See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Canon, a global leader in digital production print, today announces an expansion of its production portfolio and its entry into the B2 sheetfed inkjet market with the varioPRESS iV7, a new inkje...

May 28 2024

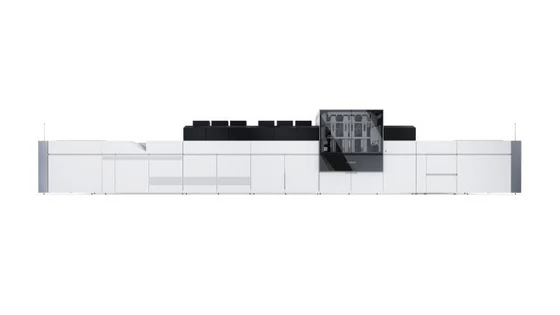

Canon, a global leader in digital production print, today announces an expansion of its production portfolio and its entry into the B2 sheetfed inkjet market with the varioPRESS iV7, a new inkjet press capable of producing 8,700 B2 4/0 sheets per hour (4,350 B2 4/4 sheets per hour). Printing up to 4.5 million B2 images per month in 24/6 operation, the varioPRESS iV7 aims to set a new standard in the digital B2 segment, delivering an outstanding combination of eye-catching quality, unparalleled productivity and versatile media support. Based on a mix of innovative and proven Canon technologies, and developed as a new platform specifically for the requirements of the B2 market, the varioPRESS iV7 will empower commercial printers to migrate jobs from digital presses and shorter runs from offset. Visitors to the Canon stand in Hall 8a at drupa can discover details of the varioPRESS iV7 in an interactive animation and samples display. The first installations of the press in the EMEA region will be in the second half of 2025.

The varioPRESS iV7 can produce 8,700 B2 4/0 sheets per hour on coated and uncoated media up to 450gsm.

Building on the continuing success and the proven technology of the varioPRINT iX3200/2100 B3 digital sheetfed inkjet presses, the new Canon varioPRESS iV7 has been engineered to address the increasing pressures of commercial print service providers (PSPs), online and publishing printers and book producers. Its exceptional print quality, productivity and extensive media support will enable these print businesses to meet tighter deadlines and produce shorter runs and more jobs, including more premium applications. The varioPRESS iV7 will join the new varioPRINT iX1700 and the market-leading varioPRINT iX3200/2100 to create a Canon portfolio of sheetfed inkjet presses that serves a greater number of PSPs and delivers a broader range of print products with monthly volumes from 300,000 A4 images up to 4.5 million B2 images.

Unparalleled Productivity

Printing up to 8700 B2 4/0 sheets per hour, regardless of media weight, the varioPRESS iV7 delivers continuous industrial productivity with minimal operator intervention, as printhead and image quality control are automated and ink can be refilled without stopping the print run. Consequently, the varioPRESS iV7 enables customers to easily meet demanding service level agreements and turnaround times, while increasing production capacity, cutting costs and boosting efficiency. Ideal for short-run, just-in-time production, it also allows PSPs to support their customers to reduce overproduction and print inventory.

Printing up to 4.5 million B2 images per month, the varioPRESS iV7 aims to set a new standard in the digital B2 segment.

Versatile media range

With a sheet size of up to 750 x 614 mm, the varioPRESS iV7 offers a B2+ production capability. This enables the profitable production of a diverse range of applications, from magazines, catalogues, books and marketing collateral to direct mail, postcards and business cards. With its air-supported, straight and flat paper path and its innovative two-step fixation process, the press supports a wide range of coated and uncoated media up to 450gsm, including selected paper boards, and can handle heavy media at full rated speed for the smooth, high-speed production of premium applications. In combination with the press’s media handling innovations, its reliable feeding and stacking technology further improves runnability and continuous production. The varioPRESS iV7 also features Canon proven, two-step drying and fixation process, which reduces deformation and increases print robustness.

With a sheet size of up to 750 x 614 mm, the varioPRESS iV7 offers a B2+ production capability.

With a sheet size of up to 750 x 614 mm, the varioPRESS iV7 offers a B2+ production capability.

Eye-catching quality

The varioPRESS iV7 features innovative 1200 dpi printheads and water-based polymer pigment inks that, combined with Canon’s ColorGrip conditioning liquid, reproduce vibrant colours, fine text and precise line detail. In addition, multilevel drop size modulation allows different droplet sizes, producing high print quality and excellent ink efficiency. Customers can therefore print high-quality applications first-time-right at high speed with consistent colour and less waste, increasing their efficiency and reducing overall production costs.

Jennifer Kolloczek, Senior Director, Marketing & innovation, Production Printing, Canon EMEA, comments, "Canon has led the evolution of production inkjet for over 15 years, helping customers worldwide to manage their business challenges and gaining vast experience in successfully supporting commercial printers to transition to digital. With a large global base of both web-fed and sheetfed inkjet presses installed, we’ve accumulated deep expertise that we have channelled into the development of this B2 sheetfed press, the varioPRESS iV7, to address printers’ production challenges and open up further application opportunities. In particular, we aim to help printers offload the more labour-intensive, short runs – currently printed on offset presses – to the most productive sheetfed inkjet press in the market without the need to change media or bindery set-ups as the B2 format is kept."

“By introducing the varioPRESS iV7 to join the varioPRINT iX1700 and iX3200, both of which we’re exhibiting at drupa, we’re making sheetfed inkjet printing an attractive proposition for operations with volumes as low as 300,000 A4 images per month all the way up to 4.5 million B2 images per month. And we’re achieving this while delivering an unsurpassed combination of print quality, productivity, reliability and media versatility, together with the digital benefits of variable data and on-demand printing. Commercial printers searching for the ultimate B2 sheetfed factory should take a very close look at the new Canon varioPRESS iV7.”

To learn more about the varioPRESS iV7, drupa visitors can come to the Commercial Print area at the Canon stand in hall 8a

Canon and Heidelberger Druckmaschinen AG (HEIDELBERG), technology leaders in inkjet and sheetfed offset printing respectively, today announce their global sales and service co-oper...

May 28 2024

Canon and Heidelberger Druckmaschinen AG (HEIDELBERG), technology leaders in inkjet and sheetfed offset printing respectively, today announce their global sales and service co-operation in inkjet printing, with a joint focus on supporting commercial print businesses striving to establish hybrid offset/digital production to meet changing print buyer needs and increase their capability to handle shorter runs of more diverse jobs. HEIDELBERG will expand its technology portfolio by introducing an own inkjet product family based on the newly announced Canon B2 sheetfed inkjet press and the well established B3 sheetfed inkjet press. Both presses will be integrated into the HEIDELBERG Prinect workflow; Service and Saphira Ink will be delivered through HEIDELBERG.

Akira Yoshida, President & CEO and Chairman of the Board of Executive Directors of Canon Production Printing Holding B.V, comments: “Canon has channeled significant energy and investment to develop its leading inkjet technology and give customers in the commercial printing industry a clear vision of their future. HEIDELBERG boasts a unique heritage, an extensive customer base and in-depth knowledge of the needs of commercial print businesses. We are confident that our collaboration with HEIDELBERG will accelerate the move to blended offset/digital production and enable transformative innovation for many more offset print businesses worldwide.”

Dr. David Schmedding, Head of Sales of Heidelberger Druckmaschinen AG, comments: “We are confident that Canon is the ideal partner for HEIDELBERG to support our customers with best-in-class inkjet press technology, backed by deep expertise in digital applications and business development. Our aim is to offer print shops that operate sheetfed offset and digital presses simultaneously an attractive and integrated service and product portfolio. That’s why we’re excited to be able to offer our customers innovative industrial inkjet presses integrated in our Prinect workflow to gain flexible and cost-effective autonomous production.”

Currently more than 650 Canon B3 sheetfed inkjet presses have been successfully adopted by customers worldwide, giving them increased flexibility and agility to produce a broad spectrum of shorter-run work efficiently and profitably. Building on this track record, the new Canon B2 sheetfed press promises ideal levels of digital productivity, quality and media versatility for industrial customers when it becomes available.

The new HEIDELBERG inkjet portfolio is being shown on the Heidelberg stand in Hall 1 at drupa 2024 (Düsseldorf, Germany, 28 May—7th June). Visitors can see a technology animation of the new B2 sheetfed inkjet press on the Canon stand in Hall 8a, and the press is slated for availability in Q4 2025.

For products including an inkjet printer, garment printer and auto colour chart reading portable table Epson's DS-C480W and DS-C420W series of document scanners ...

May 28 2024

For products including an inkjet printer, garment printer and auto colour chart reading portable table

Epson's DS-C480W and DS-C420W series of document scanners became one of a small percentage of entrants to win a Best of the Best award, the highest distinction in the Red Dot: Product Design 2024 awards. This marks the fifth time that Epson has won Best of the Best. Epson also received Red Dot awards for a business inkjet printer, garment printer and an auto colour chart reading portable table.

Best of the Best award-winning design

Document Scanners: DS-C480W (DS-C380W in Australia and New Zealand) and DS-C420W (DS-C320W in Australia and New Zealand) Series

DS-C320W

These compact desktop scanners help save space. The U-turn paper feeding vertical layout, frontal operation and flattened back achieve space saving, which helps contribute to an environment where the user can work comfortably and smoothly.

DS-C380W

Red Dot: Product Design winners Business Inkjet Printers: WorkForce Enterprise AM-C4000, 5000 and 6000

These high-speed A3 inkjet printers are intended for medium-sized to large offices. These inkjets don't use heat to fire ink*, and therefore consume less power than laser equivalents. Together with a simple structure that saves resources, these printers are designed to minimise environmental impact. The exterior is white, clean, rounded and unimposing.

WorkForce Enterprise AM-C6000 / 5000 / 4000

Garment Printers: SureColor SC-F2200 Series (SureColor F2260 in Australia and New Zealand)

These garment printers can directly print onto T-shirts and other clothes. The compact design of these printers makes them easy to install, expand and transport. Epson has also changed the design of the operating unit to solve the issue of T-shirts being difficult to attach to the previous model. Productivity has also been improved with the new model being made easier to operate. Epson hopes that the product helps contribute to the digitalisation of the textile printing industry.

SureColor F2260

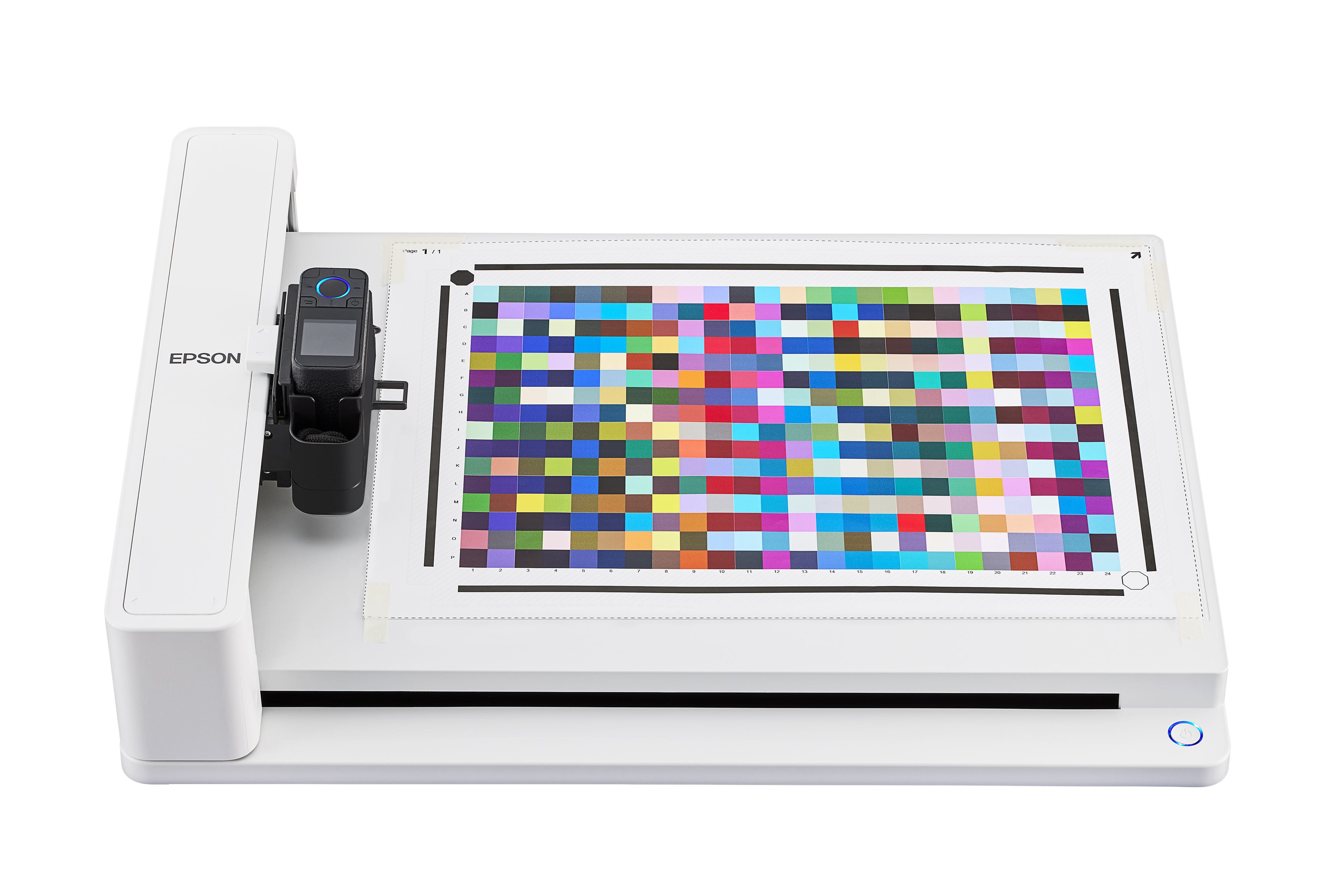

Auto Colour Chart Reading Portable Table (Auto Table for SD-10 spectrophotometer in Australia and New Zealand) spectrophotometer

This automatic colour measurement portable table makes it easy to match colours on Epson large-format printers. It works in conjunction with Epson's colour measurement device (SD-10 spectrophotometer) and colour management software (Edge Color Lite) to automatically measure colours so that anyone can match colours accurately and quickly. It can also measure soft materials such as cloth and thick materials.

Auto Table for SD-10 spectrophotometer

Conventional automatic colour measurement tables are large and difficult to carry. Epson solves this problem by using drive technology cultivated in printers to create a small, lightweight, high-precision body. It comes with a carry bag that is easy to carry and store, so you can take it to a site, open the bag, and start measuring colours immediately. For more on the Red Dot Awards go to: https://www.red-dot.org

Esko has today unveiled the CDI Crystal XPS ‘Quartz Edition’, its newest innovation that sets incredible new standards in flexographic print quality and offers a genuine alternativ...

May 28 2024

Esko has today unveiled the CDI Crystal XPS ‘Quartz Edition’, its newest innovation that sets incredible new standards in flexographic print quality and offers a genuine alternative to gravure.

“This is the pinnacle of flexo platemaking,” said Pascal Thomas, Director of Flexo Business with Esko. “In flexible packaging, gravure is still widely considered as delivering the best in print quality. With this new innovation we are giving printers a way to match that print quality in flexography. We are raising the bar on quality to the very highest level and truly enabling flexo printers to achieve the optimum results for their customers.”

A new top-of-the-line addition to the successful family of Esko CDI Crystal XPS plate imaging and exposing solutions, the CDI Crystal XPS ‘Quartz Edition’ combines the upgraded optics of the CDI Crystal with optimized Crystal Screening software.

“Our new Quartz optical technology enables users to image higher frequency surface structures at 2000lpi (Q-Cells) with an imaging resolution of 4000ppi, providing another major leap forward in flexo plate imaging speed and print quality,” said Pacal. “Imaging at 4000ppi is nearly double the current industry standard, and microcells engraved in the solid ink areas at a 2000lpi resolution is proven to significantly boost ink transfer. The Esko CDI Crystal XPS ‘Quartz Edition’ sets a whole new standard for quality.”

Market-leading flexo print quality

The innovation is primarily targeted at label and packaging converters – and their premedia plate suppliers - who are intent on delivering market-leading flexo print quality. “The hardware and software combination delivers Esko Pixel+ Q-cell screens at 2000lpi resolution, which results in a previously unattainable behavior of solid areas, smooth highlights and ink density,” said Pacal. “What’s more, this is achieved with a single optics head, reducing complexity and further simplifying the process.”

The Esko CDI Crystal XPS ‘Quartz Edition’ is compatible with solvent and water-based inks – delivering an increased density of up to 0.7 for water-based inks, which are becoming increasingly popular due to their sustainability benefits.

The new CDI Crystal XPS ‘Quartz Edition’ delivers:

• Unsurpassed quality – with smoother ink coverage, better contrast and deeper shadows

• Solid ink density – increased by up to 0.7 to achieve new levels of depth

• Solids are smoother – no pinholes or negative artefacts

• Eliminate dot-bridging - negative small elements stay open longer and dot-bridging in screens is eliminated, keeping fades and pictures cleaner

• Improved tonal range in print – higher ink laydown enables the usage of finer anilox rollers, and thus brilliant solids in combination with fine highlights and fades to zero

• Sustainability gains - reduced ink usage and compatibility with water-based inks make sustainability goals achievable

Greater accuracy, reduced ink usage, best quality print

Jan De Roeck, Director of Marketing, Industry Relations & Strategy at Esko, said that with the new Esko CDI Crystal XPS ‘Quartz Edition’, Esko continues to deliver solutions that accelerate go-to-market while meeting the needs of customers. “This is a brand-new, top-of-the-line complete flexo platemaking solution, for those looking for the very best quality in flexo printing,” he said.

Jan explained that the screening technology is an evolution from the award-winning Esko Print Control Wizard software, which uses all critical print parameters and variables – imaging resolution, exposure settings, plate, substrate, anilox, press type and inks – to simplify the flexo platemaking process. “The software standardizes the generation of Crystal Screens specifically used in combination with the XPS Crystal flexo plate LED UV exposure unit,” he said. “With the CDI Crystal XPS ‘Quartz Edition’ we are taking that to the next level, adding VQ (variable highlight Q-cells) and SQ (stochastic Q-cells) for unrivalled screening accuracy.

“This is a perfect combination of Esko hardware and software,” he added. “The Quartz cells form in a flexo plate when exposed with the UV LED technology of the XPS Crystal, providing highly consistent and repeatable plate quality.

“Put simply, the CDI Crystal XPS ‘Quartz Edition’ massively changes the game in flexo platemaking,” said Jan. “Not only does the technologically advanced system produce the most accurate and best quality plates, but it also reduces ink usage making them cleaner to use, and it does all this while delivering the absolute best quality final print.”

The new Esko CDI Crystal XPS ‘Quartz Edition’ is compatible with all existing Esko software, so users can continue running all legacy jobs without ripping them again. It will be commercially available from late 2024, available in sizes 4835, 4260 and up to 5080.

Collaboration to deliver enhanced capabilities, on-demand services, and seamless design-to-print experiences to millions

May 28 2024

Collaboration to deliver enhanced capabilities, on-demand services, and seamless design-to-print experiences to millions

HP Inc. (NYSE: HPQ) today announced a strategic multi-year global partnership with Canva, the world’s only all-in-one visual communication platform, to empower millions of Canva users worldwide to seamlessly design online, create visual content, and print locally.

The collaboration between HP and Canva aims to benefit both HP Print Service Providers (PSPs) and the Canva community worldwide, enabling anyone creating visual content on the Canva platform to seamlessly design and print within a fully integrated system. This multi-year deal will enable Canva users to design anything and print anywhere without compromising quality and authenticity.

“This partnership will deliver huge strategic value and fuel customer growth across both organisations,” said Cliff Obrecht, Canva co-founder and Chief Operating Officer.

Canva, founded in 2013, has over 185 million monthly users, including 95 percent of the Fortune 500. The launch of Canva Print in 2017 has allowed users to design and print a wide range of products—from business cards, brochures, flyers, stickers, marketing collateral, with customisation options, and even apparel – experiencing exponential growth with millions of orders annually.

Through this collaboration, the Canva community will gain expanded access to professionally printed products from HP PSPs across the globe. Canva aims to expand its print service to 150 countries by 2026, enabling shorter turnaround times and significantly reducing its carbon footprint through localised operations.

Canva Extends Reach with HP Automation Software and Global Print Service Provider Network

HP's market-leading automation software, HP PrintOS Site Flow, will help Canva extend its reach by automating production and shipping processes for PSPs. This end-to-end solution streamlines print jobs with auto-scheduling, delivering color consistency, security, barcode tracking, optimal productivity. Additionally, HP's expansion of its PrintOS Suite with new features will equip the Canva Print Operations team with powerful tools to identify, connect and manage a global SKU catalogue across HP-enabled PSPs.

Earlier this month, Canva launched Canva Enterprise, a new subscription option to cater to the growing demand from large organisations. With businesses worldwide facing the need to be more efficient and innovative, there has been an increase in demand for visual communication platforms that allow easy collaboration and interoperability. As part of the agreement, HP will implement Canva Enterprise, empowering HP's global marketing and sales teams to securely create, collaborate, and publish visual content.

“Today's announcement with Canva is a testament to HP's commitment to partnerships of this magnitude. We've been incredibly impressed by the power of Canva Enterprise and look forward to boosting our team's design productivity by removing bottlenecks that stifle creating visual content at scale,” said Haim Levit, Senior Vice President and Division President of HP Industrial Print. “Combined with the latest innovations in HP software, we are leading the industry forward, allowing users to design and print more sustainably.”

“Canva is leading the way in empowering global teams to collaborate and create high-impact visual content at speed. HP PrintOS will accelerate onboarding and ramp of new print volume to our integrated network of HP Print Service Providers, delivering the widest range of print to Canva users in every corner of the world,” added Chris Knighton, Global Sales Director, HP Industrial Software.

Localised Production Paves the Way for Sustainable Printing

The collaboration between HP and Canva also aligns with their shared commitment to sustainability. By promoting localised production, they aim to deliver high-quality design materials while reducing environmental impact.

To deliver Canva's on-demand print service, Canva's Print Operations team has collaborated with HP's graphics business and HP's Print Service Providers globally, ensuring a consistent and professional print service. HP will support Canva's expanding customer base and order volumes, helping Canva achieve its objective of printing anything, anywhere, at speed. For more information, please visit www.canva.com/print.

For more information about HP and Canva at drupa 2024, you can visit HP Industrial's official social media hub on LinkedIn at HP Digital Print. You can also see HP's innovation firsthand at drupa 2024 in Hall.

Designed for high-quality poster, graphic, signage, and fine art printing Epson is set to release its most advanced 64-inch ...

April 16 2024

Designed for high-quality poster, graphic, signage, and fine art printing

Epson is set to release its most advanced 64-inch SureColor P-Series large format printer to date, the P20560. This new model succeeds the top selling SureColor P20070 and will be showcased for the first time in Australia on the Epson stand during Visual Impact Brisbane from the 17th to the 19th of July 2024.

New SureColor P20560 64-inch large format printer

The SureColor P20560 comes with significant upgrades compared to the current model, offering faster processing speeds and an expanded 12-colour ink set that is shared with the SureColor P7560 and P9560, providing a wider colour gamut and up to 99% Pantone coverage*. The SC-P20560 is fed by a newly designed bulk ink system and ships with 12 cost-effective 1.6L ink packs designed for high-volume print jobs. A new 4.3-inch optical touch colour LCD, optional 1Tb SSD and Adobe PostScript 3 improve workflow and efficiency with the SC-P20560. Epson Edge Print PRO RIP software is also bundled with the machine, making it a comprehensive solution for professional printing workflows.

New SureColor P20560 bulk ink system

The SC-P20560 shares the same 2.64-inch PrecisionCore™ printhead as the current model, which has become known for outstanding image quality, but the printhead adds two additional lines to support the 12-colour ink set. Usability improvements that streamline workflows and media handling include the availability of Epson Media Installer, Epson Print Layout and Epson Print Automate, as well as a spindle less roll adaptor, optional take-up reel for roll-to-roll printing, front operation, and easy media roll loading.

New SureColor P20560 in production environment

More about the new SureColor P20560

The new 64-inch machine delivers a range of features designed to enhance business productivity, including:

The SureColor P20560 64-inch will be available in Australia from July 2024 and in New Zealand shortly after that. RRPs will be announced closer to the time of release.

Unified and user-friendly workflow streamlines quality inspection and ensures 100% accuracy, compliance, and print readiness

April 16 2024

Unified and user-friendly workflow streamlines quality inspection and ensures 100% accuracy, compliance, and print readiness

The leader in document quality control software for regulated industries, GlobalVision, is proud to announce an advanced integration with longtime technology partner Esko, with their flagship product WebCenter, further enhancing the efficiency and accuracy of the packaging artwork and content management process.

The integration brings together Esko WebCenter - a web-based platform specifically tailored for CPG and pharmaceutical teams to manage all aspects of the packaging management workflow from creation to approval and distribution - with GlobalVision's industry-leading automated proofreading platform, Verify. The result is a unified and user-friendly workflow that streamlines quality inspections and ensures 100% accuracy, compliance, and print readiness.

Key Features of the Integration include:

Single-Click File Inspection Tools for Compliance - Built-in automated text compare, spell check, graphics, barcode and braille inspections ensure that files are compliant with global regulatory requirements by checking files as they move through the WebCenter workflow.

Security & Data Protection - The closed-loop integration ensures that files leaving WebCenter are securely transferred to Verify, prioritizing data security and protecting sensitive information.

Seamless Artwork Management Workflow - Reduce the number of revisions needed, improve productivity, and create more synergy in the artwork management workflow by connecting Verify to WebCenter, allowing for single click file transfers between the two.

The Verify integration in WebCenter brings together speed, precision, and security in one cohesive solution to address the unique challenges faced by artwork, labeling and quality control teams and empowers them to save time and maintain compliance by automating proofreading throughout the artwork management process.

Michael Malz, Chief Product Officer at GlobalVision says: “Esko and GlobalVision teams have been hard at work for many months to bring this new integration to life. Accessing GlobalVision tools from within the WebCenter workflow has been a key function our shared customers have been requesting, as it brings quality inspections right where users need them.”

Jan De Roeck, Esko Director of Marketing, Industry Relations & Strategy added: “We are dedicated to developing solutions that accelerate the go-to-market of packaged goods. We are always keen to ensure our customers are making the very most of their Esko software and we are delighted to have worked with GlobalVision on this integration.”

To learn more about GlobalVision’s official release of the Esko WebCenter/Verify integration, visit https://eskointegration.globalvision.co/.

SEI Laser Converting is based in Buja in the northeast corner of Italy. The company is part of the international SEI Group that has installed more than 7,000 machines in 53 c...

April 16 2024

SEI Laser Converting is based in Buja in the northeast corner of Italy. The company is part of the international SEI Group that has installed more than 7,000 machines in 53 countries around the world since it was established in 1982. Engaged in a variety of markets from automotive to packaging, the Group prides itself on its ability to offer innovative solutions that help its customers to attract new business.

Its involvement with manufacturing technology for the label and flexible packaging sectors brought SEI Laser Converting into contact with Vetaphone back in 2010 when it developed its narrow web laser die cutting capability into a fully modular converting line known as the Labelmaster for roll to roll and roll to sheet applications.

The Labelmaster series, which is available in 350mm and 600mm web widths, is a high-performance system for the self-adhesive label converters involved in production for the food and beverage, wine, beauty, healthcare, textile, and industrial sectors. In addition, flexible packaging, anti-counterfeiting, and promotional work are growing areas of importance, with the Labelmaster machines’ ability to work with substrates from paper and carton to plastic films and foils.

According to Raffaella Copetti, Purchasing Manager at the Buja site: “It was our entry into the film and foil area that first alerted us to the need for surface treatment, and after extensive market research, we identified Vetaphone as our preferred supplier.” Renowned as the inventors of what is known globally as corona treatment, Vetaphone has a unique knowledge bank relating to all types of polymer-based materials and invests heavily in R&D to ensure that its technology keeps pace with the rapidly changing demands of today’s packaging market.

In fact, it was Vetaphone’s attention to detail on each customer job that appealed to SEI, whose business philosophy is closely aligned. The modular concept of the Labelmaster makes it highly adaptable to individual customer requirements with the benefit that it can be reconfigured after installation to cope with changes in market demand. According to Giuseppe Rossi, Vetaphone’s Sales Manager for Italy: “This sits well with our technology, because Vetaphone corona systems can be finely tuned to meet the specific demands of different substrates and they are also upgradeable as the need arises.”

In today’s competitive packaging market, the Labelmaster’s QR/Barcode reader allows job changes on the fly for maximum productivity. With laser die cutting now a well-proven industrial process, SEI Laser Converting offers the most efficient digital business model with web to label, web to sticker, and web to flexible packaging. In this fast-turnaround environment it is essential to have accurate control of all elements and guaranteed reliability. “We have nothing but praise for the way in which Vetaphone works with us on all of our projects, and only positive feedback from our customers on the reliable performance of their corona systems,” concluded Raffaella Copetti.

Kwik Kopy, a leading franchise business in the design, print, and signage industry, proudly announces the commencement of their Mega-Conference, titled "World of Possibilities: Emp...

April 16 2024

Kwik Kopy, a leading franchise business in the design, print, and signage industry, proudly announces the commencement of their Mega-Conference, titled "World of Possibilities: Empowering US to Make Possible!" The event, scheduled from April 20th to 23rd, promises to be a transformative experience for Kwik Kopy and its franchisees.

The 2024 Conference signifies a remarkable milestone for Kwik Kopy, showcasing the exceptional progress achieved under the visionary leadership of Sonia Shwabsky. With a strategic focus on leadership, brand consistency, industry recognition, wide format expertise, peer learning, post-COVID resurgence, community collaboration, superlative service, and community strength, Kwik Kopy emerges as a trailblazer in the dynamic design, print, and signage segment.

Sonia Shwabsky, CEO of Kwik Kopy Australia, expressed her pride in the company's achievements, stating, "Our dedication to continuous growth and innovation has propelled us forward amidst challenges and opportunities. This year's Conference underscores our commitment to our core values and purpose."

The conference agenda is replete with sessions on leadership, customer understanding, e-commerce integration, sustainability, website transformation, and investment in growth. Through engaging presentations, insightful discussions, and interactive sessions, attendees will gain valuable insights into Kwik Kopy's pivotal role in shaping the future of the industry.

"We are entering a world of possibilities, where innovation and collaboration drive growth," Sonia added. "At Kwik Kopy, we empower our franchisees to seize opportunities and turn possibilities into reality. Together, we will continue to evolve and thrive."

With over 200 attendees, including franchisees, suppliers, industry experts, and special guests, the conference promises to be a gathering of minds committed to excellence and growth. Noteworthy highlights include presentations from the CEO, Marketing, and Operations teams, keynote addresses by industry leaders, workshops on sales, cyber-security, e-commerce, and the launch of Kwik Kopy's new Leadership Cadetship and Scholarship program.

The conference culminates in a spectacular Awards night, hosted under the stars for the first time, celebrating excellence and innovation within the Kwik Kopy community. Attendees will witness the unveiling of Kwik Kopy's new website and e-commerce platform, marking a significant step towards becoming the leading franchise in the Marketing Communications space.

With a mission to empower franchisees, drive growth, foster innovation, and prioritize community, Kwik Kopy is poised to lead the design, print, and signage industry into a future brimming with possibilities.

Avery Dennison, a global leader in adhesive technologies and display graphics, is proud to announce the launch of the Wrap Like Royalty 2024 Competition. Building on the success of...

April 02 2024

Avery Dennison, a global leader in adhesive technologies and display graphics, is proud to announce the launch of the Wrap Like Royalty 2024 Competition. Building on the success of the

well-known Wrap Like a King challenge, the competition returns with an expanded format, with more categories, vehicle types, and grander prizes.

Catering to the creativity and talent within the vehicle wrapping community, Wrap Like Royalty offers three exciting new application classes for participants, in the place of the previous one

all-encompassing class. Giving expanded opportunities for more wrap queens and kings to win and be recognised:

● Color Change Class

● Print Design Class

● Fantasy Class

Wrap Like Royalty 2024 also expands to four vehicle categories, up from the previous one:

1. cars and caravans,

2. boats and jet skis

3. trucks and trailers

4. Commercial Vehicles - vans, buses, and trucks.

Prizes and Recognition

To elevate the stakes, Wrap Like Royalty 2024 boasts combined prize packages worth over $30,000. The most coveted reward awaits the three Global Winners who will enjoy a glamorous

four-night hotel stay in Las Vegas during the exclusive SEMA Show 2024, among other prizes.

Could it be you who wraps their way to Vegas fame?

Entering the Competition

Participants are encouraged to stretch their imagination and skill across various categories. For full terms and conditions, and to enter, visit Wrap Like Royalty. Should you wish to know more about the competition or require assistance, reach out to your Avery Dennison representative.

Join us as we cheer for the artisans of the wrap world and eagerly anticipate the stunning

artistry they will bring to Wrap Like Royalty 2024 (https://www.wraplikeroyalty.com/).

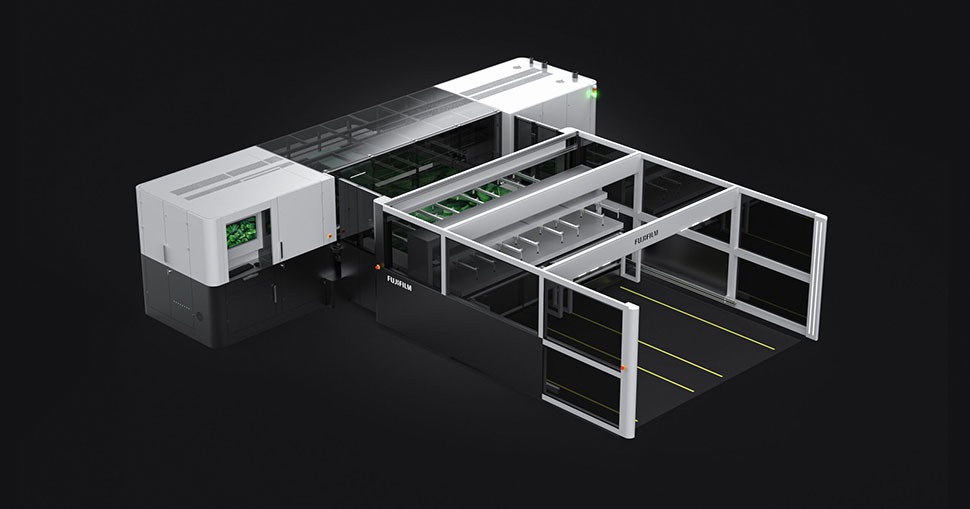

Fujifilm will preview at drupa 2024 its Automation system to give its customers the option to upgrade their high end Acuity Hybrid wide format machines with a full solution....

April 02 2024

Fujifilm will preview at drupa 2024 its Automation system to give its customers the option to upgrade their high end Acuity Hybrid wide format machines with a full solution.

The robotics unit allows a single operator to run the machine and facilitates a pallet-to-pallet process for rigid substrates.

The robust system, which was designed to support and speed up production lines, comprises a loading option to feed rigid substrates onto the printer and an unloading system to unload material from printer to pallet. It can be set to deliver full or half automation.

The system has four lanes and allows four rows of material to be printed simultaneously. Each lane has two suction arms to pick up materials and a vacuum that can be adjusted to carry a variety of substrates and surfaces with different weights. There is also an optional ionization unit which removes unwanted static from substrates that are typically challenging to print on.

The automation system’s user-friendly GUI seamlessly communicates with the printer while allowing the operator to continuously monitor the materials being handled. The automation unit includes a specially designed latching system, patented by Fujifilm, which enables it to be quickly connected to the printer.

In addition, for use with a hybrid printer such as the Acuity Ultra Hybrid LED, it has a feature on each side of the doors allowing easy access to the roll system. This feature facilitates an efficient changeover when using a hybrid printer – from roll-fed to flatbed, for example – maximising its functionality and versatility.

Fujifilm strives to ensure the longevity of its partnerships. The automation system was therefore designed to support the growth of its customers’ printing businesses and is compatible with current and upcoming technologies in the Acuity Ultra Hybrid range.

At drupa 2024 (stand A02, hall 8B), Fujifilm Group will showcase this exceptional technology, demonstrating the unloader function on a brand new machine. Customers will be able to see the system in action while Fujifilm highlights to the market how adding this technology to daily production lines can increase uptime, streamline processes and generate more business.

Label Power has been crafting top-tier labels for more than 15 years. Therefore, we are always thrilled whenever an exceptional product emerges, improving our process even further....

April 02 2024

Label Power has been crafting top-tier labels for more than 15 years. Therefore, we are always thrilled whenever an exceptional product emerges, improving our process even further. The AP380 is the latest product from Primera, featuring intuitive controls and an incredibly easy set-up, it allows for quick adjustments and seamless integration into existing production lines. Operators can save up to nine settings for optimal label spacing, streamlining the labelling process, and enhancing consistency. With a built-in rewinder, LED counter and five roller locations, it comes with all the bells and whistles that place it firmly ahead of the competition.

The AP380 is built to be able to handle a wide array of cylindrical containers of all shapes and sizes, including bottles, jars, cans, and tubes. It can accommodate containers with widths from 25mm to 239mm and diameters from 15mm to 170mm, providing unparalleled versatility. Even for those containers with slight irregularities or tapering, the AP380 ensures seamless label application.

With a labelling capacity of up to 1500 containers per hour, you can achieve a 30% increase in production speed compared to previous models. Moreover, you can apply labels to both the front AND back of the container at the same time. But you won’t be trading accuracy for speed, the AP380 uses precision sensor technology that automatically adjusts based on a labels thickness and the built-in spring-loaded pressure arm applies labels firmly and without wrinkles, ensuring consistent and beautiful results every time.

The AP380 is on display at both our Brisbane and Melbourne showrooms. Bring in your jars and bottles and we’ll show you exactly what this machine can do. If you’re based in Sydney, our consultant can bring the AP380 to you for a demo on-site. Online demonstrations are also available by appointment. You can see more about the AP380 on our site here or [CP1] you can contact us today on 1300 727 202 or at websales@labelpower.com.au.

Visitors to drupa 2024 will discover the future of automation and the latest advances in digital cutting technology, when Kongsberg Precision Cutting Systems (Kongsberg PCS) debuts...

April 02 2024

Visitors to drupa 2024 will discover the future of automation and the latest advances in digital cutting technology, when Kongsberg Precision Cutting Systems (Kongsberg PCS) debuts its latest innovations developed to unleash businesses’ potential and maximise productivity, creativity and sustainability.

The game-changing new Kongsberg Ultimate will be making its eagerly-anticipated public debut at the global exhibition, and the company has now revealed it will also give a sneak preview of the new addition to its automation line – a new seven-axis robot cell that allows customers to increase throughput utilising multiple pallets and multiple cutting systems, a further step towards ‘lights-out’ automation.

“This is our first drupa as a standalone business,” said David Preskett, Kongsberg PCS Vice President of EMEA and APAC. “We are incredibly proud of the significant advances we have made recently, and we are excited to showcase our very latest innovations. As well as having a first opportunity to see our new Kongsberg Ultimate that is transforming corrugated production, drupa visitors will also be the first to learn about our incredible new seven-axis, rail-mounted Robotic Material Handler (RMH) system. Seven axes provide significantly greater reach and flexibility, increasing the freedom to design the layout of a production cell to match customer needs. Multiple loading and unloading points can be located with greater flexibility within the cell and nested close to the cutting systems, and as the system is also modular it can grow to meet the evolving needs of a business.

“We are excited to demonstrate at drupa how both our market-leading Kongsberg cutting tables and MultiCam CNC solutions boost throughput, streamline production through automation and deliver optimum results - and all while maximising sustainable production, user experience and safety,” he said. “An array of innovative designs and samples made from a variety of materials will highlight the creative freedom that packaging and sign and display manufacturers enjoy with Kongsberg PCS machines, while our latest technological advances in automation underline how we are committed to tackling the major pain point faced by businesses today - maximizing throughput without compromising quality or creativity.”

New Kongsberg Ultimate: customer-centric innovationDavid said it was this customer-centric approach that made the launch of the new Kongsberg Ultimate such a game changer for the corrugated production industry, adding it was exciting to have a large platform like drupa to demonstrate how this next generation Kongsberg technology redefines expectations.

“Through our customer centric research, exclusive preview events and feedback sessions during development, testing and beyond, we work closely with our customers and partners to ensure they benefit from maximum return on their investment in Kongsberg PCS technology,” said David. “It is important to us that we develop solutions that not only give our customers the creative freedom they need to achieve their specific goals, but that also deliver the very best user experience while ensuring maximum operator safety. Likewise, using recycled materials in the manufacturing and assembly process, and incorporating materials that have less impact on the environment also demonstrates our focus on a sustainable, efficient, and forward-thinking approach to production. The Kongsberg Ultimate achieves all this, setting an incredible new benchmark in productivity and innovation.”

Automating the future with new technologySpeaking about the latest developments in automation on show at drupa 2024, David said: “We are looking forward to demonstrating how we are harnessing the latest technology to enable businesses to unlock their potential, supercharge productivity and to maximise their return on investment. We will be giving a first look at our new generation seven-axis robot cell, with its innovative rail mounting and improved interfacing that delivers complete unattended production for a fully automated process, further maximizing efficiency.”

Setting the standard in CNC routing“Our commitment to quality, productivity and efficiency is reinforced with the power and capabilities of our impressive MultiCam Apex3R CNC router, which sets the standard in routing with its perfect balance between performance and precision,” said David. “Already massively popular in the USA, drupa visitors will have the opportunity to see the impressive CNC router in action as we now increase its distribution across EMEA and APAC.”

The flagship in the MultiCam range of advanced routing and CNC cutting systems, the Apex3R is one of the most versatile CNC routers on the market. Its combination of power, flexibility and an extensive selection of innovative tools make handling materials such as metals, rubber, foam and textiles simple.

Summarising the company’s plans for drupa 2024, David concluded: “We are more driven than ever to provide the innovative solutions that packaging, sign and display manufacturers need to meet today’s ever-changing demands, and those of tomorrow. With our new technology and a commitment to addressing customer pain points, we cannot wait to show our innovations at drupa.”

To discover the latest innovations from Kongsberg Precision Cutting Systems at drupa, visit stand B43 in Hall 8A of the Messe Düsseldorf from May 28. For more on the entire range of digital finishing solutions and tools from Kongsberg PCS, visit www.kongsbergsystems.com. For more on the complete range of CNC routing and tools from MultiCam, visit www.multicam.com.

Landa Digital Printing announces that it is launching the next generation of its market leading B1 digital print technology, the Landa S11 and S11P Nanographic Printing Presses.

April 02 2024

Landa Digital Printing announces that it is launching the next generation of its market leading B1 digital print technology, the Landa S11 and S11P Nanographic Printing Presses.

The new Landa models offer extreme production versatility while reaching 11,200 SPH print speed. The increased speed drives superior economics for customers looking to increase productivity while reducing job turnaround times.

Commercially available at Drupa 2024 and utilising artificial intelligence technology, the new Landa presses will also offer a new PrintAI module which enhances print quality even further. It ensures a perfect fit for even the most demanding folding cartons and commercial print applications requiring micro text and other brand protection features. PrintAI opens the door to additional profit generating opportunities for many businesses.

Gil Oron, CEO, Landa Digital Printing comments, “We’re delighted to announce the launch of the Landa S11 and S11P. Following the success of our customers with current Landa S10 and S10P models and based on deep understanding of the industry’s future needs, we are taking Nanography to its next level. The new Landa models enable printers and packaging converters to not only increase print quality, but also elevate productivity and profitability while further reducing job turnaround times.

“As a mature and proven technology platform, we’re proud that over 50 Landa presses are now at the heart of many businesses in 14 countries around the world - with more than 20% of our customers having placed a repeat order for a second or third press. Considered a critical growth engine for folding carton converters, commercial printers, and point of purchase specialists, we’ve entered a new era of print production with Nanography. A time when previous technology limitations have been removed, and print buyers can finally have what they want, when they want it – beautiful print, with unlimited design potential produced economically, at market leading turnaround times, and with the environment always in mind.”

New 11K Module

The new Landa S11 and S11P models include a new ink drying system that enables transfer of dry ink from the blanket to the media, at the higher speed of 11,200 SPH. Unlocking additional productivity and improving economic benefits, the new high-speed capability is key for printers and converters looking to produce more jobs, with shorter deadlines.

Press Customisation

The new Landa S11 and S11P can be customised to the exact requirements of every customer. This means that each new press comes with a choice of four or seven colors, a continuous printing capability, an optional in-line coating unit, and the opportunity to purchase the 11K Module elevating productivity to 11,200 SPH and/or the PrintAI module.

Gil Oron, concludes: “The new Landa modules provide a significant premium to customers. While much of the new S11 series is based on the same robust and proven S10 platform, with the additional capabilities launched today, customers can expand their service offering or break into profitable new markets. More widely, there’s no question that the B1 digital print revolution is underway, with Landa presses helping many print houses and converters to meet some of the industry’s biggest challenges - and take advantage of some of its biggest opportunities.”

Agfa, a global leader in imaging and printing solutions, today unveiled its enhanced and rebranded inkjet printer portfolio. Under the baseline ‘Powerful by Nature’, the printers h...

March 26 2024

Agfa, a global leader in imaging and printing solutions, today unveiled its enhanced and rebranded inkjet printer portfolio. Under the baseline ‘Powerful by Nature’, the printers have been imbued with a fresh identity, now sporting names of formidable animals that reflect their unique strengths. No fewer than three new inkjet printers are making their global debut at the FESPA Global Print Expo in Amsterdam this week (March 19-22).

A Beast for Every Need

“We are thrilled to unveil our transformed and enhanced inkjet printer portfolio, where proven wide-format inkjet technology meets the power of three brand-new beasts,” says Arnaud Calleja, Vice-President Digital Printing Solutions at Agfa. “Our overarching ‘Powerful by Nature’ portfolio theme emphasizes that the performance of our printers stems from the way they have been designed. Whatever environment a printing company operates in, whatever its markets or applications, whether seeking high productivity, quality or versatility, there’s an Agfa printer that will deliver impressive results and give their business a boost.”

The following new inkjet printers will be showcased at the FESPA Global Sign Expo in Amsterdam:

Jeti Condor RTR5200 HS – Global debut

The Jeti Condor RTR5200 is the latest addition to Agfa’s inkjet printer lineup. This roll-to-roll inkjet printer with an impressive 5.2-meter wingspan sets the standard for both speed (up to 672 m²/h) and image quality in the roll-to-roll printer market.

The Condor handles a wide variety of flexible substrates at up to three rolls simultaneously. It is field-upgradable with light colors and features white and varnish for increased design and application options. The printer also soars high above its competitors thanks to its multiple media handling solutions for large and heavy rolls, and its extensive range of money-, labor- and floor-saving options that automate the complete printing and finishing process on the fly.

Jeti Bronco H3300 S – Global debut

With the hybrid Jeti Bronco H3300, Agfa adds another power horse to its assortment. Building on the proven reliability of the Tauro hard- and software, this swift 3.3 m high-end UV LED inkjet printer prints a variety of sign & display jobs in six colors plus white, with optional primer. Continuous board feeding enhances productivity efficiency even more, whereas independent dual-roll printing allows for the simultaneous printing of differently sized rolls or diverse media.

In the first stage, the Bronco will be available with two rows of print heads. However, its horsepower is field-upgradable to a four-row version, making it an investment that will boost printing companies’ productivity and ROI and let them saddle up for future success.

Anapurna Ciervo H3200 – Global debut

Since the introduction of the first Anapurna over 20 years ago, the family has kept evolving. The new 3.2 hybrid Ciervo approaches any printing job with great agility, ready for whatever crosses its path, and thus proves a perfect fit for printing companies that are looking for a versatile printer to tackle a wide range of print jobs.

The Ciervo brings enhanced print quality and a much higher productivity than its predecessor – boasting an almost 70% increase in printing speed in Production Mode. The continuous board feeding capacity enables efficient printing on rigid materials, at up to four boards simultaneously.

Beside these three new additions to its inkjet printer family, Agfa will also showcase two of its other beasts at FESPA:

Onset Grizzly X3 HS

The imposing Onset Grizzly X3 HS is an extremely high-speed flatbed inkjet press that combines heavy-duty operations with outstanding print quality. With a speed of up to 1450 m²/h, fast set-up and multiple automation options – including loading/unloading robots – it lets printing companies roar through workloads in a cost-efficient way and get their claws into high-volume graphics and packaging jobs.

The Grizzly runs on Agfa’s GREENGUARD Gold-certified inks, characterized by their excellent print quality, wide color gamut and low print consumption thanks to Agfa’s patented Thin Ink Layer technology. With the newly developed white print mode, the Onset applies white ink 40% faster compared to using non-Agfa ink.

Jeti Tauro H3300 UHS

Agfa brings its fastest hybrid wide-format inkjet printer to FESPA. Its rugged reliability enables 24/7 print production of superior quality at up to 3.3 m wide and 905 m²/h, while its multiple automation options boost production efficiency even more.

Capable of printing corrugated cardboard in one pass, as well as applying varnish, the Tauro H3300 is ideal for both packaging and display needs. With its versatile configurations, this sturdy beast unleashes fierce performance, allowing printing companies to charge ahead with primal force.

Additional Workflow Power

All printers are seamlessly driven by Agfa’s Asanti workflow software, a unique all-in-one print production hub that automates the entire print production process, saving time and money. The browser-based Production Dashboard offers insights into production time, ink and media usage, and interfaces seamlessly with MIS/ERP systems for optimized quotes and post-calculations. Asanti carries the G7 System Certification from Idealliance, confirming the ability to ensure uniform color reproduction across varied printing processes and substrates.

In addition to Asanti, complementary tools like StoreFront (web-to-print) and PrintTune (print standardization and monitoring) are being demonstrated at FESPA.

Beastly Prints

A broad array of inkjet print samples are being showcased for visitors to discover and draw inspiration from. Notable highlights include eye-popping displays printed with varnish, wallpapers, self-adhesive PVC-free media, colorful door and clothes hangers, a 100-meter roll of Agfa’s Synaps synthetic paper, and diverse world maps.

Industrial Inkjet Expertise

Agfa’s industrial inkjet experts are also available at the booth to discuss special UV- and water-based inks for dedicated industrial applications, as well as its comprehensive industrial printing solutions using water-based inks: the InterioJet (laminate décor paper printing), the Alussa (leather decoration), and the high-speed SpeedSet Orca 1060 for the packaging market, which was officially introduced to the market late last year.

Brother International Corporation announced it will enter the signage market in the industrial garment printing industry with the new WF1-L640 64-inch latex wide-format printer. Th...

March 26 2024

Brother International Corporation announced it will enter the signage market in the industrial garment printing industry with the new WF1-L640 64-inch latex wide-format printer. The platform is designed with a wide range of business applications in mind including banners, window-wall-floor graphics, outdoor & display signage, trade show graphics, vehicle wraps, advertising and interior decoration.

This new latex wide-format printer takes on a new business area for Brother utilizing the company’s ink and printhead technology cultivated through the development of garment printers. The latex ink developed for the WF1-L640 achieves a wide array of colors and rich expressiveness, and in addition to having high weather resistance for outdoor advertisements, is water-based, making it environmentally friendly and safe to use such as in restaurants, educational institutions, and medical institutions.

Brother’s latex ink formula offers a wider color gamut with CMYK over the industry standard. The WF1 printer has an integrated curing system for the ink with no additional wait time needed for outgassing as with other chemistries.

“Brother’s industrial printing division continues to grow and innovate when it comes to services and solutions” commented Lawrence Davenport, Vice President of Brother’s Industrial Products Division.

The printer’s industrial piezo print heads allow variable drop sizes starting at 5 pico liters. Controls are easily accessed via a 7-inch touch screen and professional production RIP software.

FLXflow options include new ‘Float’ function, which makes it easier for operators to handle heavy substrates, and ‘Instant Switch’ function to transition quickly between ‘Hold’ and ‘Float’ for e...

March 26 2024

FLXflow options include new ‘Float’ function, which makes it easier for operators to handle heavy substrates, and ‘Instant Switch’ function to transition quickly between ‘Hold’ and ‘Float’ for even easier media handling.

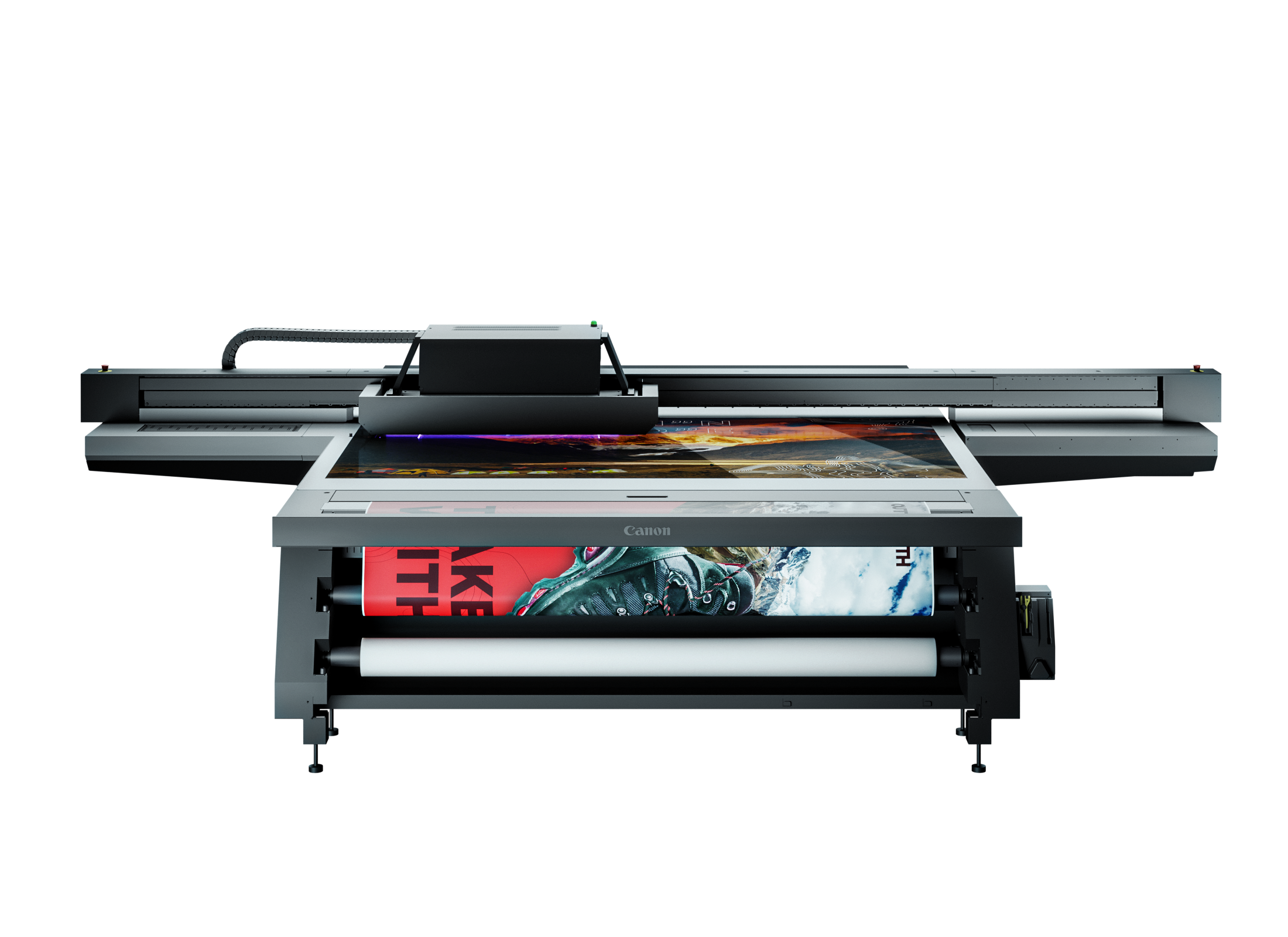

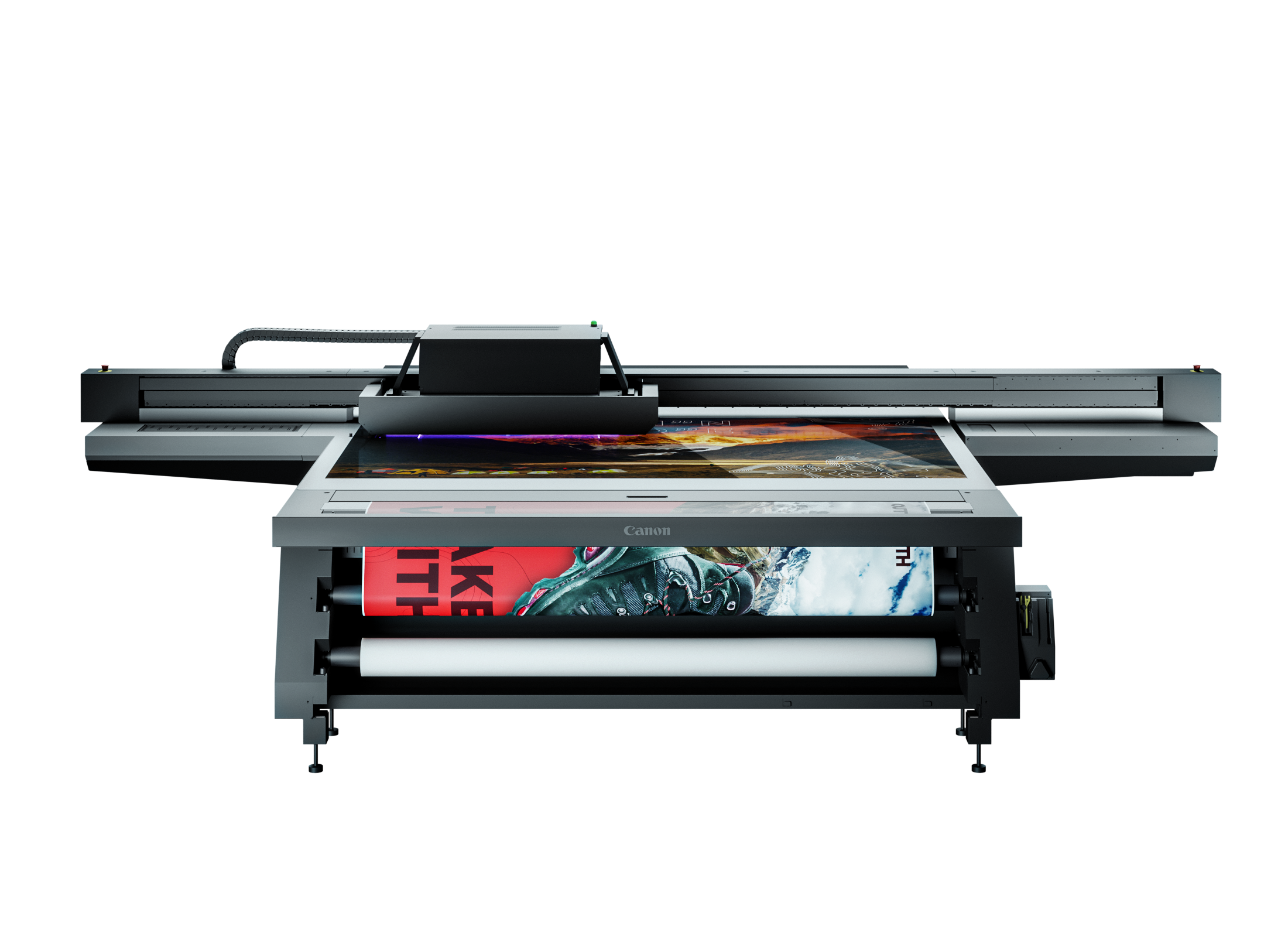

Canon today announces the Arizona 2300 series with FLXflow technology, which brings new productivity features to the flatbed printer series. Previously known as FLOW technology, the new FLXflow offers not only the original ‘Hold’ functionality, which helps to hold media down on the flatbed table, but also the new optional ‘Float’ and ‘Instant Switch’ functionalities to improve media handling. Further features, such as additional quality modes, image layout controls and improved workflow integration, together with an interface that connects automation systems for continuous loading and unloading media, deliver increased workflow efficiency and productivity.

Optimised usability

Catering to the mid-to-high volume market for large format graphics, the Arizona 2300 FLXflow supports a wide variety of substrates and applications. This enables customers, both in-house or commercial print service providers (PSPs), to continuously adapt to evolving consumer trends, such as the growing demand for personalised and made-to-order applications, while ensuring that customisation remains economically viable, even for samples and one-off orders.

Offering a unique, patented way not only to hold but also to float the media, FLXflow comes with three functionalities – Hold, Float and Instant Switch – allowing users to move heavier and irregular-sized media faster and more easily around the table. The Hold functionality, a feature of the original FLOW technology, works by keeping the media in place with a patented airflow technique. Using automatic measurement and adjustment of airflow levels to firmly and accurately hold various types of media in place, the functionality results in flexible positioning with far less masking.

The new Float functionality is an optional feature that pushes air from the table upwards to create a cushion, enabling the easy positioning of heavy or challenging substrates and reducing the risk of media damage or waste. It also results in the smoother registration of all types of media, with a ‘floating without drifting’ functionality enabling several pieces of media to be precisely positioned at the same time. The Instant Switch feature allows the operator to easily change from Hold to Float by using the foot pedals for simple operability of the printer, making it easy to remove media from the table.

Elevated and textured printing for endless creativity

The latest release 2.1 of PRISMAelevate XL doubles the printing height to 4 mm (0.157”) to help customers create stand-out, tactile artwork for elevated print applications that enhance and expand their product offering. It enables customers to explore new applications, such as high-value, textured, permanent signage, product decoration, awards, décor materials and package prototyping, as well as applications for the visually impaired. PRISMAelevate XL software makes prints durable without the need for additional finishing steps, such as lamination, coating or spray varnishing, and results in less waste and higher production efficiency.

Maximise Uptime

Arizona 2300 FLXflow customers can also take advantage of the new Advanced Image Layout Controls, which allow last-minute adjustments at the printer, giving additional flexibility when positioning substrates on the table and reducing waste of expensive materials. Productivity is further enhanced by service support tools such as PRISMAservice, which provides predictive maintenance and facilitates authorised remote assistance by qualified service technicians to maximise uptime.

In-field upgradability

Customers of the current Arizona 2300 with FLOW technology can upgrade their printer to the latest version with FLXflow functionalities, including the optional Float and Instant Switch features. Upgrades also include new features like the Advanced Image Layout Controls. Or they can add PRISMA XL Suite workflow software to provide a preview function, which allows users to see what the final product will look like before it’s printed, while allowing them to make any necessary adjustments. Saving time, this makes it possible to preview complex, multi-layered, textured jobs and also to provide cost estimates before printing.

Peter Wolff, Chief Marketing Officer and Senior Vice President, Canon Production Printing says: “At Canon we’re focused on the continuous development of our flatbed technology by working closely with the market and our customers to evolve our products, from our printer ranges to the software that supports them. With that in mind, we’ve designed our Arizona 2300 FLXflow to be versatile and deliver high-quality, applications with even greater workflow efficiency and productivity, while our service support tools such as PRISMAservice, help to maintain the highest uptime for our customers for maximum productivity. And with the new functionalities of our FLXflow technology, with its added ‘Float’ capability, it’s making life much easier for operators to handle irregular or heavy substrates, opening up opportunities to produce an even wider range of applications.

“Combined with our latest release of PRISMAelevate XL, capable of delivering prints at 4 mm (0.157”) elevation, the possibilities have been opened up even further. Customers continuously surprise us with the creative applications they produce, and we can’t wait to see what they create with these new functionalities.”

Designed with circularity in mind

Offering reduced waste and lower energy consumption than its predecessors, the Arizona 2300 FLXflow has been designed with the circular economy in mind. FLXflow technology requires less masking and underlays to hold media in place, resulting in less waste. As LED-UV printers, the series also consumes at least 15% less energy compared with its UV-halide predecessors, and offers power-saving features such as first-time-right printing and instant-on functionality. Its inks are UL GREENGUARD Gold certified, which ensures prints are safe for use in sensitive environments such as hospitals, schools and other public places.

Customers can also take advantage of Canon’s remanufacturing programme, where they can trade in their well-loved, well-used Arizona printers when purchasing a replacement. These older systems are inspected, serviced and prepared for sale as refurbished printers, further extending the lifespan of the Arizona.

The Arizona 2300 FLXflow will be available from June 2024, and it will have its live debut at ISA, Orlando (FL), USA from April 10-12th, 2024. PRISMAelevate XL 2.1 is available from April 10th via accredited partners as well as Canon’s direct sales organizations.

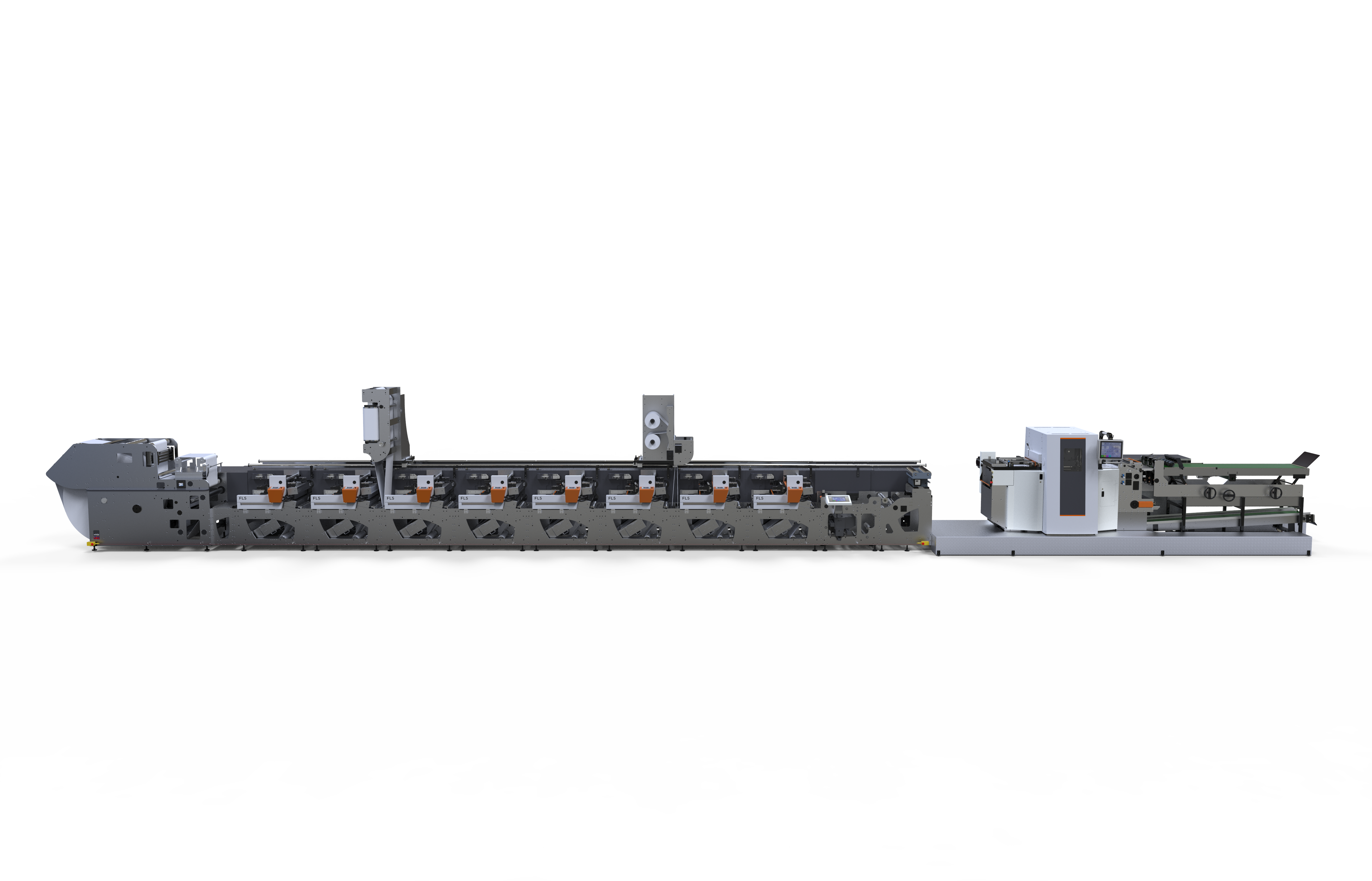

Canon will demonstrate its commitment to become a significant, trusted partner to the label and packaging markets, and show a new digital press and concepts that confirm its clear ...

March 26 2024

Canon will demonstrate its commitment to become a significant, trusted partner to the label and packaging markets, and show a new digital press and concepts that confirm its clear progress towards that goal. Indicating the importance of labels and packaging as strategic areas for growth, a dedicated zone on the Canon stand will feature live production of multiple label, corrugated and folding carton applications.

Labels

Canon will show the new LabelStream 2000 digital label press at drupa, the first time it has appeared outside Japan. Based on innovative Canon technologies and designed for industrial-scale label printing, the LabelStream LS2000 is Canon’s first water-based inkjet label press. Announced in October 2023, the device prints CMYK plus white on self-adhesive substrates, with a new ink set designed to comply with food safety standards. Visitors to Canon at drupa will be able to see live label production on paper and film media, printing the labels on the LabelStream LS2000, which are then ready for varnishing, die-cutting and slitting on a nearline converting device, the Grafisk Maskinfabrik DC330Mini. Print samples from the Canon group company Edale FL3 flexographic label press will also be available.

Corrugated

As evidence of its commitment to expand into the corrugated printing market, Canon will also introduce its concept for a single-pass, industrial-scale digital corrugated printing system, targeting corrugated packaging converters and designed to combine offset-like print quality at a 1.7 m print width, productivity of up to 8,000 sqm/hr and new levels of cost-efficiency. A 3D model, print samples and technology animations of the system, which is already in development, will be shown on the stand.

Visitors interested in digital printing on corrugated can see live production of packaging prototypes and short-run promotional packaging on large ‘format Arizona and Colorado printers. For packaging producers and print service providers, these solutions enable personalised, short-run, on-demand packaging production. The new Arizona 2380XTF FLXflow technology flatbed printer (See separate press release dated 25.03.24 for details of this product) will print a variety of display and packaging applications on a wide range of media, including corrugated. White, varnish and the opportunity to print elevation up to 4mm with PRISMAelevate XL give full design freedom for high-quality packaging and packaging that can be "read" by the visually impaired.

A UVgel Print Factory, comprising a Colorado M-series roll-to-roll printer and a Fotoba Jumbo Roll JRL 170 feeder and JRR 170 Rewinder, will be shown printing on a liner material for later lamination to a corrugated base to create a high-quality printed package, as a digital alternative to conventional litho lamination. Replicating the litho lamination process with digitally printed liner material offers short-run, high-quality packaging that can be personalized or versioned, while the durability of UVgel prints means that additional top coat lamination is not always necessary. With FLXfinish+, customers can achieve a premium look and feel without any extra cost to the print service provider.

Folding Carton

Thanks to its 2022 acquisition of Edale, Canon has started to establish a presence in the folding carton market. At drupa, an inline folding carton production process will be shown, taking preprinted reels which then will be embellished live on the Edale FL5-Single-Pass Carton Production Line, adding either cold foil, cast & cure or varnish. The carton will move inline to the Edale FDC600 flatbed die cutter for cutting, creasing, braille/embossing, and waste stripping, ultimately delivering finished carton samples in a single pass.

Folding carton print samples digitally printed on other Canon presses, such as the toner-based imagePRESS V1350 and the sheetfed inkjet varioPRINT iX3200, will also be available on the stand.

Further demonstrating its intention to become a key supplier to the packaging market, Canon will also provide its outlook on industrial-scale, digital sheetfed, folding carton production printing, targeting converters who are interested in exploring the benefits of digital print.

Peter Wolff, Chief Marketing Officer and Senior Vice President, Canon Production Printing, comments: “While flexo and offset printing processes are suited to the mass production of high-volume jobs, converters are now struggling to maximize plant productivity in the face of more frequent reprints, short runs and versioning, as brand owners create ever increasing numbers of SKUs - all in the context of significantly reduced turnaround times.

“As the global leader in high-volume production inkjet, our digital presses already operate side-by-side with analogue equipment in complex, high-volume, industrial environments across a variety of commercial print segments, giving us a good understanding of converters’ requirements. Our market-leading inkjet expertise, experience with challenging substrates, and extensive track record of building high-performance production lines, together with the additional insight gained from our acquisition of Edale, mean Canon is ideally placed to help label, corrugated and folding carton converters to gain competitive advantage by increasing operational effectiveness and differentiating their offering.

“Working with a diverse range of technology partners, we are highly proficient in devising complete end-to-end solutions, hybrid workflows and smart automation. Our systems, together with Canon’s ongoing expert technical and business development support, have enabled hundreds of businesses worldwide to unlock additional productive capacity and tap into profitable new revenue streams and business models. We’re committed to extending those same advantages to label and packaging converters.”

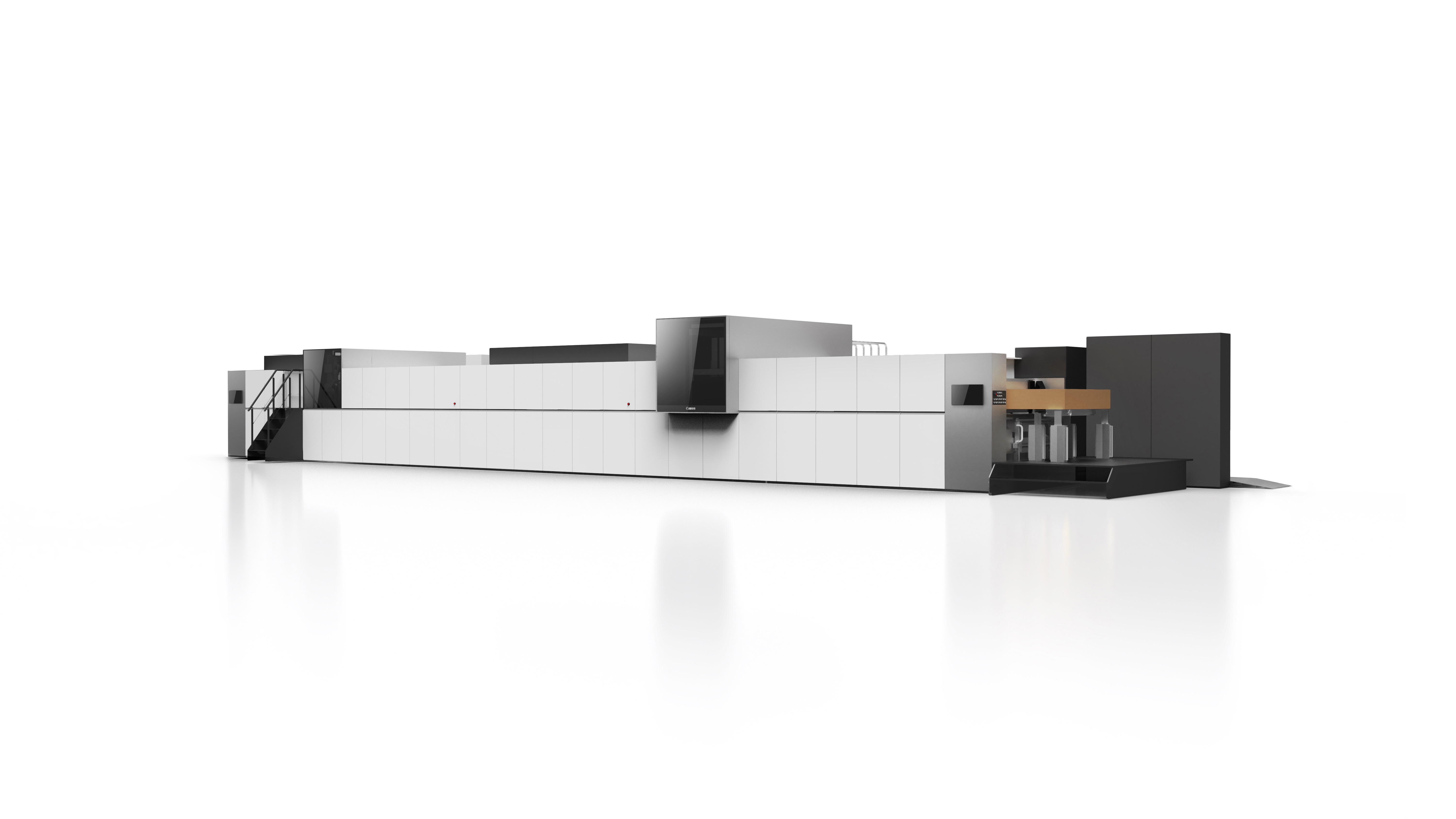

The new ColorStream 8200 and 8110 models extend the production speeds of the ColorStream 8000 series to meet additional customer needs while delivering proven print quality, reliability and appl...

March 26 2024

The new ColorStream 8200 and 8110 models extend the production speeds of the ColorStream 8000 series to meet additional customer needs while delivering proven print quality, reliability and application flexibility.

Following the success to date of its ColorStream 8000 series of high-speed, web-fed inkjet presses, Canon today expands the series with two new models, the ColorStream 8200 and 8110. The ColorStream 8200 is now the most productive model in the series, with a maximum speed of up to 200 meters per minute (656 feet per minute). At 110 meters per minute (361 feet per minute), the ColorStream 8110 is ideal for print service providers (PSPs) wanting to invest in a new ColorStream press while maintaining existing finishing equipment.

Since its launch in 2011, the ColorStream range has proved to be an attractive investment for high-volume print production environments, with more than 1800 towers having been installed worldwide. Building on that customer demand, the new Canon ColorStream 8200 is the most productive and automated ColorStream press to date, minimizing the need for manual intervention and offering excellent uptime and efficiency. Operating at maximum speed, the ColorStream 8200 delivers 2,692 A4 pages per minute (2,860 Letter pages per minute). That level of productivity makes it perfect for business communication, transactional and book printers and PSPs needing to handle production peaks with ease while producing a mix of output, including transactional statements, publications, books, direct mail and product inserts.

Offering a print quality equal to the existing ColorStream 8000 models, the new ColorStream 8200 and 8110 models feature native 1200 dpi printheads and highly pigmented water-based polymer inks, for a wide color gamut on uncoated, recycled, inkjet-coated and inkjet-treated paper without pre-treatment. The use of durable, long-life components in the ColorStream 8200 and 8110, together with automation features, such as auto splice handling and tight communication with inline finishing devices, reflects Canon’s focus on supporting customers to achieve peak productivity, while at the same time reducing the environmental impact of its products and operations.

To maximize the efficiency of the ColorStream 8000 series, customers can combine it with PRISMAproduction, an integrated and scalable, high-performance workflow and production management platform that automates and integrates data input and conversion, prepress and print output. Enhancing files for high-performance production printing, PRISMAproduction enables AFP and PDF pre-flighting and make-ready, data enrichment and page composition in one flexible print workflow via a single platform. The batching functionality in PRISMAproduction also allows customers to optimize their order processing and production sequence in line with the ongoing trend in the reduction of run lengths, resulting in efficient output handling on the ColorStream 8000 series.

Peter Wolff, Chief Marketing Officer and Senior Vice President, Canon Production Printing, comments:

“Customers of the ColorStream 8000 series have been delighted with the robust build and print quality of these presses, praising their level of automation, exceptional uptime and consequential OEE performance. With the introduction of the new flagship ColorStream 8200, we’re now helping to boost their productivity even further without compromising reliability or quality. And as business communication printers and publishers are keen to produce books on more easily recycled, uncoated papers, we’re confident they will find the new ColorStream particularly appealing.”

The new ColorStream 8200 will have its global debut on the Canon stand in Hall 8a at drupa 2024, as a part of an inline, on-demand book production solution. With integrated inline Hunkeler finishing equipment, the press will produce book blocks with auto splice handling, changing formats, variable page counts and variable book spine lengths for any run length at the maximum printing speed of 200 meters per minute (656 feet per minute), delivering outstanding productivity, efficiency and quality in both print and finishing.

For more information about the ColorStream 8000 series, go to https://cpp.canon/products/colorstream-8000-series/.

New ProStream 2000 series offers customers both high-quality coated and uncoated media applications at an appealing cost/performance ratio, while ProStream 3160 delivers 160m/min p...

March 26 2024

New ProStream 2000 series offers customers both high-quality coated and uncoated media applications at an appealing cost/performance ratio, while ProStream 3160 delivers 160m/min productivity, making it the ideal solution for commercial printers wanting the ultimate in performance.

Also announced today is the new ProStream 3160, the 160m/min flagship model of the ProStream 3000 series. A new polymer pigment ink set, also included with the ProStream 2000 series, ensures high, consistent offset print quality at rated speed, while extending the media grammage/speed range. Both the ProStream 2000 series and the ProStream 3160 enable ultra-fast production, allowing print businesses to move even higher volumes of work from offset and legacy technologies.

Printing at up to 133m/min on standard offset coated, uncoated and inkjet optimized media from 28gsm up to 150gsm, the ProStream 2000 series offers a better cost/performance ratio and is 20% shorter than the ProStream 3000. It also consumes 10% less energy[1] than the ProStream 1800. The new series is the ideal inkjet investment choice for general and specialised commercial print service providers, who are predominantly producing high-quality applications on lower weight media or on a wide range of media types and weights and want to migrate high-volume work from offset to digital. Papers up to 300 gsm are supported at reduced speed. The ProStream 2000 series will, however, equally appeal to book printers, who principally produce applications on uncoated media but are looking to diversify into coated media, as well as to business communications companies that want to expand beyond traditional print jobs, such as reports, invoices and statements, to premium direct mail, brochures and newsletters through a cost-efficient and flexible means of production.

The new series comprises two models – the 80m/262ft per minute ProStream 2080 and the 133m/436ft per minute ProStream 2133 – and can print duplex up to 1,790 four-colour A4 impressions per minute or 11,300 B2 sheets per hour, equating to 62 million US letter/58 million A4 impressions per month, on web widths up to 558mm.