AstroNova launches new digital colour desktop printer AstroNova GmbH, the European headquarters for AstroNova, Inc., has introduced a powerful digital color desktop printer, the QuickL...

August 07 2018

AstroNova launches new digital colour desktop printer

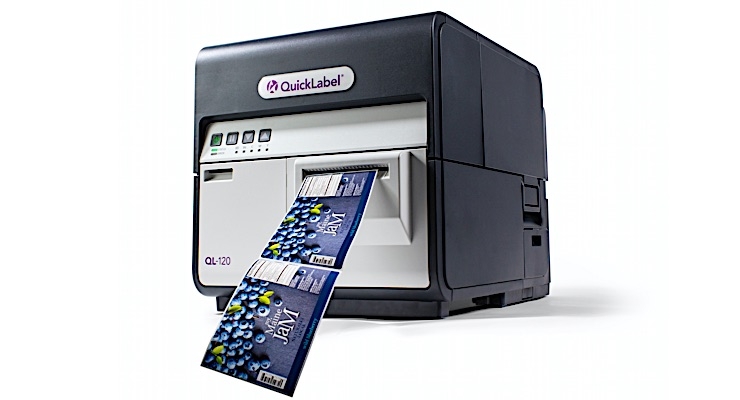

AstroNova GmbH, the European headquarters for AstroNova, Inc., has introduced a powerful digital color desktop printer, the QuickLabel Kiaro! QL‑120 high-quality label printer. The product marks the company's expansion into the area of product identification. The Kiaro! QL‑120 is built on the company's color label printer, the Kiaro!.

The versatile QL‑120 surpasses the Kiaro! with a faster print speed, new features and ease of use.

Its fast printing speed of up to 300 mm/s makes the QL‑120 the fastest desktop color label printer in the QuickLabel series by AstroNova Product Identification. Its 1200 dpi resolution ensures that even the smallest font sizes and images are printed sharply. The printer's water-based ink and color range allow printing on a wide variety of materials.

Even with water-based ink, QuickLabel's QL‑120 offers greater durability, as well as resistance to water, oil, and solvents. Thanks to its resistance to various fluids, the QL‑120 is ideal for the food, chemical, cosmetic and E-liquid industries.

Its electric cutting feature for post-printing label-web cutting and its ability to print individual labels with zero label loss make the QL‑120 an economical and intelligent colour desktop printer for high-quality labels. The QL-120's simple integration into label dispensing systems and networks and its automatic periodic cleaning feature, which requires no separation of the label web, delivers smart label printing and integration into automated production.

Avery Dennison and L'Oréal collaborate to eliminate label waste Avery Dennison Corporation and L'Oréal Australia, in conjunction with Australia's leading waste management...

August 07 2018

Avery Dennison and L'Oréal collaborate to eliminate label waste

Avery Dennison Corporation and L'Oréal Australia, in conjunction with Australia's leading waste management company, Wasteflex, are collaborating on a recycling program to deliver zero waste to landfills.

Avery Dennison's liner recycling program, dubbed the first of its kind by the company in the South Asia Pacific and Sub-Saharan region, supports the company's sustainability goal to help customers reduce waste from its products. This liner recycling program will help brands divert glassine paper liner (waste from label application process) from landfills into recycled products. Through this program, L'Oréal Australia will divert over six tons of glassine paper liner in Australia into recycled paper for use in the recycled paper industry.

"As a materials science innovator committed to making a meaningful difference, we see sustainability as both a responsibility and an opportunity to lead. With our liner recycling program, brands now have a solution that will enable them to reduce the environmental impact from discarded label liner waste," says Anil K. Sharma, vice president and general manager, Label and Graphic Materials, South Asia Pacific and Sub-Saharan Africa, Avery Dennison. "We are delighted to partner with L'Oréal Australia and Wasteflex on this sustainability journey."

"The savings from this program have been significant, but the biggest benefit for L'Oréal Australia is being able to meet our zero waste to landfill through the services and expertise of Wasteflex and Avery Dennison," says David O'Leary, national logistics manager, L'Oréal Australia.

"Wasteflex is proud to be part of the Avery Dennison liner recycling program," says Matt Tamplin, chief executive officer, Wasteflex. "Through this program, we can offer the industry an exciting new solution that is easy to implement and will improve sustainability and commercial outcomes for business."

"As the pioneer of the pressure sensitive label industry, Avery Dennison has always focused on helping customers and brand owners achieve their goals by delivering label materials that can elevate brands, improve productivity and help products become more sustainable," says Marcel Cote, strategic marketing director, Avery Dennison. "With the launch of our Avery Dennison Liner Recycling Service, we can offer a sustainable solution to divert glassine paper liner from landfills and into recycled paper products."

Avery Dennison shortlisted for Label Industry Global Awards Shortlisted as one of three finalists, Avery Dennison received the nomination for its recent introduction of a Sustainabilit...

August 07 2018

Avery Dennison shortlisted for Label Industry Global Awards

Shortlisted as one of three finalists, Avery Dennison received the nomination for its recent introduction of a Sustainability Procurement Program, a collaborative evaluation platform providing sustainability ratings and performance improvement tools for the company’s global supply chain.

The program rates suppliers in four key areas of activity: environmental, fair business, supply chain, and labor practice. The program’s overall objective is to engage suppliers in a continuous improvement process related to sustainability.

To operate this Sustainability Procurement Program, Avery Dennison partnered with EcoVadis, a leading sustainability performance rating solutions provider. The platform delivers simple and reliable scorecards to monitor supplier best practices. A total of 21 internationally recognized sustainability criteria are reviewed and separated into four criteria themes: environment, social, ethics and supply chain.

Renae Kezar, senior director, global sustainability at Avery Dennison said: “The Sustainability Procurement Program helps us to assess compliance and recognise high performing suppliers. In addition, EcoVadis has provided a straightforward method for discussion with our suppliers on topics of social and environmental awareness. It is not only about a “score” but we have dialogue around waste, increasing recycled content, the different certification schemes, and how to work together to improve the industry."

Canon Launches Océ LabelStream 4000 5-Color UV Inkjet and Flexo Hybrid Press Canon, a world-leader in imaging solutions, today launches the new Océ LabelStream 4000 serie...

August 07 2018

Canon Launches Océ LabelStream 4000 5-Color UV Inkjet and Flexo Hybrid Press

Canon, a world-leader in imaging solutions, today launches the new Océ LabelStream 4000 series, an industrial-scale UV inkjet press with optional flexo printing, embellishment and finishing units. With an industry-leading productivity range of 950 - 1672 sqm/h the press looks set to carve out a commanding presence in the growing label printing market.

The latest addition to the production printing portfolio underlines the Canon and Océ strategy to invest in growing industrial printing segments. Combining the virtues of UV inkjet printing with conventional technologies, this innovative label press delivers unrivalled value-add in terms of time, cost and value, enabling converters to select the best combination for any production requirement.

Christian Unterberger, Chief Marketing Officer & Executive Vice President Production Printing Products (PPP), outlines what makes the new label conversion solution special: “The Océ LabelStream is based on the inkjet DNA of Canon and Océ. With this comprehensive solution package optimized to benefit from current market dynamics, label converters can boost their profitability for short and medium job sizes, and amaze customers with labels of exceptional quality and customized messaging.”

The new press has a key role to play in the wider company strategy, as Crit Driessen, Vice President & Head of Digital Packaging PPP, explains, “Océ is keen to break into forward-looking markets, and industrial packaging printing offers excellent opportunities for new revenue streams. Digital products currently account for only a relatively small part of this market worldwide, but the share expected to grow rapidly. We are confident that market players will appreciate the Océ LabelStream’s productivity and customizing abilities as a way to add value to label printing.”

At its core the Océ LabelStream 4000 series is a 5-color UV inkjet press (CMYK and white) with a print speed of 48 m/min. It offers print widths of 330 mm (13”) or 410 mm (16”) and an optional performance mode of 68 m/min for less demanding print jobs. Providing a one-pass digital high opacity white of more than 80% at standard press speed the opacity of analogue printing technologies such as rotary screen and flexo can be matched.

Latest Xaar 2001 UV inkjet printheads with a resolution of 720 x 600 dpi and different quality modes guarantee the reproduction of fine details, smooth tones, vibrant color and solids on a wide range of standard label stocks including PP, PE, BOPP plus selected special substrates.

The system can be expanded to a full hybrid configuration with a custom mix of additional flexo, embellishment and finishing units turning it into a fully integrated single-pass label conversion line to meet various demands and budgets.

This mix of conventional and digital technologies enables fast, affordable production of high-quality self-adhesive labels – for example for fast moving consumer goods, cosmetics and pharmaceuticals. Along with the ability to deliver cost-efficient print-to-order run lengths to avoid overproduction digital printing offers an unbeatable advantage in this segment: customization. As more brands move to attract customers’ attention through customized packaging it is obvious that digital printing can add significant value to increase sales and enhance brand awareness.

The Océ LabelStream offers maximum flexibility and gives users the freedom to complete orders at short lead times: easy set-up and make-ready accelerate system availability. Production costs stay low, delivering a speedy return on investment.

Label converter will benefit from the best package in the industry based on Canon’s inkjet DNA. Innovative technologies integrated into comprehensive end-to-end solutions and supported by first-class global service and business consultancy will help to develop and grow a sustainable and profitable digital business.

Christian Unterberger is confident that the new Océ LabelStream will hit the mark: “The new Océ LabelStream 4000 series is the next step in advancing our market strategy. We plan to grow in the packaging market and ultimately play a leading role.”

Commercial availability of the Océ LabelStream 4000 series in Europe will be end of 2018.

Epson SurePress L-4533A/AW receives 91% Pantone coverage certification The Epson SurePress L-4533A/AW digital label press comes the news that the press has been evaluated and approved ...

August 07 2018

Epson SurePress L-4533A/AW receives 91% Pantone coverage certification

The Epson SurePress L-4533A/AW digital label press comes the news that the press has been evaluated and approved by Pantone for its capability to achieve 91 percent of the PANTONE Solid Coated colours within delta E of 1.5 CIEDE2000.

The Epson SurePress L-4533A/AW is certified to reach its full Pantone coverage capabilities when used in conjunction with the Avery Primax 250TC/S692N/BG40W/BW6033B PS label media and Epson ink.

L4533 MainUnit 001a 002The 91 percent coverage certification is so wide that Epson regularly uses the XCMYK input profile versus GRACoL®, the industry’s current standard, and SWOP profiles made for earlier generations of pre-digital six colour equipment. The L-4533 uses a 4-colour work flow with the RIP and the press determines the orange and green automatically, saving time, simplifying the operation and improving the day to day accuracy of the jobs. In a rapidly changing printing and packaging landscape, this certification helps underscore Epson’s commitment to helping converters and their customers create engaging colour labels.

According to a study by the Journal of Experimental Psychology, colour helps people store images more efficiently than colourless scenes, showing that colour labels are more memorable and consequentially recognisable. Studies by CCIColor – Institute for colour Research also show that between 62 and 90 percent of people’s subconscious judgment at initial viewing of a product is based on colour alone3, further pushing the need for greater colour achievability in the label market. The expanded colour selection allows owners of the Epson SurePress L-4533A/AW to address more applications, such as flexible packaging with photographic images.

ID Products, a company that specialises in labels, screen printed overlays and more, has been using the SurePress L-4533A/AW to create nutrition labels, craft beer labels, pharma labels, and more. Adding this press into its production workflow has expanded ID Products’ customer base as well as its reach into new and exciting market verticals. With its wide colour gamut and precision, the SurePress L-4533A/AW has reinforced ID Products’ foundation on delivering perfect and consistent quality, enabling the business to meet their customers’ high expectations for colour accuracy and dependability.

“Our business has been built on providing perfect and consistent quality, and we measure colour at the beginning, middle and end of runs with multiple light sources. I can say, the SurePress results have exceeded my expectations – colours are consistent time and time again,” said Luke Philippas, director of manufacturing and engineering, ID Products. “Using the SurePress, we are able to re-run jobs from months ago with little to no colour adjustment. This is not the first digital technology we have put into production, but it is the best.”

Designed for prime label converters and commercial printers, the Epson SurePress L-4533A/AW is an easy-to-operate, six or seven-colour inkjet digital label press for high-quality, short-run label printing. Delivering exceptional print and colour quality, as well as innovative features, the SurePress L-4533A/AW allows printers to expand their service offerings.

“Pantone’s certification of the SurePress L4533A/AW underscores the wide colour gamut this digital label press delivers to converters,” said Mike Pruitt, product manager, Epson America, Inc. “With the increasing demand for vibrant colour labels, this certification further shows that Epson is able to provide a solution to enable businesses to create brilliant and vivid colour labels while delivering high-quality results.”

www.epson.com.au

Mactac expands roll label products with Lintec portfolio Mactac has announced the expansion of its roll label product offering with the addition of Lintec Corporation’s roll labe...

August 07 2018

Mactac expands roll label products with Lintec portfolio

Mactac has announced the expansion of its roll label product offering with the addition of Lintec Corporation’s roll label product portfolio.

Lintec, a comprehensive manufacturer of adhesive-related products and specialty papers, purchased the pressure sensitive adhesives manufacturer in 2016 to expand and strengthen its label business in North America. In order to better service customers, the two organizations are consolidating roll label sales activity and have started transitioning the first phase of the consolidation.

“We are extremely pleased with and confident in the transition of our product portfolio to Mactac,” says Kazuyoshi Node of Lintec USA. “Partnering with Mactac’s stellar sales team will truly help us better serve our customers.”

The addition of the Lintec products expands Mactac’s high performance film and adhesive product offering. Lintec products now being sold by Mactac, include:

- Cryogenic labelstocks for label applications requiring temperatures as low as -320 degrees Fahrenheit (-196 degrees Celsius).

- Security labelstocks for industrial and automotive tamper-evident solutions.

- Industrial labelstocks for extreme chemical and abrasion resistance.

- High adhesion labelstocks such as those that deliver strong adhesion to oil contaminated surfaces.

- Bubble-free labelstocks offering bubble-free application and resistance to outgassing.

- The products are designed for durable goods and industrial labeling applications, including power tools, appliances, electronics, compliance labels, and warning and instructional labels, as well as identification of test tubes and promotional labeling.

They are typically used to identify products, track or relay information, or instruct or warn consumers about a product’s proper usage.

“Lintec is a phenomenal organization and a true leader in adhesive product development,” says Kim Hensley, marketing manager, Mactac Performance Adhesives. “Above all else, Lintec is known for producing high-quality products, and Mactac is incredibly honored to have the opportunity to broaden our product portfolio with solutions from the best of the best.”

Afinia Label unveils mid-run digital label printer Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the rel...

July 18 2018

Afinia Label unveils mid-run digital label printer

Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the release of the L701 Industrial Color Label Printer. The L701 is the newest addition to Afinia’s family of products. The L701 offers the speed and performance of Memjet in a new, smaller and more affordable configuration geared toward installations requiring multiple printers across several production lines or locations.

This full-color printer can print directly to inkjet-printable, diecut labels and tag stock. The L701 supports printing roll-to-roll, roll-to-cut – with the option of printing and presenting the label – and can accept fanfold stock for applications where space is at a premium. The L701’s five (CMYKK) 150ml capacity ink cartridges offer convenience and economy over smaller systems on the market, and can produce labels in full-color, with photo-quality, at print speeds up to 40 feet (~12 meters) per minute.

According to Afinia, the L701 has a lower price point, making it a more affordable option where multiple printers are required, and has the smallest footprint available of any production class color label printer currently available. “With the addition of the L701, Afinia offers the most comprehensive line of color label printers available today,” says Mike Atkins, National Sales Manager for Afinia Label. “The L701 has incredible print quality and speed, and it fits a perfect price point between the low volume, economy priced color label printers, and the high volume, production-level printers on the market. This combination of speed and economy will enable manufactures across many industries to implement full color label printing across multiple production lines.”

Nathan Daniel, EMEA Sales Manager for Afinia Label, is excited about how the L701’s purchase price will open the door to a new group of users. He says. “The low price point of the L701 allows those who, in the past, may not have been able to stretch their budgets to a higher yield printer, to take advantage of the many benefits gained by this print technology.”

The L701 is currently available through Afinia Label’s worldwide network of dealers. “We believe the L701 at this price point and size will enable companies to move away from buying printed labels. This will allow purchasers and packaging engineers the flexibility to more efficiently manage their label inventory without sacrificing the look of their brand,” concludes Atkins.

Arrow Systems Unveils New finishing Unit Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market...

July 10 2018

Arrow Systems Unveils New finishing Unit

Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market. The Arrow Eco 300 is a tabletop blade finisher that can diecut up to 15” wide. The system features its own cutting software, as well as inline matrix removal.

“We believe this system has a place in the digital market as it fills a need for a low cost alternative to the blade and laser finishers we offer," says Shaan Patel or Arrow Systems, Inc. “The compact design allows it to be used with any roll-to-roll digital printer, and it can also be used for prepress sampling. It is an extremely economical way to get into diecutting your own labels”

The Eco 300 allows users to switch away from pre-cut media and use continuous media to be cut after printing, which can save users of small digital roll printers a lot of money. “Pre diecut media is extremely expensive, and having an option that allows you to cut your own media without breaking the bank is a nice option for brand owners to have," adds Patel.

SATO LAUNCHES COST-EFFECTIVE, ECO-FRIENDLY LABEL SOLUTION SATO, a global leader in the development of Auto-Identification and labelling solutions has launched an environmentally...

July 10 2018

SATO LAUNCHES COST-EFFECTIVE, ECO-FRIENDLY LABEL SOLUTION

SATO, a global leader in the development of Auto-Identification and labelling solutions has launched an environmentally responsible direct thermal linerless labelling solution with lower total cost of ownership.

The groundbreaking pressure-sensitive label technology with specially formulated release coating and optional perforated tear lines removes the need for a release liner. This results in measurable benefits for businesses that are considering switching to a sustainable labelling alternative.

Detlev Mueller, General Manager DACH and CEE at SATO commented: “No liner waste equates to lower transportation, storage and waste disposal costs. Businesses who switch to SATO linerless labels can dramatically reduce their carbon footprint and improve safety standards for their employees – there is no risk of injury through slippage, for example, if the backing liner is taken out of the equation.”

Mueller continues: “And perhaps most appealing to European businesses looking for a viable eco-friendly solution in line with today’s global trends, linerless labels include up to 40% more labels per roll than labels with a backing liner. It really is a win-win situation for both the company and the environment.”

SATO self-adhesive linerless labels are compatible with SATO industrial and portable printers such as SATO’s flagship CLNX Series and its recently launched mobile PW2NX Series. The solution is suitable for a wide range of applications such as price markdowns, shipping labelling and shelf-edge labelling for industries including retail, healthcare and warehousing.

In addition to the standard linerless label, SATO offers the StripeStikTM label as a complementary addition to the range for retailers. StripeStik is an innovative linerless-on-linerless labelling solution for grocery and non-grocery retail that offers enhanced security and the ability to mark-down products multiple times.

UPM Raflatac unveils new range of wash-off film labels UPM Raflatac is taking another step forward in its drive to label a smarter future by announcing that it has developed a r...

July 10 2018

UPM Raflatac unveils new range of wash-off film labels

UPM Raflatac is taking another step forward in its drive to label a smarter future by announcing that it has developed a range of wash-off film labeling solutions for a variety of end uses that can help brands create a circular economy. This will also enable them to meet or even accelerate their sustainability targets.

These clear, white and metalized film labelstocks – featuring UPM Raflatac's RW85C wash-off adhesive and a PET liner made from 90% post-consumer recycled (PCR) content – have been recognized by the Association of Plastic Recyclers (APR) as exceeding its strict standards for recyclable label products. Now available in the Americas and Asia Pacific market regions, the labels are suitable for labeling PET containers in the food, beverage, home care and personal care segments.

Thanks to the RW85C wash-off adhesive, the labels are able to undergo common PET recycling processes without contaminating any of the PET flake by-products. During the caustic washing process, the polypropylene labels easily separate from PET containers and float, allowing more high-value, clean PET flakes to be recovered. The clean flakes can then be converted back into PET containers, which promotes a circular economy and reduces the amount of plastic pollution in landfills and the environment.

"As the global drive to reduce plastic waste continues to gain speed, more and more packaging companies are looking for new and innovative solutions to maximize the recyclability of their PET containers," says Junion Zhao, director, Films Business, APAC, UPM Raflatac. "We are pleased to bring these wash-off labeling materials to market for our customers and brand owners aiming to achieve their sustainability targets."

"Exceeding the APR's standards for recyclable label products on PET packaging was very important for us when we developed these new film labels with RW85C adhesive," adds Daryl Northcott, director, Films Business, Americas, UPM Raflatac. "UPM Raflatac recently became an APR Recycling Demand Champion, which means we are committed to boosting circular packaging solutions and incorporating post-consumer recycled content into our materials, and these new label materials do exactly that."

Colordyne Technologies launches laser finishing system Colordyne Technologies, a digital labels and packaging equipment manufacturer, has introduced the 2800 Series Mini Laser, ...

June 25 2018

Colordyne Technologies launches laser finishing system

Colordyne Technologies, a digital labels and packaging equipment manufacturer, has introduced the 2800 Series Mini Laser, an off-line or near-line finishing system. The new addition to Colordyne's suite of solutions marks the first of the company's finishing-only product offerings.

The 2800 Series Mini Laser features the same reliable finishing technology as Colordyne's 2800 Series Mini Laser Pro. It laminates, laser diecuts and removes matrix waste in a single pass. This solution is ideal for accompanying roll-to-roll digital printers, such as the 2600 Series Mini Press, to complete the short run, custom label and tag production process.

"Other companies sell digital label and packaging equipment. We sell digital label and packaging solutions," says Andrew Matter, president of Colordyne Technologies. "We have brand owners and private label manufacturers using our digital printers that typically source pre-diecut material from outside vendors because they do not have the space or resources to manage a multitude of dies. We wanted to provide a solution for these customers to bring label finishing in-house to take full control of their label production."

The 2800 Series Mini Laser is suitable for finishing labels off-line or near-line, and it can create custom diecut blank labelstock for use on digital benchtop solutions. Since it uses a laser for diecutting instead of traditional rotary or blade cutting, it can produce more jobs in less time, with lower consumable costs, the company says. The laser technology eliminates the need for expensive dies and knives, making it a more cost-effective solution long term.

The 2800 Series Mini Laser offers a max cut width of 7.87" and a max cut length of 47.24" with speeds up to 60 fpm. It allows users to easily and affordably execute complex cuts in any quantity to create custom labels.

Like Colordyne's digital print systems, the 2800 Series Mini Laser features an intuitive and visual user interface that allows operators to make cutting adjustments on-the-fly. Transitioning from one cut to another is completed quickly with its built-in job library that allows users to save and reopen diecuts on-press. Setup times between jobs are nearly eliminated compared to traditional finishing.

"Every product we engineer has our customers in mind," adds Matter. "We decided to offer the 2800 Series Mini Laser for companies that do more than labeling such as brand owners and private label manufacturers. There was a gap in the market for this type of application, so we stepped in to fill it."

The 2800 Series Mini Laser can fit anywhere from a press warehouse to an office, thanks in part to its compact size and low level of noise. While this solution is user friendly enough for companies new to packaging production to operate, it laminates and cuts with the precision needed for converters.

Canon has entered the digital label printing market with the launch of the Océ LabelStream 4000. Océ LabelStream 4000 is a roll-to-roll industrial-scale UV inkjet ...

June 05 2018

Canon has entered the digital label printing market with the launch of the Océ LabelStream 4000.

Océ LabelStream 4000 is a roll-to-roll industrial-scale UV inkjet press, offering CMYK+W printing and available in a number of configurations to suit different needs in self-adhesive labels and flexible packaging. The white printing station is positioned ahead of the CMYK units, with two types of white ink available providing opacity from 67 percent (True white) to 80 percent (Alpine white), depending on application. Two widths are available – 330mm and 410mm –, with 48m/min and 68m/min production speeds available. This equates to a production range of 950-1,672 sqm an hour, depending on resolution.

Océ LabelStream 4000 features the latest Xaar 2001 printheads with an achievable resolution of 720 x 600 dpi. It can print on a wide range of standard labelstocks including PP, PE, BOPP plus selected special substrates. Applications include beauty and personal care, beverages, beer and spirits, household, industrial, pharmaceutical and promotional.

The inkjet press can be configured as a standalone digital press, with in-line finishing or as a hybrid platform. This allows the addition of a variety of value-adds, such as lamination, cold foil, delam/relam, turnbar and flexo color units, both before and after the inkjet engine. Canon identified the mix of conventional and digital technologies as enabling fast, affordable production of high-quality self-adhesive labels.

It has been developed in collaboration with label industry specialists Edale and FFEI, which has allowed Canon to achieve a fast entry to market, having commenced conversations with partners at Labelexpo Americas 2016.

The latest addition to the production printing portfolio underlines the Canon and Océ strategy to invest in growing industrial printing segments. Christian Unterberger, chief marketing officer and executive vice president of production printing products (PPP) at Océ Printing Systems, commented: ‘The Océ LabelStream is based on the inkjet DNA of Canon and Océ. With this comprehensive solution package optimized to benefit from current market dynamics, label converters can boost their profitability for short and medium job sizes, and amaze customers with labels of exceptional quality and customized messaging.’

His colleague Crit Driessen, vice president and head of digital packaging PPP, added: ‘Océ is keen to break into forward-looking markets, and industrial packaging printing offers excellent opportunities for new revenue streams. Digital products currently account for only a relatively small part of this market worldwide, but the share expected to grow rapidly. We are confident that market players will appreciate the Océ LabelStream’s productivity and customizing abilities as a way to add value to label printing.’

LabelStream 4000 is seen as a platform, with configurations tailored to a printer's specific needs and allowing maximum productivity, while also allowing Canon to establish and build a presence in mutiple package printing markets, starting in labels with flexible packaging, folding carton and corrugated on the horizon

Unterberger concluded: ‘The new Océ LabelStream 4000 series is the next step in advancing our market strategy. We plan to grow in the packaging market and ultimately play a leading role.’

Commercial availability of the Océ LabelStream 4000 series in Europe will be towards the end of 2018, with plans to enter the US market after that.

Colordyne Technologies launches laser finishing system Colordyne Technologies, a digital labels and packaging equipment manufacturer, has introduced the 2800 Series Mini Laser, ...

May 27 2018

Colordyne Technologies launches laser finishing system

Colordyne Technologies, a digital labels and packaging equipment manufacturer, has introduced the 2800 Series Mini Laser, an off-line or near-line finishing system. The new addition to Colordyne's suite of solutions marks the first of the company's finishing-only product offerings.

The 2800 Series Mini Laser features the same reliable finishing technology as Colordyne's 2800 Series Mini Laser Pro. It laminates, laser diecuts and removes matrix waste in a single pass. This solution is ideal for accompanying roll-to-roll digital printers, such as the 2600 Series Mini Press, to complete the short run, custom label and tag production process.

"Other companies sell digital label and packaging equipment. We sell digital label and packaging solutions," says Andrew Matter, president of Colordyne Technologies. "We have brand owners and private label manufacturers using our digital printers that typically source pre-diecut material from outside vendors because they do not have the space or resources to manage a multitude of dies. We wanted to provide a solution for these customers to bring label finishing in-house to take full control of their label production."

The 2800 Series Mini Laser is suitable for finishing labels off-line or near-line, and it can create custom diecut blank labelstock for use on digital benchtop solutions. Since it uses a laser for diecutting instead of traditional rotary or blade cutting, it can produce more jobs in less time, with lower consumable costs, the company says. The laser technology eliminates the need for expensive dies and knives, making it a more cost-effective solution long term.

The 2800 Series Mini Laser offers a max cut width of 7.87" and a max cut length of 47.24" with speeds up to 60 fpm. It allows users to easily and affordably execute complex cuts in any quantity to create custom labels.

Like Colordyne's digital print systems, the 2800 Series Mini Laser features an intuitive and visual user interface that allows operators to make cutting adjustments on-the-fly. Transitioning from one cut to another is completed quickly with its built-in job library that allows users to save and reopen diecuts on-press. Setup times between jobs are nearly eliminated compared to traditional finishing.

"Every product we engineer has our customers in mind," adds Matter. "We decided to offer the 2800 Series Mini Laser for companies that do more than labeling such as brand owners and private label manufacturers. There was a gap in the market for this type of application, so we stepped in to fill it."

The 2800 Series Mini Laser can fit anywhere from a press warehouse to an office, thanks in part to its compact size and low level of noise. While this solution is user friendly enough for companies new to packaging production to operate, it laminates and cuts with the precision needed for converters.

Gallus has developed Smartfire, a new digital label printing system designed as an affordable option for short runs. Debuting at the Gallus Innovation Days event on June 26-28, ...

May 27 2018

Gallus has developed Smartfire, a new digital label printing system designed as an affordable option for short runs.

Debuting at the Gallus Innovation Days event on June 26-28, 2018 in St Gallen, Switzerland, Smartfire is described as being, ‘designed for constantly changing short runs and furthermore represents an affordable solution for any label printer who is interested in going into digital label printing.’

Other technologies to be shown at Gallus Innovation Days 2018 are to include: Gallus Labelfire, equipped with a fully integrated screen printing unit; Gallus Labelmaster Advanced with automatic transverse and longitudinal register control; Gallus RCS 430 with flying imprint and fast UV ink drying thanks to a UV booster; and Gallus ECS 340, featured with web shifting for the manufacture of multilayer labels.

On top of that, the Gallus screen printing department will be presenting the whole production process of a Screeny A-Line printing plate, from screen exposure with the new Phoenix UV LED exposing system by Heidelberg, to the development of a new automated washing and drying system by Gallus Screeny, to the final assembly of the ready-to-print screen printing plate.

Heidelberg equipment presentations will cover in-mold printing with the rotative die-cutter Speedmaster XL 160-DD, and 3D printing with the Omnifire 250. Cerm will introduce new mobile features for its business management software.

Additionally during Gallus Innovation Days 2018, Gallus and Heidelberg experts will be showing how digitization will change the label business and how the two companies are going to jointly support their customers in ‘mastering this paradigm shift’.

Primera Technology has launched its RX500 Colour RFID label and tag printer. RX500 is the world’s only full-colour RFID on-demand RFID label and tag printer. Labels are en...

May 27 2018

Primera Technology has launched its RX500 Colour RFID label and tag printer.

RX500 is the world’s only full-colour RFID on-demand RFID label and tag printer. Labels are encoded, verified and printed in a single pass. Finished labels are then cut with the internal guillotine-style cutter and dispensed one at a time. On-demand printing makes the printer ideal for applications such as visitor or trade show badges where just a single label at a time with unique information is required. Batches of many labels or tags at a time can also be encoded and printed.

The built-in UHF RFID reader/encoder module is supplied by Honeywell. It is compliant with EPC Global Gen 2 Class 1 and ISO 18000 –b and –c specifications for the widest range of deployments in real-world applications.

Print resolution is up to 4800 dpi with print speeds of up to 2.5 inch (63.5 mm) per second. A single full-color ink cartridge is utilized for ease of replacement in the field.

'Printing full-color RFID labels and tags adds a new, value-added feature to the technology,’ said Mark D. Strobel, Primera’s vice president of sales and marketing. ‘With RX500, you can add color coding, graphics and high-resolution photos to RFID labels and tags. With color, you’re essentially adding an extra layer of accuracy and safety in applications such as medical file folder labels, visitor badges, photo wristbands and specimen tracking labels.’

Supported substrates include matte and gloss inkjet papers, vinyl, polypropylene and polyester. A high-degree of water, smudge and smear-resistance is achieved through advanced, third-generation dye-based inks and the print surfaces of inkjet labels such as Primera’s TuffCoat microporous labels. Most popular UHF inlays from major RFID companies can be encoded.

RPC M&H Plastics has created a range of packaging solutions designed to be easily posted through letterboxes to cater to the growing e-commerce market. With the rise of t...

April 21 2018

RPC M&H Plastics has created a range of packaging solutions designed to be easily posted through letterboxes to cater to the growing e-commerce market.

With the rise of the omnichannel, more and more brand owners are looking for packaging solutions that cater to e-commerce and home-delivery retail streams, including Garçon Wines’ slimline wine bottle, featured by Packaging Europe last year. M&H’s new Postal Pack range addresses this demand for a range of solid and liquid products. Ideal for mail order, the pack is available with varying neck and closure specifications to fit different product requirements. The standard solid dose variants are available in 150ml, 200ml, and 320ml, which the standard liquid option complementing the range at 300ml.

M&H’s foil sealed, tamper-evident closure and retained wadding, ensures that freshness and security is guaranteed for each delivery.

M&H Plastics commented: ‘With today’s fast moving modern life, the postal pack is the perfect complement to any e-commerce product range in various markets. From spices & ingredients in the food markets, to OTC medicines all can be easily posted through the letterbox, ready for when you get home.’

Durst, has confirmed that Italy’s Italgrafica Sistemi will be the world’s first customer for the new

March 21 2018

Durst, has confirmed that Italy’s Italgrafica Sistemi will be the world’s first customer for the new Omet XJet. Powered by Durst, the integrated hybrid solution for a wide range of high-performance labels and packaging printing will be installed at its headquarters in Castelgomberto, in the province of Vicenza, in the early summer.

Together with Omet, the two companies are providing a complete hybrid print and finishing line to Italgrafica Sistemi that will offer an unlimited flexibility and a wide range of final applications with a consistent cost reduction. It chose the Omet XJet because of the ability for inline multi-process configurations that finalizes products in a single pass.

Italgrafica Sistemi is an €11m-turnover company with 50 employees who work two shifts. With 18 printing lines already running at Italgrafica Sistemi, the new Omet XJet provided through Lirma Print, a Durst and Omet distribution partner, is expected to replace two of the flexo lines as demands continue to increase for short-run, personalised technology in a single pass. It will open up new opportunities for cold foiling, printing on reverse and adhesives, as well as varnish and diecutting.

Francesco Niorettini, general manager of Italgrafica Sistemi, says the total cost of ownership and benefits to his customers were crucial in the decision-making. “This investment opens up a new world of opportunity,” he says. “It allows us to give far more choice to the market and produce so many more different types of labels for any kind of job. By including the Durst Tau, we will be able to broaden our portfolio by combining all the technologies together.

“What is also really important is to ensure that we retain the same high level and definitions produced with flexo and offset – and the Durst/Omet hybrid will enable this. Other factors in our investment decision included the 50% increase in speed, the low service and consumable costs, as well as the fact that both Durst and Omet have good reputations in the marketplace,” he adds. “We’ll be saving huge amounts of money and time. We expect a 20% saving in overall production costs and will benefit from faster start-up times, which will enable us to offer a wider product range. As one example for, say, a four-color job we expect to increase the productivity of the machine by 40% with faster setups. In addition, we will be saving around 70% in material waste by using digital.”

Helmuth Munter, segment manager, Labels & Package Printing at Durst, explains, “Italgrafica Sistemi is one of the increasing numbers of forward-thinking companies that are seeing the huge benefits of using the best technologies in a complete ‘all-in-one’ printing process. This ability to combine digital inkjet printing with conventional pre- and post press printing and finishing world, offers our future customers a highly cost effective solution.

“In addition, the feedback we received from our recent Durst Digital Days has also convinced us of how customers perceive future market opportunities to increasingly involve UV inkjet digital in flexible configurations or as a complementary technology. It’s the future.”

The jewel in the crown of the Durst and Omet partnership, the new Omet XJet is the new hybrid printing platform integrating Durst’s Tau RSC 330 digital inkjet system with Omet X6 flexo stations and converting units. Durst inkjet technology, together with Omet X6’s finishing and converting units, assure reliability and excellent results at every run, with the advantage of obtaining the final product in one single passage.

The Omet XJet hybrid broadens the opportunities for label printers thanks to its flexible configuration. Italgrafica Sistemi’s configuration provided through distribution partner Lirmaprint will feature an unwinder, two flexo units, the Tau 330 RCS, another two flexo units, a diecutting mono twin system, and a rewinder. The Vision automatic registration system is also included and the system has an option to print on adhesive, laminate and other applications to create coupons and special labels, including peel-back versions. It can be seen as three presses in one or used as a hybrid solution, flexo standalone or digital standalone, according to the length of the run or the level of personalisation required.

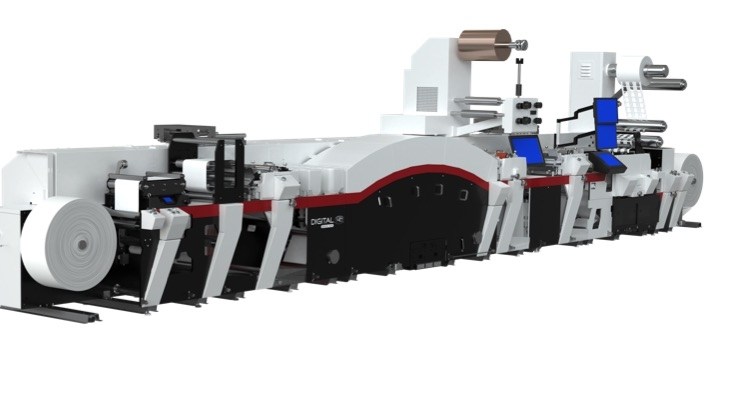

Label press manufacturer Mark Andy is continuing its commitment to hybrid printing with the announcement of a suite of enhancements to its Digital Series platform. The production-class digital s...

March 21 2018

Label press manufacturer Mark Andy is continuing its commitment to hybrid printing with the announcement of a suite of enhancements to its Digital Series platform. The production-class digital solution has been reimagined to bring greater levels of productivity and profitability to the modern converter. Building off the platform’s successes, Mark Andy says the latest true hybrid offering will take on the name Digital Series HD and combines flexibility of inline converting, high-resolution digital print, and best in class production capability.

Digital Series HD can be configured with 5 through 8 digital colors and can support integrated inline or future-proof near line converting options.This added flexibility enables Mark Andy’s portfolio of digital hybrid solutions to reach a larger percentage of the addressable market in terms of budget as well as unique application or workflow needs. The base roll-to-roll configuration is ideal for those just entering the production digital space. As their digital business expands, the modularity of the platform enables the shift to inline finishing to better utilize the high speed platform.

Expanded gamut now offered in a high-chroma ink set (CMYK + OVG) complements an existing richly pigmented white ink formulation, which delivers output comparable to rotary screen. Mark Andy product development reports the ink provides 3 times the opacity of flexo white and more than double that of conventional EP white, measured in excess of 80%. Digital white can be run without trade-off in speed at the platform’s standard of 240 fpm.

The most notable alteration to the Digital Series HD press comes in the form of the digital module. Once a flat table section, the new platform now showcases an arched IDS. The arch design accepts unsupported films and improves operator ergonomics, enabling quick and clean ink changeover. New print head technology housed in the module also matches the industry’s quality standard of 1200 dpi.

Digital Series HD also comes with further configurability in the way of 3 head cleaning options- manual, automatic, and semi-automatic. This variety translates to less downtime, improved head health and reduced costs for converters. Additionally, the platform now offers a more advantaged VDP tool in response to market demand for sophisticated personalization.

Digital Series HD is supported by Mark Andy’s industry leading web-transport system, maintaining production class speeds of 240 fpm. In addition to digital and converting flexibility, the press retains its limitless configurability of inline flexo options. All accessories available on the former Digital Series or Performance Series platform are supported by Digital Series HD, now and into the future.

When speaking to the new product developments, Tom Schelmbauer, VP of Engineering, Mark Andy, says, “The Digital Series platform was already incredibly successful, evidenced by our 2017 FTA Technical Innovation Award. Digital Series HD builds on these successes and delivers the highest quality, most productive hybrid solution on the market.” The product line extension also ensures every business has a digital growth path with Mark Andy. “Our users all have flexibility to upgrade their press as business continues to grow. We designed the press with modularity in mind because we understand demands are constantly changing. Mark Andy is prepared to tackle market shifts with our customers.”

For more technical specifications of the Mark Andy Digital Series HD, visit www.markandy.com/digitalseries.