October 12 2021

Kodak today announced a revolutionary new digital press and innovative additions to its comprehensive portfolio of digital and offset solutions designed to help printers boost their profitability and capitalise on new opportunities for growth.

Kodak today announced a revolutionary new digital press and innovative additions to its comprehensive portfolio of digital and offset solutions designed to help printers boost their profitability and capitalise on new opportunities for growth.

The revolutionary KODAK ASCEND Digital Press takes high-end Packaging and Retail Signage to new heights

The new KODAK ASCEND Digital Press is the perfect solution for commercial printers and digital service providers who want to succeed in the growing Retail/POP and Packaging markets. The KODAK ASCEND Digital Press is the first electrophotographic (EP) press designed to print heavy weight substrates at long lengths with eye-catching, high-margin CMYK and flat foil embellishments in one pass. It is more flexible than traditional presses and more productive than flatbed inkjet systems, offering production speeds up to 572 sqm/hour (5280 sqft/hour). Its large sheet length of up to 122 cm (48 inches) allows the press to offer 23% more print area than a B2 sheet. The new press enables printers to deliver sustainably recyclable print by using environmentally friendly KODACHROME Dry Inks, which are Indirect Food Contact rated. Kodak’s new press is a more cost-effective solution for producing Retail/POP and Packaging applications than traditional presses or flatbed inkjet devices.

The ASCEND Digital Press will be available Q2 2022 in North America and Europe.

KODAK PRINERGY On Demand Access puts cloud-based workflow within reach of small to mid-size commercial printers

With PRINERGY On Demand Access, Kodak is introducing a cost-effective expansion of its cloud-based PRINERGY On Demand Platform. This new option makes the printing industry’s most secure and highest performing software platform affordable for more printers of any size, with or without digital presses.

The new SaaS solution provides full connectivity to digital presses, Microsoft Azure-backed security and the scalability the PRINERGY On Demand Platform is known for. PRINERGY On Demand Access includes preflight, colour management, file management, backup and routing as well as built-in KODAK INSITE Prepress Portal functionality for file submission, remote customer collaboration and online approvals. Available in Q1 2022.

New KODAK PROSPER Digital Varnish for highly flexible digital coating of paper-based packaging

The new KODAK PROSPER Digital Varnish is a unique, water-based varnish that can be jetted as an area or spot coat to printed packages using KODAK PROSPER S-Series or KODAK PROSPER Plus Imprinting Systems. The eco-friendly PROSPER Digital Varnish can be applied in perfect register with design elements and creates a matte protective layer providing rub and water resistance to paper-based packaging applications.

As PROSPER Digital Varnish is applied only where needed and doesn’t require plate making for spot coating, it helps printers eliminate the costs, effort, waste and environmental impact associated with traditional post-coating methods. The new varnish provides an environmentally friendly, water-based alternative to solvents and UV coatings.

The KODAK PROSPER Digital Varnish will be available worldwide by the end of 2021.

Enhanced KODAK Mobile CTP Control App offering more management and reporting capabilities

The KODAK Mobile CTP Control App is an app that allows remote control and monitoring of up to 10 KODAK CTP Platesetters, reducing a dependency on onsite labor for managing jobs in queue, status updates, and more. The enhanced version of this one-of-a-kind app provides access to real-time and historical data with customisable reporting to save time on data analysis, help prioritise actions, and improve plate-making efficiency. The new version of KODAK Mobile CTP Control App is now available worldwide to download for Android and iOS mobile operating system.

Executive quote:

“The innovations announced today reflect Kodak’s continued commitment to developing breakthrough solutions that enable our customers to improve their productivity and profitability and successfully expand their customer base,” said Jim Continenza, Kodak’s Executive Chairman and Chief Executive Officer. “With innovations like the KODAK ASCEND Digital Press, we are opening up new profitable application opportunities for printers. We continue to deliver on our promise to provide a complete range of solutions that offer Print that Pays.”

For additional information on Kodak, visit us at Kodak.com and engage with us on Twitter @KodakPrint and on LinkedIn at Kodak Print

Esko has launched its latest plate making solution, the CDI Crystal 4260 XPS, delivering more automation, enhanced quality, increased simplicity and improved reliability to the plate room.

September 28 2021

Esko has launched its latest plate making solution, the CDI Crystal 4260 XPS, delivering more automation, enhanced quality, increased simplicity and improved reliability to the plate room.

The CDI Crystal 4260 XPS can be operated with just one hour of training, with single touch operation using an intuitive screen interface and enables unattended operation. The award-winning Esko XPS Crystal technology optimally combines UV main and back exposure, using LEDs that always emit consistent UV light as opposed to traditional exposure frames, which use lightbulbs with fluctuating output.

“Today’s prepress departments face a number of challenges that make the desire to offer the combination of quality, speed and competitive pricing a key driver of investment and organisational decisions,” said Pascal Thomas, Director of Flexo Business at Esko. “The impact of Covid-19 has only compounded the demands on the packaging prepress and printing sector – be that increasing production complexity, shorter run lengths or a need for fast turnaround to meet their brand customers’ need for speed to market.

“Maintaining prepress quality and efficiency in the face of such complexity is challenging, when also needing to manage product and service quality and minimise costs to remain competitive. The answer lies in digitising, automating and connecting the prepress and plate making process to drive down costs, increase quality and speed, and eliminate waste and errors in resources, time and materials. To that end, we are introducing the newest member of the Esko CDI family, the CDI Crystal 4260 XPS.”

The combination of the CDI Crystal flexo imager with the XPS Crystal exposing unit offers a perfect, consolidated flexo plate making workflow with the highest return on investment. “Redefined from scratch, the integration and automation of the digital imaging and LED UV exposure processes improves consistency and overall ease of use for prepress operators,” said Pascal. “This solution not only frees up valuable time but also reduces maintenance and the footprint of the flexo equipment, keeping costs to a minimum.”

The CDI Crystal 4260 XPS excels in efficiency, reducing manual steps by 50% and reducing errors by 50% to create less plate waste, alongside reducing operator time by as much as 73%.

Further driving productivity in the plate room, Esko introduced the PlateHandler, a robotic device connecting the CDI Crystal imager with the XPS Crystal exposure unit. “A prepress operator is usually required to manage multiple devices to produce a plate, which demands considerable time and attention to what is going on, and often incurs a risk of error,” explained Pascal. “Integrating the Esko PlateHandler into the system reduces the number of operator touchpoints, freeing up to 50% of their time and enabling them to attend other more value-adding tasks such as quality control, plate storage and plate mounting,” he said.

“Similarly, the new Esko PlateFeeder-S has been designed to solve a number of common issues. For example, it enables distortion-free transportation of plates, avoiding damage when they are transferred manually from storage to the CDI,” said Pascal. “The table can also be tilted to pass through doors and docked onto the CDI to ensure perfect plate positioning and digital connection to the CDI Crystal. Its cover sheet can also be removed to provide free access from all sides without static charge input.”

Integrating the PlateFeeder-S into the setup also prevents idling between plates due to the operator attending to other tasks, boosting productivity further by enabling an additional plate to be positioned for automated transportation into the CDI Crystal immediately when available. “The operator only needs to attend the machine once within each imaging cycle, to load a new plate and unload the exposed plate from the XPS Crystal,” said Pascal.

“What’s more, manual positioning is prone to errors and can be time intensive. But with the PlateFeeder-S, once docked, it becomes visible on the CDI touchscreen and integrates into the automated workflow enabling the operator to position a new plate at any time during the 15-minute imaging process,” he said. “Built-in sensors also secure accurate plate loading via the PlateHandler, avoiding plate waste and further errors. The PlateFeeder-S eliminates 100% of the plate loading idle time on the CDI Crystal XPS resulting in uninterrupted plate making, reducing system idling by up to 40% and delivering a 40% reduction in human touch points.

“With a CDI Crystal 4260 XPS with PlateHandler and PlateFeeder-S working continuously with optimum throughput and minimum operator attention, there is complete platemaking automation. The overall impact can be an increase in plate making productivity of up to 15%.”

For more on these and all the latest Esko innovations, visit www.esko.com

Konica Minolta has introduced the AccurioPress C7100 series digital colour presses, which are packed with innovative technologies to create more profitable business opportunities. From intelligent ...

September 07 2021

Konica Minolta has introduced the AccurioPress C7100 series digital colour presses, which are packed with innovative technologies to create more profitable business opportunities. From intelligent automation and enhanced finishing to flawless quality, advanced capabilities, and exceptional durability, customers have the power to grow their businesses through a press that works smarter.

The AccurioPress C7100 is a new high speed print engine and follows on from the success of the AccurioPress C14000 Series and AccurioPress C4080 Series. It runs at 100 colour pages per minute (ppm) with the AccurioPress C7090 at 90ppm. With a focus on optimising performance, offering new and advanced print products, and growing the entire business, the AccurioPress C7100 series serves more customers and completes more jobs with innovative technologies that power success.

Helping customers expand and streamline businesses

Tatjana Ferguson, product marketing manager, Konica Minolta said, “The launch of the AccurioPress C7100 Series completes the full refresh of our production colour line up. The C7100 series builds on the success of its predecessor, the C6100, with feature enhancements for the agility and productivity demanded by professional printing. The new models will make a powerful impression in the market, helping customers expand what they can offer as well as helping them streamline their business and achieve greater productivity.”

Sue Threlfo, general manager, production and industrial print, Konica Minolta Australia, said, “Konica Minolta is constantly innovating to help customers rethink their agility. In a world where the only constant is change, Konica Minolta works collaboratively with customers to support their transformations, predict potential challenges and create solutions to provide assurance for them and the future of the industry.”

Flawless quality

Konica Minolta’s latest Simitri V toner is eco-friendly and formulated for performance. Fast melting, energy efficient, and low maintenance, it reproduces superb quality on a wider range of media up to 400 gsm. Combined with an output resolution of 3,600 dpi equivalent x 2,400 dpi, outstanding results are achieved from even the longest print runs.

Advanced capabilities

With auto-duplex banners up to 900mm and the flexibility to handle embossed and textured media, handling of the machines is so simple that the most complex projects can be run by a single operator.

Intelligent automation

By instantly detecting the precise stock being used, the optional Intelligent Media Sensor IM-101 significantly reduces production time. At the same time, the optional IQ-501 Intelligent Quality Optimiser ensures perfectly consistent colour quality and front-to-back registration on every print with real time quality and variable data print (VDP) inspection.

Enhanced finishing

As with the entire AccurioPress portfolio, a wide range of finishing and other functions are also offered in addition to booklet-making, stapling, perfect binding, and wire binding. Konica Minolta’s TU-510, the world’s first inline trimming unit, successfully introduced with the C14000 series, is available for the AccurioPress C7100 Series. The TU-510 is a four-edge trimming unit that can trim, crease, and perforate, allowing for full-bleed finishing support for long sheets, booklets, direct mail, and offers a dedicated business card option.

Exceptional durability

Reliability drives profitability. Among the new technologies built into the engine are a more durable lubricated drum, double corona wires with automatic cleaning, an optimised paper transport solution and a double swing registration system for improved paper compatibility and feeding accuracy.

The AccurioPress C7100 Series is designed to support highly responsive print environments. It offers a choice of controller options including a Konica Minolta controller and controllers from EFI and CREO.

For more information www.konicaminolta.com.au‚ÄØ

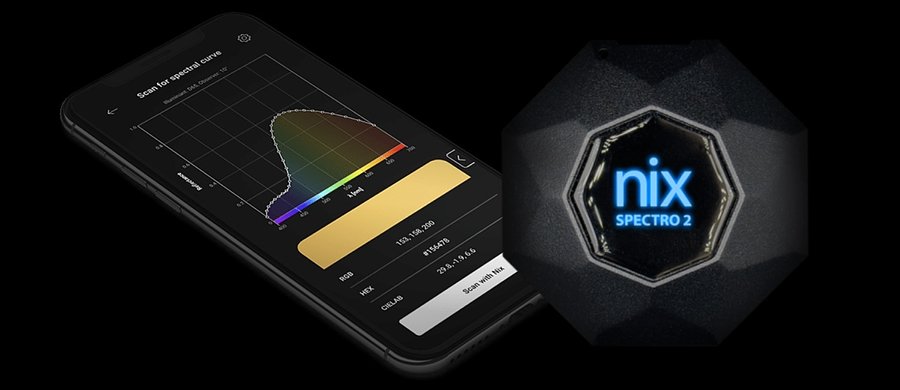

The Nix Spectro 2 is a full-featured, portable spectrophotometer that will revolutionise the paints and coatings industry. Finally, custom paint formulations can be performed at front-of-the-counte...

June 01 2021

The Nix Spectro 2 is a full-featured, portable spectrophotometer that will revolutionise the paints and coatings industry. Finally, custom paint formulations can be performed at front-of-the-counter or outside of the store with the full accuracy of a benchtop.

Hamilton, Ontario: Nix Sensor Ltd., a technology-based company that designs, manufactures, and retails high-precision sensing technology, such as the award-winning Nix Mini, announced today the launch of the Nix Spectro 2. A professional-grade, accessible, and cost-effective spectrophotometer that offers a new way for industry professionals to capture and communicate spectral data.

“The product development and engineering teams at Nix have been listening closely to the needs of our customers around the world and the message is clear; paint matching and custom formulation must be brought to the masses, especially in the COVID-19 era. Brands must also extend outside of their traditional retail settings if they want to stay competitive. To accomplish this, we needed to build a device that is not only portable, durable, and accurate, but most importantly, easy to use. I am proud to say that we have achieved all of these goals and more with the Spectro 2. I’m excited to see how this technology will once again revolutionize the retail/online paint experience.”

- Matthew Sheridan – CEO/Founder of Nix Sensor Ltd.

The Nix Spectro 2 is the only portable spectrophotometer of its kind to capture spectral data across 31 channels (10nm bins over 400-700nm) while being durable enough to be used on a job site and easy enough to be directly used by a homeowner.

Smaller than a tennis ball, but made from solid aluminium, the Nix Spectro 2’s innovative portability will quickly usher in a new era of “on-site” color matches, formulation, and color communication. Accelerated by the worldwide COVID-19 pandemic and by software tools like Nix Sensor Ltd.’s Paint With CHIP app (paintwithchip.com), we expect the disruption of the traditional retail paint model to continue to accelerate throughout 2021 and beyond.

The Nix Spectro 2 is launching Spring 2021 and a pre-order signup to receive 25% off is available for a limited time at nixsensor.com/nix-spectro-2/.

Canon Australia announced the latest addition to its highly acclaimed imageRUNNER ADVANCE DX portfolio, the C478i Series. Ideal for hybrid workspaces, the A4 range offers the perfect solution for f...

May 31 2021

Canon Australia announced the latest addition to its highly acclaimed imageRUNNER ADVANCE DX portfolio, the C478i Series. Ideal for hybrid workspaces, the A4 range offers the perfect solution for fast tracking small to medium-sized enterprises’ digital transformation journey with integrated hardware and software for optimum collaboration. The series includes the imageRUNNER ADVANCE DX C478i[1] and the imageRUNNER ADVANCE DX C478iZ[2] which offers enhanced productivity with additional finishing options in an integrated device.

Optimum productivity and usability

The imageRUNNER ADVANCE C478i Series multifunction printer is centred around simplicity, combining an intuitive user interface with fast functionality and high-quality images to ensure tasks can be managed efficiently. Personalised workflows allow users to pick and choose what works best for them and cloud documents can be accessed and stored at any time using uniFLOW Online. Advanced scanning technology can dramatically reduce time spent naming and saving scanned files to a user’s cloud storage service. Additionally, the series offers effortless maintenance with a suite of user maintenance videos, and Canon’s mess-free all-in-one toner cartridge reduces downtime with smooth replacement of consumables.

Enhanced mobility, security and sustainability

Workers and contractors can work on-the-go with expanded mobile OS support. The Canon PRINT Business (mobile app) makes managing workflows easy and can be used with Apple® and AndroidTM. The imageRUNNER ADVANCE C478i series offers robust security with Encrypted SSD data storage, TPM 2.0 and cloud backup which provides comprehensive 360° security. McAfee Embedded Control is standard to prevent programs from being tampered and unauthorised programs from being executed during runtime. The imageRUNNER ADVANCE C478i series satisfies key sustainability demands of hybrid workspaces with quiet operation for minimal disruption and reduced costs from improved energy consumption.

“Over the last year the emergence of the hybrid workplace has fundamentally shifted the technology requirements of businesses,” says Ted Matsumoto, General Manager - B2B Product Marketing, Canon Australia. “Canon is proud to build on its imageRUNNER ADVANCE DX portfolio with the intuitive C478i Series which offers smart technologies that deliver high productivity and streamlined workflows for increased efficiency. Ideal for SMEs operating at home or in the office, Canon is confident we’re helping our customers with their digital transformation journey and the challenges of hybrid working.”

Key Features - imageRUNNER ADVANCE DX C478i Series

Canon Production Printing Australia have announced the ColorStream 8000 series of continuous feed inkjet printers, setting a new standard for high volume production environments.

May 31 2021

Canon Production Printing Australia have announced the ColorStream 8000 series of continuous feed inkjet printers, setting a new standard for high volume production environments.

An addition to the market-leading ColorStream family, the new flagship represents the next stage in the evolution of the platform with its combined advances in productivity, print quality and application flexibility.

Built on a decade of continuous innovation in response to customer feedback, the ColorStream 8000 series has been designed to meet the current and future production challenges of corporate and public sector in-plants, print and communication service (transactional and direct mail) providers and specialised commercial printers, such as those producing books, manuals or pharmaceutical leaflets.

The series features new 1,200dpi printheads that yield a stunning and consistent print quality – even at the highest speed – from the first print to the last, reproducing smoother gradients, homogeneous tints and sharper detail, and minimising typical inkjet technology artefacts.

The ColorStream 8000 series also uses a new water-based pigment ink set with latex polymer, which delivers a very wide colour gamut that meets Fogra process standards, perfect droplet formation, and deep black and vibrant colours on uncoated paper without any pre-treatment.

Craig Nethercott, Managing Director, Canon Production Printing Oceania comments, “the 8000 series features advanced technology that takes the ColorStream to a new level of quality, efficiency and productivity.

“We now have the ability to produce more in less time, broaden application reach, explore new markets and grow profit streams.”

The ColorStream comprises two models, 8133 and 8160, representing the maximum print speed of each (133m/min and 160m/min). With print speeds of up to 2,152 A4 images/min (15 – 70 million A4 images per month), the ColorStream 8000 series is set to easily handle production peaks and reduce run and labour costs by consolidating volumes from offset and continuous feed toner presses onto the ColorStream.

Mr Nethercott continues, “the productivity of the series is further improved by the fact that everything that could be automated has been, making the series exceptionally easy to operate and freeing up operator time for other value-added activities. The many automated tasks add to the remarkable uptime (over 90%) of the ColorStream 8000 series, giving users a reliable solution they can really trust.”

The Proactive Maintenance available with the ColorStream 8000 series offers additional peace of mind in production planning by delivering predictive maintenance, enabling targeted machine downtimes for service and avoiding unpredicted downtimes during production.

Mr Nethercott adds, “in a fast-moving market, finding new applications can be crucial to staying competitive. The ColorStream 8000 series features an improved print quality and the ability to print on a wide variety of uncoated, recycled and inkjet treated papers from 40gsm to 160gsm as standard (and selected papers up to 220gsm). So now, print and communication service providers can now proactively respond to the challenges of today’s market and provide high quality promotional applications next to transactional, direct mail and book (mono and full colour) applications.

“This capability is enhanced by the design of the press’s paper path, which, with a maximum print width of 560mm, gives impositioning freedom to create outstanding promotional pieces and maximise book formats.”

First ColorStream 8000 series customer

DATEV eG is the third largest provider of business software in Germany, one of the largest European IT service providers and the first Canon customer to install a ColorStream 8000 series printer.

The cooperative of tax consulting professionals supports a total of 2.5 million companies, self-employed persons, municipalities, associations and institutions, and manages the complete production of customers' business documents as a full-service provider.

Operating a high-performance, modern and highly secure Digital & Print Solution Centre (DPSC) in Nuremberg, it produces, on average, more than 1.1 billion pages per year, ranging from promotional and informative mailings to invoices and reminders to high-quality account statements and insurance policies.

Based on customer demand for the fastest ColorStream version, the ColorStream 8160 will be available from the date of launch, 25 of May, while the ColorStream 8133 will follow early in the second half of 2021. Both models will be available in mono and full-colour configurations.

Customers can see the new ColorStream 8000 series by requesting a virtual demo.

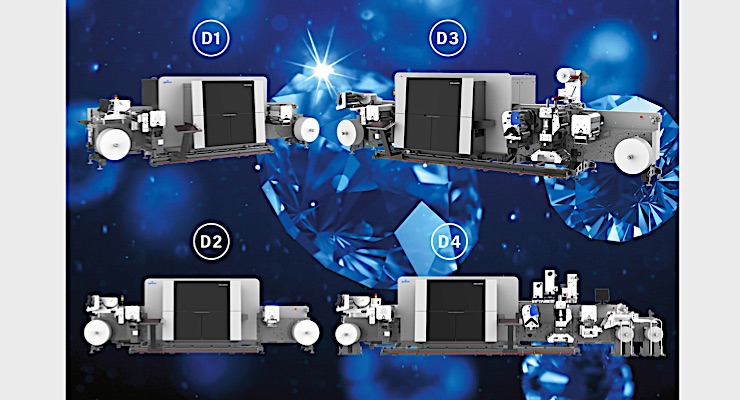

In order to meet constantly changing customer demands, Gallus is launching the "Diamond Core Series" to enhance its Labelfire product offering. From now on, four models of the Gallus Labelfire will...

May 20 2021

In order to meet constantly changing customer demands, Gallus is launching the "Diamond Core Series" to enhance its Labelfire product offering. From now on, four models of the Gallus Labelfire will be available – concisely and clearly defined – and tailored to the different market requirements. Digital white with high opacity is optionally available for all models.

The heart of each Gallus Labelfire is the digital print unit, the so-called “diamond core," the company states. This Digital Print Unit (DPU) enables high-quality 1200 x 1200 dpi UV inkjet printing with Samba printheads by Fujifilm. Excellent printing results are produced with pinning modules specially adapted for the inks and printheads, as well as the enhanced simulation of the Pantone Plus colour scale. In addition, all models of the Labelfire Diamond Core series convince with their high production speed with up to 70 m/m and the ability to print a variety of substrates.

"With the Gallus Labelfire Diamond Core Series, we offer a suitable range for all types of printers, regardless of their level of experience and scope of requirements," explains Thomas Schweizer, head of business management at Gallus. "In addition, we offer a fully comprehensive service. With buying this machine, all maintenance work is included in the price for the first year of operation and thereafter our customers can choose from three service basic packages with the option of flexible expansion, from the low-cost basic rate to the all-round carefree package."

In four different machine configurations, the Labelfire Diamond Core models are divided up from D1 to D4 in order to acknowledge the market demands.

The models D1 und D2 are the "working horses” of this series. They print on an industrial scale, stable, reliably and quick, direct from roll to roll. Clearly defined, with or without digital white, they are suitable for all printing companies, which have no need for inline finishing. The Labelfire D1 is the 4-colour entry level machine system into the 1200 dpi digital printing and suited for commodity labels with changing small run lengths.

The Labelfire D2 is the alternative with seven colours: CMYK plus gamut extension green, orange and violet for challenging designs like cosmetic and body care products. With the seven colours, the D2 enables up to 94% of the simulated Pantone Plus colour scale.

Whether 4-colour or 7-colour, with or without digital white, Gallus' hybrid technology offers expanded flexibility due to integrated inline finishing and embellishing modules. The Labelfire D3, the UV inkjet press with four colours, (CMYK) and the Labelfire D4 with 7 colours (CMYK GOV) are always equipped with a flexo and a diecutting unit for easy single-pass printing – from file to finished diecut label in one printing pass. In addition, as required, with either a laminating/varnishing module or a cold foil unit, a cost-effective production of finished labels is thus guaranteed even for very small print runs.

At Dscoop Edge Fusion 2021, HP Inc. today announced a new wave of innovations for HP Indigo digital printing, supporting momentum, growth and digital transformation. P...

May 20 2021

At Dscoop Edge Fusion 2021, HP Inc. today announced a new wave of innovations for HP Indigo digital printing, supporting momentum, growth and digital transformation.

Print service providers (PSPs) worldwide continue to adopt HP Indigo digital printing, with more than 125 HP Indigo presses already installed to date from the new technology portfolio announced in March 2020.

“Despite the challenges of the past year, Indigo customers have continued to lead the transformation of the graphic arts industry. Our R&D labs continue to deliver on our promise, releasing new capabilities, products and solutions to support the growth of our customers,” said Haim Levit, HP Indigo vice president and general manager, in a keynote address to Dscoop Fusion, a global gathering of HP Graphic Arts print service providers and solution partners with over 8000 members.

Transformation in commercial printing

Since its introduction last year, HP Indigo’s new commercial portfolio gained significant momentum worldwide, including long-term investments in new fleets by Cimpress and Shutterfly. The portfolio empowers commercial printers to continue expanding the digital transformation in the market. The HP Indigo 100K Digital Press – the most productive digital B2 press in the market3 – is leading this trend with more than 30 units already installed, enabling commercial printers to shift greater volumes from offset to digital.

To drive digital expansion in commercial print even further, today HP Indigo announced a new set of features, expanding the capabilities of its drupa portfolio:

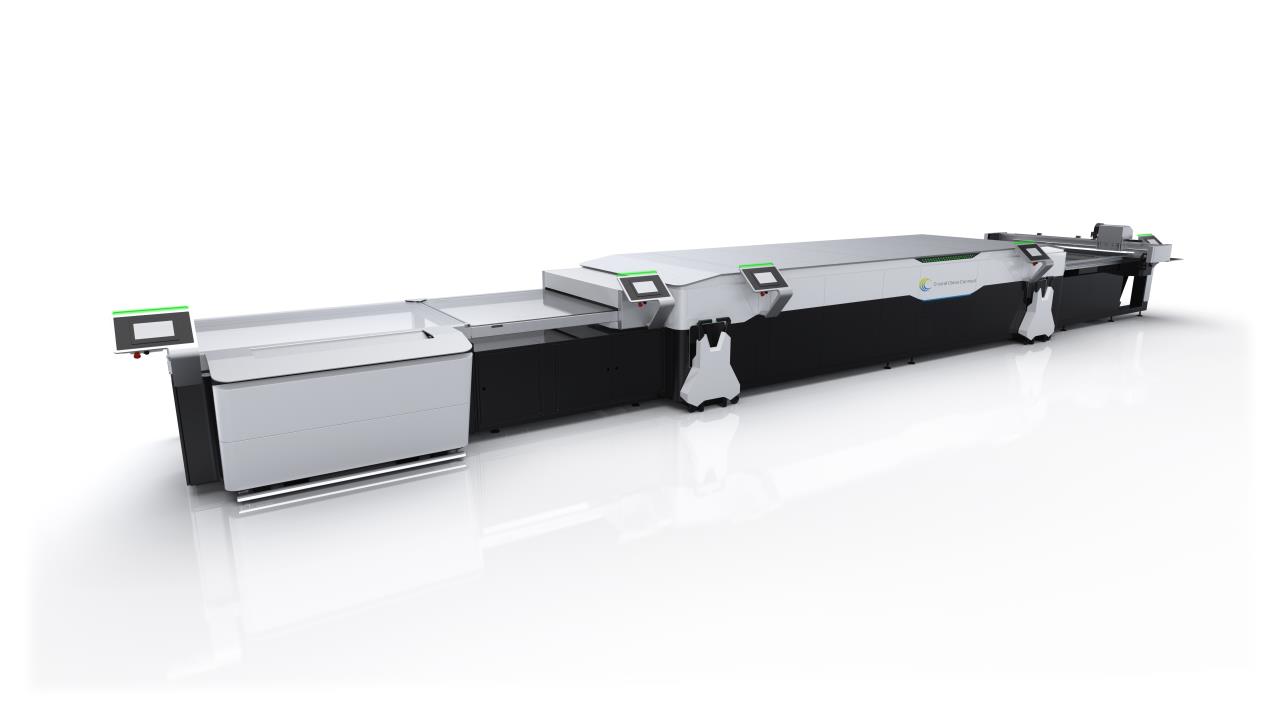

The ultimate range in flatbed production printing is now even faster, with the introduction of robotics technology for the automatic loading and unloading of media. Following the succe...

May 11 2021

The ultimate range in flatbed production printing is now even faster, with the introduction of robotics technology for the automatic loading and unloading of media.

Following the success of Fujifilm and Inca Digital’s Onset X HS range, the ultra-high productivity large format series now comes with automated technology to assist with long run production. It also slashes job changeover times and reduces the need for manual intervention between runs.

Utilising Dual Flex and High Five robotics, the range includes a semi-automatic (manual load and automatic take-off) configuration and a fully automatic loading, take-off and stacking system, designed specifically to handle flexible and difficult materials, such as unconditioned corrugated board.

“The new automation options available with the Onset X HS range are the result of close collaboration with our current Onset X customers,” says Matt Brooks, Head of Products & Solutions at Inca Digital “Longer run, full automation is becoming more and more common, and with the introduction of highly sophisticated robotic arms from ABB and Inca’s uniquely designed sheet pick-up technology, our Onset X customers can now produce extremely high volume, high quality print work in even less time. The ultra-high productivity and rapid job changeovers optimise production levels like never before.”

There are four automation options for the Onset X HS range – the 3/4 semi-automatic system, a fully automatic material loading system, a fully automatic handling system for unconditioned corrugated board, and a fully automatic handling system with integrated flexible loading.

The 3/4 automation system allows for single sheet, multiple sheets or double-sided print in registration. The operator loads sheets onto a preload table and the system takes over the rest, stacking it on a pallet for simple removal of the printed media. What’s more, the system allows the operator immediate, direct access to the bed and registration points for quick switch between manual and semi-automatic work.

The fully automatic material loading system is designed to handle conditioned and dimensionally stable sheets. It works in conjunction with the 3/4 handling unit to provide full automation, handling multiple sheets with highly accurate registration. The loader can be moved away from the machine to allow access to the print bed.

The corrugated board solution incorporates a fully automatic handling system, specially designed to handle difficult materials like unconditioned corrugated board. Vacuum-to-vacuum transfer ensures precision handling, from the robotic arm pickup to placement on the print bed and stacking of the printed board.

Dual Flex – this unique fully automatic solution with integrated flexible loading enables printers to transition seamlessly between lay table loading and dual robot automation. This solution provides full capability to load and unload flexible, semi-rigid and rigid sheets with a seamless switch from one operation to the other. In full automation mode, the dual robots also offer an optional “flip to print” mode – High 5 – for front to back, double sided print requirements without manual intervention.

“A fast and powerful handling system is vital for the Onset X to perform to its full capacity, helping to maximise job turnaround speeds and job changeovers for longer runs,” continues Brooks “We’re delighted to be launching these advanced automation solutions to the market, helping our customers to achieve optimum productivity and print quality, and we have already seen a great deal of interest in these new types of automation solutions”.

“Fujifilm has enjoyed a long and successful partnership with Inca Digital since the two companies together pioneered the world’s first wide format UV inkjet printers in 1999,” says Kevin Jenner, European Marketing Manager, Fujifilm Wide Format Inkjet Systems. “The Onset X range has been setting the standard for quality and productivity in the sector for some years now and we’re delighted to be able to offer our customers yet another step up in speed and efficiency.”

Esko and Asahi Photoproducts have showcased their fully automated flexo platemaking line CrystalCleanConnect at this year’s virtual.drupa event. “With CrystalCleanConnect w...

April 27 2021

Esko and Asahi Photoproducts have showcased their fully automated flexo platemaking line CrystalCleanConnect at this year’s virtual.drupa event.

“With CrystalCleanConnect we have brought together key hardware and software technologies from both organizations to deliver a number of breakthrough advantages from design to print,” said Pascal Thomas, Director of Flexo Business with Esko. “CrystalCleanConnect delivers a cleaner, more environmentally balanced operation that simplifies the flexo platemaking process, improves safety and boosts print quality consistency.”

Esko, the global developer of integrated software and hardware solutions for the packaging and labels markets, has collaborated with Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, on the innovative flexo platemaking solution. CrystalCleanConnect fully automates the entire platemaking process, from imaging and exposure through to plate production, reducing the number of steps in the flexo platemaking process from 12 to just one. This equates to a reduction from 36 minutes in platemaking and plate cutting to just 2.5 minutes of operator time to complete all processing steps.

“With CrystalCleanConnect, the operational benefits to businesses are as pronounced as the environmental benefits,” said Pascal. “With the removal of so many process steps, there’s an immediate 90% reduction in required operator time, which not only eliminates the potential for human error but also delivers immediate efficiency gains. Quality is assured through Asahi and Esko technologies working in complete harmony, and the combination of improved efficiency and quality delivers an average increase of 25% in press OEE.”

A holistic approach to connecting technologies

Dieter Niederstadt, Technical Marketing Manager for Asahi Photoproducts said: “Flexo needs to simplify processes while improving quality, consistency and profitability. In doing so, flexo can create new business opportunities and positively transform into a printing technology in balance with the environment.

Esko_Asahi_CCC_Logo“This breakthrough innovation is different in many ways to other solutions on the market,” Dieter said. “It is not just an assembly of available plate making processes delivered inline, but rather a holistic approach to connecting technologies, up and downstream of the prepress value chain, using an intelligent automation hub as the backbone and heart of the solution. CCC is truly pushing boundaries to the current scope of plate automation delivering a mount-ready plate as well as being the first automated production solution without the need for VOC-based washout solvents in in the platemaking process.”

Pascal Thomas added: “At Esko, we have long been dedicated to improving the platemaking experience, in terms of quality, productivity and connectivity. Together with Asahi Photoproducts, we are taking the flexo platemaking process to a brand-new level, enabling our customers to be even more competitive while also ensuring they can meet today’s demands for flexible and sustainable supply.

“With CrystalCleanConnect, our ultimate objective is to improve our customers’ overall business performance and profitability,” said Pascal.

For more information, visit www.asahi-photoproducts.com/en/CCC

FUJIFILM Corporation (President: Kenji Sukeno) today announces the Jet Press 750S High Speed Model, featuring the industry’s fastest* output speeds of 5,400 B2 sheets per hour for a sheet-fed...

April 27 2021

FUJIFILM Corporation (President: Kenji Sukeno) today announces the Jet Press 750S High Speed Model, featuring the industry’s fastest* output speeds of 5,400 B2 sheets per hour for a sheet-fed digital inkjet press.

This new model retains all the features of the current Jet Press 750S for commercial and folding carton package printing applications:

(1) High image quality outperforming that of offset printing

Utilising advanced ultra-high-density and high-precision “SAMBA” printheads and aqueous pigment “VIVIDIA” ink, the Jet Press 750S High Speed Model is able to produce ultra-high quality print equal to or even better than offset.

(2) High-speed output of 5,400 sheets per hour

The Jet Press 750S High Speed Model has the highest productivity available* for a sheet-fed inkjet press, 1.5x faster than that of the current Jet Press 750S.

(3) Flexible

According to the type of job being run, high quality mode (3,600sph) and high performance mode (5,400sph) can be switched for maximum flexibility.

(4) Improved total cost of ownership

The High Speed Model makes it possible to transfer a wider range of offset jobs to digital to reduce the total cost of ownership.

(5) Upgradeable

On site upgrade is available for new and current Jet Press 750S owners.

The Jet Press 750S High Speed Model is being showcased at virtual.drupa (April 20th to 23rd) via a concept video, and is also being featured on Fujifilm’s new website, https://believinginprint.fujifilm.com

The Jet Press 750S High Speed Model is scheduled to be available in Autumn 2021.

Fujifilm will continue to contribute to the development of the world’s printing industry by developing and providing innovative products for the digital printing market, the popularity of which is ever increasing.

*As of April 2021, in B2 inkjet digital machines.

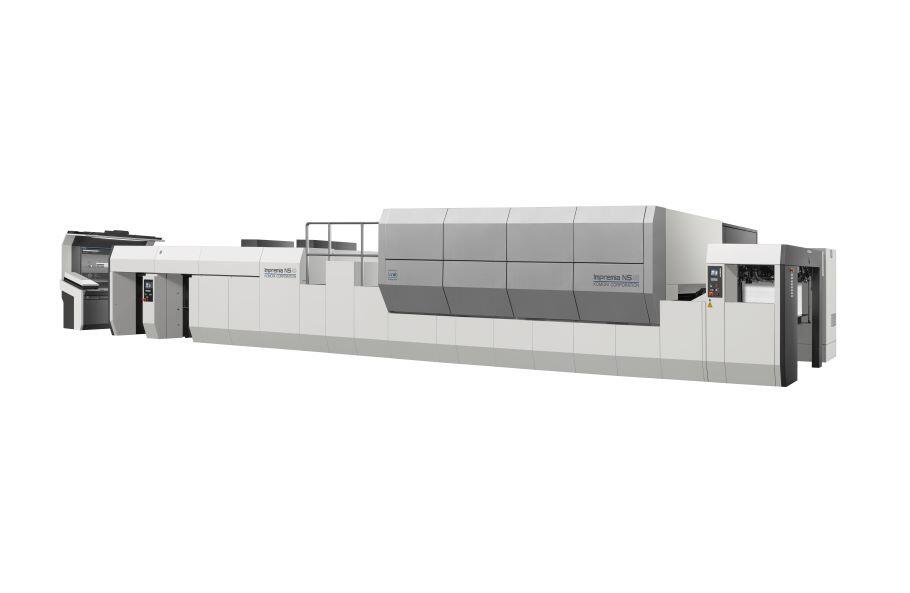

A new B1-size digital press to pioneer new business fields Komori has launched the 40" Sheetfed Nanographic Printing® System Impremia NS40 sales. The machine confi...

April 27 2021

A new B1-size digital press to pioneer new business fields

Komori has launched the 40" Sheetfed Nanographic Printing® System Impremia NS40 sales. The machine configurations are available in two models: 4-colour + coater and 7-colour + coater.

Komori presented this model at the Komori Web Session* at virtual.drupa,

Introducing a new digital press, with the impressive productivity and profitability needed to expand customers' businesses by meeting growing demand for short and medium runs including variable printing and versioning for immediate turnaround on jobs such as packages, displays and point of purchase. Supported by Komori's previously amassed technologies, and with unique designs such as use of image transfer blankets, the press achieves B1 print speeds of 6,500 sph. As a "digital offset" press, the NS40 is the peak of digital presses and is made possible only by Komori.

■Features

B1 printing speeds of 6,500 sph

With standard aqueous inkjet printers, the ink is ejected directly onto the substrate, allowing moisture from the ink to soak into the substrate. This, in turn, requires a large amount of energy to dry the printed sheets, and prevents high-speed printing.

With the Impremia NS40, however, printheads instead eject aqueous Nanoink® onto an image transferring blanket, which forms a thin layer. The ink then dries on the blanket and is transferred after the inner moisture has dissipated, preventing moisture from penetrating into the substrate as deeply and allowing for high-speed drying. This unique innovation is what allows for top-class printing speeds of 6,500 revolutions.

Helps achieve impressive productivity and profitability for small to medium runs

Able to print at speeds of 6,500 revolutions with no need to change plates or ink, the Impremia NS40 is perfect not only for short packaging but also for jobs demanding short turnarounds, and heavy use of special colours, such as point of purchase. In terms of both productivity and profitability, the NS40 greatly excels at jobs such as short and medium runs where standard offset presses fall short.

Reduces time spent for corrections and on-site confirmations

The Impremia NS40 can produce acceptable sheets from the first sheet, with no need to change plates or ink. Compared to offset presses, this can greatly reduce the time spent, from corrections to final printing and on-site confirmations, even for short to medium runs of many different printed items.

Excellent post-press compatibility

Allows for the same post-press processing as with offset presses, such as offline aqueous press coating, PP lamination, board lamination, punching and folding.

Reduces costs, environmentally friendly

-Productivity

Costs remain unchanged even when producing only the necessary amount, eliminating the need for inventory, for more effective use of space.

-Costs

Efficient paper use, even for package and display printing.

-Environment

Conforms to strict European and American foodgrade safety standards such as for Nestle and the FDA.

For more information, please visit www.komori.com

Konica Minolta Australia has launched a new line of versatile colour digital production presses. The AccurioPress C4080 Series high-speed digital press offers robust and user-friendly production. I...

April 20 2021

Konica Minolta Australia has launched a new line of versatile colour digital production presses. The AccurioPress C4080 Series high-speed digital press offers robust and user-friendly production. It’s the perfect fit for businesses looking to expand their production capabilities with advanced automation and ease of use for various applications. The AccurioPress C4080 Series will help power business growth through intelligent automation, outstanding image quality, and print application diversity. It supersedes the C3080 Series and also includes the AccurioPress C4070 and AccurioPrint C4065, lighter versions of the C4080 that can bridge the gap between an office and production printer with the same image quality at a more affordable price point.

The AccurioPress C4080 Series is built on the same engine as the AccurioPress C14000 Series launched last year. It is highly versatile, delivers outstanding quality and performance, and is packed with an array of advanced automation features to boost productivity and expand capability.

The AccurioPress C4080 runs at 81 ppm (A4) colour while the AccurioPress C4070 runs at 71 ppm (A4) colour, and the AccurioPrint C4065 runs at 66 ppm (A4) colour.

Tatjana Ferguson, product marketing manager, Konica Minolta, said, “The C4080 Series is another important step in enhancing Konica Minolta’s line of colour production printers, providing an easy transition into digital printing with inline finishing options allowing prints to be boxed and shipped right off the press. The advanced automation, high quality and productivity, and a myriad of finishing options provide endless opportunities for printers to expand into new markets and develop new revenue streams.”

Outstanding media versatility for ready-made print products means the C4080 Series can print on thin to thick stocks (62 to 360 gsm), banner stocks up to 1300mm (simplex) and up to 900mm (duplex) at full rated speed. The AccurioPress C4080 expands application possibilities and offers envelope printing without the need for an additional fuser. It also offers an array of versatile inline finishing options for unmatched productivity.

One of these options is the unique, TU-510 Inline Trimmer Unit, which can trim, crease, and perforate inline. With this Inline trimmer Unit, it is now possible to produce fully finished output inline with additional options for inline creasing, business cards (up to 130 business cards per minute), postcard cutting and perforation (vertical and horizontal).

Other inline finishing options enable booklet making, perfect binding, punching, stapling, inline trimming, and stacking to meet customers’ needs and tap into new revenue streams.

The AccurioPress C4080 Series can be equipped with Konica Minolta’s IQ-501 Intelligent Quality Optimiser option. This is a fully automated, closed-loop quality management tool that performs automatic density correction and front-to-back registration prior to printing.

New to the AccurioPress C4080 Series is the external media detection sensor, an optional sensor for measuring and identifying media, ensuring the correct media settings are selected. Together, the Inline Trimmer Unit, external media detection sensor, and Intelligent Quality Optimiser make it possible to produce fully finished, high-quality, ready-to-be-boxed output quickly and easily without the need for skilled operators. For customers, this means increased uptime, productivity, quality, and ultimately profit.

The AccurioPress C4080 provides outstanding image quality with 3600 (equivalent) x 2400 dpi resolution. The Line Stacker option supports long sheet bypass and offers operators the advantage of offloading while the machine is still running.

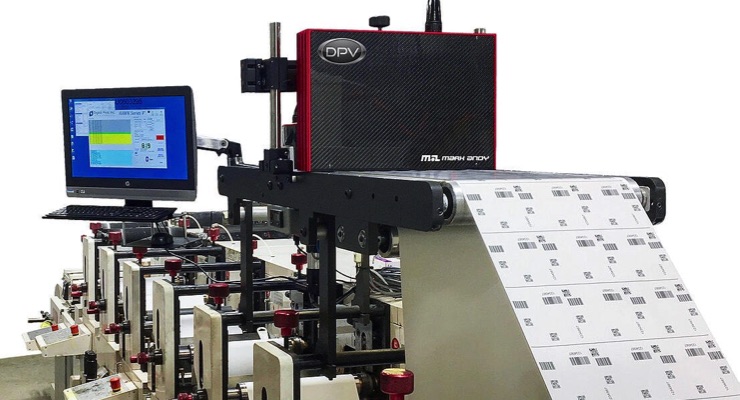

Mark Andy, Inc. has launched Digital Plus Variable (DPV), an inkjet module designed to simply and cost-effectively adds single-colour variable data to any new or existing digital, flexo, or finishi...

April 20 2021

Mark Andy, Inc. has launched Digital Plus Variable (DPV), an inkjet module designed to simply and cost-effectively adds single-colour variable data to any new or existing digital, flexo, or finishing machine without compromising speed.

With advanced printhead technology and a robust design, Mark Andy says DPV is the ideal variable data solution for a broad range of industrial and commercial printing applications, such as labels, forms, direct mail, tickets, gaming, promotions, tags, and pharmaceutical packaging.

“Digital Plus Variable is flexible, durable, and operator-friendly. The system utilises the latest 30 & 40 kHz print module for high-speed data transfer and high-quality inkjet printheads that deliver 600 dpi cross-web print resolution and 300 to 600 dpi in process direction, with speeds up to 500 fpm,” says Scott Warhover, VP engineering, Mark Andy.

The monochrome digital print bar offers adjustable drop size and shaving to ensure premier barcode readability, while internal heaters minimise the impact of external temperature changes to guarantee superior printing. An integrated head cap and automated service mode reduce printhead maintenance, increasing pressroom efficiency.

“The DPV is a straightforward press upgrade that is a benefit to any pressroom because it is an inexpensive low-risk solution with high return. Total cost of production is nearly 90% less than the standard cartridge-based offerings in the market, and the system is also highly dependable, allowing converters to integrate fast variable data to their production for a fraction of the cost,” concludes Warhover.

Available for immediate order, DPV joins Mark Andy’s digital portfolio, including the new Digital Series iQ, Digital Pro and Digital Series HD.

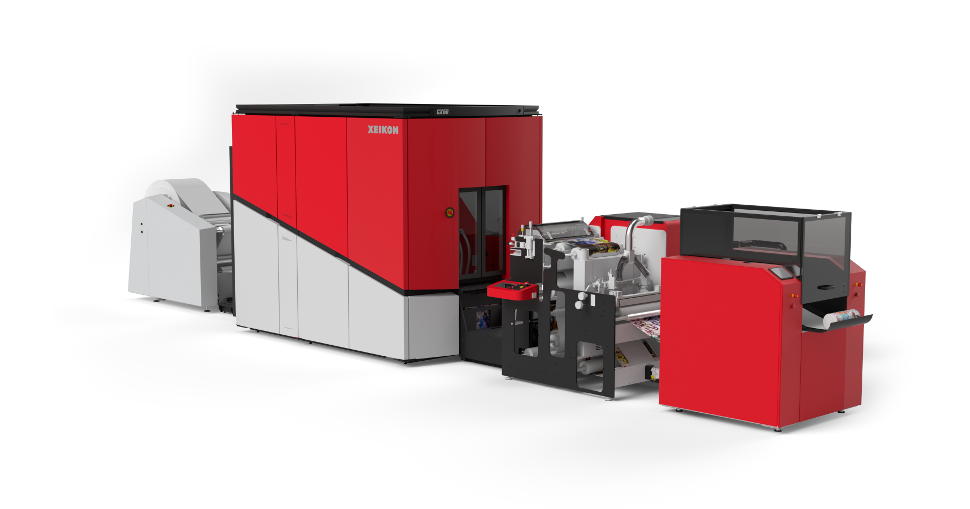

Xeikon announces an eco-friendly, cost-effective digital answer to today’s wallpaper production challenges. As a key part of Xeikon’s Wall Deco Suite and with Xeikon’s bespoke and...

April 20 2021

Xeikon announces an eco-friendly, cost-effective digital answer to today’s wallpaper production challenges. As a key part of Xeikon’s Wall Deco Suite and with Xeikon’s bespoke and environmentally friendly dry toner technology with extended colour gamut, the new Xeikon CX50 is introduced.

The Xeikon Wall Deco Suite is an all-in-one streamlined solution including inline finishing – all developed to cost effectively produce creative wall decorations including custom illustrations and photomurals in short runs. Meeting today’s consumer demand for individualised home interiors, the Xeikon CX50 digital press offers unlimited creative freedom across a wide range of substrates where every printed product can be unique.

Dimitri Van Gaever, Market Segment Director for Graphic Arts, states, “Xeikon has once again led the way in bringing to market a complete end-to-end solution for wall decoration production. What we have put together is a complete automated Wall Deco factory coming together to produce a quality finished coreless roll. The Xeikon CX50 digital press fits perfectly into our portfolio for wallcovering applications, midway between the Xeikon 3050 REX entry level option and our high-end Xeikon CX500 digital press. For higher speeds the Xeikon CX50 can be upgraded from 20mpm (65ft/min) to 30mpm (98ft/min). With Xeikon’s dry toner technology and advanced colour management capability with new generation interfaces and cloud connection, the Xeikon CX50 simplex digital press is designed to offer maximum OEE and TCO.”

The wall decoration business has huge potential, however online ordering, stricter environmental controls and consumer demand for unique products is presenting a number of challenges for conventional wallpaper companies. Xeikon is dedicated to helping its customers improve business profitability and drive growth through our creative solutions. Xeikon has designed and developed its Wall Deco Suite to give businesses an all-in-one cost-effective solution which can give them every advantage in the marketplace.

Like all of its presses, the Xeikon CX50 is driven by Xeikon’s powerful and intelligent X-800 digital front end for full automation and integration. Xeikon’s Digital Front End (DFE) workflow is a true differentiator and enabler and can be integrated with common ERP and MIS systems. The X-800 workflow, which is the same across all Xeikon dry toner solutions, features a ‘poster layout’ function for murals and wallcoverings to ensure spot-on registration for seamless installation. Accuracy of colour reproduction is guaranteed by an integrated on-press inline spectrometer and an optional registration camera. The Xeikon CX50 press provides superior colour consistency and an extended colour gamut. Xeikon’s developed dry toner is available in CMYK, Red, Blue, Green, Orange and Magenta, plus additional colours such as one-pass opaque white and colours produced on customer request. Inline finishing equipment has been specifically designed to work within Xeikon’s Wall Deco Production Suite and includes inline water-based varnishing, slitting, waste removal and coreless rewinding, providing a fully finished wallpaper roll, ready-to ship, in one operation.

Van Gaever concludes, “Part of Xeikon’s ongoing value proposition is to offer the market choices to help customers drive business growth. We believe a successful and cost-effective investment in a digital production solution works best when it is based on expected and realistic print volumes. The Xeikon CX50 press is ideal for those working in wall decoration production with flexible orders and shorter runs. With its capability to upgrade to higher speeds, an investment in this press ensures and secures future business growth. With Xeikon’s long standing expertise, we can help our customers make relevant and appropriate choices. We are recognised as a ‘go to’ trusted advisor and solutions provider. With the introduction of our Xeikon CX50 digital press for Wall Decoration, we strengthen our comprehensive portfolio so that our customers can find everything they need from Xeikon.”

Anatol and Leapfrog Machinery are working together to bring Aussie printers some of the world’s most sophisticated range of screen printing machinery including the only all-electric automatic...

March 09 2021

Anatol and Leapfrog Machinery are working together to bring Aussie printers some of the world’s most sophisticated range of screen printing machinery including the only all-electric automatic printing press.

Known throughout Australia as the place to go for Screenprinting, Leapfrog Machinery is proud to welcome the Anatol range of products into their offering.

Anatol strives to provide quality equipment to screen print faster, more consistently and more efficiently.

Mr. Debney from Leapfrog Machinery explains: “With leading product innovations like the all-electric Volt, to technological advancements to help us provide excellent after sales customer support, the relationship between Leapfrog and Anatol will benefit Australian Screen Printers with better equipment coming into Australia, backed by a reputable, trusted local Australian Business.”

Established in 1983, Leapfrog Machinery is known to supply screen printing equipment based on customers’ needs. After identifying the gap in the Automatic screen printing market in Australia, Leapfrog Machinery have worked to secure the Australian distributorship of Anatol. This distributorship covers all screen printing equipment including both Automatic and Manual Screen Printing Press, LED UV Exposure Units, Electric and Gas Dryers along with Small Format Presses.

The strength for innovation shown by Anatol can be seen throughout the product range. With a wide range of equipment configurations to suit individual business needs, Australian Screen printers can be assured that they will receive customised solutions enabling them to take their business to the next level of productivity and profitability.

Leapfrog Machinery is experienced at importing and servicing screen printing machinery throughout Australia and look forward to a long and healthy relationship with Anatol.

Leapfrog Machinery are the exclusive distributors for Anatol Australia wide.

For information contact Leapfrog Machinery (0)2 9482 4999 www.leapfrogmachinery.com.au

Xeikon America, Inc. today expanded its graphic arts and commercial product portfolio with the launch of the Xeikon SX20000 digital colour press. This is the second duplex press to come to market b...

March 09 2021

Xeikon America, Inc. today expanded its graphic arts and commercial product portfolio with the launch of the Xeikon SX20000 digital colour press. This is the second duplex press to come to market based on Xeikon’s SIRIUS dry toner technology, and it presents an excellent value proposition for printers looking for a cost-effective machine that will give them superior image quality, perfect registration front-to-back and exceptional colour quality control. With a high level of application flexibility, this versatile press will suit print providers working in the production of high-quality books and direct mail, PoS materials, security print and general commercial print applications. The Xeikon SX20000 is available for physical and online demonstrations at Xeikon’s Global Innovation Centre in Antwerp, Belgium, and is globally commercially available now.

“In today’s printing world, we all know it’s about delivering value which encompasses quality, performance, sustainability and competitive pricing,” said Dimitri Van Gaever, Xeikon Market Segment Director. “With the launch of the Xeikon SX20000, Xeikon is offering printers in the graphic arts and commercial print markets a press with unequalled capabilities at an attractive investment level. The Xeikon SX20000 has all the innovations of its flagship predecessor, the Xeikon SX30000, which makes it a consistent, reliable all-around performer, able to run at a printing width of 20 inches (508mm) on a broad range of substrates at 1200x3600dpi at speeds of 66 feet per minute (20m/min) or 1700 B2 sheets per hour. This single pass, duplex press is geared towards printers looking to streamline and optimise the production of high value, premium quality print with high coverage content on high quality papers. On top of that, the Xeikon SX20000 offers scalability with upgrades available in both speed and colour stations. With this new press, we are bringing to market a full rotary machine based on SIRIUS dry toner technology driven by Xeikon’s powerful X-800 workflow for full automation.”

Xeikon envisions two big markets for digital with this new addition: book printing and direct mail

Xeikon has noted the significant resurgence in printed book production in the last couple of years. Book sales have risen sharply due to easy availability through online channels and renewed interest in high quality books. The rise in demand is stimulating book publishers and printers to look at their business strategies, and many are now choosing quality over speed. With Xeikon’s SX20000 digital colour press, designers and printers have no limitations. Rotary printing makes it simple with perfect registration and imposition on much longer substrates, so no repeat size, fixed sheet format or frame length. This becomes a significant advantage in the finishing department. On this single pass duplex press, there are no coverage limitations, no special inks – just load the substrate reel onto the Xeikon and off it goes – no fine tuning, no magic, just a quality result!

Xeikon’s strategy is to offer the Xeikon SX20000 as a highly versatile and flexible print production platform, perfect for specialised jobs such as quality targeted direct mail. Many direct mail companies are using high quality papers for a limited audience as well as the 5th station on the press for brand colours. To develop SIRIUS dry toner technology, Xeikon built on the four major areas of toner development, imaging technology, fusing technology and media conditioning, and every key component impacts on the overall quality result. A ground-breaking and innovative platform, SIRIUS delivers the widest application and substrate range combined with lower running costs and a compelling overall total cost of ownership (TCO) and overall OEE.

“We believe the launch of the Xeikon SX20000 comes at the right moment in time,” added Van Gaever. “Printers looking for a roll-fed machine with maximum efficiencies, a powerful workflow for full colour control and automated imposition plus all the processes necessary to compete, need look no further. Many printers working in the graphic arts and commercial print markets are aware that they need to streamline their operation, reduce their total cost of operation (TCO), increase productivity and uptime and also review their equipment. Printers looking for new revenue streams and considering a broader range of applications may be restricted because of printing equipment limitations. Our single pass duplex press is unique, designed to maximise and deliver a market leading performance and unequalled sustainability. The Xeikon SX20000 has everything and more to guarantee business growth and become the cornerstone of any print business.”

For more information about Xeikon, visit www.xeikon.com

Canon Australia unleashes eight new large format print models with the introduction of the new imagePROGRAF TZ-30000 Series, and a refreshed imagePROGRAF TX Series. Canon Aust...

March 02 2021

Canon Australia unleashes eight new large format print models with the introduction of the new imagePROGRAF TZ-30000 Series, and a refreshed imagePROGRAF TX Series.

Canon Australia today unveils a fresh line-up of 5-Colour Multifunction (MFP) and Single-function (SFP) large format printers, complete with a diverse range of solutions and newly-developed scanner accessories to meet the needs of high-production to entry-level businesses in the CAD and GIS markets[1].

Sitting at the helm of Canon’s MFP line-up is the new 36-inch model imagePROGRAF TZ-30000 Series – a new category of production printer for Canon, comprising new technologies for high productivity, high-image quality prints, paired with the fastest print speeds of any imagePROGRAF to date. Optimised to be the ideal choice for customers in architecture, engineering, construction and manufacturing, as well as professional print service providers and copy shops; the imagePROGRAF TZ-30000 Series can be further enhanced with the optional addition of the newly developed Global Scanning Z36 scanner. Compared to its predecessors[2], the 36-inch wide Z36 scanner is reduced in size and weight for a more integrated feel and enhanced operability for end users.

Taking CAD, GIS and poster printing to a new level of productivity, Canon Australia today also updates its successful imagePROGRAF TX Series of large format printers with six new models: the 24-inch imagePROGRAF TX-2100, 36-inch imagePROGRAF TX-3100 and 44-inch imagePROGRAF TX-4100, plus the multifunctional imagePROGRAF TX-2100 MFP Z24, imagePROGRAF TX-3100 MFP Z36 and imagePROGRAF TX-4100 MFP Z36 – which are complete with the integration of the Global Scanning Z24 and Z36 scanners respectively. These new high-speed, high-capacity, multipurpose devices deliver unrivalled print quality, enhanced media handling and advanced security while maintaining a familiar ‘Canon workflow’ – ideal for architecture, engineering and construction (AEC) businesses, retail stores and in-house print departments.

Introducing a new category of speed, productivity and image quality: Canon imagePROGRAF TZ Series

For fast-paced businesses working to tight deadlines, the new Canon imagePROGRAF TZ-30000 Series combines high speed output with a stack of features to support continuous productivity and efficiency. With excellent media handling and the scope to produce high-quality applications including CAD/GIS drawings, renderings, maps and posters, this robust printer is the ideal choice for customers in architecture, engineering, construction and manufacturing, as well as professional print service providers and copy shops. For an even more efficient workflow, the multifunctional imagePROGRAF TZ-30000 MFP Z36 integrates the printer with a precision scanner in one device.

Printing at speeds of up to four A1 CAD pages per minute[3], the new imagePROGRAF TZ-30000 MFP Z36 is the fastest in the imagePROGRAF Series. With 700ml high-capacity ink tanks and dual roll feeding, the printer maximises output and minimises downtime, comfortably handling production volumes between 300 and 500 square metres a month, supported by Direct Print Plus workflow management software and a high-capacity stacker holding up to 100 A0 sheets.

Designed for maximum productivity, the imagePROGRAF TZ-30000 MFP Z36 comes with ‘hot swap’ media rolls and inks, making it the first Canon imagePROGRAF printer to enable users to replenish media and ink on the fly during printing. The smart roll set takes the guesswork out of media loading: the user simply places the roll into the feeder and the printer does the rest. From the moment the print button is clicked, the first A1 CAD print can be in the user’s hands within up to 19 seconds[4].

The CPP printer driver and CPP Publisher Select job submission tools help to achieve efficient printing with reduced misprints by monitoring the media width and the remaining amount of media before printing.

The imagePROGRAF TZ-30000 MFP Z36 uses Canon’s superior LUCIA TD ink technology, enabling high-quality output from CAD drawings to maps and posters, on a wide range of coated and uncoated media. Fine black lines and text can be reproduced clearly and with minimal feathering, even on uncoated media. Furthermore, due to the weather resistance of the inks, vivid colours are prevented from fading, even when using plain inkjet paper.

Space-saving, ergonomic console design means that operations such as ink tank and media roll changes happen at the front of imagePROGRAF TZ-30000 Series models, while completed prints are removed from the top of the device.

The MFP Z36 model packs even greater functionality into a smaller footprint, thanks to the integration of a high-quality multi-function scanner with dual LED light source system. This MFP model is easy to install and particularly suited to smaller office spaces. It comes with a large free-position touchscreen with easy-to-use preview functions and rich image editing capability.

For optimum security, all file data can be erased from the hard disk once each print job is completed, and optional PIN code and interface security can be used to prevent unauthorised access.

Pricing for the new imagePROGRAF TZ-30000 and imagePROGRAF TZ-30000 MFP Z36 will be available through Canon and authorised dealers from June 2021. Product demonstrations will be available on request from June via Canon Australia. For more information, please click through to the product pages for the imagePROGRAF TZ-30000 and imagePROGRAF TZ-30000 MFP Z36.

A new level of productivity, precision print, and vibrant colour: Canon imagePROGRAF TX Series

Whether printing vibrant, high-quality posters or multiple copies of high-definition CAD drawings, the new imagePROGRAF TX Series delivers borderless prints at the push of a button, either from a PC or direct from a USB stick. Quick start-up time and rapid processing eliminates delays, and with continuous high-speed printing at up to 3.2 pages per minute and no trimming required, productivity is assured.

Designed for absolute ease of use, when the roll of media is placed in the imagePROGRAF TX Series feeder, the printer automatically detects the media type and width, while the intuitive control panel with its 4.3-inch touchscreen gives accurate media information at a glance.

For high-volume jobs, a dual roll option supported by ‘hot swap’, high-capacity ink tanks enable up to 350 metres of uninterrupted printing from two rolls of the same media, or if needed, will switch between two rolls of different media types. The optional high-capacity, front-located stacker can hold up to 100 A0 prints and can be easily folded away when not in use to save space.

Maintaining its reputation for unrivalled print quality, the new imagePROGRAF TX Series combines Canon print heads and five-colour, full pigment LUCIA TD inks to deliver fine lines, pin-point text and vibrant colours even on plain paper – ideal for high-precision CAD drawings and posters. For prints that will be used outside, the inks offer excellent weather resistance and can be used with Canon’s water-resistant media.

For fast, efficient scanning and printing, the multifunctional imagePROGRAF TX-3100 MFP Z36, and imagePROGRAF TX-4100 MFP Z36 models incorporate a newly developed, lightweight Z36 scanner that uses SingleSensor™ technology. This innovation saves time and performs an accurate, even scan across the full width, without the need for stitching or calibration.

According to Ted Matsumoto, General Manager – B2B Product Marketing, Canon Australia: “In developing our newest range of large format printers, we set out to address a number of industry needs, from users of low-end LED plotters to low-yield, high-quality production businesses. With the introduction of the imagePROGRAF TZ Series, we’ve brought forth a robust production solution that balances productivity and efficiency while significantly reducing large format print and finishing times to help customers deliver on the tightest deadlines. I’m certain that this latest addition to the imagePROGRAF family raises the bar for customers and will match the growing demands of any business needing streamlined and hassle-free large format print production.

“Furthermore, the initial imagePROGRAF TX Series released in 2018 has proved to be hugely popular with customers to date. Now, with growing demand for fast and flexible delivery of prints on demand, this newly improved line-up is optimised to customers’ changing needs, with outstanding productivity features that enable faster and more efficient printing of posters and CAD/GIS drawings. From the imagePROGRAF TZ Series to the imagePROGRAF TX Series, I’m confident that our new large format printer line-up offers a model to meet the everyday large format print needs of any business.”

Pricing for the new imagePROGRAF TX Series models will be available through Canon and authorised dealers from February 2021. Product demonstrations will be available on request from February via Canon Australia. For more information, please click through to the product pages for the:

· 24-inch imagePROGRAF TX-2100

· 36-inch imagePROGRAF TX-3100

· 44-inch imagePROGRAF TX-4100

· Multifunctional imagePROGRAF TX-2100 MFP Z24

· Multifunctional imagePROGRAF TX-3100 MFP Z36

· Multifunctional imagePROGRAF TX-4100 MFP Z36

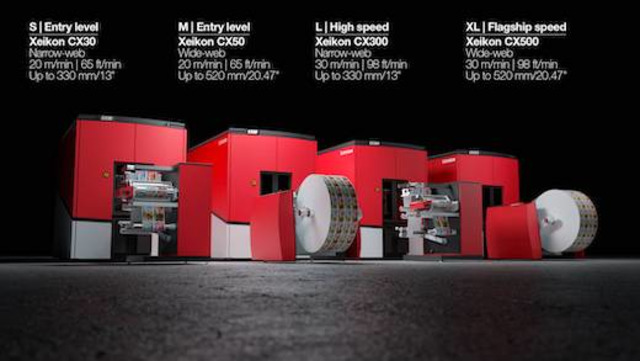

Xeikon announces the addition of two new digital label presses – the Xeikon CX30 and Xeikon CX50 Xeikon America, Inc. today announced the addition of two new digital label presse...

March 02 2021

Xeikon announces the addition of two new digital label presses – the Xeikon CX30 and Xeikon CX50

Xeikon America, Inc. today announced the addition of two new digital label presses – the Xeikon CX30 and Xeikon CX50. Building on its sixth generation platform and based on CHEETAH 2.0 technology with new generation interfaces and cloud connection, these new presses are designed to offer maximum overall equipment effectiveness (OEE). The Xeikon CX30 and Xeikon CX50 fit perfectly into the Xeikon portfolio between the Xeikon 3030 REX and Xeikon 3050 REX entry-level presses and the higher-end Xeikon CX300 and Xeikon CX500. Xeikon has designed and developed the two new presses to suit any label printer operating on ‘middle capacity’, that is: 20,000-40,000 m2 or 30,000-55,000 MSI in all end-use segments. The press excels particularly in the pharmaceutical, food, and wine & spirit label sectors. The new machines are available for online demonstrations from Xeikon’s Global Innovation Centre in Antwerp, Belgium, and commercially available worldwide in the first quarter of this year.

“Part of the Xeikon strategy going forward is to make sure every label printer and converter has the maximum choice to purchase a Xeikon press that can help them drive business growth,” said Filip Weymans, Vice President, Marketing at Xeikon. “A successful and cost-effective investment in a digital production solution works best when it is based on expected, realistic print volumes. Xeikon’s CHEETAH 2.0 series offers competitive running costs, and printers have the opportunity to successfully expand the capabilities of their press (by upgrading either in speed or width, or both). The Xeikon CX30 and Xeikon CX50 are appropriate choices for printers and converters looking at digital for the first time with future plans to expand and grow their operation – also for online label printers who are seeing their business explode.”

Both the Xeikon CX30 and Xeikon CX50 are ‘middle capacity’ presses that can be upgraded on site:

For higher speeds, both the Xeikon CX30 and Xeikon CX50 can be upgraded from 20mpm (65ft/min) to 30mpm (98ft/min) with the Xeikon CX300 or Xeikon CX500. For greater width, the Xeikon CX30 (330mm or 13”) can be upgraded to the Xeikon CX50 (520mm or 20.47”) or the Xeikon CX500

CHEETAH 2.0 technology is based on Xeikon’s scalable press architecture that includes five print stations and a full rotary process with a variable repeat length. Each station utilises Xeikon’s dry toner process and a variety of print widths up to 512mm (20.3”) using an LED imaging head operating at 1200x3600 dpi and delivering offset/gravure image quality. The two new presses use Xeikon’s QB dry toner based on CHEETAH 2.0 technology, which excels in the digital print landscape by offering superior colour consistency across the web and ensuring the highest volume of output with reduced waste. The toner is available in CMYK, Red, Blue, Green, Orange, extra Magenta (gamut extension colours), Super Black, plus technical colours such as One-pass opaque white, UV and reflective clear as well as colours produced at the customer’s request. The QB toner achieves top quality results on a broad range of standard flexo substrates. The pigments used in the QB toner are of the highest grade and FDA-certified as food safe, and also offer the highest levels of ‘light fastness’ in the market. The labels shine not only after printing but for long afterwards.

The Xeikon CX30 and Xeikon CX50 are both driven by Xeikon’s powerful and intelligent X-800 digital front end for ultimate efficiency and full automation. Xeikon’s Digital Front End (DFE) workflow is a true differentiator and enabler and can be integrated with common ERP and MIS systems. Accuracy of colour reproduction over time and between presses is guaranteed by an integrated on-press inline spectrometer. Xeikon’s X-800 workflow holds variable data capabilities unseen in the current market, allowing the label printer and converter to explore a variety of high value applications with a basic press investment.

“With Xeikon’s long standing expertise, we have developed the deeper understanding that can help label printers and converters with all aspects of running a successful digital business, from choice of equipment (10 label presses) and choice of technology (Dry toner and UV inkjet) to workflow integration and expert colour management services,” said Weymans. “We are recognized as a go-to trusted advisor and solutions provider. Xeikon wants to help label printers and converters transform their label manufacturing into digital label manufacturing – not just digitising the printing aspect but also the other aspects of the manufacturing processes inspired by digital printing. With the introduction of the Xeikon CX30 and Xeikon CX50, we continue to build and structure our comprehensive portfolio so that our customers can find everything they need with Xeikon.”

For advice, please go to our online service (https://transform.xeikon.com/). For more information on the Xeikon CX30 and Xeikon CX50 and to book a demonstration, please contact info.americas@xeikon.com. For other products and solutions from Xeikon, visit www.xeikon.com.

Canon Australia today announces the latest addition to its best-selling imageRUNNER ADVANCE DX portfolio, the C5800 Series - a true hub for digital transformation in effortlessly bridging physical ...

February 23 2021

Canon Australia today announces the latest addition to its best-selling imageRUNNER ADVANCE DX portfolio, the C5800 Series - a true hub for digital transformation in effortlessly bridging physical and digital workflows to empower hybrid workforces. Comprising four models capable of producing high yield colour printing at various print speeds – including hero model, imageRUNNER ADVANCE DX C5870i at 70 pages per minute (PPM); imageRUNNER ADVANCE DX C5860i at 60 PPM; imageRUNNER ADVANCE DX C5850i at 50 PPM; and, imageRUNNER ADVANCE DX C5840i at 40 PPM[1] – Canon’s new C5800 Series is designed to boost the productivity, serviceability and security of medium to large-sized enterprises.

With accelerating societal changes and the emergence of remote and decentralised working, this fundamental shift in behaviour has impacted the role of the office and ultimately what is needed from office technology. To support business continuity, drive digital transformation and facilitate unrivalled user experience between the office and remote working locations – thanks to the seamless integration of uniFLOW Online – the imageRUNNER ADVANCE DX C5800 Series has been developed to support businesses thrive in today’s hybrid working reality.

Empowering productivity

The imageRUNNER ADVANCE DX C5800 Series excels in streamlining document workflows by combining super-fast colour print speeds, ranging from 40 PPM up to 70 PPM, and enhanced connectivity with the latest scan technology, making it ideal for medium to large enterprises that require high volume, productive output. Designed to enable consistently secure, productive and effective working as part of technology ecosystem that is location-agnostic, the imageRUNNER ADVANCE DX C5800 Series truly empowers productivity.

Canon’s imageRUNNER ADVANCE DX C5800 Series combines the reliability and durability of its predecessors[2] in one flagship model – imageRUNNER ADVANCE DX C5870i – through offering enhanced serviceability with long life parts and easier replacement capabilities. For maximum uptime and drive efficiency, each model in the C5800 Series features quick sleep recovery, powering on in just six seconds and quick starting in four. Anti-streak, multi-feed detection and blank page removal, further reduces processing time and improves the scan performance. To save valuable time getting documents ready for use, the series delivers a broad range of embedded finishing options.

Supporting digital transformation

Digitisation is crucial to making sure teams can connect and collaborate, especially in today’s hybrid working reality. The imageRUNNER ADVANCE DX C5800 Series is the latest in Canon’s portfolio which is pivotal to customers embarking on their digital transformation journey. As a hub where print transforms into digital, Canon’s C5800 Series allows businesses to connect employees with workplace apps and plug documents straight into their workflows through one single platform.