users with high uptime and reliability, outstanding performance, superior printing uniformity and accuracy, long printhead life and minimal maintenance needs. The EFI Reggiani open house has created huge interest in global textile market opportunities, with nearly 300 customers and journalists attending to see the new BOLT in action.

"The innovative development of our new single-pass printer comes from Reggiani's speed of innovation in digital textile printing, its 70 years of history, and our proprietary knowledge of high-volume analogue rotary printing," said EFI Reggiani Vice President and General Manager Adele Genoni. "Our EFI colleagues' proven, worldwide expertise in single-pass technology and, most importantly, EFI Reggiani's serious commitment to listening to and addressing our textile customers' needs, have allowed us to achieve incredible results with our newest print technology. The EFI Reggiani BOLT re-writes the rules of digital textile single-pass printing, delivering superior throughput and quality with a highly competitive return on investment for customers. We are excited to bring this technology to our customers and see their businesses succeed and grow."

Cutting-edge printhead technology and high-performance ink delivery The BOLT offers an innovative, low-maintenance, fast-startup recirculation printhead that delivers better, more-uniform printing with superior uptime. Thanks to its cutting-edge printhead concept and high-performance ink delivery system, the BOLT has throughput speeds of up to 90 metres per minute (more than 8,000 square metres per hour) at a 600 x 600 dots per inch (dpi) resolution. It features high-end greyscale imaging in drop sizes from 5 to 30 picolitres, and also provides premium-quality 600 x 4,800 maximum-dpi resolution printing, allowing customers to address the full range of design needs. The printhead has been developed in partnership with a leading printhead manufacturer, and will be available exclusively for EFI Reggiani.

High-end capabilities, with reduced downtime The EFI Reggiani BOLT meets growing requirements for high-quality, ecologically sustainable digital textile imaging in apparel, décor and other markets. Paired with an EFI Fiery digital front end (DFE) print server offering unique, high-speed processing capabilities on demand, the BOLT printer is a robust, industrial platform designed for 24/7 operation and continuous productivity that drives high-volume throughput while reducing the cost per metre. Additional new features and enhancements on the printer include:

Enhanced maintenance features - The printer's contactless wiping system prolongs printhead life and quality. Plus, the printer comes with an assisted alignment system for its test calibration scan unit, and features extractable printing beams for easier maintenance.

Extended colour gamut and superior image quality - Thanks to EFI expertise in colour management and flexible colour configurations, customers can easily reproduce a wider variety of work, including designs featuring plain colours, geometric patterns, fine lines, deep blacks and smooth gradients.

Proprietary IP combining digital and rotary technologies - One or more analogue printing stations, which may be easily connected as an optional feature, can be integrated into the digital printer for special effects.

Efficient, high-powered EFI Fiery technology

The Reggiani BOLT is a Fiery Driven printer, featuring an EFI Fiery DFE with RIP and colour management technologies running on Fiery XB bladed hardware for maximum performance. Fiery technologies for the printer give textile printing businesses the ability to successfully produce highly challenging jobs with the finest detail, demanding colours, smooth gradients and more. EFI colour scientists developed special algorithms and custom screening for this Fiery system to deliver vivid print results, including high saturation without losing detail, and superior colour even when using the fastest print mode.

Fiery technologies for the new Reggiani BOLT printer also will include a 1-year subscription to EFI Fiery DesignPro, a powerful textile and fashion design suite that runs inside designers' Adobe Creative Cloud applications. Fiery DesignPro reduces the time needed to create colour books, repeats, colourways and prepare files for production to minutes instead of hours. Together, the new Reggiani BOLT single-pass printer and Fiery technologies address key market trends as customers face pressure for faster time-to-market, quick fashion cycles, shorter print runs and more customisation.

EFI Reggiani high-speed innovation in digital printing for textiles The BOLT printer is the newest in an important series of EFI Reggiani innovations. In the last 15 months, the team has developed a totally renewed range of digital scanning printers with cutting-edge technologies, launching a new model every quarter to offer customers solutions to whatever their requirements may be for easily scalable textile printing. The list of EFI Reggiani advancements includes two recent launches - the COLORS digital printer, which provides unparalleled performance with up to 12-colour printing, and the TERRA pigment ink with binder solution featuring in-line polymerisation, a process that speeds up customers' printing with one of the industry's greenest production technologies.

Fujifilm announces faster Jet Press 750S sheet-fed B2 Press Fujifilm today announces its third generation B2 inkjet press, the Jet Press 750S. With higher productivity of 3,600 B2 shee...

December 07 2018

Fujifilm announces faster Jet Press 750S sheet-fed B2 Press

Fujifilm today announces its third generation B2 inkjet press, the Jet Press 750S. With higher productivity of 3,600 B2 sheets per hour, and a range of other changes which further improve the already impressive up-time, versatility, colour capability and quality, the Jet Press 750S is now the fastest, full colour, B2 sheet-fed digital press on the market.

The Jet Press 720S was the first B2 inkjet press to gain a foothold in the market, and was ahead of the game in terms of productivity and quality. With over 150 Jet Press installations worldwide, more and more print buyers have recognised the new standard in digital print that this press delivers. Now with the continued, steady increase in demand for short run work, the introduction of the Jet Press 750S means that more and more jobs are going to fit the sweet spot of this new industry-leading press.

The target for this press is not the toner-dominated, on demand market where runs of ones and twos predominate. The Jet Press 750S is likely to be highly competitive for print runs up to 5,000, depending on ink coverage, allowing it to compete with, and out-perform, offset presses in the production of high quality, short run print jobs. This makes it an ideal investment for a much larger range of commercial and packaging printers.

Like the Jet Press 720S, the new press is the perfect blend of old and new technologies. Built on an offset chassis, it features superb sheet-to-sheet, front and back registration and up-time on a par with offset, combined with the very latest industry-leading Samba inkjet printheads, to deliver print quality that out-performs offset.

Enhanced productivity and up-time

Customers of the Jet Press 720S have already benefited from the highest up-time for a digital press in the industry, with figures above 90% often quoted. The Jet Press 750S is set to improve on this still further thanks to two new features. The first is a new printhead self-cleaning process called ‘Overflow Cleaning’ which carries out head cleaning at times when the press is between jobs or the printhead assembly is in motion. The second is a new Active Head Retraction (AHR) system which lifts the print bars from the drum when a paper deformation is detected (<3mm), reducing the likelihood of paper jams caused by damaged paper.

The increase in top line press speeds has been achieved by the further development of two major parts of the press. The first is the inclusion of the next generation of Samba printheads. Printing on paper moving at the higher speed of 3,600 sheets per hour requires a corresponding speed upgrade to the number of ink droplets deposited per second. The jetting frequency of the new generation Samba printheads has therefore been increased from 25 kHz to 33 kHz to speed up dot placement and counteract the increased effects of possible turbulence. It also has the additional benefit of reducing dot placement variations, therefore improving quality.

The second new technology contributing to increased efficiency and speed is the introduction of a completely new drying system, in which a printed sheet is passed onto a transfer belt heated via rollers, with a vacuum applied as the sheet passes through the drying section to keep it dimensionally stable. Drying is carried out via a combination of the heated belt and hot air applied from above. As well as operating at higher speeds, this new system allows greater control and fine-tuning of temperatures, extending the range of substrates that can be printed.

The combination of a larger sheet size (increased from 750mm x 532mm to 750mm x 585mm), even better up-time, a 33% faster press speed, and quicker finishing mean the overall ability of this new press to print longer runs and improve job turnaround times still further is significant.

Exceptional quality and colour capability

The Jet Press 720S has already built a formidable reputation for exceptional print quality, and here the Jet Press 750S is no different. It features the same Rapid Coagulation Primer technology, allowing it to be used with standard coated and uncoated offset paper stock, benefits from the same superb sheet-to-sheet registration, and the addition of the latest generation of Samba printheads improves dot placement accuracy even further. The Jet Press 750S also features the same extended colour gamut called ‘MaxGamut’ which, depending on the media used, allows up to 90% of the Pantone library of 1,872 colours to be printed within a Delta E of 3 or less, providing an exceptional colour match on a four colour press.

To improve the press’s capability with regards to spot and Pantone colours even further, Fujifilm has added a new module to its XMF ColorPath tool, called XMF ColorPath Brand Color Optimizer. This new module enables users to profile the entire Pantone library for any chosen media type, and will ensure that each and every Pantone colour is printed as accurately as physically possible. What is unique to Brand Color Optimizer, however, is the ability to predict how accurately a Pantone colour will be printed before actually printing. This means decisions about printing a specific job can be made up front, and no time is wasted trying to achieve what is not possible.

Finally, in addition to the In-Line Scanning (ILS) system also found in the Jet Press 720S, the Jet Press 750S incorporates a new optional ImageConfidence scanning system as further reassurance. This uses a proprietary AI algorithm to evaluate the full print area of a B2 sheet on-the-fly, ensuring every sheet matches a pre-approved image.

Perfect for packaging

Currently, around a third of all current European Jet Press customers already produce some form of packaging on the press. With its 33% speed boost and variable data printing at full speed, the new Jet Press 750S is ideally suited to printing versioned and short run packaging to coincide with specific events, localities or store promotions.

The introduction of the Jet Press 750S is likely to accelerate this trend. It can be modified to accommodate heavier weight folding carton stock (up to 0.6mm in thickness), and printed sheets from the press have been tested and found to be compatible with a wide range of analogue and digital coating, foiling, lamination and cutting solutions. An automatic bridge is also available to connect to online coating solutions.

Fujifilm is now also able to offer a food safe ink, making the Jet Press 750S the first B2 digital press approved to print primary food packaging. This new, low migration, aqueous food safe ink complies with stringent regulations, including Swiss Ordinance 817.023.21 and European Commission Regulation 1935/2004, and has been specially formulated for coatings to be applied inline (via a bridge) or near line.

Other features

Remote usability has also been improved on the Jet Press 750S, with users able to carry out job management tasks, including allocating new jobs and certain press functions, remotely via an iPad (additional option).

Finally, the new press, like the Jet Press 720S, features excellent de-inkability of printed sheets, while the new drying system, which requires 23% less power, offers an additional environmental benefit.

Says Taro Aoki, Head of Digital Press Solutions, Fujifilm Graphic Systems EMEA: “In the Jet Press 750S, we have retained and enhanced all of the features that gave the Jet Press 720S such a formidable reputation, to create a new industry benchmark for the production of short run print. With its increased speed and up-time, the press is likely to be competitive for a much larger range of offset jobs, and gain a much larger share of the B2 market. We look forward to helping printers take advantage of all the opportunities that this will present.”

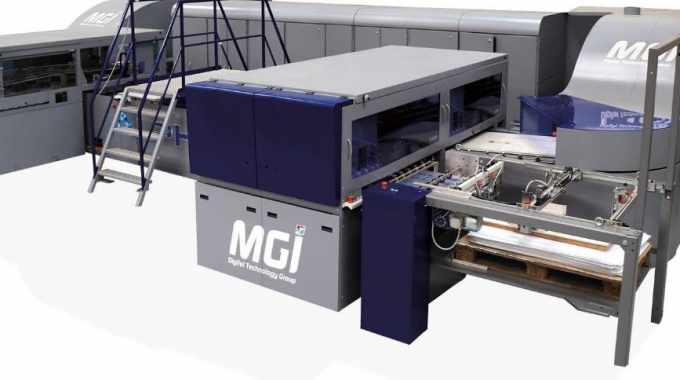

MGI integrates Memjet DuraLink into new AlphaJET B1 inkjet press MGI Digital Technology has become a global OEM partner of Memjet and will integrate its DuraLink printing technology in...

December 07 2018

MGI integrates Memjet DuraLink into new AlphaJET B1 inkjet press

MGI Digital Technology has become a global OEM partner of Memjet and will integrate its DuraLink printing technology into AlphaJET, its new B1 inkjet printing and embellishment press for high-volume print and packaging markets.

MGI is a France-based manufacturer of digital printing presses and finishing technology. AlphaJET is said to ‘consolidate the functionality of traditionally separate, disconnected operational workflows such as primer coating, printing and embellishment’. AlphaJET utilizes DuraLink for CMYK color impressions with 1600 dpi resolution. White and clear varnish inks use UV inkjet technology for ‘best-of-breed’ convergence of digital printing methods. This powerful array of high-speed ink deposition processes allows the AlphaJET to both print and embellish corrugated flute board, paper, plastic and synthetic substrates at 1800 B1 sheets an hour.

AlphaJET is claimed as the first 40in-plus sheet-fed press to integrate the DuraLink inkjet printheads, ink and modules. It is also the first 5-color digital printing system to offer decorative special effects such as 2D/3D UV dimensional textures and variable embossed foil, according to MGI.

Michael Abergel, managing director at MGI, said: ‘Memjet has developed superb core technology with the DuraLink architecture and ink modules. In addition, its teamwork and technical support for the AlphaJET product has allowed us to quickly achieve unprecedented functional advancements. The AlphaJET has been designed to introduce a new model of printing, packaging and finishing productivity. For such an important product, we found an ideal business partner in Memjet; it understands the spirit of innovation that drives MGI.’

Memjet general manager Eric Owen added: ‘The launch of the AlphaJET comes at a time when print markets are experiencing a high demand for inline digital printing, embellishment and finishing. To capture that opportunity, MGI chose the modular nature of DuraLink — its extremely fast speeds, 1600 x 1600 resolution and affordable cost — to develop an industry-changing solution. This is a valuable partnership for MGI, Memjet and the print market as a whole.’