See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

January 31 2022

| ||

Electronics For Imaging, Inc. is announcing that it will be prioritizing technology investments to accelerate growth in its fast-growing industrial EFI Inkjet business to continue to lead the industry in the analog-to-digital transition, as well as in its market-leading Fiery business. As part of this focused strategy, EFI has completed a sale of its eProductivity Software (“EPS”) packaging and print productivity software business to an affiliate of Symphony Technology Group (“STG”). EFI and EPS will continue to collaborate with their joint customers and partners to ensure mutual success.

This realignment allows EFI to accelerate investment into its Inkjet and Fiery business units to capitalize on the growth opportunities available in existing segments the company serves, as well as drive expansion into markets that are beginning the transformation toward digital.

“We have never been more excited about the opportunity in the industrial inkjet markets and our ability to leverage Fiery, the leading Digital Front End (DFE) technology for digital color printing, to continue to drive the analog-to-digital transformation in all high-value segments of imaging – while increasingly serving new adjacencies including e-commerce, direct-to-garment, and other rapidly growing segments,” said Jeff Jacobson, EFI’s CEO and Executive Chairman. “We are making significant investments to continue to be the clear leader in the Packaging & Corrugated, Display Graphics, Textile, and Building Materials/Decor markets.”

“The potential of the high-growth industrial inkjet markets is the impetus for us to accelerate our investments in market-leading products and services that drive the analog-to-digital transformation. Industrial inkjet imaging is one of the greatest opportunities I have seen in my 35 years in this industry,” Jacobson added. “The sale of the software business provides our industrial inkjet and Fiery teams the focus that will best position them for success.”

Industrial Inkjet: Capturing Unprecedented Opportunity

The industrial inkjet space is ripe with opportunity in existing and adjacent vertical markets. EFI Inkjet will continue to drive its leadership in high-volume, shuttle and single-pass inkjet technology, which the company has currently implemented in award-winning, high-performance products for the Packaging & Corrugated, Display Graphics, Textile, and Building Materials/Decor verticals. EFI will also leverage its industry-leading expertise in hardware, mechanical control software, high-speed electronics, services, cloud-connected devices, and ink innovations to deliver the next generation of versatile, high-volume, superior-quality printers and presses.

Following the realignment, EFI is making investments in R&D to strengthen its position in core markets while entering new categories – including the development of technologies to address new applications for the textile space and for packaging.

“The future of print is digital, and this realignment further solidifies EFI’s technology leadership position and accelerates growing our innovation edge as a provider of the world’s leading digital printers for the Packaging & Corrugated, Display Graphics, Textile, and Building Materials/Decor markets,” said Scott Schinlever, Chief Operating Officer and General Manager, EFI Inkjet. “This sets the stage for our customers to continue to produce more in less time, with less labor, at higher quality, with a reduced environmental impact, and will allow us to drive our level of inkjet knowledge and expertise into promising new market applications.”

Fiery: Driving Digital Print Innovation and Growth

The Fiery business unit, under the continued leadership of Fiery Chief Operating Officer and General Manager Toby Weiss, remains as the world’s premier DFE provider, enabling the high performance required across many vertical markets including packaging, signage and commercial print with advanced Fiery solutions driving high-end printers and presses from many major equipment manufacturers.

“The Fiery portfolio of products incorporates world-class color algorithms, advanced cloud technology, and many other best-in-class proprietary solutions that reduce production time and increase print quality,” said Weiss. “Working in close consultation with our partners, the investments we are making in the future of Fiery technology will foster even stronger solutions – including leading-edge cloud offerings through an EFI IQ™ suite of products that continues to help customers achieve new levels of automation, accuracy and profit potential in digital printing.”

Productivity Software: Investing for Growth under New Ownership

EPS’ new owner, STG, is a leading private equity firm that focuses on investing in software, data analytics, and software-enabled technology services companies, and will support EPS to deliver enhanced value to its packaging and print customers and accelerate global growth. STG completed this acquisition on December 30, 2021. The price and terms of the deal were not disclosed.

Moelis & Company LLC served as exclusive financial advisor, and Sidley Austin LLP acted as legal counsel, to EFI in the sale of EPS. Paul Hastings LLP acted as legal advisor to

Entries are now open for this year’s Printing Industry Creativity Awards, hosted by the Print & Visual Communications Association. The State Awards will r...

January 27 2022

Entries are now open for this year’s Printing Industry Creativity Awards, hosted by the Print & Visual Communications Association. The State Awards will run across the country in March and April, and will be the precursor to the 39th National Print Awards, to be held during PacPrint at the end of June.

Industry businesses are being urged select their best examples of ‘print perfection’ in the 32 Awards categories, which cover everything from conventional and digital print, to design and effectiveness. Nominations are also open for the recognition awards, which celebrate personal and business achievement.

Peter Harper, CEO of event organiser Visual Connections, says a judging panel is currently being assembled, with an open invitation for anyone interested in providing their expertise to the process to make contact.

“We have already made contact with experts across a variety of industry sectors, with the intention of assembling a panel of experienced experts who are qualified to judge the diverse array of high quality entries we know will soon be flowing in from all parts of Australia,” Harper says.

“We are keen to hear from anyone who may be able to assist, particularly those who may have recently retired from the industry or who have specialist expertise relating to a specific category, in order to maintain the freshness and impartiality of the Awards judging.”

As for print service providers, Harper says there’s no time to lose in identify potential entries, selecting flawless copies for judging, and completing the entry process.

“Entry forms are up on the website at www.printingawards.com.au and I’d encourage anyone who believes they have produced Award-worthy work this year to get prepared now and send those entries in,” he says, adding a reminder that entries which win Gold at the State level will be automatically entered into the ‘best of the best’ National Print Awards competition for 2022.”

Entry to the Awards costs $80, with PVCA members able to claim their first entry free of charge and enjoy a member only price of $50 per entry. Entries are open now and will close at COB on Friday 25 March, 2022.To view the competition categories, enter your printed work, or download nomination forms for the recognition awards, go to www.printingawards.com.au

January 27 2022

Keypoint Intelligence, the world’s leading independent provider of testing services and analytical information to the document imaging industry, has announced that multiple Epson products have won Buyers Lab (BLI) 2022 Wide Format Pick Awards in the Signage category.

SureColor S60660L CISS

This round of Picks acknowledges the products that gave the best performances in Keypoint Intelligence lab testing in the previous 24 months.

The BLI 2022 Wide Format Pick Awards go to the following Epson models - SureColor S60660L CISS for Outstanding High-Production CMYK Eco-Solvent/Latex 54"/64" Printer, the Epson SureColor S80660L CISS for Outstanding Gamut Expansion Eco-Solvent/Latex 54"/64" Printer and the Epson SureColor R5000 Series for Outstanding Enhanced CMYK Eco-Solvent/Latex 54"/64" Printer.

SureColor S80660L CISS

Keypoint Intelligence Director of Research & Lab Services EU/Asia, David Sweetnam, said, “Because of the pandemic, these awards cover tested products launched over the last two years, with several vendors submitting for the first time. There was stiff competition, but in the end, Epson won across three of our Wide Format Signage Pick categories. These devices delivered impressive productivity and have noteworthy usability design coupled with the class-leading output quality that we have come to expect. Epson’s new resin ink devices are targeted at the latex ink market, while the other two winners are equipped with Epson’s new Edge RIP and bulk-ink formulation matched up to the same standards of performance that helped their cartridge-based siblings claim BLI Awards in 2018.”

SureColor R5000L

Epson Australia’s Business Marketing Manager, Large Format, Gordon Kerr added, “Epson’s signage business has grown dramatically over the last ten years and our range has expanded to include cut sheet, roll-to-roll and flatbed solutions using aqueous, eco-solvent, resin, UV and dye sub ink. Our focus from the very beginning was image quality and customer satisfaction and we wanted to produce machines that would offer superior quality output on the widest range of media while ensuring reliable and cost-effective operation. From our engineers to our ink chemists, our manufacturing to sales team, we are truly honoured to have won so many of these prestigious awards.”

FESPA has launched the promotional campaign for its FESPA Global Print Expo 2022 and

January 27 2022

FESPA has launched the promotional campaign for its FESPA Global Print Expo 2022 and European Sign Expo 2022 events, scheduled to take place from 31 May – 3 June 2022 at Messe Berlin, Germany.

The campaign strapline ‘Experience Print in Motion’ highlights how, despite the challenges of the past two years, the speciality print market and the technology that supports it continue to evolve and progress.

“Speciality print businesses are back up and running and making future plans, and FESPA Global Print Expo 2022 will give them fresh momentum, supporting them with investment decisions and ideas development at a critical time in the sector’s sustained recovery”, says Michael Ryan, Head of FESPA Global Print Expo. “After more than two years dominated by virtual alternatives, business decision-makers really need the energy and connections that only live events enable. The true value of a FESPA event for exhibitors and visitors is the wider experience: close-up views of technology and consumables; making human connections; networking with like-minded business people; being inspired and discovering the latest technologies and consumables. In Amsterdam last autumn, we took the first steps to bringing colour back to speciality print. Now we all need to experience print in motion.”

Berlin has previously hosted highly successful FESPA exhibitions in 2007 and 2018, and the facilities and travel connections make the venue a popular destination amongst exhibitors and visitors. Occupying eight halls, the 2022 event will provide a platform for technological innovation in digital wide format, screen and textile printing. International manufacturers are lining up for the event, with over 250 suppliers including Brother, Canon, Durst, Fujifilm, HP, Kornit, Mimaki and M&R fully committed to the event to date.

Enhancing the visitor experience at FESPA Global Print Expo 2022, FESPA’s popular Printeriors interior décor feature will highlight the many opportunities in printed interior décor, again taking the form of an interactive visitor experience. World Wrap Masters will also return, offering visitors the chance to see European vehicle wrappers compete for the title of World Wrap Master Europe 2022, followed by the show-down of the regional competition winners in the World Wrap Masters final.

Lighting the way in hall 5.2 will be European Sign Expo, Europe’s largest exhibition for signage and visual communications. The 2022 event will be a showcase of technology solutions and materials, enabling brand owners and communications professionals to see the application opportunities in areas including channel lettering, dimensional signage, engraving and etching, LED and sign solutions.

The event website at www.fespaglobalprintexpo.com is now live including the latest event information, an up-to-date exhibitor list, interactive floorplan, COVID-19 guidance and visitor information.

Visitor registration will be open on 1 March 2022, but participants can register their interest now at https://www.fespaglobalprintexpo.com/why-visit/register-your-interest-form-2022.

Known for its innovative auto feed cutting solutions, Intec Printing Solutions Limited, releases the ColorCut FB9000PRO Automatic Digital Die Cutter as its flagship flatbed cutting model.

Bigger and faster – the new FB9000PRO lands itself right at the top of Intec’s ColorCut product offering and becomes the new flagship model through its impressive new features! By combining cutting, creasing, perforating and scoring in a single pass ensures that the FB9000PRO offers rapid, automated and unattended production for the creation of packaging and P.O.S, paper, synthetic projects and kiss-cut sheet label production. The system is completed with a 2,000 auto feeder/stacker, vacuum suction conveyor belt cutting table and media collection tray to offer true unattended capability.

Mark Baker-Homes, director of business development states, “We are incredibly excited to introduce the FB9000PRO into our very successful ColorCut flatbed cutter range. This product offers a quantum leap in speed and functionality, as well as bringing new styling cues that will permeate across our ColorCut range over the coming year. Our new flagship model ensures any business, that wants to bring unattended quality cutting automation in-house, can do so with confidence.”

The FB9000PRO cutter.

Rapidly processing jobs at speeds of up to 1,200mm/s with an SRA3 sheet cut in 15-45 seconds (depending on file complexity), the FB9000PRO can handle a variety of media types up to 1,000 micron thick including folding box board, card, paper, synthetics, soft boards, vinyl and label stocks and large sheet sizes up to 550mm x 850mm.

Its dual tool head provides separate cutting and creasing tools that operate independently of each other to reduce operation time and improve productivity. The cutting tool applies a class-leading 1.2kg of cutting pressure to achieve crisp cuts on up to 1,000 micron media and an industry first for this type of cutter of 1.5kg creasing pressure, to achieve deep, clean creases. Productivity is further enhanced with the ability to specify different speed modes for ‘blended’ or multi speed cut and crease operations on the same job.

Using QR codes for cut file recognition, the cutters CCD camera quickly reads the code to retrieve the printed sheets associated cut file, and four corner marks to ensure accuracy of cut and crease with the printed artwork and compensate for any sheet placement skew or print stretch. This function also enables the operator to instantly view the job on screen and set the desired cutting features from the systems material database. This means that different aspects of the file can have different treatments applied to them and also predetermine the order they are worked on.

The cutter is driven using the Production Studio package (included with the system), which is part of Intec’s acclaimed ColorCut Pro software suite. This can be used as a stand-alone application with the cutter or as part of a networked solution when used in conjunction with Intec’s ColorCut Pro Server Station. The ColorCut Pro software suite offers sophisticated features with Job Library Manager workflow application and the new Template Maker application for producing vector box templates, to load into Adobe Illustrator or CorelDRAW, for use with the cutter.

High speed sheet feeding.

The auto sheet feeder provides exceptional pneumatic efficiency and material handling to deliver a solution which is perfectly synchronized with the FB9000’s continuous conveyor cutting belt. Accommodating both landscape and portrait feed orientations, the feeders pick-up arm is easily adjusted to accommodate wide or narrow media.

The cavernous media stacker is easily lowered to load up to 2,000 SRA3 sheets (25Kg) or a stack height of up to 22.5cm and raises simultaneously as each sheet is fed, from the top of the stack, to offer true unattended production.

Product video of machine in operation

https://youtu.be/M5K-xu9wwLM

Link to brochure:

https://intecprinters.com/wp-content/uploads/2021/12/FB9000PRO_UK_web-2.pdf

G7 colour certification live courses are returning in 2022, conducted by David Crowther of Colour Graphic Services and the Idealliance. A refreshed and updated pr...

January 27 2022

G7 colour certification live courses are returning in 2022, conducted by David Crowther of Colour Graphic Services and the Idealliance. A refreshed and updated programme will provide certified training as G7 Expert or G7 Professional, reflecting all the latest developments in cutting-edge print technologies and colour management. Idealliance G7 certification is now a recognised qualification across multiple print disciplines – offset, digital, wide format, flexo and hybrid.

The dates for the next live Zoom online G7 course is 21st to 25th February 2022. As always, places are kept limited over the five days so as to enable quality, personal if needed attention.

G7 Live Online Training is hosted by Idealliance, featuring instructor led hands-on training. G7 Expert Trainer David Crowther will lead this multi-day training focusing on G7 based print and packaging applications, and G7 integration, maintenance, and process control across all print and proofing applications through cutting edge, online learning. Attendees will receive extensive practical hands-on demonstration, discussion, and collaboration to earn certification as G7 Experts.

The online training is offered over five consecutive half-days, 10:00am to 2:00pm AEST, and features leading print technology, workflows, and solutions, to give students the experience and ability to implement and replicate the processes used during G7 training in their own facilities, using their own technology.

The structure of training is also designed to closely resemble a common print workflow, and includes additional content and supplemental resources from the G7 Trainers and Idealliance. The training includes enhanced content on managing additional print, including meeting customer expectation in dealing with different substrates, uncoated vs coated stock, and specialty coatings. Training content, reference material, and print standards resources have also been updated to remain as a leading resource for print and color supply chain control experts looking to establish themselves as recognised industry leaders.

Crowther says: "Training consists of a variety of components, including shared slides, video, whiteboard illustrations of critical concepts, press runs and print calibration simulations, and hands-on analysis. Students are strongly encouraged to participate in hands-on activities utilising their own colour management tools and solutions. It's very comprehensive and results is certification as either a G7 Expert or Professional qualification."

The cost for the five-day course is between USD$1,799 and USD$2,619, depending on whether it is 'Expert' or 'Professional' certification and if a student or company is an Idealliance member.

Bookings and further information can be obtained by emailing:

David Crowther E: david@idealliance.org.au

January 27 2022

SA International (SAi), the leading provider of software solutions for the signmaking, digital printing, textile and CNC machining industries, has today announced the launch of FlexiDESIGN for macOS for sign and printmakers.

SAi FlexiDESIGN is the leading design software for the sign and print industry. Now available in both PC and Mac versions, FlexiDESIGN is the perfect addition to any shop looking to add additional design seats.

SAi’s popular FlexiDESIGN program that was previously available for PCs only, is now available for Mac users. Unlike other software, SAi’s FlexiDESIGN software was engineered from the ground-up for the sign and print industry, so it includes unique tools that make every aspect of job preparation and production faster.

FlexiDESIGN for macOS is packed with features including:

Native 64-bit application

The ability to send to remote Windows production manager

Variable data

User data backup

Vector erase tool

Crop marks for manual trimming

Color palette libraries

Easy-to-define cut lines

Free e-mail and phone support

Free software upgrades

Standard vectorizing tools*

FlexiDESIGN for macOS is now available globally as a subscription. To purchase the design software visit www.thinksai.com or contact your authorized SAi reseller.

WHSmith is a leading global retailer with a presence in over 25 countries, serving its customers from over 1,300 stores across the globe. The company opened their...

January 27 2022

WHSmith is a leading global retailer with a presence in over 25 countries, serving its customers from over 1,300 stores across the globe. The company opened their first Australian store in Melbourne then added new stores in Sydney, Adelaide and Perth shortly thereafter. Recently WHSmith had a requirement to completely revamp their in-house printing operations and for that they turned to Epson reseller Orion Print and Epson’s Heat-Free WorkForce Pro WF-C579R, WF-C879RTC and WorkForce Enterprise WF-C17590 printing solutions.

WHSmith Australia, Head of IT Support, Saurav Chand, explained, “WHSmith had two major challenges when it came to our printing requirements – our multiple locations and where they were placed, along with a busy customer-facing environment where uptime was of prime importance. The challenge for every WHSmith store was that their printer was either in a regional or difficult-to-get-to location such as a hospital or airport, so we decided to change this and make the entire operation far more efficient. We initially had multiple technology partners, including Orion Print, who supported multiple printers across our business. Orion have good customer service and offered an excellent Epson solution that met our requirements perfectly so that’s what we purchased and installed.”

WorkForce Pro WF-C579R

Orion Print Management is one of Epson Australia's Premier Partners. They

improve organisational effectiveness by providing comprehensive content

management, accelerating shared business processes by facilitating information-sharing across boundaries for better business insight.

Chand continued, “We had over 40 printers in multiple stores each of whom used to spend tens of thousands of dollars in signage printing. When we did the cost evaluation, we found it was far more. It was cost effective to replace all of our printers with Epson’s Heat-Free WorkForce Pro WF-C579R, WF-C879RTC and WorkForce Enterprise WF-C17590 printing solutions. Epson's Heat-Free print technology means fewer moving parts, so they are more reliable and have increased up time. The high-yield inks of up to 8 times longer than comparative lasers give our staff fewer disruptions and thus more time to attend to their customer’s needs.”

WorkForce WF-C879RTC

With minimal interventions in both service and consumables replacement as one of their key criteria, along with price-performance, WHSmith was able to clearly see and understand the benefits the Epson solution would bring to the table.

Chand added, “Epson excelled on both counts, the reliability of their Heat-Free Technology not only improved staff morale but also customer service capability. The Epson high-yield ink consumables for both the A4 up to 50,000 pages and

A3 up to 100,000 pages provide us with the minimal disruptions we were looking for. It also enabled us to dramatically reduce our overall running costs.

In short, switching to Epson’s Heat-Free Technology printing solutions gave us a cost and time-effective solution for our business so we can easily print, scan and manage with efficient reporting and easy troubleshooting.”

WorkForce Enterprise WF-C17590

As much as WHSmith appreciated the cost savings of the Epson devices, the

real return-on-investment here was the extra time staff could spend with their

customers. As a result, with Epson’s low cost and efficient printing solutions and Orion Print Management proactively and professionally managing their fleet, the WHSmith IT Management team were able to focus more of their time on key IT projects.

Saurav Chand concluded, “Epson products, services and solutions stand head and shoulders above their competition as they are far easier to manage and troubleshoot. Using Epson Heat-Free Technology and solutions also gives WHSmith a number of key benefits as, critically, we now save tens of thousands of dollars every year, have made our stores more efficient and given every head office team member the ability to organise and print signage for any store across Australia at the simple click of a button.”

January 27 2022

The latest addition to Xante's UV flatbed printer lineup, the Xante X-55, takes Xante's proven UV print technology to the next level with a larger bed size (50x55”), and doubles the production speeds of its flatbed UV products. Based on up to four Epson i3200 four-channel printheads, the CMYKW X-55 prints in bold vibrant colour on virtually any rigid media including wood, glass, stone, metal, acrylic, coroplast and is powered by the award-winning iQueue Adobe Postscript/PDF workflow software.

The X-55 UV flatbed printer will quickly produce full colour signage, decorative items, personalised awards, or unique promotional items in minutes. With a bed size of 55x50” customers will be able to print up to six 18x24” signs simultaneously, dramatically increasing speed and efficiency of production. With Xante’s iQueue Adobe PDF workflow customers can now achieve magnificent multi-panel wall art, accurately manage spot colours, control print quality, create multi-up imposed layouts and much more.

With adjustable print head height up to 3” and resolutions up to 2,880 DPI, the X-55 will allow for printing on a wide array of media with amazing speed and image quality. Printing on dark substrates or clear material is also simple using the white option controls embedded within iQueue Workflow. Users have the option where, when and how white ink is applied. While the bed size and imaging area are large, the footprint is still compact with a footprint of only 7.5’x7.5’ allowing shops of almost any size to add X-55. The standard X-55 configuration will contain two Epson i3200 Printheads at a economical price of $59,995 and a four printhead configuration is $64,995 for environments where high speed and production are critical.

“The Xante X-55 demonstrates our commitment to the continued expansion of our outstanding flatbed UV Printer lineup. The world of print is changing and Xante is investing in that future,” stated Robert Ross, CEO and president of Xante.

Xante UV High Density inks for the X-55 and all of our UV printers are sold in economical 1/2 litre bottles. These inks provide outdoor durability and impressive colour quality. The Xante X-55 is currently in full production and customer installs begin in January 2022.

On a global stage open to professiona...

January 26 2022

On a global stage open to professional vehicle wrap installers from more than 40 countries worldwide, “Faure Le Page” Lamborghini Huracan project by Grafico Group emerged as the Asia Pacific Continental Winner of Avery Dennison’s prestigious global “Wrap Like A King” 2021 Competition.

After a year’s break in 2020 due to the pandemic, the popular annual Wrap Like A King Competition returned in 2021 with a few adjustments to the competition structure and prizes to offer a more rewarding experience for participants. Wrap installers had the opportunity to submit their best full print or colour change car wrapping projects, and the international judging panel selected winners from 12 regions across Europe, North America, and Asia Pacific, and just 3 Continental winners from amongst those Regional winners in the final round.

A Rewarding Experience

“We are ecstatic!” exclaimed Damian Corney, Founder and Creative Director of the Melbourne-based design, print, and signage expert Grafico Group. “This win, amidst the ongoing pandemic, is especially rewarding considering the time and circumstances behind the project. Our design, production, and installation team members used Avery Dennison vehicle wrap solutions to transform a supercar into a head-turning vehicle that proudly reflects the House of Fauré Le Page brand qualities.”

The Grafico team used the Avery Dennison MPI 1105 Easy Apply RS Cast Digital film; a premium high-gloss cast film with superior 3D conformability, stunning printability, and maximum durability for complex surfaces with curves and recesses, for a smooth, seamless application of the Fauré Le Page design onto the aerodynamic curves of the Lamborghini. The team added Avery Dennison 1480Z Matte, a matte clear conformable cast overlaminate, over the wrap for maximum UV and weathering protection for the printed graphics.

For its win, Grafico has nominated Charity Drive Days, a Registered Charity Association run by car enthusiasts that want to make a difference by raising funds for people in need, to receive the $1,000 donation in its name.

“Grafico has been working with Charity Drive Days for many years now,” explained Damian. “We have been involved with many of the charity’s events over the years and together, we have helped raise millions of dollars for worthy causes such as those providing daily support for children and families living with cancer. In these pandemic times, I know that the charity will be very grateful for this donation, and we are happy to have made this happen with our win as the Asia Pacific Continental Wrap King for 2021.”

Coveted Prize in the Global Vehicle Wrap Industry

“Congratulations to the team at Grafico on their well-deserved success!” said Jordan Leach, Business Director, Graphics Solutions, Australia/New Zealand (ANZ) and Southeast Asia (ASEAN), Avery Dennison. “The international panel of judges for this year’s Wrap Like A King were unanimous in their vote for Grafico’s ‘Faure Le Page’ Lamborghini Huracan project, giving it high scores for visual transformation, production quality, skill of installation, stunning street appeal, and creative design.”

The Wrap Like A King 2021 Competition officially ran from September 1 to October 31, and the winners finalised in November 2021. The three final Continental winners of Wrap Like A King 2021 were “Faure Le Page” Lamborghini Huracan project by Grafico Group for the Asia Pacific Region, “The Goddess – La Dea” project by Wraproad for Europe, and “ColossXL” project by Colossal Motorsports for America.

All Continental winners will receive a prize pack worth over $3,000 including a Continent Winner Trophy, Wrap Like A King swag, gift vouchers, a Vlog kit, banner stand display, and Avery Dennison social media exposure.

“Wrap like a King is one of the most coveted titles in the global vehicle wrap industry. Through this competition, the installers get the opportunity to showcase their best work and gain fame and recognition from their peers across the globe,” said David Newman, Senior Marketing Manager, Asia Pacific, Avery Dennison.

The opening of one of the most advanced production facilities in Hilden, Germany, moves the production of Graphics Solutions materials to the next level and reflects all the strength...

December 14 2021

The opening of one of the most advanced production facilities in Hilden, Germany, moves the production of Graphics Solutions materials to the next level and reflects all the strengths and capabilities of 3M.

This state-of-the-art expansion to existing graphic film operations at the Hilden facility will significantly increase manufacturing capacity for the production of 3M Graphics Films.

The $133M investment will see the introduction of two new production lines capable of producing an additional five million square meters of film per year and illustrates 3M's commitment to invest in capacity to meet customer demand.

The facility's location accommodates the rapidly growing market for 3M Commercial Solutions products.This investment not only increases capacity but enables our markets to be serviced quickly and efficiently.

The site is being celebrated as an Industry 4.0 plant demonstrating the cutting edge of graphic film manufacturing. Engaging Six Sigma Black Belts to implement LEAN initiatives has allowed the plant to reach optimum efficiencies and deliver on its productivity targets, including state of the art automation and a focus on clean energy.

The new Hilden Production facility embodies the core values, strengths and capabilities that 3M represents:

The new Hilden Production facility embodies the core values, strengths and capabilities that 3M represents:

“This investment in Hilden further demonstrates our commitment to leadership in the Commercial Solutions world,” said Silvia Perez, President, 3M Commercial Solutions Division.“We are proud that this high-investment, next-generation site with global reach has been established in Europe and we are excited that this is just the first step of a longer-term investment plan.”

“This new facility reaffirms 3M’s commitment to the graphics business and will support our growth needs in Australia as well. “We remain committed to providing world class sustainable products for our customers and improving service levels and quality that is expected of us as a market leader,” said Amit Laroya, Senior Vice President, Transportation and Electronics Business Group, Asia.

The Grand Opening happened on October 14, 2021 and will be attended by key stakeholders from the 3M Commercial Solutions Division, the pioneers behind the development of the new facility, and key dignitaries from the German Government, who will commemorate the momentous occasion.

This was followed by virtual events in other Areas and the event for Asia happened on the 9th of November 2021, where the key customers and valuable partners were invited to join and be part of this great milestone from 3M Commercial solutions division.“As we focus on increasing our penetration in the Asia region for the Commercial Solutions division, this strategic investment in graphics, which is one of the core portfolios for us, will support our commitment and help us create more value for our customers more efficiently,” said Manohar Raghavan, Director, 3M Commercial Solutions Division, Asia.

3M is a trademark of 3M.

About 3M

At 3M, we apply science in collaborative ways to improve lives daily as our employees connect with customers all around the world. Learn more about 3M's creative solutions to global challenges at www.3M.com or on Twitter @3M or @3MNews.

Epson has been placed on the prestigious A List for both climate change and water security for the second consecutive year by international environmental non-profit CDP, which evaluates companies' environmental activities.

Epson was recognised for steadily reducing greenhouse gases by proactively transitioning to renewable electricity, and for having expanded and improved the comprehensiveness of its information disclosure in line with the recommendations of the Task Force on Climate-related Financial Information Disclosure (TCFD), which quantifies management risks associated with climate change as required by CDP.

CDP evaluates companies' environmental activities on behalf of more than 590 institutional investors worldwide with a combined $110 trillion in assets. The results of the questionnaires are also used to assess companies in terms of environmental performance for the world's leading socially responsible investment (SRI) indexes used by ESG investors.

Out of the more than 12,000 companies that were evaluated, Epson was one of a small number to receive a double A, an acknowledgment that Epson is a leader in sustainability. In addition to being an important statement to institutional investors making ESG investment decisions, Epson believes that this prestigious listing sends a powerful message to customers looking for environmentally conscious products and services, as well as to business partners and other stakeholders.

As stated in Epson's Environmental Vision 2050, which was revised in March 2021, Epson seeks over the next 10 years, we will invest approximately 100 billion yen on decarbonisation, closing the resource loop, and environmental technology development to reduce GHG emissions1 in the supply chain by more than 2 million tonnes.

A key milestone will be to switch to renewable energy for all of Epson's electricity needs by 20232. In addition to this investment, the company will concentrate management resources on developing products and services that reduce the environmental impacts of its customers.

More information

For more about CDP go to: https://www.cdp.net/en

For more information about the 2021 A List companies, evaluation methodology, and evaluation criteria go to: https://www.cdp.net/en/companies/companies-scores

For more on Epson's environmental initiatives go to:

https://global.epson.com/SR/

December 14 2021

The press is equipped with an additional UV booster enhancing the curing of Saphira Digital Labelfire UVLM inks at higher printing speeds.

In an intensive development effort Gallus and Heidelberg engineers have further developed UV inkjet printing to enable the production of certified food-compliant labels with the Gallus Labelfire. The low migration version of the Gallus Labelfire is designed to produce food-compliant packaging in accordance with EU regulations and Swiss Ordinance. For this purpose, the joint Gallus/Heidelberg development team developed the Labelfire UVLM ink series, which is suitable for food contact packaging. The UV curing technology of Labelfire was also further optimised to improve the migration properties of the ink film.

“The Gallus Labelfire Low Migration represents a real innovation. Compared to the previous press, it makes no compromises when it comes to print quality, colour gamut and lightfastness of the inks”, says Uwe Alexander, Product Manager Digital at Gallus, describing the new digital press. Thomas Schweizer, Head of Business and Product Management at Gallus adds: “Indeed! We call it innovation because, together with Heidelberg, we have achieved a new level of UV inkjet technology. This includes the formulation of the ink and a matching curing technology. This enables our customers to comply with the relevant EU regulations as well as the guidelines of Swiss Ordinance and Nestlé Guidance Note in order to produce food-compliant labels and packaging.“

A prerequisite for the food-compliant production of labels and packaging is compliance with the relevant legislation and, in addition, the specifications of distributors and brand owners. Labelfire UVLM inks therefore comply with the requirements of EU regulations No. 10/2011, No. 1935/2004, No. 2023/2006 (GMP), Swiss Ordinance, Nestlé Guidance Note and EuPIA guidelines.

However, the use of such inks alone does not guarantee automatic compliance with the migration limits required for certification of such labels.

The new curing system of Labelfire Low Migration

An important production step takes place after inkjet printing with curing of the inks. In addition to the new ink series, the innovative machine system therefore also includes a highly effective UV dryer system to ensure optimum curing.

Directly after printing, the substrate is fed into a dryer with an inert chamber, which is flooded with nitrogen. The extensive exclusion of oxygen leads to optimised curing of the inks. An optional UV booster enhances curing of the Labelfire UVLM inks at higher printing speeds even at maximum production speed.

In addition to this new UV drying system, the Gallus Labelfire Low Migration is equipped with UV and oxygen sensors that measure production parameters. This supports the quality assurance processes in label and packaging printing.

"We are proud to offer our customers a machine system that prints flexibly and efficiently, but furthermore it allows a very broad range of applications and thus also addresses various market segments. The Labelfire Low Migration is perfect for a successful entry into digital packaging printing for the food and pharmaceutical markets," Thomas Schweizer concludes.

Two Gallus Labelfire presses have already been producing food-compliant labels and packaging in line with legal requirements for the European market for months in a field test study. Since October this year, the Gallus Labelfire Low Migration has been sold on to customers as a series machine.

December 14 2021

“Automation is the only way to consistently deliver high volumes of short-run jobs while meeting customers' quality and schedule expectations."

HP has announced the PrintOS Integration Hub @ hp.io, a portal where HP provides technical information on how to integrate with HP Indigo devices and solutions, and achieve automation across vendor solutions. Due to the upswing in e-commerce orders, printers need to increase automation through multiple systems, spanning from submission, printing, finishing and fulfilment solutions, through to shipping and tracking.

“Automation is the only way to consistently deliver high volumes of short run jobs while meeting customer’s quality and schedule expectations” said Gershon Alon, Head of HP Indigo Solutions. “Customers are struggling to hire and maintain skilled personnel. Cross-vendor automation increases employees’ efficiency and enables the production of much more work with existing staff and resources”.

An example of cross-vendor automation is the improved integration between the PrintOS Production Pro DFE for Commercial Print and Heidelberg Prinect, which automates production and avoids human errors. Customers can now maintain a unified automated workflow, for both their analogue jobs and their digital Indigo press jobs, and manage them from their Heidelberg MIS.

"The enhanced connectivity between Heidelberg Prinect and HP Indigo presses enables Heidelberg customers to integrate the Prinect Business Manager (MIS), the offset prepress capabilities, and digital presses into one workflow," says Christopher Berti, Vice President Product Management Prinect. “That brings the benefits of higher efficiency, fully leveraging the original investment (e.g. offset prepress system), and the flexibility of using the same workflow for both worlds: offset and digital printing.It helps close a major gap on the road to printshops achieving end-to-end integration”.

“The Prinect integration with Indigo digital presses enables a single data entry point via JDF, reduces touch points and therefore human errors” said Liesbeth Van Assche, Process Architect at Artoos Group. “We send our jobs from Prinect to the HP Indigo digital press and our press operator does not deal with any job parameter settings, file preparation, imposition, or proofing. Press operators are 100% focused on printing the job and insuring the quality of the job”.

Automating color is also a key focus area for HP Indigo. On top of the already-supported Idealliance G7 color certification, PrintOS Color Beat now also automates Fogra color certification for new-generation HP Indigo commercial and labels-and-packaging presses including the HP indigo 100K, HP Indigo 15K, HP Indigo 12000 VP, HP Indigo 25K and HP Indigo 35K.

The FograCert PSD Colour Data allows print service providers to get a fully automated verification to the most widely used Fogra colour standards requested by print buyers and brands, validating that the press meets the highest color standards. With a touch of a button. The compliance of a given print job is certified against Fogra PSD, ProcessStandard Digital (ISO/TS 15311-2) and can be easily communicated with the print buyer, the brand or the QA team.

Automatic Alert Agent 2.0 for HP Indigo Series 4 digital presses (HP Indigo 12000 and 15K). This inline inspection system scans every printed sheet and compares it to its digital print file, automatically identifying possible print defects. AAA 2.0 now automatically diverts defective sheets to scrap and reprints them, all in real time with no human intervention, and no interruption to production. The system leverages advanced Industry 4.0 Artificial Intelligence (AI) and Machine Learning (ML) algorithms, increasing accuracy and speed, to provide productivity and profitability for PSPs.

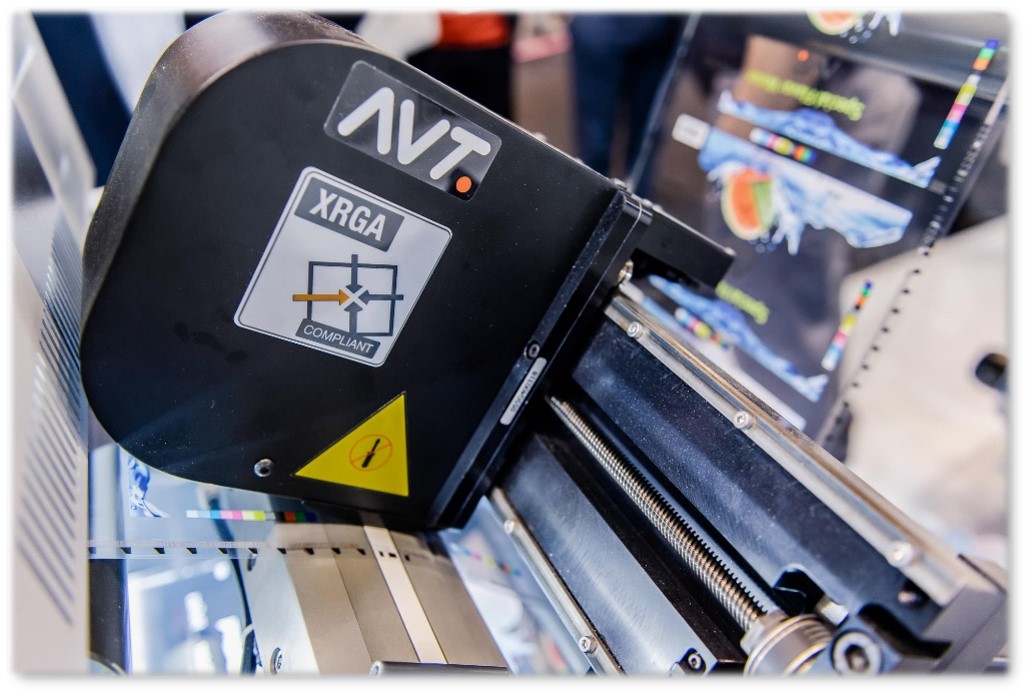

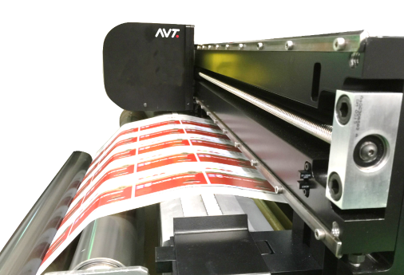

Latest Esko AVT innovation for print inspection at packaging converters delivers measurements “hundred times faster”

Packaging converters can now benefit from faster and more accurate inline colour inspection, with the launch of the latest innovation from Esko, AVT SpectraLab XF.

Unveiled at the recent Esko Innovation Summit, AVT SpectraLab XF is a unique inline colour measurement solution based on a new, super-fast X-Rite sensor. With XRGA-compliance, AVT SpectraLab XF delivers the ability to measure during make-ready and production, ensuring colour and quality consistency across the entire print cycle.

“When it comes to brand recognition and value, colour consistency and quality are absolutely crucial,” said Guy Yogev, Esko AVT Senior Director of Product Marketing. “The uniformity of a brand’s packaging color inspires trust and loyalty among consumers. But achieving perfectly reproduced brand colours for packages and labels requires converters to print to the numbers and monitor colour accuracy - all while manufacturing at high speeds and volumes.

“Meeting this standard can be challenging, especially with increasing demand for shorter production runs as brands seek to grow market share with targeted campaigns, brand extensions and limited editions,” he said. “Using handheld manual measurement falls short of this challenge - measuring only a few points per roll is insufficient, time-consuming, and requires frequent operator intervention. AVT SpectraLab XF has been developed to help converters meet these brand expectations, through effectively measuring and monitoring during run-time and make-ready and ensuring converters print to colour target.”

Delivering accurate and automated colour measurement for the full array of packaging applications, AVT SpectraLab XF incorporates a new X-Rite spectral sensor and can measure a complete vertical colour bar in a single repeat. Smaller, 4-5mm patches can be supported depending on press speed and a new LED lamp with M0, M1, and M2 correlates to offline inspection standards.

“AVT SpectraLab XF is fast, accurate, and saves converters valuable time,” said Guy. “This new solution is capable of measuring colour targets and in-image colours in a much faster run time, delivering measurements one hundred times faster than before, with higher frequency and many more measurements per roll,” he said. “The technology delivers much better targeting and accuracy, and importantly can work with very flexible materials.”

Guy explained that as AVT SpectraLab XF also enables measurements during make-ready, converters can save significant, valuable time in ensuring colour accuracy, as well as reducing job change time. “With the support for as small as 4mm targets or patches, users can also enjoy a saving on material trim area, while the optional data import/export option gives the ability to send data to various colour reporting systems, as well as ink-room interfaces such as X-Rite IFS.”

Incorporating AVT SpectraLab XF into the inline inspection system not only saves time in setup, but it also maximises operator efficiency. “The system provides both visual inspection as well as colour measurement and enables every aspect of process and quality to be monitored. Using the BestMatch optional module, AVT SpectraLab XF suggests possible actions on press and saves time as well as reducing the workload further,” said Guy. “It measures L*a*b*, Delta E, density and dot gain on flexible packaging and folding carton applications, comparable with offline devices, but all at point of print with no press stops, for maximum efficiency.

To find out more about AVT SpectraLab XF, visit the Esko website. For details of the full range of Esko solutions, visit the Esko Innovation Hub at innovation.esko.com.

About Esko

Esko is a global provider of integrated software and hardware solutions that accelerate the go-to-market process of packaged goods.

For each stakeholder in the process, Esko solutions enable them to work efficiently and deliver right-first-time packaging and marketing content on time, every time.

Our goal is to make it easier for CPG and pharma businesses to manage their packaging, labeling, regulatory and marketing content. With our packaging management platform, brand marketing and packaging teams can increase their productivity, reduce costs, and save time.

For packaging and label trade shops, premedia service providers and printer converters, we digitize, automate, and connect the entire print production process with software and hardware solutions for CAD design, prepress processes, flexo platemaking and print inspection.

Facts & numbers

For further information, please visit www.esko.com

December 14 2021

It focuses on the commitment to a robust sustainability strategy comprised of three key pillars: operations, products and services, and collaboration.

December 07 2021

Enables on-the-go colour matching for design and production applications

Epson has launched its SD-10 spectrophotometer, a highly accurate, compact and affordable spectrophotometer. Battery powered and equipped with a precision MEMS Fabry-Pérot tuneable filter, the SD-10 is small enough to fit in your hand or pocket and recently won a Good Design Best 100 award 2021.

Key features of the SD-10 spectrophotometer

• Compact hand-held design (35 x 80 x 80 mm)

• Self calibrating and simple to operate

• Large aperture lens with a wide spectral range

• All-in-one with a high-capacity lithium ion battery for mobile operation

• Take spot readings, compare colours or a patch set

• Downloadable iOS and Android app extends functionality

• Integrated annular multi-spectrum light source & LCD display

• USB & Bluetooth® interfacing, supports M0, M1e and M2 standards

• One year warranty with service cover extendable to five years via CoverPlus

The SD-10 spectrophotometer can be used to digitise colour readings and colour matching for a faster and more accurate workflow. It can be linked with a smart device to centrally manage colour information for smoother and more precise printing. Being portable it allows users to measure colours anytime, anywhere.

In short, the SD-10 solves colour matching problems in a wide range of print and design-related work, such as those commonly found in the sign & display industry.

When producing printed matter, there are often issues around accurate colour matching, particularly with corporate logo colours. The user-friendly SD-10, Epson’s first portable spectrophotometer, helps solve problems related to colour matching that were, until now, the work of a specifically trained and experienced operator.

Now, by using the SD-10 spectrometer, anyone can easily measure and quantify colours without specialised knowledge, so colours and processes can be standardised.

With an easy-to-read LCD screen, you can easily measure colours and convert them into accurate values. It’s also easy to connect the SD-10 to a smart device via Bluetooth and the Epson Spectrometer app is simple and straightforward to use, even for those who are new to colour measurement. Wired and wireless connection with a PC is also possible.

The SD-10 measures colour quickly and accurately using nine light sources arranged in a ring. You can even reduce the time required for colour matching further as you can get accurate values immediately that are unaffected by any uneven shape on the media’s surface.

Accordingly, the SD-10 can also be used for media with uneven surfaces, such as fabric, and the colour measurement results are not affected by any external environment.

The SD-10’s main body measures just 35 mm(w) x 80 mm(d) x 80 mm(h) and it weighs just 190 g, making it compact in size and easy to carry. It is also suitable for use in meetings and colour matching in the field such as on construction sites. In addition, as it has a built-in battery and can be used without requiring a cable, it is very easy to handle.

The Epson Spectrometer app displays the numerical values measured by the SD-10 as a colour picker with readings in a variety of formats including LAB, CYMK, LCH, RGB and more. In addition to being able to compare approximate colours and numerical values, you can also compare the colour differences between two measured colours and display the difference numerically.

Moreover, the app also identifies similar colours of measured colours, colour scheme examples and complementary colours, and similar PANTONE® colours.

By linking with the functions of Epson’s genuine Epson Edge Print and Epson Edge Print PRO software, you can then get the exact colour you want with any Epson large-format inkjet printer.

Good Design Awards

Good Design Awards are presented annually for designs that benefit and enrich our lives and society.

Epson’s SD10 was described by the judges as they said, “The ability to match colours objectively based on numerical output instead of human sensory perception promises great benefits in terms of colour matching accuracy and efficiency. The digitisation of the last remaining analogue part of the printing process should remove a bottleneck and enable rapid advances in efficiency. The fact that the product is reasonably priced, thanks to sensor technology developed in-house and that the product fits neatly in the hand are also very appealing. The GUI is intuitive. It displays colours as numerical values and visualises differences in colour differences with a dedicated application that was developed at the same time. Coordination with familiar colour samples such as PANTONE is also being considered, and it is not difficult to imagine its widespread use in the future.”

For more information on the new Epson’s SD-10 spectrophotometer colorimeter go to: www.epson.com.au/large-format-printers/Products/LargeFormat/displaymain.asp?ID=SD-10

The new flatbed cutters Azon Presto and Azon Presto+ are completely focused on any DTF solution.

As the demand of the market is still growing, even with the situation of the Covid-19, customers are constantly searching for new business opportunities. In regards to that, Azonprinter has decided to expand its current portfolio with two new products – Azon Presto and Azon Presto+.

The new flatbed cutters Azon Presto and Azon Presto+ are completely focused on any DTF solution. Even though the cutters are built for use with the current solutions Azon Pronto and Azon Pronto+, they can be used with any other DTF solution.

Both Presto solutions are built with high class technology, giving the way to the new functionalities, such as high cutting precision for small text string (easy to tear of the scraps), advanced algorithm (elimination of distorted, rounded or lifted corners), half/perf cut (perforation cutting), fast registration marks detection by CCD camera.

Presto and Presto+ offer fast speed for volume production – servos bring out smooth acceleration, big torque, precise cutting/plotting and excellent durability.

For more information, please visit our web page www.azonprinter.com

December 06 2021

Nilpeter is taking high-end offset printing to new levels with the MO-Line FUSION, the clear choice for both short, medium, and long run production.

The Quest for Perfection

In premium wine & spirits and health & beauty, the quest for perfection in every detail is an obsession – and that must be reflected in the production of the label, too. It’s that passion that inspired Nilpeter to develop the MO-Line of offset presses. With more than 200 installations world-wide in the last 25 years, the MO-Line has set the standard for excellence in quality and productivity.

Now, Nilpeter is taking high-end offset printing for these value-added markets to new levels of performance, efficiency, and ease of use, with the MO-Line FUSION.

A custom-made combination press with a host of analogue and digital embellishment technologies inline, this is the platform for unmatched label quality – whether competing in high-volume or short-run markets.

“Built with high levels of automation, MO-Line FUSION minimises manual adjustments, and ensures faster setup times and reduced start-up waste. In short, the MO-Line FUSION is the complete solution for the printer looking for efficient, productive, and market leading technology,” says Jakob Landberg, Sales & Marketing Director, Nilpeter A/S.

Integrating Value-Added Embellishments

The MO-Line FUSION is based on Nilpeter’s common press platform. This enables seamless integration of value-added techniques, inline and customised according to specific requirements with the flexibility to add new technologies, as needs change in the future, too. A modern printing press, the MO-Line FUSION offers the best from both the analogue printing and the digital embellishment world - the digital high-build varnish unit, new high-power FP-5 hot foil and embossing units, and flexo units for spot colour applications, to name a few.

“The MO-Line FUSION has no limitations related to materials compared to digital technologies in the market. Few printers in the world have this freedom to print unique, high-value labels – which adds a competitive dimension for the printer,” Landberg continues.

Lowest cost per label - for long and short runs

With fast setup times, and quick job turnover, the MO-Line FUSION boasts the lowest cost to print for premium labels – outperforming alternative short-run technologies such as translative offset and digital technologies. In short, MO-Line FUSION is the clear choice for both short, medium, and long run production.

Ease of use for maximum productivity

Based on sleeve tooling technology with a high degree of automation, the MO-Line FUSION is built to maximise productivity and user-friendliness for the printer. A smart intuitive interface and computer-aided controls mean minimal manual intervention. Jobs and settings are automatically recalled.

“Current FA-Line flexo operators will already feel at home with the new FUSION platform and will easily be able to add offset printing to their skill set - and vice versa,” Landberg concludes.