See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

November 09 2021

Rayjet Laser, a division of Trotec Laser, is pleased to announce the addition of the R400 laser cutting and engraving machine to its R Series product line. Now also available for online purchase, the R400 features an ergonomic working area, sophisticated and intuitive workflow software, and the industry’s highest safety standards – providing the industry with a reliable, user-friendly, cost-effective, and locally supported solution for cutting and engraving a broad range of materials.

Designed to comply with stringent production standards and European manufacturing and design principles, the R400 joins the R500 as the only laser safety class 2 systems in their price range—meaning that R Series lasers meet U.S. manufacturing safety requirements for use in public spaces, and do not require operators to wear protective gear such as safety goggles. R Series lasers, which are also CE certified, include safety features such as a double interlock system and a safety kill-switch.

The R400 system features an open, ergonomic design with a 40.5 x 24.8 inch bed size that fits most standard material sheet sizes, and up to 100 Watts DC of laser power, allowing you to easily and efficiently cut and engrave a wide range of materials such as plastics, paper, textiles, acrylics, wood and many more materials. The included Rayjet Manager workflow software provides easy, step-by-step instructions with logical and intuitive functions, allowing you to make a fast transition from job layout to final product.

To accommodate the different needs and preferences of a diverse customer base, R Series lasers are now also available for online purchase though the company’s new Engraver’s Network website at: engraversnetwork.com.

“With R Series lasers, you really get the best of both worlds,” says Warren Knipple, President at Trotec Laser. “They are simple to use, yet you can produce highly sophisticated and precise designs. They are cost-effective but still meet the most stringent standards for safety, design and manufacturing. And to make things even easier, you can choose to buy them online, or you can consult a local representative to assist you with your purchase,” Knipple says.

Epson has earned its second successive platinum rating for sustainability from EcoVadis. The platinum rating, which was established in 2020, indicates that Epson was ranked among the top 1% of companies in the industry. Epson had received a gold rating the previous three years.

The platinum rating was awarded in recognition of Epson’s global sustainability initiatives. In the four themes assessed by EcoVadis, Epson received high scores for the environment, sustainable procurement, labour and human rights and ethics, putting it in the top 1% of companies in the industry.

Epson Global President Yasunori Ogawa said, "We’ve put solving issues in society, and especially achieving sustainability, at the heart of Epson’s corporate vision and business strategy. It’s a tremendous honour to receive this Platinum rating for the second successive year. In addition to setting ambitious goals to achieve our Environmental Vision of becoming carbon negative and underground resource1 free by 2050, we are continuing to implement measures to ensure good governance and social responsibility across our supply chain, including acquiring RBA2 certification at some of our key manufacturing plants. Most of all, however, I believe this Platinum rating communicates that to our customers Epson is a company that can be trusted, is determined to achieve sustainability and will fulfill its responsibility as a good corporate citizen.”

EcoVadis provides an independent, trusted, common platform for evaluating and rating more than 75,000 groups and companies in the world using sustainability assessment criteria that are based on the sustainability standards of thousands of external sources such as NGOs, labour unions, international organisations, local governments and auditing organisations.

Fully focused on solving societal issues, Epson has identified four materialities including “achieving sustainability in a circular economy” and “advancing the frontiers of industry” and is committed to creating products and services that contribute to its goal of achieving sustainability and enriching communities.

The company is leveraging its efficient, compact and precision technologies to generate innovations in areas like inkjet printing that minimise environmental impacts and increase productivity. Epson is dedicated to solving societal issues and to achieving the Sustainable Development Goals of the United Nations.

Epson seeks to achieve social sustainability and publishes details about its environmental initiatives, the creation of social value, corporate governance, and other sustainability activities in its Integrated Report and Sustainability Report. Information is also posted on the Sustainability pages of the corporate website.

For more on Sustainability at Epson go to: https://global.epson.com/SR/

November 01 2021

Epson has won a 2021 Good Design Award for a total of eight products, five of which are sold in Australia and New Zealand. Good Design Awards are presented annually for designs that benefit and enrich our lives and society.

The first winners are the SureColor T7760D and SureColor P8560D Large-Format Inkjet Printers. These 44-inch LFPs are for CAD, photo and POP applications. Epson kept their depth within 500mm, making these printers ideal for printing and processing even in limited spaces, such as in the back of small shops. The sides and back are flat so that the units can be installed flush against walls. Moreover, their perfectly flat top and height make them useful as a worktable. The design is the same as that used for office printers so that they fit into their surroundings.

SureColor T7760D

The judges said, “These large-format, 6-colour pigment ink inkjet printers support B0+ paper and have an exceptionally well-thought-out, polished design. Epson not only considered usability but also where and how they would be installed. The sides and top are flat, and most operations can be performed from the front. With all sides flat except the front, the printers can fit perfectly flush against the wall on three sides. This feature is apparent in the appearance of the products themselves. These printers can be placed back-to-back in the middle of a room to create an island that can be used as a worktable, thanks to the perfectly flat top. Some other interesting design ideas have also been implemented, such as an LED that is provided inside a black peephole in the center of the top so that you can see prints in progress.

Next on the winners list was the SureLab D1060 Commercial Photo Printer. This minilab printer is loaded with features required by professional photofinishing services. The box shape enables multiple units to fit neatly on shop counters. With a new duplex feeder, users can now perform double-sided cut printing in addition to roll paper printing as on the SL-D1060’s predecessor. The use of ink packs increased the amount of available ink by 25%1 and reduced the amount of space needed to store used ink by about 55%.1

SureLab D1060

The judges commented, “The printer is designed such that limited space can be used efficiently. In the vertical direction, the operation panel is tilted back at an angle so that it can be operated even when objects are stacked on the unit. In the horizontal direction, meanwhile, all maintenance tasks can be performed from the front so that there is no need to access the sides. The use of high-capacity ink packs reduces both labour and waste. It is apparent that this product was designed based on careful research and analysis of the usage environment.

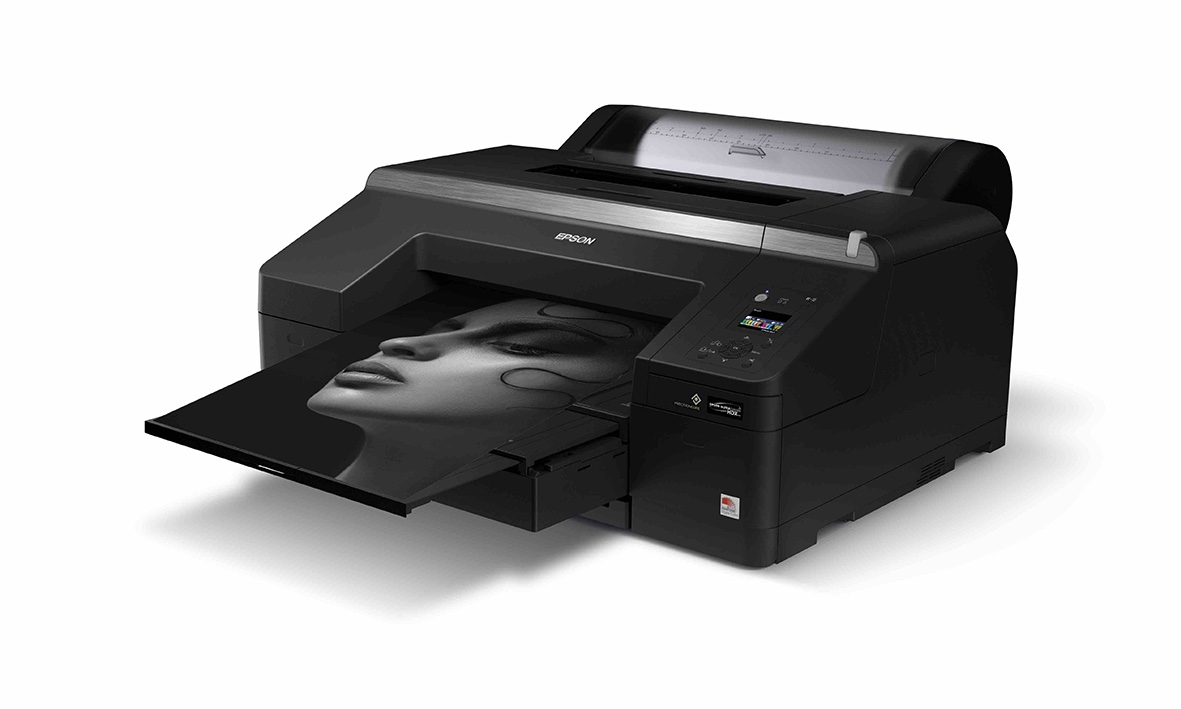

SureColor R5000

Further winners were the SureColor R5000 and SureColor R5000L Resin Ink Printers. These resin-ink printers are for wallpaper and large sign production. These are the first printers in Epson’s SureColor series to use resin ink, which is compatible with a wide variety of media. The high-capacity ink packs reduce maintenance time and, when empty, take up 90% less storage space than used cartridges2. A wide window and LED lighting allow users to quickly check prints, and a resin exterior is used for the parts operated by people for their safety.

The Judges said, “This is a high-performance machine with a design that is well organised. The large viewing window, which is in the centre of the dark tone body and can be illuminated by a light inside the printer and the touch panel are inclined for both good visibility and operability. The quick-drying resin ink is water-based instead of organic solvent-based, and the high-capacity ink packs exhibit design excellence, offering high-level features, usability and environmental performance. With the ability to alternate between two packs of the same colour on the SC-R5000L, the ink packs can be hot swapped without interrupting printing. They also generate 50% less waste than cartridges.”

EH-LS300B

Another winner was the EH-LS300B Home Theatre Projector. The EH-LS300B is a home projector equipped with an ultra-short throw lens. With a picture up to 120 inches, a Yamaha 2.1-channel speaker system that provides excellent sound quality and integrated video content features, you can easily enjoy an immersive viewing experience simply by setting up the projector next to a wall. Epson designed this projector for use in a living room. The use of fabric to fit the texture of an interior space hints at the level of detail paid to the design.

The judges commented, “Here is an example of a home projector that is both elegantly styled and has great functional performance. The form of the device is quite minimal. Its simplicity belies the fact that this is a great short-throw projector that works to deliver a great image, large and clear under normal lighting conditions. The surfaces and textures are beautifully crafted, and the overall affect is a good, well-designed home product. To deliver good performance, this device is still relatively large, and it will be interesting to see in the future how the footprint or volume can be reduced to improve the design further.”

More on The Good Design Award

The Good Design Award, which began in 1957 as the Good Design Selection System (or G Mark System), is a leading design evaluation and commendation system. It has become world renowned, attracting a large number of entries from companies and groups around the world. Awards are presented annually as a way to promote quality of life and the use of design in solving social issues. The symbol of the award, the G Mark, is widely recognised as a symbol of excellence in design.

For more on the Good Design Award go to: http://www.g-mark.org/

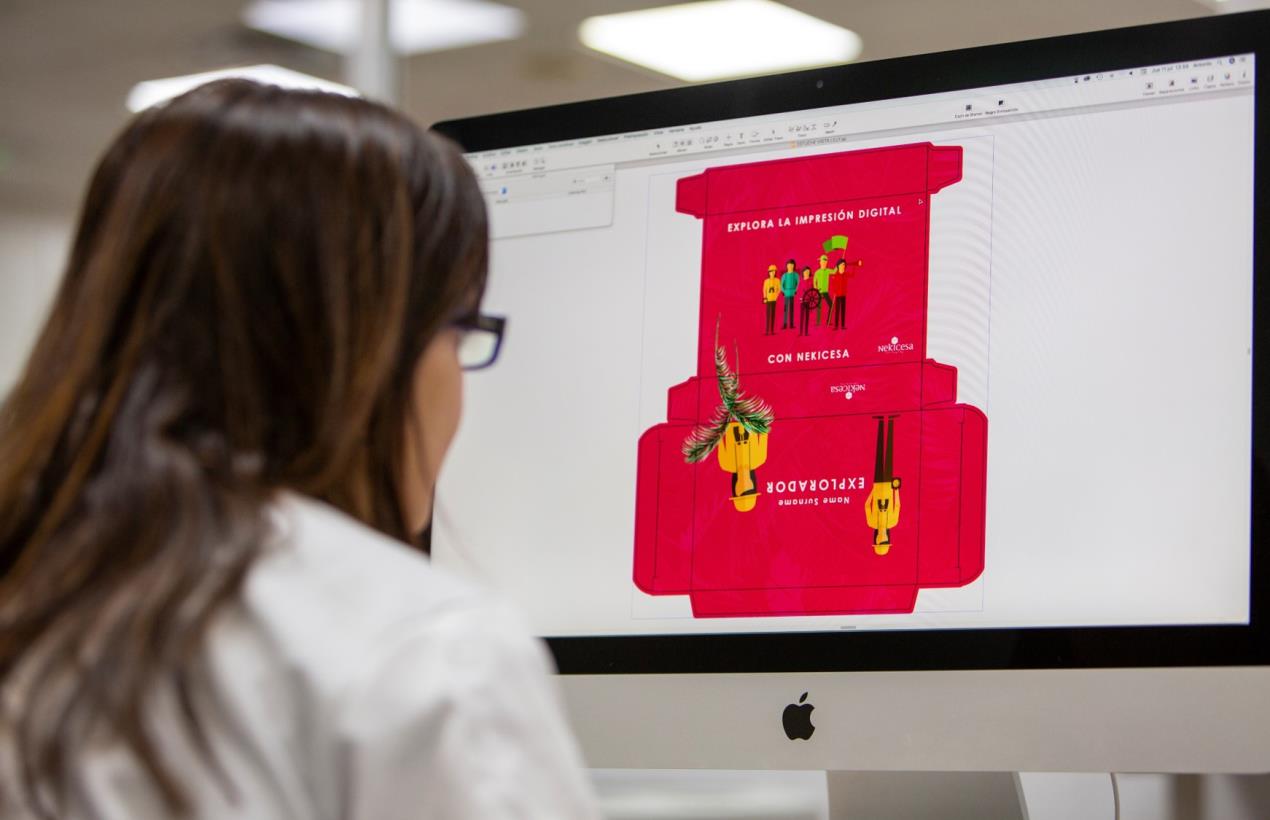

Essentra Packaging has become the first global packaging manufacturer to begin rolling out cloud deployment of the Esko Automation Engine workflow solution across its European prepress departments.

Following a successful trial at its plant in Lublin, Poland, Essentra Packaging has now begun a program to integrate Automation Engine at many of its locations throughout Europe, taking advantage of the SaaS (Software as a Service) deployment to simplify IT infrastructure while enjoying the efficiency and productivity gains delivered through the automation and digitization of processes.

“We had been looking to standardize our systems and processes in the prepress area for a long time,” said Mark King, Technical Manager (Packaging Division) with Essentra Packaging. “A SaaS deployment is essential for a business like ours because of the number of sites that we have in different locations, and the fact that each site can be using different systems. We wanted a complete solution that is scalable for our business, and Automation Engine SaaS ticks all the boxes for us.”

The high-performance workflow automation solution from Esko, Automation Engine is flexible to adapt to changing business needs, scalable and customized to optimize individual prepress workflows. “It enables businesses like Essentra to automate, standardize and improve prepress workflow with accelerated benefits across their entire organization,” said Paul Land, Product Manager with Esko. “It automates prepress tasks and integrates with business systems, which speeds up the process, and significantly reduces the error rate and need for operator intervention.

“With the next generation Automation Engine, we introduced a cloud-based deployment option,” he said. “Essentra Packaging had previously expressed a desire to move from an on-premise installation of Automation Engine to a SaaS solution that sits in a cloud-based environment, so they were invited to join our pre-release program.”

Mark King explained that Essentra Packaging has achieved some of its growth through acquisition, with the result being different systems and software levels across the business. “Our Lublin facility was selected as the pilot site as it is a multi-product manufacturer, so in terms of development we could experience the new system across both cartons and labels. Following that successful first deployment, we now have a robust plan to roll out the system across the packaging division.

“What Automation Engine SaaS enables us to do is standardize, to bring the sites into line and work to one standard process,” he said. “The workflows are stored centrally and can be accessed from all the sites within our group. This provides us with the flexibility to share knowledge and share artwork - all in a consistent format. By creating these specific workflows for specific jobs, our operators can consistently produce the same job, day in and day out, with the same outputs, even from operator to operator. That improves efficiency and ensures that every job meets all quality standards and is delivered on time.

“For example, one of the things we've seen in terms of major time savings is when looking at imposing jobs,” said Mark. “When we're using a manual process, it can take anything up to 30 minutes, but with Automation Engine SaaS that is reduced to a matter of just two to three seconds.

“Another benefit with the SaaS solution is that the software is continually updated, so we can adopt the new features more quickly,” he said. “This means that we have the agility and flexibility to adapt and change based on customer demand, with the automated workflows updated instantly based on the customer’s requirements.”

To watch a short video in which the Essentra team discuss their experience with Automation Engine SaaS, visit: https://www.esko.com/en/company/testimonials/essentra-uk-increasedagility-automationenginesaas

For more on Esko Automation Engine, visit www.esko.com/en/products/automation-engine

For more on Essentra Packaging, visit www.essentra.com/en

November 01 2021

Xeikon has announced version 2.0 of its Panther UV inkjet technology with the launch of two new label presses: the Xeikon PX3300 and Xeikon PX2200.

As the company’s wide portfolio evolves in line with advances in technology, the new presses, which are replacing the existing Xeikon PX3000 and Xeikon PX2000, feature advancement in 2 areas – applications and building blocks – to digitalize print manufacturing.

Filip Weymans, Vice President Marketing, states, “We are defining a pathway to full digitization of print production and manufacturing. Responsiveness has become key for any business and can only be achieved effectively by digitalizing all print manufacturing processes, and not just printing. The foundation for a digitalized environment lies with collecting data in a digital manner. The data volume, captured in real time, creates the information that is required by label converters to make fact-based decisions. Another aspect is the interfacing connections in production between machines and operators, helping to transfer job information between the different production processes or drawing the attention of operators when it is really required. The cloud-connectivity, machine-machine and man-machine interfaces of our UV inkjet presses will enable label printers to take operational excellence to the highest levels. They offer great potential to maximise OEE, increase sustainability and make an operation robust for any future challenge.”

The new Panther 2.0 series also offers new opportunities for label printers to expand their applications portfolio. Xeikon’s new robust substrate handles technology featuring a new splice table, web detection capability and cooled roller at the curing section. This makes it possible to print high-quality labels on a wider choice of substrates, including clear-on-clear facestock, which requires a high-quality opaque white to make the design stand out. Both presses can be configured with a fifth print station for white ink and can print on a wide range of self-adhesive media in addition to clear-on-clear, including coated paper, vinyl, PP, PE, PET, and metalized.

The Xeikon PX2200 and PX3300 presses leverage the advantages of dedicated PantherCure UV inks, which meet the demands from brand owners for high-gloss, durable labels with high scuff resistance. The Panther DuraCureTM UV technology produces high-gloss effects and stands out across the widest colour gamut while delivering exceptional long-term durability for multiple applications such as industrial, chemical and household labels, as well as high-end labels for the premium beer, spirit, beverage and health & beauty market sectors.

Driven by the powerful Xeikon X-800 digital front end (DFE), the new Panther UV inkjet presses offer superior and consistent print quality in combination with industry leading productivity. The cloud connectivity is achieved through the X-800, providing access to both machine data and job data, e.g. ink consumption, printing time etc. The latest generation of Xeikon’s X-800 enables unique applications on the Panther series, such as haptic printing. This tactile layer of white delivers the sought-after embellishing effect inline with full colour printing for designing labels with enhanced tactility and luxury feel. Also for variabilization, starting from black and white and going to colour numbering and to the most complex full colour variable data application through Xeikon’s new Vari-One option.

With the addition of 2 new presses, the Panther 2.0 series now comprises of 7 different UV inkjet press. This includes the Xeikon PX30000, available with 6 (CMYKOV) or 8 (CMYKOV+WW) print stations. It will now be accompanied by the Xeikon PX2200, 220mm wide, available with 4 or 5 print stations, and the Xeikon PX3300, 330mm, available in 4 and 5 print stations or HC-high capacity. With high-performance levels and low-energy consumption, Xeikon’s Panther series of presses are now equipped with cloud connection and next-generation HMI. This helps operators monitor the workflow to maximize productivity by avoiding downtime and bottlenecks and make changes on the fly while maintaining full colour control. It gives label printers complete quality assurance on every job. Xeikon’s new interfaces also allow presses to communicate with other equipment such as Xeikon's finishing and embellishments units.

Weymans concludes, “Xeikon’s UV inkjet presses can address any request from label converters. This can mean replacing an older UV flexo press to be more effective, being cost competitive within the high-end to medium-run label market, expanding the digital application space of existing liquid toner businesses, or providing entry-level investments that allow any printing company to embark into the digital label space. By being part of Xeikon’s broader label portfolio (press, consumables, workflow, converting, embellishing, services), converters can over time expand their investment in width and colour, or expand their workflow capabilities with ERP or MIS systems. With over 30 years of experience in digital innovation, Xeikon has a deeper understanding that enables them to offer not only the latest innovations and technologies but also a full suite of support services.”

November 01 2021

The Supervisory Board of Heidelberger Druckmaschinen AG (Heidelberg) appointed Dr. Ludwin Monz (58) as the new CEO to succeed Rainer Hundsdörfer (65). Ludwin Monz will take over from Rainer Hundsdörfer at the start of the new financial year on April 1, 2022.

"The Supervisory Board of Heidelberg would like to thank Rainer Hundsdörfer for his extraordinary commitment as CEO of the company. He has succeeded in steering the Company successfully through the COVID-19 crisis, while at the same time setting the course for the Company's further strategic development and establishing new business such as e-mobility," said Dr. Martin Sonnenschein, Chairman of the Supervisory Board.

For his part, Rainer Hundsdörfer acknowledges the trusting cooperation with the Supervisory Board as well as within the Company: "These have been very challenging years here at Heidelberg. We successfully defied the pandemic and strategically realigned Heidelberg through our successful transformation. I am proud to be part of the Heidelberg family. I wish my successor Ludwin Monz a good start to the new financial year and continued success."

Dr. Ludwin Monz is Chairman of the Management Board of MDAX-listed Carl Zeiss Meditec AG until the end of December 31, 2021. "With the appointment of Ludwin Monz, Heidelberger Druckmaschinen AG is gaining a suitable face to drive forward its strategic realignment," emphasizes Dr. Martin Sonnenschein. "He is a proven expert in high technology and innovation with capital market experience."

Dr. Monz has been a member of the Management Board of Carl Zeiss Meditec AG since 2007 and has been Chairman of the Management Board since 2010. He was also appointed to the Group Management Board of Carl Zeiss AG with effect from January 1, 2014. After studying and obtaining a doctorate in physics at the University of Mainz, Dr. Monz went on to the National Institute of Standards and Technology in Gaithersburg, USA, and the Gesellschaft für Schwerionenforschung GSI, in Darmstadt, where he worked as a scientist. He is also an MBA graduate of Henley Management College in the UK. In 1994, he joined ZEISS as a scientist. Two years later, he became head of Geodetic Systems Development, then overall head of the business unit. In 2000, he then moved to the Medical Technology division of ZEISS.

Looking ahead to his new role, Dr. Ludwin Monz comments: "For me, Heidelberger Druckmaschinen AG is a flagship of German mechanical engineering. I see enormous potential for the future in the broad expertise of its employees, its widely branched global organization, and its long-established brand."

In addition, it is planned to extend the Management Board contract with CFO Marcus A. Wassenberg until 2027 as scheduled. With this decision, Heidelberg is relying on continuity with regard to the financial stability achieved and the strategic realignment initiated by the successful transformation. "Under the direct leadership of Marcus A. Wassenberg, Heidelberg's transformation program has been successfully implemented. Measures introduced are showing measurable success. We look forward to a successful future together," said Dr. Martin Sonnenschein.

November 01 2021

Angus Scott (LIA President) and Peter Munro (LIA) attended Imagination Graphics to award Matthew Zunic with his certificate of achievement for his nomination in the 2021 awards.

The Award - sponsored by Heidelberg, recognises dedication to excellence and a commitment to ongoing learning and development.

Matthew was nominated by Terrey Nolan from TAFE, for his willingness to learn and his ability to achieve consistently high results.

Angus wanted to thank Heidelberg for their ongoing support and give thanks to Emmanuel Buhagiar, owner of Imagination Graphics, for supporting Matthew and hosting their visit, which included a tour of the facility.

Pic: L to R, Angus Scott (LIA President) , Matthew Zunic, Peter Munro (LIA)

Matthew Zunic, Emmanuel Buhagiar, Peter Munro

November 01 2021

NUtec Digital Ink is expanding its range of UV-curable inks optimised for LED lamp curing with the addition of the Ruby R20-HYB ink.

The Ruby R20-HYB ink is a general purpose, fast curing, hybrid UV-curable ink designed for rigid or roll-to-roll applications and is optimised for LED curing.

The R20-HYB formulation is designed for compatibility across a broad range of printer models using Ricoh® MH5420/5440 Gen 5; Ricoh® MH5220 Gen 5s and Kyocera® KJ4A printheads and performs well in a demanding, high speed printing environment.

Featuring a superior colour gamut for brighter, more vivid images, the Ruby R20-HYB UV-curable ink is ideal for both indoor signage and outdoor advertising and is offered in 1L bottles in CMYK and light colours.

This latest development in NUtec Digital Ink’s product offering fulfils an increasing demand for more environmentally-sensitive solutions, as LED lamp curing is considerably less energy-intensive with a smaller carbon footprint than traditional or conventional lamp curing.

November 01 2021

With PreCut Center, Zünd has launched software that facilitates cut-file preparation for applications involving unprinted materials. With PreCut Center, fully nested cut files can be prepared in a few simple steps. The software significantly reduces the workload in file preparation, generates optimal material yield, and eliminates the potential for error.

Zünd's new software solution creates a simple and highly efficient workflow for generating cut files for unprinted materials. PreCut Center simplifies file preparation and output and lets the user select a level of automation based on individual production requirements. All it takes is a few simple steps to create a fully nested file. Whether users prefer a manual or automated process, the software allows for selecting the workflow that makes the most sense for a given production scenario.

After importing the desired shapes into Zünd PreCut Center - ZPC, the user assigns them to the corresponding recipes. Recipes are basically road maps for creating cut paths based on specific parameters. The recipes can be imported or created as needed by the user. The next step entails defining materials and material parameters. The shapes are subsequently nested on the unprinted material. This process results in optimal material yield with minimal waste and reduced production time. In addition, PreCut Center - ZPC also lets the user integrate selected metadata. Information printed with each job facilitates job tracking and, once the cutting is complete, enables quick and accurate attribution of cut parts to corresponding orders.

PreCut Center is available in two versions, Basic and Pro. Users can select the version and associated features according to their needs. Zünd PreCut Centre's open architecture permits importing cut shapes and data from multiple sources. PreCut Center Pro provides fully automated nesting capabilities at the push of a button and lets users individually edit nested layouts and cut paths. In the last step, Zünd PreCut Center generates a cut file in .zcc format and makes it available for subsequent import into Zünd Cut Center - ZCC. An option also exists for outputting files in .dxf format.

October 25 2021

French software creator Caldera has announced the release of the latest iteration of its award-winning RIP program, CalderaRIP Version 15, to coincide with the company’s 30th anniversary. On October 15, Caldera users will be able to upgrade their RIP for enhanced performance, increased flexibility and a clutch of new features which will further enable them to meet the challenges of the large-format digital printing industry.

Highlights of the new version include six new features that will be available to all Version 15 users, as well as additional special inclusions for CalderaCare subscribers. Additionally, OS Support has been expanded in readiness for the release of MacOS Monterey and more than 20 new Print & Cut drivers have been added to V15 ISO. Along with the new version of CalderaRIP, the company is releasing V1.12 of CalderaDock, the toolbox which allows users to manage the licenses and installation of all their Caldera solutions. It now comes with an improved interface for attaching and switching RIP licenses and the Sync&Deploy module to allow users to install their drivers and profiles remotely.

According to Arnaud Fabre, Product Manager at Caldera, “For our 30th anniversary, we’ve demonstrated our commitment to leveraging our customers’ workflows by adding a range of new features to our RIP. I’m delighted to see that entering our fourth decade, we are still fueled by innovation, while our customers continue to benefit from our rock-solid foundation as we address new challenges together.”

The new features included in Version 15 will contribute to making it one of the most versatile RIP packages on the market. A new White Under Marks feature has been created for improved cutting accuracy on non-white media such as dark, transparent or metallic substrates, while the new Wide Contour Offset greatly improves the accuracy of the cutting process on shrinking or distorting textile substrates. Users will be able to automate their trimming workflow using the ASP (Automatic Slicer Positioning) functionality of the Fotoba XLA 170. This feature is unique to CalderaRIP and saves on manual processes while delivering maximum cutting speed, flexibility and precision.

Version 15 also includes a new Preview feature to help keep track of nested jobs in high-throughput production environments. It facilitates job inspection and verification, before and after printing, and can be used to easily identify jobs inside the nest and check marks to minimize errors and media waste. The existing TileOrder feature has been improved, and there’s a new update of the Pantone Fashion and Home Interior Spot Colors library.

Along with these enhancements to the RIP software, Version 15 comes with new features for CalderaCare subscribers, including a PrintProof feature to set up an efficient customer verification workflow and avoid unwanted waste, and a new date filter in CalderaJobs to help operators easily find any job they need to reprint or archive. SmartImport has also been improved in order to further automate job submission workflows.. All Version 15 users will further benefit from changes to CalderaDock – the new V1.12 embeds an improved interface, plus remote deployment using Sync&Deploy.

Samin Sarkar, General Manager, says, “CalderaRIP Version 15 continues our long tradition of putting our customers’ needs at the heart of what we do. Each new iteration of the RIP is designed to drive their businesses forward by providing the most advanced comprehensive digital printing software available.”

October 25 2021

The winners of the 2021 Epson International Pano awards have been announced and the overall winner of the 2021 Open Competition was Joshua Hermann from the USA with three entries, 'Eternal Triangle', 'Morning Burn' and 'Ancient Backwaters'.

Explaining how his winning entries came to pass Hermann said, “It is an honour to have my images selected in the Open Category alongside so many wonderfully talented photographers. One of the great things about photography is its ability to inform. Growing up in south Louisiana and coming to know the swamp and marshlands from an early age, the unique beauty and interesting ecology of the area has stuck with me throughout my life. I hope to share the beauty of these places through my imagery, allow people to get a closer look into the uniqueness of these areas and ultimately to inform them of the importance of protecting these wetlands. When shooting Eternal Triangle, I observed a cypress tree generally has a wide flaring base. Due to its watery habitat, it develops this triangular base and root protrusions called cypress knees to help it stand in the soft, soggy bottom. As I paddled amongst the trees on this foggy morning the triangular trunks stood out in a symmetrical fashion. To me, it looked like enumerable triangles receding into the fog. I named this picture Eternal Triangle as an ode to one of my favourite jazz compositions by the great Sonny Stitt.”

Describing Morning Burn Hermann said, “When conditions are right and cool moist air begins to warm over water in the swamp, mist begins to form over the water. If you are lucky enough for the mist to stick around when the sun breaks the horizon, a wonderful show takes place. There is a short window of time where the sun begins to set the mist ablaze with light. As I paddled, the scene constantly changed in front of me while the sun inched higher above the horizon. I stopped in front of this grove and setup my camera as the swamp put on a light show went on in front of me.”

On Ancient Backwaters Hermann added, “Like trees in most of the US, many of the old growth cypress groves were felled during the logging era. Today there are a few places were these 1,000 plus year-old giants still stand. You will usually find these in pockets of backwater that were too hard for loggers to reach, or because the trees themselves were hollow and the trunks weren't the ideal shape for lumber. When I find these ancient monoliths in backwater ponds and sloughs, I am immediately transported to the swamp lands of ancient times.”

The Epson International Pano Awards showcases the work of panoramic photographers worldwide and is the largest competition for panoramic photography.

This year the competition received 5,378 entries from 1,245 professional and amateur photographers in 97 countries - amazing stats for a competition held in the middle of a global pandemic - all of whom were competing for thousands of dollars cash and prizes with main sponsor Epson Australia alone providing prizes that included an Epson SureColor P7070 printer, an Epson SureColor P5070 printer and an Epson EB-1780W ultra-slim projector.

The overall winner of the 2021 Amateur Competition was Daniel Trippolt from Austria with his Shining Night, Legendary Peaks and Shining Heart entries.

Trippolt said, “I discovered my passion for photography when I was 12 years old when my father gave me my first camera. Every free second of my free time was used to take photos of everything and everyone. From animal photography to sports, architecture and portrait photography, I tried everything and found my greatest passion and hobby in landscape photography. Here I am very much into hyperreal landscape photography, which distinguishes me from most Austrian landscape photographers. Landscape photography has become a huge part of my life, even if I don't have as much time to invest as full-time landscape photographers. The Covid crisis in the last two years has limited my landscape photography hobby a lot, which is why I'm all the more happy about my success in this competition.”

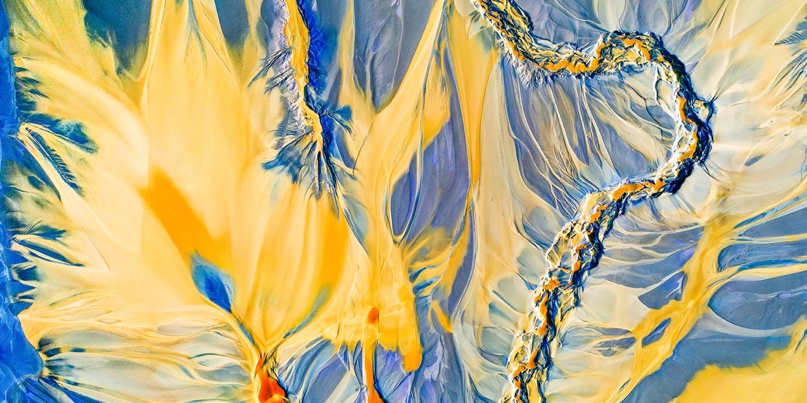

The Epson Digital Art Prize was won by Manuel Enrique González Carmona from Spain who said about his ‘Anatomy Lesson’ entry, “Minerals, water and water currents are the ingredients with which nature creates these ephemeral landscapes. With each rainy period the canvas is transformed. This canvas is actually a raft of toxic waste from a copper mine, located in the province of Huelva, Spain, which was captured by aerial shooting. These ephemeral formations will disappear with the next intense rains. I live only one hour away from this scenery, so I usually make a visit every week. There are always completely new structures and details that allow you to make countless abstractions and figurations. I often have the feeling that an abstract expressionist painter has created a large canvas and that I am capturing fragments of this work of art with my drone.”

Competition Curator, David Evans said, “We thought 2020 was a challenging year but 2021 took things to a whole new level. That said, despite the pandemic and so many other challenges the entries this year were nothing short of amazing. We are, yet again, overwhelmed with the level of support from entrants and sponsors, especially Epson and we thank you all so very much and also congratulate all this year’s winners and entrants.”

Craig Heckenberg, Managing Director, Epson Australia said, "Who would have thought the Pano Awards would again be so successful during such another challenging year. This commitment to excellence and continued success are two of the many reasons Epson has been a proud sponsor of the Pano Awards for the past 12 years we are delighted, but not surprised, at its continued popularity. The quality bar is raised every year and Epson is proud that our technology helps the photographers realise their passion and bring these amazing images to life. Epson congratulates all of the winners and entrants and as always, we stand amazed at their incredible passion and creativity.”

The judging panel for The Epson International Pano awards includes some of the world's top panoramic photographers and industry professionals.

To view all the winning and top image galleries go to: https://thepanoawards.com/2021-winners-gallery

For enquiries and more information contact David Evans at contact@thepanoawards.com

To say Epson has smashed sales of large, continuous ink tank printers into orbit is an understatement. The company having now sold over 60 million EcoTank printers* is officially the number 1 ink tank printer vendor worldwide¹ and occupies over 62% of large ink tank printer sales globally¹ – that’s 45% more than any other printer manufacturer¹. To celebrate these milestones the company has released its next generation in its EcoTank range for the Home and Home Office. Critically, none of the new models use any ink cartridges at all, replacement ink bottles that provide thousands more printed pages start at just $14.99 and all models come with the new, intuitive and clever Epson Smart Panel™ app.

An innovative interface, the Epson Smart Panel app transforms iOS® or Android™ mobile devices into an intuitive control centre for select Epson printers and scanners.

To view the Epson Smart Panel app in action click here or go to:

This powerful tool makes it incredibly easy to set up, monitor, print, scan and more using your Epson product, right from your hand-held device. With quick-configuration features, it offers easy product setup on your wireless network and automatically detects the Epson product you are using.

You can customise the Smart Panel to your own preferences and requirements as it’s been built to offer everything you need including easily accessing troubleshooting tips in one convenient app.

Very clever. Very useful. Very Smart.

So what’s so special about the new EcoTank Home printers?

The new EcoTank Home printers launch today (with the Home Office models to follow shortly) and consist of the new ET-1810, ET-2810, ET-2820 and ET-2850 models. These new models are specifically targeted and priced at entry level and budget conscious homes, are ideal for families and in particular home schooling. They also include WiFi for easy connectivity.

To say recent times have been challenging would be another great understatement. That said, one thing that’s become apparent is how home has become the “everything” place as many have adapted to hybrid work and school environments and having a reliable printer that can meet those new demands has become an absolute necessity.

From printing important presentations to endless school assignments and entertainment, families are increasingly dependent on performance printing technology to streamline workflows and stay productive.

Epson’s new EcoTank range uses innovative, heat-free, cartridge-free printing technology which delivers value and convenience for the ideal home printing experience.

The new EcoTank all-in-one printers offer cartridge-free printing with high-capacity, easily refillable ink tanks for zero ink cartridge waste. Users can save up to 90 percent² with replacement ink bottles versus traditional ink cartridges and each “low-cost” replacement ink set for the new EcoTank printers is equivalent to about 145 individual ink cartridges² – and enough ink to literally print many thousands more pages.

The new EcoTank Home printers include thousands of pages worth of ink straight out of the box³ and with every replacement ink set for fewer out of ink frustrations, all new models utilise EcoFit® ink bottles for easy, mess-free and worry-free filling.

So just how good, efficient and cost effective are they?

EcoTank ET-1810

Main function – Printing

Connectivity - Wi-Fi and Wi-Fi Direct

Print speed – 10 pages per minute black and white, 5 pages in colour

Number of printed pages out of the box – 3,600³ Black / 6,500³ Colour

RRP $299

EcoTank ET-2810

Main functions - Print, Copy and Scan

Connectivity - Wi-Fi and Wi-Fi Direct

Print speed – 10 pages per minute black and white, 5 pages in colour

Number of printed pages out of the box – 3,600³ Black / 6,500³ Colour

RRP $399

EcoTank ET-2820

Main functions - Print, Copy and Scan

Connectivity - Wi-Fi, Wi-Fi Direct and Apple AirPrint

Print speed – 10 pages per minute black and white, 5 pages in colour

Display screen – 1.44" Colour LCD

Number of printed pages out of the box – 3,600³ Black / 6,500³ Colour

RRP $479

EcoTank ET-2850

Main functions - Print, Auto 2-sided print, Copy and Scan

Connectivity - Wi-Fi, Wi-Fi Direct and Apple AirPrint

Print speed – 10.5 pages per minute black and white, 5 pages in colour

Display screen – 1.44" Colour LCD

Number of pages out of the box – 6,500³ Black / 5,200³ Colour

RRP $499

All four new Home models come with Epson’s world-class one-year warranty with a bonus second year free upon registration.

By using an EcoTank cartridge-free printer homes and families not only maximise productivity and enjoy the freedom to print in colour, but also can help reduce the amount of cartridge waste ending up in landfills.

The new printers leverage heat-free printhead technology that produces sharp text and impressive colour and graphics on virtually any paper type.

Epson’s new Smart Panel app is compatible with a wide range of Epson printers and scanners and to view the full list, go to https://support.epson.net/appinfo/smartpanel/guide/en/

The four new EcoTank for the Home printers are available now at www.epson.com.au and from all authorised Epson resellers and retailers.

For more on Epson’s new EcoTank Home printers go to: https://www.epson.com.au/products/printers_for_home/ecotank/?grouptypeid=33&GroupID=113

October 25 2021

Kornit Digital Ltd., a worldwide market leader in sustainable, on-demand, digital textile production technologies, announced today the release of its Kornit Presto MAX system for sustainable on-demand production of apparel and other textile goods.

The new system will make its live debut at Kornit Fashion Week Los Angeles + Industry 4.0 Event, which the company is hosting November 2-5 to showcase technology innovations, partnerships, and proven strategies driving the business case for sustainable, on-demand production of fashion and textile goods worldwide.

“Presto MAX will change the textile industry forever, transforming digital into the catalyst for modernizing the business, breaking the barriers between imagination and physical applications, connecting consumers and fulfillers on a global scale, and truly capitalizing on digital’s promise for delivering both sustainability and profitability, free of waste,” said Ronen Samuel, Kornit Digital Chief Executive Officer. “Whether your business is finished goods or ready-to-use custom fabrics, growing your own brand or supplying the world’s retailers and entrepreneurs, this technology represents the cutting edge of on-demand, unconstrained textile production, in terms of both capability, accessibility, and sustainability. Kornit empowers producers to create more with less, shrink their carbon footprint, and deliver unlimited expression while creating new opportunities and growth.”

Kornit launched its MAX technology in April, and is already field-proven via the Kornit Atlas MAX system, which is today supplying demanding global brands with the high retail quality and application variety needed to grow their product offerings and answer evolving consumers’ needs.

Kornit Presto MAX reflects the company’s commitment to expanding groundbreaking capabilities to all segments of the marketplace, building upon its continuously improving portfolio of technologies to accelerate and empower the industry’s transformation into a more responsive and responsible model.

Introducing never-before-seen capabilities to transform virtual concepts into brilliant custom fabrics for fashion, home décor, and other textile applications, Kornit Presto MAX is the first digital print system to offer white printing on colored fabrics, enhancing decoration capabilities for dark colored fabrics more broadly. It is the only single-step solution—and the most sustainable solution available—for direct-to-fabric printing, delivering the highest quality and softest feel with brilliant whites and brighter neon colors. The system is ready to incorporate future iterations and evolutions of XDi technology—3D decorative applications to produce threadless embroidery, high-density, vinyl, screen transfer, and other innovative effects.

Kornit Presto MAX is compatible with natural fabrics, synthetics, and blends, and includes advanced algorithms for smart autonomous calibration, to deliver high-quality results with short cycle times and minimal manual interruptions or defects. The system was devised for compatibility with the KornitX global fulfillment ecosystem to enable anywhere, anytime production, supporting a true distributed production model that fulfills nearer the end consumer, eliminating time and logistical waste from the experience while empowering brands to ensure quality and consistency across all systems and production sites.

Kornit Presto MAX provides the cornerstone of a smart, efficient, sustainable EcoFactory that empowers producers to cover and integrate more parts of the process, from design to finished product, to decrease their carbon footprint, use minimum manpower, and generate less waste. This means eliminating excessive time, labor, and shipping throughout the value chain, enabling proximity production to meet the accelerated demands of a web-driven global marketplace—revealing new sales channels and clever business models to grow the business long-term.

October 25 2021

The ink specialist provides a range of resources, including an Online Troubleshooting Guide, to ensure the best printing quality.

Modern press technology continues to push the limits of printing. With press speeds increasing and brands becoming ever-more discerning, Sun Chemical has taken strides to ensure that converters are generating the best quality print.

Sun Chemical offers an Online Troubleshooting Guide, which is a platform highlighting a range of common on-press challenges. By using this resource, Sun Chemical can direct users’ questions to the right experts for their applications. In addition, the company is using its social media channels, namely LinkedIn, to answer questions via the hashtag #SunSolve.

Sun Chemical has identified drying speeds as one of the more common challenges affecting printers today.

“One of the major issues we’re seeing is drying speed for the speed of the press, which can cause ink smearing or tracking,” explains Moe Rahmeh, technical customer service functional excellence director. “Those types of issues are non-starters because they’ll shut a press down quickly. Then we have all the variations of dirty print, which show themselves pretty regularly.

“Regardless of job design, everybody wants to run the fastest they can run,” he adds. “When we come in, the first thing we do is recognise the type of job we’re running, that way we can make sure we have the right ink in the press to start with. Today, you need a drying speed for high press speeds while keeping the ink wet on the plate and in the anilox. You need to dry it fast enough to where you don’t have any smearing or blocking. The biggest issue for us with drying speeds is making sure the chemistry is right. The chemistry of the ink is extremely important to be soluble enough to print.”

In order to successfully run presses at high speeds, there is a real marriage between the plates, the anilox and the ink, as they all work in concert with each other. For example, Sun Chemical has noticed a common drying issue as it relates to the anilox. According to Rahmeh, anilox technology and plate technologies are changing every day. So too is the surface treatment on the plates.

“If the customer is trying to get some real high densities on their anilox, and they’re pushing the anilox volumes up on the screen values, then you end up with some drying issues,” says Rahmeh. “You also then start getting dirty print. Sometimes just by looking at the anilox and the volume, we’ll know if we can get this issue fixed on-press or if we’ll have to go in a different direction.”

Sun Chemical has an extensive staff on-hand to help troubleshoot these types of issues. For Rahmeh, the company prides itself on asking as many questions as possible. The team has also been traveling extensively throughout the Covid-19 pandemic in an effort to help converters service their essential industries.

“We at Sun Chemical have taken a different approach to troubleshooting,” states Rahmeh. “The main thing for us is asking questions. We’re asking a lot of questions before we even get to the customer, so we’re prepared to address whatever situation we might come across.”

A big factor in Sun Chemical’s troubleshooting process is selecting the proper ink products for each customer. Tailoring a unique solution is key, as this is not a one-size-fits-all process.

“As an industry, we’ve always made the mistake – to make it simple for the customer – we’re just going to give you one ink that does everything,” comments Rahmeh. “My goal is to give you an ink that you just put in the press and run it. We try to address all those conditions within our formulations.

“At Sun Chemical, we can work with our own pigment group to develop these kinds of solutions,” he adds. “All of our solutions are coming from our experience in the field, and that’s really required. If we have all those things in place and we’re still having those kinds of issues, most of the time we find it’s just an imbalance in a viscosity or pH, and/or the anilox volume is too high or too low depending on the job design they’re running. We will come in and help you figure out the sweet spot.”

Sun Chemical has also been active in collaborating with press manufacturers, especially as they launch new press technology. “We are in constant contact with them as they develop new presses, especially as it relates to drying speeds and drying mechanisms, as well as how they set up the dryers. We’re looking at everything that goes into printing, we’re giving the suppliers advice as far as what’s needed for different substrates and the separation of the inks.”

Sun Chemical has developed a wide range of solutions for its NWTL (narrow web tag and label) customers. Not only are these troubleshooting resources available for seasoned veterans, they can serve a great need in helping those new to the industry get up to speed.

“We put a lot of emphasis on NWTL market,” says Rahmeh. “We’re collaborating with a lot of people, and that’s why I feel really strongly about what we’re doing for the entire industry.”

Efficient, high-quality, versatile digital inkjet solutions can be key to helping display graphics providers drive profitability and capture new growth opportunities. Electronics For Imaging, Inc. is working closely with those providers, presenting them innovative solutions that can drive their display graphics business forward faster in an economic recovery. This week, dozens of EFI™ customers, prospects and industry media and analysts are attending a series of EFI Ignition open house events that deliver a more-comprehensive view of growth opportunities display graphics providers can capture.

The events – one-day invitation-only presentations and demonstrations at the EFI Global Inkjet Innovation Center in Londonderry, New Hampshire – highlight the ways print providers can take their businesses to new heights by leveraging leading-edge production solutions.

“The pandemic has understandably forced the cancellation or postponement of several large tradeshows that would have served as launch events for these products, but that does not diminish our customers’ need for continued advancement and innovation,” said Ken Hanulec, vice president of Worldwide Marketing, EFI. “Our conversations with customers at this week’s Ignition event will give a strong representation of the market opportunities display graphics businesses have for success in a recovering market using our leading portfolio of innovative solutions.”

This week’s events highlight new product launches and a range of topic areas that address specific display graphics challenges and opportunities. New product launches and presentation topics include:

October 19 2021

The new, industrial, entry-level EFI Reggiani TERRA Silver textile printer from Electronics For Imaging, Inc. is making its debut at the Fespa Global Print Expo 2021 tradeshow, 12-15 October at RAI Amsterdam.

The EFI Reggiani TERRA Silver uses unique TERRA pigment ink for high-quality, highly sustainable direct-to-textile printing without steaming or washing.

“This is one of the first trade shows to return after the pandemic, and we are very excited to again meet customers in person and showcase an innovative offering that delivers superior printing results while using less time, water and energy,” said EFI Reggiani Vice President and General Manager Adele Genoni. “We are introducing this advanced EFI Reggiani TERRA Silver solution to the many print service providers at Fespa, presenting them with an ideal path to enter the industrial textile segment with a short, smart and green production process.”

The new-version TERRA Silver printer is part of EFI’s complete TERRA line-up of pigment ink printer solutions. It is a 180-cm wide printer that can print up to 190 sqm per hour with eight dual-channel printheads. The printer also features:

• A new recirculating ink system for superior reliability and minimum maintenance

• Several printing modes to ensure maximum flexibility in terms of design capability

• New, real-time image processing that eliminates time spent in image pre-calculations

• A user friendly, intuitive interface

• A more-efficient polymerisation process that takes place as printed textile goes through the printer’s on-board dryer.

In Fespa stand 1-G71, attendees can see the EFI Reggiani TERRA Silver print smoothly and precisely on knitted and woven fabrics. The printer’s quality is evident in its high-uniformity printing modes, and it delivers numerous features that enhance the production process, including an accurate WYSIWYG interface and flexible queue management.

EFI Reggiani is also a leading developer of textile inks. The EFI Reggiani TERRA pigment inks used on the Silver model deliver excellent wet and dry fastness properties and remarkable sharpness in detail. Designed to leverage EFI Reggiani digital printers’ market-proven industrial performance capabilities, these eco-friendly, water-based inks provide an extraordinary level of print durability and yield longer print head life with reduced maintenance costs. The high-performance digital pigment inks also use an innovative binder technology for fast, sustainable, and cost-competitive industrial textile printing on the widest range of fabrics. Users also gain superior print definition and colour intensity.

This year, EFI Reggiani celebrates 75 years of heritage and innovation in the textile world. Always committed to deliver to the market new cutting-edge technologies, EFI Reggiani has world-class products offering boosted uptime and reliability, high performance throughput, and remarkable printing uniformity and accuracy – all while helping customers increase the sustainability of their textile manufacturing activities. Green EFI Reggiani processes give users fast, complete and sustainable solutions across a broad range of textile applications.

In this 75th anniversary year, EFI Reggiani has also launched several other ground-breaking solutions, such as EFI Reggiani HYPER, the fastest scanning digital printer on the market, and the EFI Reggiani BLAZE, an industrial entry-level, easy-to-use printer designed to give new textile companies the opportunity to adopt digital inkjet production with a compact solution to blaze a successful path into the industry.

October 19 2021

After an exhaustive assessment and evaluation process, Epson has been named the Forbes JAPAN Number 1 sustainable company.

Sustainability has played a major part in Epson’s corporate approach and philosophy for some time with the company achieving and further targeting some major milestones in this area.

Notably Epson recently revised its 10-year long-term vision to include a definitive commitment to developing technology that significantly contributes to the environment and a long-term perspective that creates sustainable value.

Epson also recently embarked on a campaign with National Geographic entitled, “Turn Down the Heat” where they engaged with Professor Katey Walter Anthony, her research on the Arctic warming and the effects of melting permafrost ice on the speed of global warming. As part of the campaign Katey uses Epson’s innovative inkjet printers whose Heat-Free Technology uses up to 94% less energy1 and power than comparable laser printers.

Earlier this year Epson announced it will be joining RE100, a global initiative that brings together the world’s most influential businesses driving the transition to 100% renewable electricity.

The company also announced that its worldwide group sites will all meet their electricity needs from 100% renewable energy sources (renewable electricity) by 2023.

With growing global interest in societal issues such as the environment and energy, Epson established its Environmental Vision 2050 to express its commitment to environmental management, and subsequently rolled out various measures aimed at achieving this.

The Paris Agreement subsequently established decarbonisation targets, and Epson created a scenario to achieve by FY2025 science-based targets aimed at achieving these goals. This scenario included the use of renewable electricity as an important theme, and Epson made plans and implemented measures to expand its use over the long term.

The company has established its policy as it seeks to accelerate its plans to become a leading environmental company, and with the belief that climate change represents a serious corporate risk and that Epson must play a greater role in mitigating that risk as it rolls out its business worldwide.

Print Shop Analytics is the first cloud-based Prinect app available through Heidelberg Plus.

Heidelberger Druckmaschinen AG (Heidelberg) is taking the digitisation of its customer relationships incorporating useful value-added services to the next level. “Heidelberg Plus” is the new gateway to Heidelberg’s digital ecosystem, which customers can enter with a single login and access all of Heidelberg’s digital offerings. Future applications will make use of cloud technologies, IoT, Big Data, and AI to offer customers added value when it comes to running their companies.

As part of Innovation Week 2021, that took place from October 13 to 15 at the Wiesloch-Walldorf site under the slogan “Always a Step Ahead”, Heidelberg was showcasing Prinect Print Shop Analytics, the first cloud-based Prinect app offered through Heidelberg Plus that will become availa-ble to customers in the course of the coming year. This is a tool that enables users to determine the current performance of a print shop based on real-time data from the most important KPIs.

Monitor KPIs in real time with Print Shop Analytics and optimise production.

Many print shops still control their processes using outdated data and only have limited access to their current KPIs, which makes it difficult to quickly optimise many processes. Prinect Print Shop Analytics offers an integrated solution that records, evaluates, and monitors the KPIs of a print shop in real time to optimise production by suggesting concrete courses of action with the help of artificial intelligence. Customers can access it via Heidelberg Plus with an integrated user interface and single sign-on authentication. All generated dashboards, with the corresponding analytics and recommendations, are available to all authorised users at any location on their computer, tablet, or smartphone, as required. There is a notification system in place here that actively alerts the user to any problem areas.

“With the first Prinect app available in Heidelberg Plus, our Heidelberg digital ecosystem is gaining momentum, and the customer benefits of digitisation are becoming increasingly apparent,” says Ludwig Allgoewer, Global Head of Sales & Marketing at Heidelberg. "Market surveys have shown that our customers urgently want the functions of an app like Prinect Print Shop Analytics that they can use to quickly boost efficiency while systems are running, and also reduce costs at the same time."

Heidelberg is developing Print Shop Analytics in collaboration with customers

In order to make the app ready for the market as quickly as possible, while also offering the desired practical functions, Print Shop Analytics is being developed as part of a joint project between Heidelberg and Pinguin Druck in Berlin:

“Collaborating with Pinguin Druck is having a very positive effect on the user value of the very first cloud-based Prinect app,” says Christopher Berti, Head of Software Solutions at Heidelberg. “This approach ensures that the functions we include in the app reflect actual market demands.”

“Print Shop Analytics is becoming a game changer in our day-to-day work,” says Alexander Mende, Managing Director at Pinguin Druck. “I will now be notified immediately by Print Shop Analytics if one of our printing presses fails or the print shop misses its targets. These notifications are set according to my personal preferences and I can see the detailed data immediately. This feature and the recommended courses of action the tool suggests help me make the right decision to promptly solve a problem.”

Heidelberg Plus supports print shop management and offers customers additional value

With Heidelberg Plus, the company is combining existing digital applications with new services for customers. In the future, a single point of access is all users will need for a complete overview of all the digital tools and services in the Heidelberg portfolio. This will make it quick and easy to obtain information, purchase items (eShop), and monitor their business. Over 1,800 print shops already use Heidelberg Assistant (HDA) to access their production data. To obtain the relevant services, they need to be registered or have purchased specific services as a contract customer.

What is already impressing users more than anything is the option of using mobile devices to monitor machine operation, purchase consumables, or create service tickets. Regular HDA users range from large businesses with sites located in dozens of different countries to SMEs with just one site. “Key elements of the Heidelberg digital ecosystem such as HDA and the eShop have already developed very encouragingly,” explains Allgoewer. “By merging these and other existing applications, and also integrating new ones, we will further enhance the benefits for our customers.”

The company recently unveiled the new gateway to the HD digital ecosystem “Heidelberg Plus” to the public at the China Print trade show this past summer. The tool is now set to be showcased at the Print Media Center in Germany as part of Innovation Week 2021.

October 19 2021

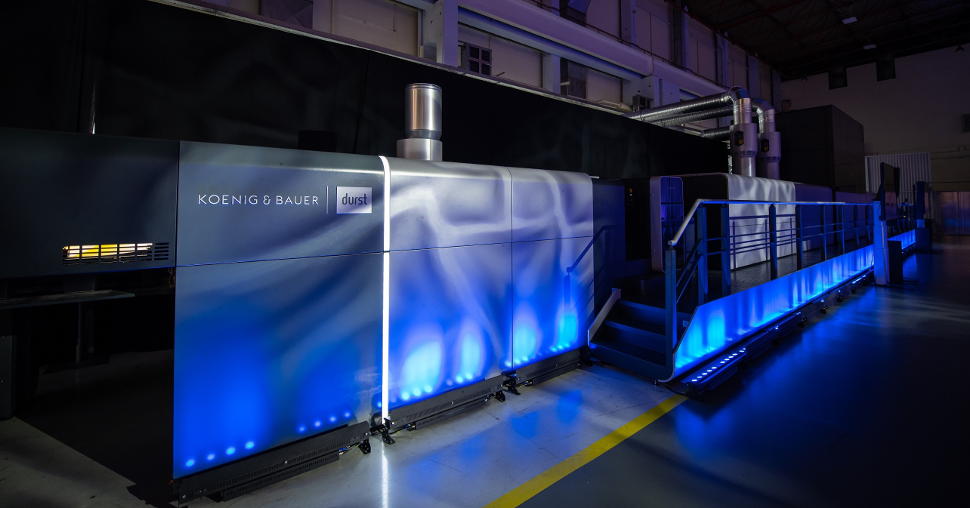

Koenig & Bauer Durst GmbH has unveiled the VariJET 106 in a world premiere with exclusive live demonstrations for customers and stakeholders in Radebeul, near Dresden, Germany, where the modular single pass sheetfed digital printing press for the folding carton market has been jointly developed by Koenig & Bauer and Durst.

Using market-proven industrial expertise from Durst and Koenig & Bauer, beta testing is due to start in the coming weeks. The first units of the VariJET 106 are due to be installed at customer sites in Europe and America in the second half of 2022. Target groups include pharmaceuticals, cosmetics, tobacco and food industries, as well as folding carton converters.

At the launch, which included presentations in the Customer Experience Center, senior executives unveiled further insights into Koenig & Bauer’s packaging strategy. Updates were provided on how the digitalisation of business processes for new products and services is progressing.

The B1 5500sph press combines the best of both worlds – digital inkjet and classic offset printing. The VariJET 106 is based on water-based inkjet processes to provide the highest print quality. The innovative digital printing system is at the heart of the collaborative development between Koenig & Bauer and Durst. The VariJET 106 platform is based on Koenig & Bauer’s standard high performance Rapida 106 platform and Durst printhead electronics, inkjet expertise and Durst workflow and RIP technology. This includes Durst Analytics, Smartshop and Workflow.

Using 7 color water-based food compliant inkjet technology (CMYK plus orange, green and violet), the VariJET 106 is suitable for food applications that meet the stringent requirements for food safe primary packaging utilising proprietary water-based ink technology. The VariJET 106 can produce personalised and individualised print products or alternate between short and medium runs.

The VariJET 106 offers:

• Modular integration of upstream and downstream processes

• Combination of digital print with proven modules of the Rapida platform

• Perfect register accuracy thanks to inline production

• Highly competitive TCO, efficient production of ultra-short to medium runs

• Reduced resource consumption, storage costs and waste

• Absolute flexibility for test packaging and new campaigns

• Fastest possible response to market demands

Koenig & Bauer and Durst first announced they had joined forces and set up an independent joint venture company in 2019. The VariJET 106 is the first product jointly and developed by the two companies. Already in production and part of the Koenig & Bauer Durst portfolio are the Delta SPC 130 Series and the CorruJET 170 Series – aimed at corrugated packaging.

The VariJET 106, Delta SPC 130 and CorruJET 170 are designed with core technologies to provide automated, productive, food safe printing systems. They deliver shorter response times, more variants, shorter run lengths, individualisation and enable more and more small value orders. They also answer the increasing customer demand for brand security, sustainability and the ability to meet brand owners’ requirements for multichannel communication including e-commerce.

Robert Stabler, Managing Director, Koenig & Bauer Durst, said: “This world premiere marks a proud moment – and what a journey it has been! We are really excited by the progress we have made and the opportunities with our VariJET 106 despite these testing times. We have beta sites at an advanced stage of planning. These potential customers already have a vision for mass customisation will be working with us in partnership Feedback from our customers is that shorter run lengths, mass customisation and the need to be more agile are the compelling reasons for moving to digital production.

“Successful companies need to be able to embrace the trends that are occurring and offer solutions. Brand owners continually want their products to stand out, require shorter lead times, while at the same time eliminate waste and conform to sustainability and track-and-trace requirements. Brand owners are also looking to ensure the new production methods are reliable, compliant and cost effective while converters need to have the capabilities and competencies to mass customise without any compromise on quality. We deliver on this.”

October 19 2021

Electronics For Imaging, Inc. has unveiled its newest digital front end (DFE) and workflow solutions for display graphics and industrial printing, EFI Fiery XF/Fiery proServer version 7.3 and EFI Fiery Prep-it workflow software.

Print shops managing numerous wide- and superwide-format inkjet printers and cutters want a single DFE and automated workflow software that can simplify and integrate their operation, reduce operator training, and achieve consistent high-quality colour output. Fiery XF 7.3 with Prep-It addresses these challenges by adding the technology that highly productive organisations need.

Hundreds of new supported printers

Print shops with mixed-manufacturer printers can achieve greater production efficiencies with less operator training by having one RIP technology. Fiery XF 7.3 software and the EFI Fiery proServer digital front end (DFE) now have added support for more than 180 new printer drivers from Agfa, Canon, d.gen, Durst, HP, Mimaki, Mutoh, Roland DG, and Teckwin among others, bringing the total number of Fiery-supported printer models to more than 1,200. Customers can also now request a driver for an additional 400+ printers to complete support for their shop’s installed printer base.

More efficient and flexible ways to print and cut

Customers are no longer tied to one cutting workflow when they own multiple different types of equipment with the new capability to mix and match cutting equipment with print and cut printers. Fiery XF 7.3 increases productivity through QR code support for cutting solutions from Zünd, Esko Kongsberg, iCut, EuroSystems OptiScout v8, and MATIC cutters.

Faster, more-powerful colour management

This release also includes a new printing mode that can reduce the processing time of jobs that include spot colours by up to 50%. Users can choose between presets that select the highest accuracy (e.g., for proofing applications with certain spot colour settings) or highest speed as their priority when processing jobs.

Print businesses with wide-gamut printers can make the most of their printer’s color capability with a new Clean Colors mode that delivers more-intense, vibrant prints. The newly supported PrintWide2020 ICC profile produces greater colour saturation and contrast for higher-impact prints while, at the same time, maintain G7 tonality, a neutral gray balance and realistic skin tones.

Automated cutting workflows and cut path control with Fiery Prep-it

The new EFI Fiery Prep-it software launching in November can dramatically improve cutting preparation and production in wide- and superwide-format printing. Prep-it delivers industry-leading true-shape nesting saving more media versus competitive solutions due to its superior image placement. Automated workflows, double-sided nesting control, sophisticated cut path editing and more significantly accelerate print to cut production. The exclusive Fiery XF integration with Fiery Prep-it to enable the support of more than 1,300 cutters for the Fiery Prep-it and Fiery XF combination.

Offerings tuned to the unique needs of proofing vs production markets

Fiery XF 7.3 now offers two versions that are more specifically tuned to the needs of proofing and production customers. The two different product configurations give customers in each segment exactly what they need, including the Fiery Color Profiler Option, at the right price – with room to grow when their businesses and needs change.

“The advanced, highly automated Fiery XF, proServer and Prep-it solutions we are launching make end-to-end production more efficient and more profitable for customers,” said John Henze, vice president, sales and marketing, EFI Fiery. “These new innovations reflect our ongoing goal to help wide- and superwide-format print customers deliver the very best possible prints as quickly as possible.”

The latest Fiery XF software release is now available for all users with a current EFI Software Maintenance & Support Agreement or an EFI Enhanced Service Program. Users can purchase Fiery Prep-it software from EFI, or from authorised EFI Fiery resellers.