See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

FUJIFILM Dimatix(R) Inc., the world’s leading provider of inkjet printheads for commercial and industrial printing, is pleased to announce the release of the Samba cartridge for use with the ...

April 13 2021

FUJIFILM Dimatix(R) Inc., the world’s leading provider of inkjet printheads for commercial and industrial printing, is pleased to announce the release of the Samba cartridge for use with the Dimatix Materials Printer (DMP).

Based on state-of-the-art silicon micro-electro-mechanical systems (Si-MEMS) design and manufacturing of the Samba G3L printhead, the Samba cartridge is the most advanced technology in inkjet printing, now available for use with all DMP-2800 model printers.

The new Samba cartridge brings the most modern features, capabilities and function to an already popular and versatile printer. It provides a native drop volume of 2.4 pL which has the potential to create ultra-fine line widths from a single dot size of 30 μm. Accounting for smaller scale applications, the Samba cartridge offers use of a small capacity 1.5 mL cartridge, which requires considerably less fluid when screening fluid formulations for jettability and cured ink properties.

To enable a full-service solution from R&D applications to commercial production, the Samba cartridge offers the same internal jet design, jetting characteristics, and native drop volume as the Samba G3L printhead, which allows an easy transition from R&D applications to commercial production with the Samba G3L printhead.

The success of the DMP has been in expediting the fabrication of prototypes for a wide variety of inkjet applications including flexible electronic circuits, RFID antennas, 3D printed materials, and DNA arrays. The addition of the Samba cartridge for the DMP will enable developers to utilise this versatile printer for a smooth transition from small-scale feasibility design and testing stages, to industrial scale manufacturing for commercialisation.

“Today, we launch an innovative product that puts the large-scale Samba G3L printhead jet design into a small cartridge form factor. In unifying the jet design of the DMP Samba cartridge with that of the high-performance and scalable Samba G3L printhead, FUJIFILM Dimatix provides a path from R&D to full-scale production manufacturing, which will be invaluable to the growth of functional printing,” said Martin Schoeppler, President and CEO, FUJIFILM Dimatix, Inc. “We believe that the ability to analyse in-flight drop formation and jetting characteristics, joined with direct development on an industrial inkjet printhead jet design at a small scale, will facilitate R&D to transition to a production environment, and FUJIFILM Dimatix will help customers achieve this by starting with the Samba family of products.”

The Samba cartridge is available to order now.

For more information please visit http://dimatix-5352080.hs-sites.com/samba-how-to

Kongsberg, one of the most trusted and established names in the digital finishing industry, enters a new era, transforming into a standalone company, Kongsberg Precision Cutting Systems (‘Kon...

April 13 2021

Kongsberg, one of the most trusted and established names in the digital finishing industry, enters a new era, transforming into a standalone company, Kongsberg Precision Cutting Systems (‘Kongsberg PCS’). The transformation follows the acquisition of the business by OpenGate Capital.

The transformation of Kongsberg PCS brings with it the opportunity to innovate and expand the business into new markets. This marks a new chapter for Kongsberg PCS, a brand with a rich heritage spanning more than half a century.

“This is truly an exciting day for everyone at the company,” said Stuart Fox, President of Kongsberg PCS. “Since 1965, the Kongsberg name has been synonymous with innovation. Our systems have led the industry in delivering precision, reliability and quality through seven decades. Following the acquisition by OpenGate Capital, we will now focus on our future, and the next generation innovation and growth.”

Founded in Norway in 1965, Kongsberg was purchased by Esko (then Barco) in 1998. In December 2020, Esko agreed the sale of Kongsberg to private equity firm OpenGate Capital. The acquisition includes the original research and development facility in Kongsberg, Norway, and the production facility in Brno, Czech Republic.

“This is an opportunity for the Kongsberg team to realize its ambitions, and to explore new markets,” added Fox. “We will be developing strategic initiatives to further innovate our digital finishing hardware and software solutions, as well as growing the Kongsberg brand beyond the packaging industry.

“Whilst we are excited about the future, we are also committed to ensuring we honor our heritage. We have an incredible team of 400 people, many of whom have been a part of the Kongsberg family for more than 30 years,” said Fox. “The Kongsberg values that are important to our customers – the strength, the performance, the longevity of the machine – will endure.

“Sales, service, consumables and spare parts will all continue as usual,” added Fox. “Customers will receive the same level of service during the transition and they can look forward to business as usual throughout 2021.

“We will continue investing in our table technology, and in the coming months we will be showcasing the latest developments with our automation solutions,” said Fox.

Mutoh Europe nv, EMEA business unit of Mutoh Industries Co. Ltd., Japan, today announced release of a new 64” (162 cm) wide, high quality 8 channel piezo drop-on-demand roll fed dye sublimati...

April 13 2021

Mutoh Europe nv, EMEA business unit of Mutoh Industries Co. Ltd., Japan, today announced release of a new 64” (162 cm) wide, high quality 8 channel piezo drop-on-demand roll fed dye sublimation inkjet printer, called XpertJet 1682WR.

Engineered and designed in Japan, this new dye sub printer model is the successor to Mutoh’s award winning ValueJet 1638WX dye sub printer.

The XpertJet 1682WR printer has been developed for high quality graphics for transfer onto all possible types of polyester coated or polyester based rigid substrates, gadgets and flexible materials. Applications encompass in-store textile displays, personalised interior décor, custom apparel, soft signage, sportswear, customised promotional products, giftware and more.

Featuring a high level of print production efficiency, the XPJ-1682WR accommodates two gold plated piezo variable drop print heads producing stunning results in 4, 6, 7 or 8 colour ink setups. The piezo print heads are capable of firing drops from 2.8 picolitres up to 33.9 picolitres.

Cleverly designed, the XpertJet 1682WR combines multiple product enhancements which will deliver optimum quality results and an excellent user experience. A newly developed multi-stage pressure roller system will enhance media feed stability for a wide range of sublimation papers. Rolls can be easily installed thanks to a new enhanced roll off system and newly developed media flanges. Continuous printing is made possible with the different motorised take-up systems, for rolls weights up to 30, 40 or 100 kg and roll diameters from 150 to 250 mm.

The XPJ-1682WR printer also integrates Mutoh’s new “Media Tracker” technology. With this new feature, the user can print a barcode on the roll of media in use before it is removed from the printer. When reloading the same roll of media, the XPJ-1682WR will read the barcode and will automatically detect how much media is left on the roll.

Available immediately, this dual head high quality dye sublimation printer will fit both startup and established businesses wanting to extend their product portfolio.

The new XpertJet 1682WR model will be sold exclusively through Mutoh’s channel of certified & trained distributors throughout Europe, the Middle East & Africa.

Mutoh XpertJet 1682WR – Highlights

• Successor to Mutoh’s popular and award winning ValueJet 1638WX

• Transfer sublimation printing up to 1625 mm (63.97”)

• Two gold plated piezo drop on demand heads on board, drop sizes from 2.8 pl to 33.9 pl

• Typical production speeds between 10 m²/h and 48 m²/h

• Up to 8 colour setup

• New multi-language & intuitive OLED operation panel

• Easy access illuminated print platform

• Enhanced media handling & transport

• Ready for volume printing : 30, 40 or 100 kg motorized take up systems

• “Media Tracker” feature to easily track remaining media left on a part-used roll

• Environmentally friendly printing - high level of operator safety

Mutoh Australia will have stock available in May.

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters, today announced a second round of 2021 training dates for the company’s successful Roland Acade...

April 13 2021

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters, today announced a second round of 2021 training dates for the company’s successful Roland Academy Online courses.

Due to high demand and a number of sold-out sessions, a new round of Roland Academy Online dates has been added for May through to July. Delivered online by expert Roland DG trainers in a small group setting, the 1 to 2-hour sessions continue to receive great feedback from attendees. Last month, Phil Walding from Labelman Limited said that the UV session he attended “was an excellent opportunity to increase awareness of Roland UV printers... The course was well put together and excellently presented... I can't recommend highly enough.” Shawn Lynch from Print to a T commented that the training he received was “top notch” and a “great asset to a professional workflow.”

Tickets have been added for the following sessions, and are now available to purchase online:

Session 1 – Basics

Date: Tuesday, May 18 and Tuesday, June 29

Time: 10:00am AEDT

Duration: 120 mins

Price: $49 inc GST

Session 2 – Advanced Features: Cutting

Date: Tuesday, May 25 and Tuesday, July 6

Time: 10:00am AEDT

Duration: 120 mins

Price: $49 inc GST

Session 3 – Advanced Features: Understanding Colour

Date: Tuesday, June 1 and Tuesday, July 13

Time: 10:00am AEDT

Duration: 90 mins

Price: $39 inc GST

Session 4 – Advanced Features: Understanding Profiles

Date: Tuesday, June 8 and Tuesday, July 20

Time: 10:00am AEDT

Duration: 60 mins

Price: $29 inc GST

Session 5 – UV Features and Functions

Date: Tuesday, June 15 and Tuesday, July 27

Time: 10:00am AEDT

Duration: 120 mins

Price: $49 inc GST

Places are strictly limited to 8 people per class so get in quick to secure your spot.

For further information, and booking details, go to the website: https://www.rolanddg.com.au/support/roland-academy/courses/online-training

This exhibition is a must see for all professionals working in the digital print, sign and display industry. The National Gallery of Victoria will extend opening...

April 13 2021

This exhibition is a must see for all professionals working in the digital print, sign and display industry.

The National Gallery of Victoria will extend opening hours for the final days of the blockbuster NGV Triennial exhibition which closes on Sunday 18 April.

NGV Triennial has already welcomed more than 490,000 visitors since opening on 19 December 2020, and due to popular demand, the exhibition will be open from 9.00 am – 9.00 pm on Friday 16 April, and from 9.00 am – 6.00 pm on Saturday 17 and Sunday 18 April.

Visitors to the Gallery can enjoy a live DJ set by Melbourne-based DJ Nam from The Operatives on Friday 16 April at the Triennial Stage in the NGV Garden. Dining experiences on offer throughout the final days of Triennial include the Forecourt café, Gallery Kitchen, Tearooms, Garden Restaurant and NGV Garden which will host a Yering Station Wine Bar with a food menu designed to pair with the Yering Station wines.

NGV Triennial encompasses works of contemporary art, design and architecture by more than 100 artists and designers from over 30 countries and explores some of the most globally relevant and pressing issues of our time, including isolation, representation and speculation on the future.

Tony Ellwood AM, Director, NGV said ‘We have been delighted to welcome so many visitors back to the gallery since opening NGV Triennial last December. It has been inspiring to see so many of our valued community members enjoy this free and expansive exhibition, and one of our most ambitious presentations to date. We’re delighted to be able to offer our audiences extended hours for the last weekend of the exhibition.’

Offering a visually arresting and thought-provoking view of the world at this unique moment, NGV Triennial highlights include: A multifaceted work by renowned French artist JR, which brings global attention to the ecological decline of the Darling River. Further highlights include a larger-than-life mirror-polished sculpture of Venus, Roman goddess of love, by American artist Jeff Koons and an entire floor dedicated to works concerning light and illumination presented in dialogue with the NGV’s historical collection.

Exploring the themes of daylight, candlelight and moonlight inspired by and within the context of the NGV’s seventeenth and eighteenth century Flemish, Dutch and British collections, interior designer Faye Toogood has curated several gallery spaces creating a considered salon-style interior featuring newly commissioned furniture, lighting, scenography, sculpture and large-scale tapestries. Architect and designer Patricia Urquiola presents her first major installation in Australia titled Recycled woollen island 2020, which features upcycled textile furnishings hand crafted in India in the form of humorous super-sized socks, enabling visitors to pause and reflect on the NGV’s Great Hall ceiling.

Further highlights include a monumental video work by Refik Anadol spanning 10 metres high and wide, which uses artificial intelligence (AI), machine learning and quantum computing to visualise our digitised memories of nature; and a comprehensive display of works 15 large-scale single sheet bark paintings and nine larrakitj (hollow poles) by Yolngu woman Dhambit Mununggurr, and a collaboration between Kengo Kuma, one of the most respected figures in Japanese architecture, and Melbourne artist Geoffrey Nees who have created an architectural pavilion that acts as a sensorial walkway through which to approach and contemplate a newly acquired painting by South Korean artist Lee Ufan.

Free and exclusive to Melbourne, NGV Triennial 2020 is the second instalment of the NGV Triennial, which is held every three years.

To book tickets for the final weeks of NGV Triennial, visit ngv.melbourne/triennial-2020

The Exhibition Space will reflect the diverse technologies and applications along the entire value chain of the printing and packaging industry and will give visitors a comprehensive overview.

April 13 2021

The Exhibition Space will reflect the diverse technologies and applications along the entire value chain of the printing and packaging industry and will give visitors a comprehensive overview.

From April 20 – 23, 2021, the global printing and packaging sector will meet at virtual.drupa https://virtual.drupa.com featuring the three segments “Conference Area”, “Networking Plaza” and “Exhibition Space” to promote knowledge transfer and networking and to activate business. The Exhibition Space will reflect the diverse technologies and applications along the entire value chain of the printing and packaging industry and will give visitors a comprehensive overview of the product portfolios and innovations of the exhibiting companies. In addition, explanatory videos and live web sessions will provide additional details about the exhibited products and services.

Finding relevant exhibitors and products

Visitors can use the navigation in the Exhibition Space to quickly find the exhibitors they are interested in. In addition to direct entry of the company name, the search can be filtered by product category or country to obtain a relevant selection of exhibitors.

The individual exhibitor profile provides information on the company, contact persons, products, services, innovations and presentation formats. At this point, direct contact can be made with the exhibitor via a digital business card or via matchmaking.

Insights and interaction in Live Web Sessions

Exhibitors have the opportunity to interact with the community in live web sessions and present their content to a broad audience. Visitors can get an up-to-date overview of the various presentations in the event database, where they can filter by event time slots or topics. Exciting content can be expected, such as the potential of digital printing applications and automated workflows, innovations in flexo and inkjet printing as well as sustainable packaging solutions. The virtual.drupa event partners will also make major contributions to this: Leonhard Kurz, DuPont de Nemours, efi, Kodak, Komori, BlueCrest, CloudLab, Fujifilm, Hybrid Software, Koenig & Bauer, Mimaki, OQChemicals and Xeikon. All live web sessions will also be available later on demand in a video library to make the content accessible to visitors who cannot attend live due to time differences.

Exhibitors provide outlooks on industry-relevant topics

Visitors already have the opportunity now to take a look at the current exhibitor profiles and orient themselves for virtual.drupa. Together, the companies represent the diversity of the industry in their online showrooms and web sessions.

“DuPont will present the latest innovations for the Cyrel® Solutions flexographic systems and Artistri® Digital Inks for textile and industrial applications, in the online showroom and during interactive live web sessions,” reported Sam Ponzo, Vice President, Industrial Solutions at DuPont de Nemours.

“Fujifilm will present new innovative products in both conventional and digital processes,” said Hiroaki Shimosaka, General Manager Graphic Systems Business Div. at Fujifilm Corporation. “In addition, with our innovative products we demonstrate our commitment to the graphic arts industry and prove that we are a long-standing partner for our global customers.”

Filip Weymans, Vice President Marketing at Xeikon, stated: “We will be demonstrating mainly applications that involve digital print manufacturing – not just solutions for digital printing but solutions that fit in a manufacturing process and can be connected in a lot of other steps in a manufacturing process. That is how you achieve flexibility. That is how you address the questions and challenges that lie ahead of you and your business.”

Participants will get a continuous overview of the development of the exhibitors and their presentation programs. The event currently has 185 exhibitors from 30 countries and 13 virtual.drupa event partners in the Platinum, Gold and Silver categories. For all other virtual.drupa offers, free registration is required at https://virtual.drupa.com/en/Registration

For further information on visiting or exhibiting at virtual.drupa, contact Messe Düsseldorf North America; Telephone: (312) 781-5180; E-mail: info@mdna.com; Visit https://virtual.drupa.com and www.mdna.com.

Spandex Asia Pacific is pleased to announce the promotion of Ben McCauley to Managing Director, Asia Pacific. Ben has been with Spandex since 2016, most recently as our Sales Director....

April 06 2021

Spandex Asia Pacific is pleased to announce the promotion of Ben McCauley to Managing Director, Asia Pacific.

Ben has been with Spandex since 2016, most recently as our Sales Director. Ben and the local management team have successfully navigated through COVID-times, one of the most challenging times in business history. Under Ben's continued guidance, Spandex Asia Pacific is well-positioned to expand and move forward, with thanks also going out to all of our employees' effort, time and devotion.

Spandex has confidence in Ben and the rest of the Spandex Asia Pacific team, and we will continue to push our business above and beyond where we've taken it over the past four years.

Esko, a global developer of integrated software and hardware solutions for the packaging and label sectors, has confirmed the successful closing of the sale of its Kongsberg digital finishing busin...

April 06 2021

Esko, a global developer of integrated software and hardware solutions for the packaging and label sectors, has confirmed the successful closing of the sale of its Kongsberg digital finishing business to OpenGate Capital on April 1st 2021.

OpenGate Capital is a private equity firm headquartered in Los Angeles, California, with a European office in Paris and investments on five continents. The new business, Kongsberg Precision Cutting Systems, now employs ~400 former Esko employees operating from the business’ original research and development facility in Kongsberg, Norway, the production facility in Brno, Czech Republic, a new headquarters in Gent, Belgium as well as other global locations.

Mattias Byström, President of Pantone, Esko and X-Rite, said, “This sale enables both Esko and Kongsberg Precision Cutting Systems to develop their own strategic directions. Under the leadership of Stuart Fox, we’re sure Kongsberg Precision Cutting has exciting times ahead. We wish the team the very best for the future.”

For more information about Esko, please visit www.esko.com

Danish converting equipment manufacturer Grafisk Maskinfabrik has launched LR250, an entry-level label inspection rewinder, featuring a built-in missing label detection system. The new...

April 06 2021

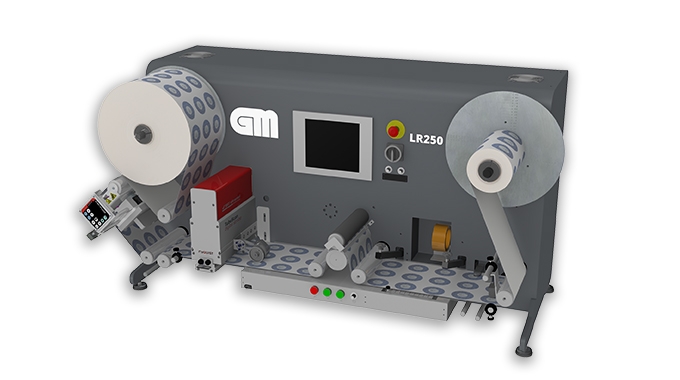

Danish converting equipment manufacturer Grafisk Maskinfabrik has launched LR250, an entry-level label inspection rewinder, featuring a built-in missing label detection system.

The new label inspection rewinder offers a built-in sensor for missing label detection. For more demanding applications, such as pharmaceutical labels, the LR250 can be configured with a video camera for 100 percent advanced print inspection and verification.

‘The LR250 is a versatile machine with some innovative built-in features that will ensure all your rolls are delivered in top condition with all labels present and correct,’ said Uffe Nielsen, CEO of Grafisk Maskinfabrik. ‘We have developed the rewinder with different inspection options, so there is a version that suits every budget without compromising on quality.’

The LR250 can process label rolls up to 250 mm (9.8in) wide at a production speed of 200 m/min (656 ft/min). It comes with a two-way rewinding capability, integrated web guide, and a label counter as standard. The adjustable splice table features pneumatic splice clamps and can be fitted with a splice detector.

The missing label feature stops the machine upon detection, calculates the error position, and reverses the web until it is aligned with the splice table. Once the missing label has been replaced, the web is re-checked, and the rewinder completes the job at full speed.

The option to integrate a video camera upgrades the machine's capabilities to include a full print quality inspection. GM has partnered with BST-Eltromat and Nikka Research to offer 100 percent quality inspection for printed labels. The camera will be connected to an external system, which checks the print for faults and verifies it against the master PDF file.

The LR250 has further been developed with tension separation for working with thin, sensitive materials and PET liners. Thanks to the centrally placed nip roller, the web can be unwound with one tension and rewound with a different tension to avoid stretching the material. A capacitive sensor for clear-on-clear labels can further extend the range of materials that can be processed.

There is space for a full UV inkjet printer for coding and marking for customers requiring variable data. GM partnered with Domino, Markem-Imaje, and Rea Jet, but other manufacturers' systems can also be fitted on demand.

‘As fault-free label production has become the norm, our customers want machines that enable them to deliver perfect rolls of labels to their customers, every time,’ added Nielsen. ‘This little label inspection rewinder is the perfect solution for that, but don’t let the size fool you. We have built the LR250 with so many clever options that it can grow with our customers’ business and tackle a wide range of label requirements.’

The cloud-based XCS Pro 2.0 delivers every advantage of quality colour control – predictability, repeatability and profitability, the company says. Xeikon has announced the launc...

April 06 2021

The cloud-based XCS Pro 2.0 delivers every advantage of quality colour control – predictability, repeatability and profitability, the company says.

Xeikon has announced the launch of its brand new XCS Pro 2.0, a fully automated suite of colour management tools. The cloud-based XCS Pro 2.0 delivers every advantage of quality colour control – predictability, repeatability and profitability, the company says.

The current high levels of e-commerce continue to drive the need for colour consistency across the whole print process for brand owners and retailers. The new colour package includes training courses plus ongoing consultancy and is offered as a "pay as you go" subscription model, making it simple and easy to adopt and utilise.

The new XCS Pro 2.0 is available immediately for demonstration.

“Historically colour management software has needed an expert to deliver results,” says Bruce Dransfield, Xeikon’s color management expert. “And this takes time. Xeikon has developed its XCS Pro 2.0 as a ‘no waste,’ ‘no expert’ fully automated colour system. Xeikon now has the first digital dry toner, web press solution which embraces self-fixing colour control, quality control and ICC profiling plus Pantone/brand colour generation to meet all industry standards. Xeikon has built its new colour management system’s architecture to enable it to remotely analyse, target and fix any colour problem in minutes. Xeikon’s cloud-based analytical tools can diagnose any color issue, and the issue is remedied with no delays, adding to significant time savings in production.”

Xeikon wants to instil a lean approach to colour management and make it practical for all their customers and users, which offers a host of advantages:

Avery Dennison Graphics Solutions today marks the launch of the newly upgraded Supreme Wrapping Film with twelve new colours in its Rugged Range and Sleek Satin collections. The compan...

March 30 2021

Avery Dennison Graphics Solutions today marks the launch of the newly upgraded Supreme Wrapping Film with twelve new colours in its Rugged Range and Sleek Satin collections.

The company’s premium range of vehicle wraps, Supreme Wrapping Film, has undergone significant development to its formulation and construction. After rigorous testing and evaluation for the Australian and New Zealand environmental conditions, Avery Dennison is announcing its enhanced performance with greater environmental resistance and enhanced durability. The warranty on gloss, satin and extreme textures films are increased by up to 300 per cent to reflect their durability.

To mark the upgrade, Avery Dennison has launched the Rugged Range and Sleek Satin collections featuring 12 on-trend colour options for vehicle owners to customise their car according to their personal preferences or styles.

The Rugged Range comprises four unique films that will give a distinctive tough textured finish to vehicles without the permanent application. The new colours are Rugged Bedrock Grey, Rugged Combat Green, Rugged Marsh Green and Rugged Onyx Black.

The Sleek Satin collection comprises eight new additions to the company’s already extensive range of satin finishes, six of which are matched to popular matte versions. The matches are Satin Charcoal Metallic, Satin Gunmetal Metallic, Satin Blue Metallic, Satin Dark Grey, Satin Anthracite Metallic, and Satin Olive Green. Two completely new additions are Satin White Snow Pearlescent and Satin Dark Grey Metallic.

“Today’s announcement of product enhancements and new collections speaks of our strength as a materials science company,” said Chris Sherry, Senior Product Manager for Avery Dennison Graphics Solutions in Australia and New Zealand. “Our team is constantly pushing the frontiers of technology to set the industry’s highest standards for performance, durability and style options. We are confident of our supercharged durability and are excited to extend the warranty for selected Supreme Wrapping Film finishes.”

Durst Group, manufacturer of future-oriented digital printing and production technologies, is restructuring its successful Label & Flexible Packaging segment. The current Segment Manager Helmut...

March 30 2021

Durst Group, manufacturer of future-oriented digital printing and production technologies, is restructuring its successful Label & Flexible Packaging segment. The current Segment Manager Helmuth Munter will retire at the end of 2021 after more than 40 years with the company. He will be succeeded in the role of Global Sales Manager Label & Flexible Packaging by Thomas Macina. The native of South Tyrol comes from HP Indigo, where he was most recently Labels Business Manager EMEA in Barcelona.

Thomas Macina’s career spanned more than 15 years at HP and he is considered a proven expert in digital printing technology. He has been in his introductory phase at the Durst Group since February and will assume his role for the EMEA region in April. This will be followed in June by responsibility for global sales of Label & Flexible Packaging products.

Until his retirement, Helmuth Munter will continue to be involved in the transition and provide advice and support to the new management team, which also includes Martin Leitner as Product Manager. Over the past ten years, the Label & Flexible Packaging segment has developed into an important business unit of the Durst Group and, with the Tau RSC printing systems, has made a significant contribution to the digital transformation in the industry. Tau single-pass printing systems now have a market share of around 40% of the UV inkjet market segment, with an installation base of more than 250 printing presses worldwide.

“We made good use of the situation in the COVID pandemic and arranged the succession for Helmuth Munter, who has been responsible for the success story in the label segment,” says Christoph Gamper, CEO and co-owner of the Durst Group. “All of us at the Durst Group would like to thank Helmuth for his great dedication, excellent performance, and loyalty. What could be better than retiring at the zenith of one’s career? We wish Helmuth all the best in this new phase of his life.”

“At the same time, I would like to warmly welcome Thomas Macina to the Durst family,” adds Christoph Gamper. “We are delighted to have gained a real market expert for the company, and someone who also has his roots in South Tyrol. The current pandemic situation has also been favourable to us as it has given us sufficient time to ensure an smooth transition. I am convinced that Thomas will continue to drive the Tau success story together with the entire label team.”

Esko has unveiled a major new release of its market-leading Automation Engine workflow solution, packed with new capabilities and for the first time available as a Software-as-a-Service (‘Saa...

March 30 2021

Esko has unveiled a major new release of its market-leading Automation Engine workflow solution, packed with new capabilities and for the first time available as a Software-as-a-Service (‘SaaS’).

“Designed and built by packaging experts, for packaging experts, Automation Engine has established itself over many years as the benchmark for optimised prepress workflow automation,” said Jan De Roeck, Esko Director of Marketing, Strategy and Industry Relations. “This latest release represents a major step forward for Automation Engine. It introduces a cloud-based deployment option and an intuitive new web-based user experience that ensures even the most casual user will be able to initiate, communicate and work across teams effectively.

“This new Automation Engine will make prepress automation more accessible and easier to use for both long-time customers and for companies that are just starting out on their automation journey,” said Jan. “Users can access their personalised, secure, workspace at any time, from anywhere, in the new My WorkSpace application. For customers looking for even more flexibility, we are proud to introduce our new cloud-based offering, which takes the prepress experience to a new level in terms of quality, productivity and connectivity.

“With Automation Engine SaaS, we are giving customers the opportunity to enjoy the operational benefits of standardised automated workflows while embracing the freedom of cloud-based computing,” he said. “Not only does Automation Engine SaaS reduce IT infrastructure overheads and headaches – such as flexible up-and-downscaling of server capacity, security, backup, guaranteed uptime and availability - but it also helps to boost operational productivity and cross-site working.”

Esko Automation Engine is the automated workflow solution that automates prepress tasks and integrates with business systems, which speeds up the process, and more importantly reduces the error rate and need for operator intervention. “Flexible to fit with individual business needs, scalable and customised to optimise individual workflows, Automation Engine has become the beating heart of the prepress process,” said Esko Product Manager Paul Land. “With this new release, the heart of the prepress is beating stronger than ever.”

On top of the My WorkSpace application and next generation user experience, the newest release of Automation Engine includes a new ‘drop zone’ feature, which makes launching workflows quicker and easier by enabling users to search and select workflows, drag and drop files to it, edit parameters and initiate - all from one location.

“Quick and easy viewing of files for detailed quality checks is now made easy with a browser-based viewing tool,” added Paul, “while new Jobs and Products views grant users the ability to efficiently search jobs and assets, access files, view their status and launch workflows from one workspace.

“With Automation Engine SaaS, we enable easy access and fast deployment, reducing the need for IT support or additional operational costs,” said Paul. “SaaS users simply access the software online using the new subscription-based model, which enables businesses to significantly reduce IT maintenance overheads. Utilising common software across locations is made easy and the SaaS model means there’s no longer any need to download and manually install the latest software versions onto individual computers whenever a new update or release is issued.”

Being a subscription service, a simple, flexible and transparent tier-based pricing model offers a predictable cost to help with IT budgeting and management. “With the price including a storage allowance and no bandwidth charges, the SaaS model guarantees a low step-in price and faster ROI for customers,” said Paul. “With IT and licensing costs now reduced through automation and outsourcing, this delivers a flexible pricing model that scales with the needs, size and growth of a business.”

Esko developed Automation Engine SaaS in response to the ongoing challenges faced by its customers, and feedback from early adopters has been very positive.

"With Automation Engine SaaS we can centralise resources in terms of expertise, software and hardware, delivering cost and time savings and reducing operational risks,” said Mark King, Technical Manager – Division, Essentra Packaging. “Therefore, this is great timing and exactly in line with Essentra’s strategy for 2021 and beyond.”

Meanwhile, Marybeth Foss, Senior Enterprise Prepress Architect, Fortis Solutions Group, praised the SaaS solution’s reduced IT requirements. “The biggest benefit for us has been the hands-off IT deployment and maintenance,” said Marybeth. “The simplicity of the cloud-based offer means that we have the ability to build and grow, but without the traditional infrastructure considerations and challenges. It keeps us operationally agile and ideally prepared for the future.”

swissQprint is launching Karibu S – the speed version of its Karibu UV roll to roll printer. S stands for speed – and that means increased productivity combined with astonishingly good ...

March 25 2021

swissQprint is launching Karibu S – the speed version of its Karibu UV roll to roll printer. S stands for speed – and that means increased productivity combined with astonishingly good print quality. Another plus: both Karibu and Karibu S are capable of automatic double-sided printing.

Karibu, the UV roll to roll printer from swissQprint, now has a powerful big brother: the new speed model. Created for print service providers who run multiple shifts to produce large volumes of items such as banners, non-durable poster prints and XL billboards. Karibu S combines an output of up to 330 square metres per hour with impressively sharp images and edges.

Special print head configuration

Karibu S features a defined print head configuration: four print heads are in operation for each process colour – and that explains the high throughput rate. What is more, all swissQprint large format printers have nine dual-configurable colour channels, so one channel is left free. Typically, this channel is configured with white to print items such as transparent films.

Universal and highly flexible ink

swissQprint's portfolio includes an optimised ink for its dedicated roll to roll printers. It features a broad adhesion profile and is very flexible. This means that print service providers can use almost every conceivable type of roll media. And the ink can stand up to everything that the material has to take: cutting, folding, stretching, and so on.

Automatic double-sided printing

As a new feature, both Karibu and Karibu S can handle automatic double-sided printing. Thanks to a camera system and QR codes, the process takes place automatically – with high efficiency and reliability. Supported by the Lory output software – developed in-house by swissQprint. Managing print jobs is made very simple thanks to intuitive graphic user guidance.

A profitable investment

Both Karibu models feature the same robust design as all swissQprint products – ensuring lifespans well above the average. With their low operating costs, the versatile UV roll to roll printers offer the promise of high added value throughout their long lifetimes. And the high standard of quality that is typical of swissQprint.

More information: www.swissqprint.com

Epson has taken delivery of and installed Australia’s first high productivity SurePress® L-6534VW industrial UV digital label press at their new Experience Centre in Yennora, Sydney.

March 24 2021

Epson has taken delivery of and installed Australia’s first high productivity SurePress® L-6534VW industrial UV digital label press at their new Experience Centre in Yennora, Sydney.

The new SurePress L-6534VW prints at speeds of up to 50 meters per minute for higher productivity with improved reliability and usability.

It also uses wide gamut CMYK inks with a high opacity white as standard and includes an innovative in-line digital varnish which delivers smooth gloss, matte and spot finishes.

The L-6534VW label press combines Epson PrecisionCore® printheads around a central impression drum in conjunction with a narrow platen gap, delivering precise droplet placement without web meandering or skewing. Its LED pining system also helps deliver finer tonal gradation and sharp images.

Epson’s proprietary Nozzle Verification Technology (NVT) and automatic head maintenance efficiently help the L-6534VW label press print through each shift without operator intervention.

As the L-6534VW label press supports a wide range of label applications including food and beverage, the labels it produces are also weather resistant.

Standard features for the L-6534VW include corona treater, web cleaner, ioniser and additional UV curing kit for increased ink adhesion on difficult substrates, all of which combine to help the press provide the highest level of versatility in print production.

More detail on key features of the L-6534VW

PrecisionCore linehead

The PrecisionCore linehead is the key behind the high performance and reliability of the SurePress L-6534VW. Each of the six lineheads are comprised of PrecisionCore print chip modules (printheads), delivering precise quality with accuracy and high resolution. Smooth and natural gradation and colour tone,

from highlight to shadow, can be reproduced with 600 x 1200 dpi resolution using a minimum droplet of 3 picolitres and Variable Sized Droplet Technology.

High Productivity

Epson's PrecisionCore linehead, highly accurate web feeding technology and Epson-developed UV ink enable high-speed printing up to 50 m/min with high reliability and reduced down time. The L-6534VW saves you time on every job with its many automated and efficient productivity features.

All LED UV Colour Pinning Control

Epson’s own LED UV pinning system semi-cures and stabilises, controlling ink spread for finer tonal gradation, sharp images and vivid colour. UV light is applied immediately after each colour is printed. This allows perfectly round drops to be placed in their correct positions.

Centre Drum Web Handling

The Drum Platen is a highly accurate web feeding technology which prevents

meandering and skewing of the web. The gap between the printhead and substrate is kept to a minimum, which enables accurate ink placement, for crisp text and fine lines.

Meandering and skewing of the web does not occur, because the substrate is held tightly around the drum. In comparison, the camber type platen of other presses requires manual adjustments when the substrate is changed, in cases such as Y-direction skew adjustment and colour adjustment (substantial waste of substrate). The SurePress registration adjustment is electronic.

The substrate is “fixed” to the drum, as it passes all printhead colours, hence it provides excellent colour-to-colour registration.

Nozzle Verification Technology and Auto Head Maintenance Function

Nozzle verification technology is an automatic nozzle check system with advanced ink droplet detection technology. A drive signal is sent to the piezo actuator. The same piezo element is used as a sensor to measure the pattern of the residual vibration. The residual vibration is analysed in milliseconds, reporting the nozzle status. All nozzles are checked after cleaning and before printing. A manually printed nozzle check pattern is not required to check if a nozzle is firing.

Auto head maintenance cleans the nozzles automatically to eliminate manual cleaning during each shift. It is fully automatic with no operator intervention required. Wash fluid is sprayed on the head surface and then the head is cleaned

automatically with the cleaning wiper. The auto self-head maintenance function cleans heads periodically to avoid nozzle clogging based on print duty cycle and results of the nozzle verification test. After maintenance, the press returns to printing again with no operator interaction or interruption in job sequence.

SurePress Customer Support Service by Remote Monitoring System

The operational status of the SurePress is monitored using a remote monitoring server. The L-6534VW has an extensive network of sensors which feed into a diagnostic system. This allows, at any time, a quick response and predictive

analysis, all done in advance of a repair visit.

Inline Digital Varnish

The L-6534 has the Epson innovative digital varnish ink. A gloss or matte finish can be printed selectively as a varnish. High value and very appealing accents can be added to lift the visual appearance of specific areas. The different finishes are achieved by changing the way the digital varnish is jetted from the printhead. Brand owners now have digital flexibility with spot varnishes. Digital varnish delivers smooth and even gloss, matte and spot finishes. The auto gloss varnish control function enables the appropriate amount of digital varnish to be applied to select areas according to the amount of WCMYK ink. This achieves a smooth, even and glossy finish.

High-Opacity White Ink

The single-pass high-opacity white ink provides high-density performance equivalent to screen printing and the ideal base layer for printing vivid colour on clear or metalised substrates. The bright white ink also gives the ability to print opaque, fine text and lines, even when printing clear labels for clear packaging. It offers the flexibility to print white on top of colours.

Clear film can be printed with colour ink first, followed by white ink using a printing method that allows you to view the results from the back of the film (reverse printing).

Reverse Print

L-6534VW has a function to rewind the substrate. To print white over colour (reverse print) on clear film, you can rewind and print without replacing (returning rewind to unwind manually) the roll. Waste of substrate is reduced by resuming printing after proofing by simply rewinding and resuming printing.

Epson SurePress Inks: Food Contact Materials (FCM) Compliance

Epson label inks reach major milestones in Food Contact Materials compliance. Epson inks used in SurePress inkjet label presses are compliant with EU Regulation framework (FCM EC No. 1935/2004), Good Manufacturing Practices Regulation (GMP EC No. 2023/2006), Plastics Implementation Measure Regulation (PIM EU 10/2011) and included in Swiss Ordinance (SR 817.023.21) on Food Contact Materials for food packaging printing inks.

Wide Gamut

A high concentration of pigment particles and UV pinning, which prevents ink drops from spreading or deforming, enables wide gamut and vivid colours. Wide gamut enables the reproduction of a wide range of desired colours that brand owners require. The gamut volume of L6534VW is larger than printing standards of offset coated paper like FOGRA, GRACoL and Japancolor.

You can get a demonstration of the new SurePress L-6534VW industrial UV digital label press at Epson’s Experience Centre in Yennora by contacting Epson Australia here.

Roland DG would like to extend its thoughts and best wishes to those who have been affected by the significant rain event currently inundating large parts of the East Coast of Australia. With so ma...

March 24 2021

Roland DG would like to extend its thoughts and best wishes to those who have been affected by the significant rain event currently inundating large parts of the East Coast of Australia. With so many people affected, we hope for the safety and well-being of all involved.

Roland DG’s existing Disaster Support Program is designed to assist customers affected by extreme events such as this. One way we can assist is to provide, at no cost, call-out fees and labour to review and inspect Roland DG equipment damaged as a direct result of the floods, or the resulting power outages. The Roland DG Care team can provide condition reports for any insurance claim requirements and for equipment requiring repair service work. Spare parts will be supplied under special rates (please contact Roland DG directly for more detail).

As a result of the flooding, deliveries to a number of areas along the East Coast may be delayed. We are working with our freight carriers to provide delivery updates where possible, but if you are expecting a delivery, please contact the Roland DG team to find out specifics.

Roland DG endeavours to help find additional ways to assist customers directly affected so please contact the team for more details on how we can help get your business back up and running.

The Roland DG Care team will schedule service runs in the affected regions once they can access these areas, and once it is safe to do so. Should you have any questions, or to register for the special service runs, please do not hesitate to contact Roland DG directly for assistance on 1 800 500 119, through our website booking form, or via email at service@rolanddg.com and one of our team members will assist you.

EFI and Currie Group are hosting an open house week, from 12th April to 16th April, showcasing the latest EFI product offerings to customers. The session will cover a live demonstratio...

March 23 2021

EFI and Currie Group are hosting an open house week, from 12th April to 16th April, showcasing the latest EFI product offerings to customers.

The session will cover a live demonstration on its latest EFI Pro 32r+ as well as introducing the range of EFI wide-format products such as the Pro 30f flatbed printer and the VUTEk 32h and Pro 16h hybrid printers.

The event will be at Currie Group’s Melbourne Demonstration Centre, at 2-4 Guest Street, Hawthorn.

The open house event is open to everyone in the industry, but bookings are essential and can be made by registering via: www.events.curriegroup.com.au

“We’re very excited to introduce new customers to Currie Group and those that are already part of our family to the EFI wide format portfolio," says Paul Whitehead, Business Unit Manager - Wide Format, Currie Group. "The EFI Pro 32r+ is a game changer. This new addition to the Australian and New Zealand wide format market, combines EFI’s state of the art leading technology with Currie Group’s premium service and support. I invite you to visit us at our open house where you will experience this firsthand and find out more about our market introductory offers."

https://www.efi.com/en-gb/products/inkjet-printing-and-proofing/efi-wide-format-printers/efi-pro-32r-plus/overview/

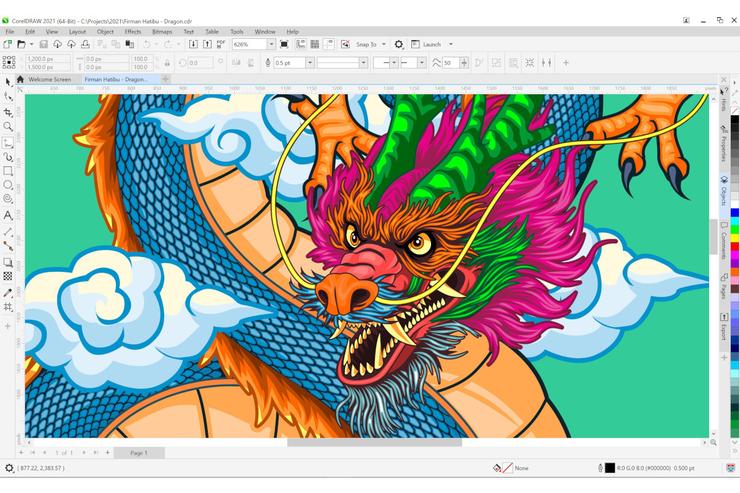

Introducing the new CorelDRAW 2021 product lineup featuring professional graphic design software, CorelDRAW Graphics Suite 2021. Available for Windows and Mac, the new suite doubles down on collabo...

March 16 2021

Introducing the new CorelDRAW 2021 product lineup featuring professional graphic design software, CorelDRAW Graphics Suite 2021. Available for Windows and Mac, the new suite doubles down on collaboration with access to next-generation tools that streamline the design and review process. Boost productivity with a flexible design space that empowers users to take control of projects and assets. Advanced illustration and photo editing capabilities make it faster than ever for designers to achieve their unique creative vision. And as our definition of workplaces is continuously redefined, CorelDRAW.app is now touch-optimised and available as an all-new iPad app, giving graphics pros new options to be creative anywhere, from virtually any device.

“The way we work has changed faster than anyone could imagine, and CorelDRAW Graphics Suite 2021 is meeting this need head on. At a time when it’s never been more challenging and important to stay connected, our collaboration tools enable teams to share inspiration and feedback in real time, whether they’re across town or across the globe,” said John Falsetto, Senior Director of Products, Graphics and Productivity. “By re-examining users’ workflows and making extensive enhancements across the suite, we’re helping designers take their projects from ideation to final output, faster.”

Offering vector illustration, layout and typography, photo editing and more, CorelDRAW Graphics Suite 2021 simplifies complex workflows and gives designers total control over how they create their best work – on Windows, Mac, web and mobile. Focusing on collaboration, productivity, and flawless results, new highlights include:

Time saving, next-generation collaboration makes it possible to connect, keep projects on track, and work together from anywhere – in real time.

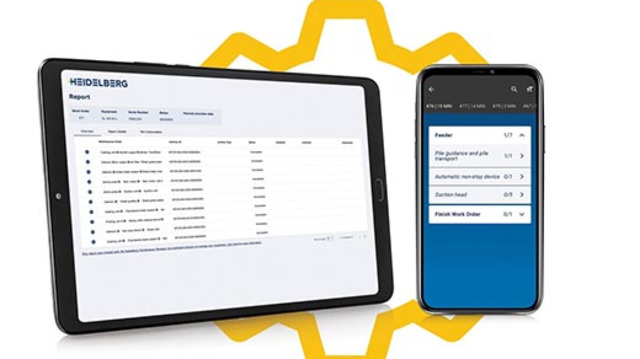

The new Maintenance Manager by Heidelberg almost completely digitises the maintenance process, reducing stoppages and significantly boosting machine uptime. Maintenance Ma...

March 16 2021

The new Maintenance Manager by Heidelberg almost completely digitises the maintenance process, reducing stoppages and significantly boosting machine uptime.

Onyx Graphics, Inc., a leading software solutions provider for the digital inkjet wide-format print industry, announced today that ONYX software is certified for the new HP Latex 700 and 800 Printe...

March 16 2021

Onyx Graphics, Inc., a leading software solutions provider for the digital inkjet wide-format print industry, announced today that ONYX software is certified for the new HP Latex 700 and 800 Printer Series. This certification applies to all ONYX RIP and Print Workflow solutions, including ONYX Thrive, ONYX PosterShop, and the newly released ONYX Go subscription, all on the company’s latest version release, ONYX 21.

The HP certification program differentiates software vendors through a comprehensive set of integration, compatibility, and performance standards testing against HP printing technologies. For this latest certification, Onyx Graphics designed the driver to support the vivid color and newly added white-ink capabilities of the HP Latex Printer Series, including sandwich mode printing for under-flood, over-flood, and spot. In addition, the ONYX driver allows for ONYX Quick Set options to automate print production, taking advantage of the speed and agility offered in this new printer series. Combined with ONYX Color and iccMAX v5. profiling, users of the HP Latex 700 and 800 Printer Series can expect superior and consistent color across their entire print production environment.

“This latest certification achieved by Onyx Graphics showcases their commitment to providing outstanding support for HP printing technologies.” Said Guyente Sanmartin, General Manager, Large Format Business, HP. “HP Latex 700 and 800 Printer Series users who choose ONYX software can feel confident in delivering outstanding quality prints to their customers.”

About the HP Latex 700 and 800 Printer Series

According to HP, the HP Latex Series introduces a range of Latex Large Format print solutions to help Print Service Providers diversity their offerings. The HP Latex 700 and 800 series brings a suite of features that enable PSPs to be more agile, tackle ambitious projects, and take on the highest value work. The new portfolio also delivers fast workflows that help businesses hit deadlines while sharpening their sustainability edge.

onyxgfx.com