See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

October 19 2021

Direct To Film (DTF) printing has been around for longer than you might think, although it’s only very recently that it’s started to gather more traction and pique the interest of garment producers both in the UK & Ireland as well as further afield.

For a long time, Direct To Garment (DTG) has been the ‘go to’ solution for those looking to print onto a wide variety of garment types and colours, but now there’s a viable alternative. Utilising white ink technology, without the need for pre-treatment, DTF offers users the capability to print onto almost any fabric type or colour with ease. Furthermore, the durable ink technology means that there’s no cracking, even on stretch materials, with high wash and rub resistance. All of that in an affordable package with ultra-low running costs.

At R A Smart (CAD & Machinery) our reputation as suppliers of premium quality textile printing solutions is supported by our selection of industry leading equipment. We take our product selection very seriously and only partner with the best manufacturers that produce high-quality machines and our DTF solution is no different.

Following extensive in-house testing we’ve partnered with a pioneering producer of the entire DTF package, with patented ink and application technology developed over the past 4 years. We’re excited to bring this revolutionary solution into the market as the exclusive distributor for the UK & Ireland. Our demo unit is fully up & running at our Cheshire based facility for customers to visit, produce samples and see this amazing technology firsthand.

Unlock the Potential of Ricoh CMYK+ PrintingWith the constant barrage of information we receive in our ever increasing multichannel world, creating impact ...

October 19 2021

Unlock the Potential of Ricoh CMYK+ Printing

With the constant barrage of information we receive in our ever increasing multichannel world, creating impact and cut-through with communication is more important than ever. Print not only provides a familiar and tactile medium to promote and inform, but increasing digital print capabilities allows Print Service Providers to offer their customers more, and in turn grow revenue and profit.

During our live technology showcase we'll introduce the new sparkling additions of Gold and Silver to the Ricoh 5th Colour portfolio, discuss and showcase potential applications and guide you through the ease of use and benefits of CMYK+ print enhancements.

Learn how to expand your services and increase profit through new Ricoh 5th colour capabilities.

Join our webinar, Thursday 21st October at 11am AEST to learn more.

https://comms.ricoh.com.au/2021-10-21-CMYK-Printing-Webinar-Registration.html

October 12 2021

Kodak today announced a revolutionary new digital press and innovative additions to its comprehensive portfolio of digital and offset solutions designed to help printers boost their profitability and capitalise on new opportunities for growth.

Kodak today announced a revolutionary new digital press and innovative additions to its comprehensive portfolio of digital and offset solutions designed to help printers boost their profitability and capitalise on new opportunities for growth.

The revolutionary KODAK ASCEND Digital Press takes high-end Packaging and Retail Signage to new heights

The new KODAK ASCEND Digital Press is the perfect solution for commercial printers and digital service providers who want to succeed in the growing Retail/POP and Packaging markets. The KODAK ASCEND Digital Press is the first electrophotographic (EP) press designed to print heavy weight substrates at long lengths with eye-catching, high-margin CMYK and flat foil embellishments in one pass. It is more flexible than traditional presses and more productive than flatbed inkjet systems, offering production speeds up to 572 sqm/hour (5280 sqft/hour). Its large sheet length of up to 122 cm (48 inches) allows the press to offer 23% more print area than a B2 sheet. The new press enables printers to deliver sustainably recyclable print by using environmentally friendly KODACHROME Dry Inks, which are Indirect Food Contact rated. Kodak’s new press is a more cost-effective solution for producing Retail/POP and Packaging applications than traditional presses or flatbed inkjet devices.

The ASCEND Digital Press will be available Q2 2022 in North America and Europe.

KODAK PRINERGY On Demand Access puts cloud-based workflow within reach of small to mid-size commercial printers

With PRINERGY On Demand Access, Kodak is introducing a cost-effective expansion of its cloud-based PRINERGY On Demand Platform. This new option makes the printing industry’s most secure and highest performing software platform affordable for more printers of any size, with or without digital presses.

The new SaaS solution provides full connectivity to digital presses, Microsoft Azure-backed security and the scalability the PRINERGY On Demand Platform is known for. PRINERGY On Demand Access includes preflight, colour management, file management, backup and routing as well as built-in KODAK INSITE Prepress Portal functionality for file submission, remote customer collaboration and online approvals. Available in Q1 2022.

New KODAK PROSPER Digital Varnish for highly flexible digital coating of paper-based packaging

The new KODAK PROSPER Digital Varnish is a unique, water-based varnish that can be jetted as an area or spot coat to printed packages using KODAK PROSPER S-Series or KODAK PROSPER Plus Imprinting Systems. The eco-friendly PROSPER Digital Varnish can be applied in perfect register with design elements and creates a matte protective layer providing rub and water resistance to paper-based packaging applications.

As PROSPER Digital Varnish is applied only where needed and doesn’t require plate making for spot coating, it helps printers eliminate the costs, effort, waste and environmental impact associated with traditional post-coating methods. The new varnish provides an environmentally friendly, water-based alternative to solvents and UV coatings.

The KODAK PROSPER Digital Varnish will be available worldwide by the end of 2021.

Enhanced KODAK Mobile CTP Control App offering more management and reporting capabilities

The KODAK Mobile CTP Control App is an app that allows remote control and monitoring of up to 10 KODAK CTP Platesetters, reducing a dependency on onsite labor for managing jobs in queue, status updates, and more. The enhanced version of this one-of-a-kind app provides access to real-time and historical data with customisable reporting to save time on data analysis, help prioritise actions, and improve plate-making efficiency. The new version of KODAK Mobile CTP Control App is now available worldwide to download for Android and iOS mobile operating system.

Executive quote:

“The innovations announced today reflect Kodak’s continued commitment to developing breakthrough solutions that enable our customers to improve their productivity and profitability and successfully expand their customer base,” said Jim Continenza, Kodak’s Executive Chairman and Chief Executive Officer. “With innovations like the KODAK ASCEND Digital Press, we are opening up new profitable application opportunities for printers. We continue to deliver on our promise to provide a complete range of solutions that offer Print that Pays.”

For additional information on Kodak, visit us at Kodak.com and engage with us on Twitter @KodakPrint and on LinkedIn at Kodak Print

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, today announced the BN-20A, a new, lower-cost addition to its VersaSTUDIO series of desktop inkjet printer cutters.

October 12 2021

swissQprint is launching a new series of models this October. The core of the new flatbed printers is cutting-edge print head technology along with advanced mechanical features that promise a quantum leap for users – especially when it comes to output quality.

swissQprint large format printers are renowned for their top quality – in terms of design as well as printing results. The Swiss manufacturer has redefined its standards and is now launching its flatbed generation 4.

Enhanced quality, increased productivity

New print heads are the centrepiece of the new generation. Maximum resolution of 1350 dpi and ultra-high-precision droplet placement significantly boost the print quality of the Impala and Nyala models. Both printers also benefit from an impressive increase in output for certain production print modes. The Oryx model is almost 40 percent faster than its predecessor, making it a truly outstanding entry-level printer.

Improved comfort and efficiency

swissQprint has incorporated various mechanical improvements into generation 4, singling out the Tip Switch Vacuum (patent pending) as a highlight. The table is divided into as many as 256 segments that users can quickly and easily switch on or off at the touch of a finger. This eliminates tedious and time-consuming masking – also in the gap between boards and dual rolls. Because there is no air leakage, the vacuum develops its full force and reliably holds down hard-to-handle media.

Modular configuration

The new range offers a host of options for individual configuration. Users can have their printer assembled exactly in line with what they require today. If their needs or requirements change, they can add a diverse range of options to the printer at any time.

The new flatbed generation from swissQprint is available for delivery via the company's worldwide distribution network as of now. Demonstrations can be arranged either face-to-face or via live streaming. swissQprint also offers a sampling service.

Further information:

swissQprint AG

Schützenwiese 8

CH-9451 Kriessern

T +41 71 727 05 05

F +41 71 727 05 06

office@swissqprint.com

October 12 2021

Xante’ is pleased to announce the introduction of its new Heavy White UV Ink for its X series of UV printers.

Current and future Xante’ X16/X33 users will be able to enjoy the new heavy pigment-loaded white ink for greater coverage, printing fewer layers and increasing production speed. For existing customers this change in white ink will be seamless and new customers will be able to take advantage of the increased production speeds.

Mark R. Priede, Vice President of Sales and Marketing, stated "Our customers are demanding greater production and flexibility. We are continuing to design new functionality for our current customers; the Heavy White ink will allow the customer to have greater coverage in a single pass. This will make them more efficient and increase overall productivity. We are always working hard to provide this for our current and future customers."

Xante’s Heavy White UV Ink is currently shipping and available. From a pricing standpoint, there will be no increase of price for this new ink technology. For more information on Xante’s Heavy White Ink or the X16/X33 please call 251-473-6502 or visit our website at www.xante.com.

Corel extends its CorelDRAW 2021 professional product family with new subscriber-exclusive updates for CorelDRAW Graphics Suite 2021 and unveils CorelDRAW Technical Suite 2021, the newest editio...

October 05 2021

Corel extends its CorelDRAW 2021 professional product family with new subscriber-exclusive updates for CorelDRAW Graphics Suite 2021 and unveils CorelDRAW Technical Suite 2021, the newest edition of its comprehensive software collection for high-impact technical design and documentation.

Whether they choose CorelDRAW Graphics Suite or CorelDRAW Technical Suite, subscribers can now enjoy a more flexible way to stay up to date with productivity-boosting dynamic asset management and collaboration workflow enhancements, additional fonts, creative templates and more to maximise their creative potential.

“Whether you’re at the office, at home or working remotely, the CorelDRAW 2021 product family includes robust suites that enable graphics pros to work how, when and where they want,” said John Falsetto, Senior Director of Products, Graphics and Productivity. “With new features, helpful content and support for the latest technologies, these new subscription-exclusive updates offer creative and technical graphics professionals maximum value and deliver on our commitment to provide everything they need for success.”

Available for CorelDRAW Graphics Suite and CorelDRAW Technical Suite, these new subscriber-exclusive updates include:

Expanding beyond graphic design, CorelDRAW Technical Suite 2021 builds on the strengths of CorelDRAW to offer a full collection of powerful tools specifically for the creation of professional technical illustrations and visual documentation.

CorelDRAW Technical Suite 2021 offers exceptional control and precision for flawless technical documentation and design. From manufacturing and engineering to architecture and high tech, CorelDRAW Technical Suite 2021 is the ultimate hub for designing detailed technical illustrations, documentation, marketing and more with total control and incredible efficiency.

“Thanks to new timesaving tools and simplified workflows, CorelDRAW Technical Suite 2021 gives technical graphics pros everything they need to create exceptional designs,” said Klaus Vossen, Senior Product Manager, CorelDRAW. “Open everything from 2D and 3D source files to photos, documents and data. Produce, collaborate on and publish technical communications all with one comprehensive suite. Illustrators can boost their productivity and create intricate graphics or virtually any kind of technical visuals with total precision and control.”

CorelDRAW Technical Suite 2021 goes beyond the new subscriber-exclusive updates to also include the following new capabilities:

Main Applications in CorelDRAW Technical Suite 2021:

Extend the power of CorelDRAW Technical Suite 2021 with XVL Studio 3D CAD Corel Edition

Transform complex 3D CAD parts and assemblies into comprehensible visualisations with the XVL Studio 3D CAD Corel Edition add-on. Available as a separate purchase for CorelDRAW Technical Suite, this powerful 3D authoring software is packed with productivity and performance enhancements, as well as added file format support. Save time with a more efficient process for updating 3D-sourced illustrations in Corel DESIGNER, and experience more control over automated updates, thanks to enriched Auto Detection and Update functionality.

Availability and pricing

CorelDRAW Graphics Suite 2021 is available on Windows 10 and Windows 11, macOS, web, iPad and mobile in English, German, Italian, French, Spanish, Brazilian Portuguese, Dutch, Polish, Czech, Russian, Simplified Chinese, Traditional Chinese, Turkish, Swedish and Japanese. Subscription is $249 USD / €349 / £299 per year. A perpetual license with included 1-year maintenance is available at the suggested retail price of $599 USD / €933 / £778. EUR and GBP prices include VAT.

CorelDRAW Technical Suite 2021 is available on Windows 10 and Windows 11 as an individual license in English, German, French and Japanese. Corporate licenses are also available in Spanish, Italian, Brazilian Portuguese, Czech, Polish, Russian, Dutch, Turkish, Simplified Chinese and Traditional Chinese. (All licenses include XVL Studio Corel Edition in a choice of English, German, French or Japanese.) Subscription licenses are priced at $499 USD / £469 / €499 a year. Suggested retail price (SRP) for a full version perpetual license with included 1-year maintenance is $1,199 USD / £1,129 / €1,199. Perpetual license upgrading pricing with maintenance is also available. GBP and Euro prices include VAT.

Access to the newly included Google Fonts library integration, dynamic asset management features and collaboration workflow enhancements are exclusively available with a CorelDRAW Technical Suite subscription, a CorelDRAW Graphics Suite subscription or licensing with maintenance.

EFI™ ProGraphics™ XA high-adhesion ink – a versatile UV LED display graphics inkjet ink from

October 05 2021

EFI™ ProGraphics™ XA high-adhesion ink – a versatile UV LED display graphics inkjet ink from Electronics For Imaging, Inc.suitable for a wide range of rigid and flexible media – is now available for EFI Wide Format flatbed and hybrid roll/flatbed printers. ProGraphics XA ink delivers superior results on corrugated plastics and other substrates with adhesion challenges.

EFI customer Kurt Kahmnke, owner of Fenton, Missouri-based Payler Signs & Graphics, has gained greater adhesion and durability on rigid substrate prints he produces on his company’s new EFI Pro 30h hybrid wide-format printer. The ink gives Payler Signs superior results compared to the UV inks the company uses on a flatbed inkjet printer.

“We’ve tested prints produced with the ProGraphics XA ink in our EFI Pro 30h printer in a variety of modes on Coroplast®, acrylic, aluminum composites and other challenging materials by spraying them with water, leaving them outside in the heat, and stacking them ink side to ink side,” said Kahmnke. “We are very pleased with the ink’s adhesion, quality, and performance and are confident that we made the right choice.”

The ProGraphics XA ink does not chip during cutting when used on standard acrylic, corrugated plastic or other fluted polypropylene media. Plus, ProGraphics XA ink is flexible enough for 180-degree heat forming applications. Bringing this advanced ink to the EFI Pro 24f, Pro 30f, Pro 16h and Pro 30h wide-format printers gives sign and display graphics operations more capabilities in the range of applications they offer to customers.

“We are pleased to bring this exceptional high-adhesion ink to our Wide Format printer owners,” said Ken Hanulec, EFI’s vice president of worldwide marketing. “We continually strive to increase the value of EFI investments, and now customers will have the benefit of ProGraphics XA ink’s versatility, durability and flexibility to extend the range of substrates and surfaces they can print on.”

When purchasing an EFI Wide Format printer, customers can choose the ProGraphics Series UV LED ink set that best meets their application needs. Other ProGraphics inks include:

MUTOH America, Inc., an industry leader in wide-format printers, has been honoured for the 10th year in a row by the PRINTING United Alliance for product excellence and quality. ...

October 05 2021

MUTOH America, Inc., an industry leader in wide-format printers, has been honoured for the 10th year in a row by the PRINTING United Alliance for product excellence and quality.

For 2021, MUTOH has won five Pinnacle Product Awards, which recognizes products that improve or advance the printing industry with exceptional contributions in quality, capability, and productivity. Entries are evaluated by a highly qualified panel of judges from across the printing industry in more than 58 categories including analogue, digital, output, and non-output technologies.

These honours were formerly known as ‘Product of the Year’ awards.

The five 2021 output categories won by Mutoh are:

[* US $]

Mutoh Australia’s Managing Director Russell Cavenagh commented: “Its great to be part of a company that’s so focussed on quality and reliability. 10 years in a row is no fluke and testimony to the quality and productivity of Mutoh printers”.

Cavenagh's counterpart across the Pacific, Brian Phipps, President and General Manager of Mutoh America commented: “We are very honoured to win the Printing United Pinnacle Award again for five of our best-in-class printers made in Japan. Competing against the biggest names in the industry and being able to demonstrate MUTOH’s commitment to excellence and quality is very rewarding.”

To learn more about all of Mutoh’s award winners and other products visit www.mutoh-au.com

Durst Group, manufacturer of advanced digital printing and production technologies, will present a wide range of end-to-end solutions for digital printing applications at FESPA 2021 in Amsterdam...

September 28 2021

Durst Group, manufacturer of advanced digital printing and production technologies, will present a wide range of end-to-end solutions for digital printing applications at FESPA 2021 in Amsterdam, October 12-15, under its slogan "From Pixel to Output".

"After such a long time, we are pleased to present our solutions to an international audience and to communicate the benefits of our 'From Pixel to Output' approach to the large format printing market" says Christoph Gamper, CEO and co-owner of Durst Group.

In recent years, Durst Group has built its own ecosystem, ranging from large-format printers with software and hardware to e-commerce portals and finishing modules, offering customers end-to-end solutions including training, support and maintenance.

"Our modular software suite helps our customers to optimize their processes and ultimately increase their competitiveness," adds Christoph Gamper. "The market is responding very positively to this approach, which is also reflected in the installation numbers in the large format segment."

With the P5 - PRODUCTION EXCELLENCE, Durst Group already launched a solid technology platform in 2018 that scores with its outstanding versatility and efficiency. In the meantime, more than 100 systems of the P5 350 series alone have been installed worldwide in a wide variety of application areas. P5 350 is a hybrid solution for both roll-to-roll and flatbed printing and covers a substrate width of 3.5 meters.

In addition, the Durst Automat feeder and stacker system can be used to equip the entire P5 product line – which includes the P5 210/HS, P5 350/HS and P5 250 WT - for full- or three-quarter automated production. Durst Automat achieves high productivity in the automated production cycle and supports the hybrid features of the P5 series with the ability to quickly change materials between roll- and flatbed printing.

The operator is actively supported in the operation by various features. Access to two rolls via the Multi-roll option makes material changes much easier in practice. In addition, the Dualroll option allows printing on two rolls with a maximum width of 1.6 meters. Moreover, when processing rigid materials, up to six boards can be printed in parallel. Light barriers at the in-feed and out-feed as well as an all-round protection system ensure the necessary production safety for personnel and machine. The high-speed version P5 350 HS with a maximum printing speed of 700 m2/h, which is more than double compared to the standard model, in combination with Durst Automat and the corrugated option, is the ideal solution for entry-level digital corrugated printing for the packaging and display sector.

The soft signage market has been recording constant growth rates for years, and in all aspects. With the introduction of the innovative P5 TEX iSUB, the Durst Group is once again setting the technology standard. At its heart is an integrated inline fixation system for direct printing on polyester fabrics, which enables a single-stage printing process and leads to greater efficiency and a significant increase in productivity. With the P5 TEX iSUB, transfer papers can also be printed and further processed. The combination of both printing methods in one system ensures flexibility in production.

The P5 Sublifix sublimation ink delivers vibrant colours, sharp images even on difficult media such as blackback or backlit for light boxes or flags. In addition to the CMYK inks, light versions of cyan, magenta and black are available to expand the color gamut. Another interesting feature of the Durst P5 TEX iSUB is the integrated finishing unit, which can be used to directly sew and stitch media. Both the P5 350/HS and the P5 TEX iSUB will be unveiled to the broad public for the first time at FESPA 2021 in Amsterdam.

In 2020, Durst added to its portfolio by acquiring a majority stake in Vanguard Digital Printing Systems. FESPA 2021 marks the first joint appearance of the two companies. The new VR6D flatbed printer will make its debut in Amsterdam and covers the mid-range performance spectrum. It features an attractive price/performance ratio and can be configured for different applications thanks to its modular design. Vanguard's solutions are meeting with a high level of acceptance among customers, particularly in North America.

"We are pleased to also be able to demonstrate the potential of the solutions to European visitors at FESPA and are convinced that Vanguard will successfully establish itself in the European market," emphasises Christoph Gamper.

Esko has launched its latest plate making solution, the CDI Crystal 4260 XPS, delivering more automation, enhanced quality, increased simplicity and improved reliability to the plate room.

September 28 2021

Esko has launched its latest plate making solution, the CDI Crystal 4260 XPS, delivering more automation, enhanced quality, increased simplicity and improved reliability to the plate room.

The CDI Crystal 4260 XPS can be operated with just one hour of training, with single touch operation using an intuitive screen interface and enables unattended operation. The award-winning Esko XPS Crystal technology optimally combines UV main and back exposure, using LEDs that always emit consistent UV light as opposed to traditional exposure frames, which use lightbulbs with fluctuating output.

“Today’s prepress departments face a number of challenges that make the desire to offer the combination of quality, speed and competitive pricing a key driver of investment and organisational decisions,” said Pascal Thomas, Director of Flexo Business at Esko. “The impact of Covid-19 has only compounded the demands on the packaging prepress and printing sector – be that increasing production complexity, shorter run lengths or a need for fast turnaround to meet their brand customers’ need for speed to market.

“Maintaining prepress quality and efficiency in the face of such complexity is challenging, when also needing to manage product and service quality and minimise costs to remain competitive. The answer lies in digitising, automating and connecting the prepress and plate making process to drive down costs, increase quality and speed, and eliminate waste and errors in resources, time and materials. To that end, we are introducing the newest member of the Esko CDI family, the CDI Crystal 4260 XPS.”

The combination of the CDI Crystal flexo imager with the XPS Crystal exposing unit offers a perfect, consolidated flexo plate making workflow with the highest return on investment. “Redefined from scratch, the integration and automation of the digital imaging and LED UV exposure processes improves consistency and overall ease of use for prepress operators,” said Pascal. “This solution not only frees up valuable time but also reduces maintenance and the footprint of the flexo equipment, keeping costs to a minimum.”

The CDI Crystal 4260 XPS excels in efficiency, reducing manual steps by 50% and reducing errors by 50% to create less plate waste, alongside reducing operator time by as much as 73%.

Further driving productivity in the plate room, Esko introduced the PlateHandler, a robotic device connecting the CDI Crystal imager with the XPS Crystal exposure unit. “A prepress operator is usually required to manage multiple devices to produce a plate, which demands considerable time and attention to what is going on, and often incurs a risk of error,” explained Pascal. “Integrating the Esko PlateHandler into the system reduces the number of operator touchpoints, freeing up to 50% of their time and enabling them to attend other more value-adding tasks such as quality control, plate storage and plate mounting,” he said.

“Similarly, the new Esko PlateFeeder-S has been designed to solve a number of common issues. For example, it enables distortion-free transportation of plates, avoiding damage when they are transferred manually from storage to the CDI,” said Pascal. “The table can also be tilted to pass through doors and docked onto the CDI to ensure perfect plate positioning and digital connection to the CDI Crystal. Its cover sheet can also be removed to provide free access from all sides without static charge input.”

Integrating the PlateFeeder-S into the setup also prevents idling between plates due to the operator attending to other tasks, boosting productivity further by enabling an additional plate to be positioned for automated transportation into the CDI Crystal immediately when available. “The operator only needs to attend the machine once within each imaging cycle, to load a new plate and unload the exposed plate from the XPS Crystal,” said Pascal.

“What’s more, manual positioning is prone to errors and can be time intensive. But with the PlateFeeder-S, once docked, it becomes visible on the CDI touchscreen and integrates into the automated workflow enabling the operator to position a new plate at any time during the 15-minute imaging process,” he said. “Built-in sensors also secure accurate plate loading via the PlateHandler, avoiding plate waste and further errors. The PlateFeeder-S eliminates 100% of the plate loading idle time on the CDI Crystal XPS resulting in uninterrupted plate making, reducing system idling by up to 40% and delivering a 40% reduction in human touch points.

“With a CDI Crystal 4260 XPS with PlateHandler and PlateFeeder-S working continuously with optimum throughput and minimum operator attention, there is complete platemaking automation. The overall impact can be an increase in plate making productivity of up to 15%.”

For more on these and all the latest Esko innovations, visit www.esko.com

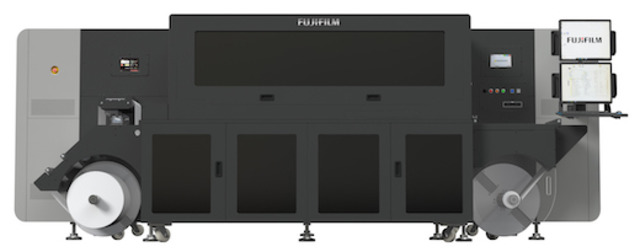

The LP350, planned for release in early 2022, is designed to meet the growing demand within the prime label market for short-runs, high quality and variable content. FUJIFILM North America announc...

September 28 2021

The LP350, planned for release in early 2022, is designed to meet the growing demand within the prime label market for short-runs, high quality and variable content. FUJIFILM North America announced its plan to showcase and preview the new FUJIFILM Digital UV Inkjet Label Press LP350 (hereafter LP350) at the Label Congress 2021 event being held at the Donald E. Stephens Convention Center in Rosemont, Illinois, on September 29th and 30th. The LP350, planned for release in early 2022, is designed to meet the growing demand within the prime label market for short-runs, high quality and variable content. By combining newly introduced UV inks with a powerful inkjet print engine, this new press offers the optimum combination of productivity and quality available on the market for a digital label press. With the North American label market experiencing unprecedented digital growth, the LP350 is positioned to help enterprising converters take advantage of these market opportunities. By using CMYK as well as orange and violet inks, the LP350 is capable of hitting 94% of the Pantone colour gamut, necessary for the prime label printing market. In addition, double white inkjet channels enable high levels of opacity for a wide variety of label applications. With the ability to print at a resolution of 600 x 600 dots per inch (dpi) with a 4-level grayscale and interstation UV pinning, the LP350 boasts exceptional print quality. The LP350 also offers excellent productivity, with the capability to print at 164 feet per minute, regardless of the number of colours or media types required for the print job. The press will be available in both 13” and 9” widths to adapt to customer needs. Additionally, the set up time and process for changing media types is simple, quick, and happens in minutes, further maximising user efficiency. Showcasing its versatility, the LP350 features newly introduced UV inks that have various resistant properties including surface durability, light fastness, and water and chemical resistance specific for label applications. The inks also offer excellent print reproducibility, density, and vibrancy, and can be used with a variety of commonly used label substrates, such as clear supported and unsupported films, foils, metalised materials, and coated/uncoated papers. Other key features include corona media treatment, built-in static elimination equipment, media cleaning, full variable print ability, chill roller for shrink applications, and end-of-press UV curing system. The LP350 also implements FUJIFILM ColorPathTM Sync, a suite of state-of-the-art cloud-based colour management tools which align output devices to designated colour targets. ColorPath Sync incorporates optimised colour correction and a simple, step-by-step interface to achieve industry-leading results in creating and maintaining colour output device alignments. From a digital front end perspective, Fujifilm has collaborated with a premier digital front end and software leader in order to provide a comprehensive, and efficient production solution in order to meet the high market demands of the label market. Today, FUJIFILM North America Corporation, Graphic Systems Division, supplies the printing industry with analog product solutions such as narrow web Fujifilm Uvijet inks, Flenex flexo plates and Illumina® LED curing systems to label converters. With the introduction of this new digital press, FUJIFILM Graphic Systems Division is able to offer the widest range of portfolio solutions, from analog to digital. Matt Bennett, global vice president business strategy for packaging at FUJIFILM North America Corporation, Graphic Systems Division, adds, “The addition of this new digital label press to our digital packaging press portfolio marks an exciting step forward for Fujifilm, demonstrating Fujifilm’s commitment to ‘Never Stop Believing in Print’. The LP350, along with the recently announced J Press FP790 for flexible packaging, underlines Fujifilm’s wealth of inkjet expertise combined with years of experience in providing high quality inks and plates for the flexographic market.” For more information about FUJIFILM North America Corporation’s Graphic Systems Division, please visit https://www.fujifilm.com/us/en/about/region/affiliates/graphic-systems.

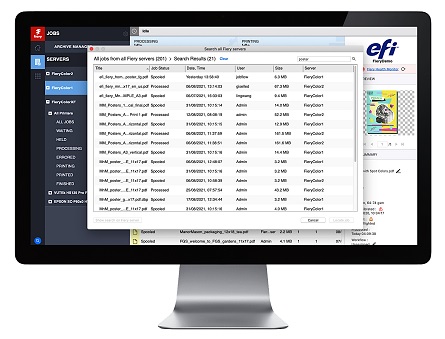

Electronics For Imaging, Inc., launched the latest update to EFI™ Fiery® Command WorkStation®, version 6.7, which helps Fiery customers improve automation and job management to better handle growing numbers of short-run print jobs. Fiery Command WorkStation enables a unified Fiery Driven™ print room, allowing users to control all Fiery servers, either local or remote, thereby gaining operational efficiencies and increasing productivity.

A long-time user of EFI™ Fiery® digital front end solutions, sedruck KG in Leipzig, Germany found that the new features in the latest EFI Fiery Command WorkStation — available as a free upgrade — helped the company better manage print jobs and improve their turnaround times on a growing volume of short-run, quick-turn print jobs.

‘Getting us back into full production faster’

“The fact that we can now search for jobs across all of our 10 Fiery digital front ends is amazing, it saves us up to 80% on time and energy per search to find what we are looking for. Having two methods to pinpoint a job or jobs is also extremely valuable, plus, the interface has been kept super-simple,” said Manfred Gebauer, head of Purchasing & Technology Process Management at sedruck KG. “This new function also provides supervisors insights into a job’s journey. Multiple hits across queues and servers can indicate production challenges that are difficult to identify in other ways, allowing us to investigate and fix issues more readily, getting us back in to full production faster. Thank you, Fiery Team.”

Many print businesses face the same kind of production pressures. According to data from industry research company Keypoint Intelligence, nearly a third of European print service providers and 55% of North American print service providers reported that dealing with a high number of small jobs is a primary challenge for their current workflow. As the number of orders increase, print service providers in many parts of the world are also facing labor shortages, a factor that makes automation more necessary than ever.

Find it, prepare it and print it better with version 6.7

The new version 6.7 of Fiery Command WorkStation – the management software that comes with all Fiery digital front ends (DFEs) for cut-sheet and wide- to superwide- format printers – addresses the most pressing job volume and labor needs of print service providers by speeding up the administration and production of print jobs with several new enhancements. Automated job tagging using print presets now helps customers classify, find, and manage jobs faster. And, a new search tool gives users the power to search for jobs across all their connected Fiery DFE servers. Both features save valuable time when managing a large volume of jobs in fast-moving print shops.

Command WorkStation – working in tandem with connected Fiery Workflow Suite software – also makes other important print job preparation tasks simpler and faster for print service providers. In the new release, for example, the Workflow Suite’s Fiery ImageViewer solution has new controls for reordering, duplicating, or deleting pages, eliminating the need to step out of the tool for simple page-level edits.

Print businesses can save even more timing by using Fiery Hot Folders with Command WorkStation 6.7 to automate server presets, imposition templates and more. And, for variable-data jobs, users also have the ability to significantly streamline job submission tasks using another integrated solution, Fiery FreeForm™ Create – a free, award-winning product for designers and Command WorkStation users.

“Getting many short-run, high-quality jobs done as fast as possible is in the Fiery DNA, and we have always been focused on the challenges of high-volume, short-run work,” said John Henze, vice president of sales and marketing, EFI Fiery. “Our customers choose Fiery because it excels in this area, and this newest Command WorkStation release gives customers even more of what they want.”

For more information about EFI Fiery Command WorkStation and other advanced print solutions from EFI, visit www.efi.com.

September 28 2021

Sun Chemical has launched its Streamline TVL 2 ink series to support the sign, display and graphics market for use with Roland’s SG2 and VG2 range of eco-solvent inkjet printers.

The Streamline TVL 2 ink series is a fully color-matched CMYK, Lc, Lm and Lk ink series supplied in 500ml pouches which are fully mixable with Roland TR2 ink series, enabling a simple and fast transition to Streamline TVL 2 inks.

Formulated with Sun Chemical’s low odor chemistry, the Streamline TVL 2 ink series is Greenguard Gold certified for low indoor emissions. In addition, Streamline TVL 2 inks are GBL free, ensuring full regulatory compliance for sales in all regions across the world.

The Streamline TVL 2 ink series provides added value for both print shops and customers by enabling same-day print and print finishing. The Streamline TVL 2 ink series allows print shops to print and laminate jobs within six hours, thus enabling customer express order requests.

Streamline TVL 2 also improves print-shop productivity, simplifying the production workflow by eliminating the need to store interim prints before they are ready for finishing.

“After thorough trials with customers across Europe and the United States, covering a wide range of substrate (media), we are excited to launch the Streamline TVL 2 ink series, which has been met with universally positive feedback for its print performance and quality,” said James Gould, Product Manager of Streamline Inks, Sun Chemical.

Bianca Willson from Multi-Color Corporation in Adelaide has been named South Australia’s LIA Heidelberg Australia Graduate of the Year at a presentation held at Fujifilm Business Innovation l...

September 21 2021

Bianca Willson from Multi-Color Corporation in Adelaide has been named South Australia’s LIA Heidelberg Australia Graduate of the Year at a presentation held at Fujifilm Business Innovation last Friday 17 September.

The prestigious biennial award is made by the Lithographic Institute of Australia (LIA) and is supported by Heidelberg Australia and Visual Connections. Nominations are received from employers for apprentices training for a wide variety of industry careers.

Bianca, who was judged the winner after an extensive interview and evaluation process conducted by a panel of industry experts, recently completed her print apprenticeship.

The other finalists for South Australia were Adam Brown from VisualCom, Nick Birbas from Multi-Color Corporation, and Fletcher Masters from Hanson Print & Design.

The graduates, their colleagues and families, enjoyed drinks and canapés at the the event, which was attended by about 30 guests – comparatively low for such events due to COVID gathering restrictions, but nevertheless a welcome opportunity to celebrate excellence, reported Gordon Wilson from the LIA SA committee.

Fletcher Masters, Nick Birbas, Adam Brown, Bianca Willson with 2019 biennial winner & LIA committee member, Jono Pitt.

“It was very pleasing to be able to recognise the achievements of these great young people, who will doubtless become some of the industry’s next generation of leaders,” Wilson said. “We sincerely congratulate Bianca on the win, and commend her fellow finalists, too, on their outstanding performance.

“The LIA has a long history of supporting education and training across our sector, and we are delighted to see the continuing high standard of graduates and, with the help of our sponsors Heidelberg Australia and Visual Connections, to be able to provide a tangible reward for their efforts as they seek to further their education and industry experience.”

To find out more about the LIA and the Graduate Awards, go to www.lia.com.au

Kornit’s first-ever impact report codifies brand vision of transforming the fashion industry with uncompromising eco-friendly production on demand: “These KPIs reflect Kornit’s co...

September 21 2021

Kornit’s first-ever impact report codifies brand vision of transforming the fashion industry with uncompromising eco-friendly production on demand: “These KPIs reflect Kornit’s core values, embedded into every aspect of our business,” says CEO Ronen Samuel.

Kornit Digital Ltd., a worldwide market leader in digital textile production technologies, today released its 2020 Impact and Environmental, Social, and Governance (“ESG”) Report. This inaugural report affirms Kornit’s commitment to achieving specific ESG goals. This includes the way Kornit conducts business, creates meaningful impact in local communities, and achieves environmental sustainability, in addition to how Kornit will continue to build a diverse and inclusive company culture, foster employee growth and development, and empower fair and safe labor practices globally.

“Our vision is to boldly transform the world of fashion and textiles for a better, more sustainable planet,” said Ronen Samuel, Kornit Digital’s Chief Executive Officer. “This report serves as our roadmap to achieving this vision.”

Mr. Samuel continued, “The fashion industry is unfortunately responsible for severe ecological damage, producing nearly 20% of global wastewater each year and over-producing an average of 30% as an integral part of its ‘normal’ course of doing business. We are laser-focused on changing that trajectory. Sustainability is top of mind at Kornit, in our spirit and in practice, every single day.”

In addition to enabling eco-friendly production processes with technology and consumables that use less water, reduce waste, and minimize the carbon footprint, Kornit technology solutions enable sustainable production on demand, which eliminates overproduction of apparel and other textile goods. A 2021 Life Cycle Assessment conducted on two flagship products, the Kornit Atlas MAX and Kornit Presto S, demonstrated that relative to traditional analog processes, Kornit’s digital production systems used up to 95% less water and 94% less energy, and produced up to 83% less greenhouse gas (GHG) emissions for the Presto S system and up to 93% less water and 66% less energy, and produced up to 82% less greenhouse gas (GHG) emissions for the Atlas MAX system.

Based on this study, in addition to past sustainability performance results and strategic projections for business growth and market expansion, by 2026 Kornit Digital’s sustainable on-demand solutions are expected to enable the production of approximately 2.5 billion apparel items in a responsible manner to deliver:

Beaver Paper Group, a leading manufacturer of sublimation media, is proving their commitment to producing sustainable products with the launch of their new TexStyles NatureSeries family of graphic ...

September 21 2021

Beaver Paper Group, a leading manufacturer of sublimation media, is proving their commitment to producing sustainable products with the launch of their new TexStyles NatureSeries family of graphic fabrics. NatureSeries is a revolutionary line of sublimation fabric made with cutting-edge sustainable CiCLO technology. In ideal conditions, fabrics made with CiClO will biodegrade at the end of their lifecycle within three to five years as opposed to 60 years for traditional synthetics in the same conditions, including recyclables.

Currently, over 44 million pounds of synthetic textiles end up in U. S. landfills each day! Since synthetic textiles are extremely popular, Beaver Paper’s fabric manager, Jeff Mills, spent almost two years researching and developing the NatureSeries Soft Knit fabric to help mitigate the negative effects of synthetic textiles and raise the bar on sustainability within the industry. Beaver Paper’s new Soft Knit with CiClO will help reduce textile accumulation in landfills.

Since it is the most widely used fabric for exhibits and retail signage, Mr. Mills focused on creating a truly sustainable soft knit fabric including attention to the products end-of-lifecycle. The new NatureSeries Soft Knit fabric will be a major rival to the many soft knit recyclable fabrics currently on the market.

“My goals in creating NatureSeries Soft Knit were to take the most popular fabric used in the industry and make it truly sustainable, and to challenge the industry to think about sustainable standards for end-of-life products that end up in our landfills,” said Jeff Mills, TexStyles Product Manager.

NatureSeries vs. Recyclable Fabric

Recycled fabric, while a step in the right direction, still ends up in a landfill at the end of its lifecycle and can remain there, in ideal conditions, for up to 60 years. On the other hand, as NatureSeries graphic fabrics hit the landfills, its CiCLO® additive technology goes to work, in ideal conditions, breaking down the fabric so that it is close to 95% degraded within 3-5 years.

“It’s exciting to be launching our NatureSeries line that highlights our commitment to producing high-level sustainable products,” said Tobias Sternbeck, CEO of Beaver Paper. “I believe our new NatureSeries fabric goes beyond anything in the industry today, in reducing synthetic textile pollution.”

How It Works

CiCLO is a sustainable textiles ingredient in the form of an additive that is combined with polyester during melt extrusion at the beginning of the fibre making process. CiCLO additive creates millions of biodegradable spots in the matrix of the plastic where microbes that naturally exist in certain environments, such as landfills, can break down synthetic materials like they do with natural fibres. Third party lab studies, using recognised ASTM Test Methods, show greatly accelerated rates of biodegradation compared to traditional synthetics in landfills, sea water, and wastewater plants.

NatureSeries Soft Knit, made with CiCLO fibres, looks and feels like traditional synthetics with the same high performance and durable characteristics but behaves more like natural fibres if they end up in the environment. The new Soft Knit fabric has been tested to ensure traits such as tenacity, pilling resistance and printability are unchanged. It is also proven to be safe for use in sustainable textile applications by a third-party OEKO-TEX ECO PASSPORT certification and meets industry requirements for safety and health.

NatureSeries graphic fabric is durable and produces the most vivid colour reproductions. NatureSeries possesses all the characteristics of high-quality polyester graphic fabrics with one exception, when it is discarded, it will not stay piled in the world’s landfills for up to 60 years.

beaverpaper.com

Kornit’s first-ever impact report codifies brand vision of transforming the fashion industry with uncompromising eco-friendly production on demand: “These KPIs reflect Kornit’s co...

September 21 2021

Kornit’s first-ever impact report codifies brand vision of transforming the fashion industry with uncompromising eco-friendly production on demand: “These KPIs reflect Kornit’s core values, embedded into every aspect of our business,” says CEO Ronen Samuel.

Kornit Digital Ltd., a worldwide market leader in digital textile production technologies, today released its 2020 Impact and Environmental, Social, and Governance (“ESG”) Report. This inaugural report affirms Kornit’s commitment to achieving specific ESG goals. This includes the way Kornit conducts business, creates meaningful impact in local communities, and achieves environmental sustainability, in addition to how Kornit will continue to build a diverse and inclusive company culture, foster employee growth and development, and empower fair and safe labor practices globally.

“Our vision is to boldly transform the world of fashion and textiles for a better, more sustainable planet,” said Ronen Samuel, Kornit Digital’s Chief Executive Officer. “This report serves as our roadmap to achieving this vision.”

Mr. Samuel continued, “The fashion industry is unfortunately responsible for severe ecological damage, producing nearly 20% of global wastewater each year and over-producing an average of 30% as an integral part of its ‘normal’ course of doing business. We are laser-focused on changing that trajectory. Sustainability is top of mind at Kornit, in our spirit and in practice, every single day.”

In addition to enabling eco-friendly production processes with technology and consumables that use less water, reduce waste, and minimize the carbon footprint, Kornit technology solutions enable sustainable production on demand, which eliminates overproduction of apparel and other textile goods. A 2021 Life Cycle Assessment conducted on two flagship products, the Kornit Atlas MAX and Kornit Presto S, demonstrated that relative to traditional analog processes, Kornit’s digital production systems used up to 95% less water and 94% less energy, and produced up to 83% less greenhouse gas (GHG) emissions for the Presto S system and up to 93% less water and 66% less energy, and produced up to 82% less greenhouse gas (GHG) emissions for the Atlas MAX system.

Based on this study, in addition to past sustainability performance results and strategic projections for business growth and market expansion, by 2026 Kornit Digital’s sustainable on-demand solutions are expected to enable the production of approximately 2.5 billion apparel items in a responsible manner to deliver:

HP Inc. has introduced a range of DesignJet and PageWide XL Pro devices to equip large format print users with the technology to navigate and thrive in the new normal. The portfolios a...

September 21 2021

HP Inc. has introduced a range of DesignJet and PageWide XL Pro devices to equip large format print users with the technology to navigate and thrive in the new normal.

The portfolios also deliver advanced photo and colour quality, enhanced precision, and new graphics application potential - all while driving improvements in sustainability.

With the two new HP DesignJet Z Pro devices, HP is offering print service providers (PSPs) and Geographic Information System (GIS) analysts the latest solutions to produce professional photo-quality prints and high precision colourful GIS-generated maps. Meanwhile, the three new HP PageWide XL Pro printers equip PSPs and reprohouses with the ability to respond faster to customer demands and diversify their existing capabilities.

“As our customers continue to grapple with uncertain business conditions following a uniquely challenging past couple of years, we know that expanding their print application reach, an ability to move fast, and outstanding colour and graphics performance define their large format printing needs”, said Daniel Martinez, General Manager, Large Format Business, HP. “This is why we’re introducing the new HP DesignJet Z Pro and HP PageWide XL Pro series. Both portfolios are designed to help users navigate uncertain demand, respond to tighter deadlines and unlock untapped potential in their own offerings.”

Highest colour quality with HP DesignJet

Marking the 30-year anniversary of the very first DesignJet product, the new HP DesignJet Z6 Pro and Z9+ Pro offer PSPs and GIS analysts respectively the highest professional photo quality and precision, along with leading security features.

Thanks to the chromatic RGB HP Vivid Photo Inks, HP DesignJet Z Pro users can now achieve 93% pantone coverage – 26% more gamut compared to the previous generation – and produce prints with the image quality of a 12-ink printer with just nine inks. Additional features such as the High-Definition Nozzle Architecture (HDNA) printheads and dual drop technology, which reduces visible grain and eliminates the need for light coloured inks, promise prints with clear details and dazzling-contrasts.

The HP DesignJet Z9+ Pro, which offers the widest colour gamut in its category, is the perfect choice for PSPs looking for a professional photo quality printer. Users can customise ICC profiles for their print jobs and achieve desired colour accuracy and consistency. PSPs also have the option to include the HP Gloss Enhancer Upgrade Kit to produce superior gloss uniformity.

Additionally, the HP PrintOS mobile app lets PSPs take more control of their print operations – from monitoring performance and reacting to issues, to sharing media pre-sets remotely. For the first time, the new HP DesignJet Z Pro printer series also incorporates the HP PrintOS Service Center application. This smart cloud-based solution enables users to gain a single, real-time view of all ongoing service cases, with updates that are accessible anytime, anywhere.

For GIS analysts looking to produce very precise maps, print sharp contour lines and text with close attention to keeping data secure, the new HP DesignJet Z6 Pro is the ideal printer. The Adobe PDF Print Engine enables excellent transparencies and layer reproductions - while HP’s HDNA printheads and HP Pixel Control deliver the highest precision, as well as smooth gradients and distinct shades of colour that are particularly needed for printing complex maps.

HP DesignJet Z6 Pro is the world's most secure large-format printer, promising the best data protection through encrypted communications and Access Control List. Features such as HP Connection Inspector, HP Secure Boot, and Whitelisting ensure the best network protection, putting all worries about data security to rest.

Both the HP DesignJet Z6 Pro and Z9+ Pro also enhance efficiency with the fastest media handling, spindle-less and automatic roll feed. The HP DesignJet Z6 Pro prints twice as fast on plain paper at the same quality while the HP DesignJet Z9+ Pro allows users to print up to 18% faster, with better quality, on satin photo media - and 46% faster on canvas.

Maximise productivity with HP PageWide XL Pro

HP has also announced three new HP PageWide XL Pro printers that enable retail PSPs and reprohouses to respond faster to customer demands, meeting tighter deadlines. Additionally, users will also be able to leverage new short-term applications including the potential to print on boards, cardstock, and paper from A2 to B1, and thickness up to 10mm.

The new HP PageWide XL Pro 5200 and HP PageWide XL Pro 8200 offer print speeds up to 20 D/A1 pages/min, and 4300 ft2/hr (400 m2/hr) and 30 D/A1 pages/min, and 5300 ft2/hr (500 m2/hr) respectively, enabling users to meet short turnaround time. With the PageWide XL Pro 8200 able to print mixed outputs of both CAD drawings and presentation boards, both printers are also capable of delivering full projects two to three times faster than before. With the new HP PageWide XL Pro 5200 and HP PageWide XL Pro 8200, users can also expand their print applications into two-sided, short-term retail posters, which can be easily managed with HP SmartStream.

Designed to help boost profits and cut costs, both the HP PageWide XL Pro 5200 and the HP PageWide XL Pro 8200 enable users to save up to 50% preparation and finishing costs. Using up to three-litre Original HP Eco-Carton ink cartridges, both printers ensure low running costs for CAD drawings and posters. Features such as the versatile stacker, inline folders and auto switch free up operation time, giving reprohouses the power to say yes to more print jobs.

The compact HP PageWide XL Pro 10000 boosts productivity with fast printing speeds of up to 700 m2 (7500 ft2) or 1,000 B1 posters per hour, and can print on different sizes materials, including paper and boards to cardstock and cutsheets. It also provides PSPs with the capability to deliver quick results with instant-dry prints on compatible substrates. With HP PrintOS, PSPs can easily control the operations of their fleet anywhere, anytime – while also enjoying simplified maintenance and fast start-up. The HP PageWide XL Pro 10000 also features the first HP large-format auto sheet feeder and versatile stacker, providing seamless end-to-end cut-sheet workflow.

HP – a partner in sustainability

The new HP DesignJet portfolio and HP PageWide XL Pro 10000 printer are all rated as ENERGY STAR 3.0 compliant and EPEAT registered, meaning they use less energy and are certified as environmentally preferred products.

The new HP DesignJet Z Pro printers are made of 30% recycled plastic, using over eight 16.9-oz (0.5-L) bottles worth of ocean-bound plastic, and are fully compatible with large format FSC-certified papers, a range of recyclable HP media and free, convenient take-back program for certain HP media.

Both new portfolios are fully compatible with HP Eco Carton Cartridges, achieving up to 80% reduction in plastic. The outer carton of Eco-Carton cartridges can be disposed of through local cardboard recycling

Inks for the HP PageWide XL Pro 10000 printer are UL ECOLOGO Certified and verified for Nordic Swan Ecolabel printing companies.

HP PageWide XL and DesignJet prints are recyclable, returnable, or non-hazardous and safe for disposal.

The new HP PageWide XL Pro series is expected to be available in all major markets starting September 15th, and the new HP DesignJet Z6 Pro and Z9+ Pro on October 1st, 2021. Pricing information available locally.

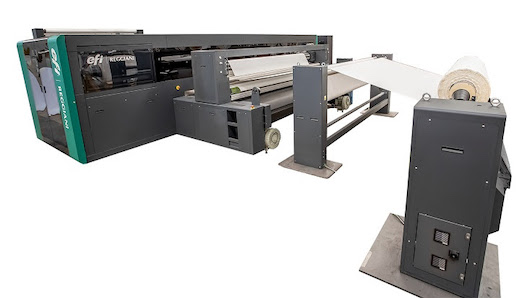

New HYPER model produces extraordinary printing quality at unparalleled speed, approaching single-pass throughput. Electronics For Imaging, Inc. is launching its third new digital text...

September 14 2021

New HYPER model produces extraordinary printing quality at unparalleled speed, approaching single-pass throughput.

Electronics For Imaging, Inc. is launching its third new digital textile printer of 2021, delivering the world’s highest real production throughput for a scanning digital textile printer. The EFI™ Reggiani HYPER is a scanning printer available in 1.8-metre, 2.4-metre or 3.4-metre widths. With an up to eight-colour configuration, the EFI Reggiani HYPER prints at up to 13 linear metres per minute in two-pass production mode, making it the fastest textile scanning printer on the market. The new printer is suitable for high-quality production on knitted or woven fabrics and is designed with smart technology that enables it to be integrated into Industry 4.0 projects.

EFI is promoting the new EFI Reggiani HYPER printer in an exhibit at the 8-11 September TME Exhibition Textile Machinery Fair, at the Istanbul Expo Center, in hall 1, stand D7.

“Our track record of accelerated innovation continues, as we make good on our promises to deliver a third new textile printer this year,” said EFI Reggiani Senior Vice President and General Manager Adele Genoni. “And, with the new HYPER model, our R&D team has outdone itself, bringing even more innovation to digital textile printing despite the constraints of the pandemic. We have learned from our customers how productivity and sustainability are key drivers to support their business through the digital transformation.”

The new EFI Reggiani HYPER targets the industrial high-speed segment of the multi-pass textile printing sector. Not only is it the fastest multi-pass printer that EFI Reggiani has ever developed, but the fastest of its kind in the market, offering extraordinary printing quality with unmatched productivity.

The HYPER’s superfast carriage with 72 printheads can print two passes with production quality at speeds up to 13 metres per minute for a 1.5-metre-wide roll, or up to 10 metres per minute for a 3-metre-wide roll. On a 3.4-metre Reggiani HYPER printer, users can print a pair of 1.5-metre-wide rolls in parallel, delivering a total throughput of up to 20 metres per minute, which is comparable to some single-pass printers currently in the market.

The printer is powered by EFI Reggiani genuine inks, with high-quality formulas developed to ensure the best performance in terms of runnability and longer printhead life while producing astonishing colour depth and brightness, as well as excellent fastness properties.

Unique printhead design for advanced productivity

“We are especially excited about filling out our portfolio with a very dependable, very fast printer that delivers greater throughput than other scanning printers,” said Genoni. “Thanks to a unique design for its 72 printheads – which recirculates ink up to the heads’ nozzle plate – and the legacy EFI Reggiani continuous ink recirculation system, HYPER is also a champion for uptime and reliability, maximising printer availability for production with excellent printing results.

“With HYPER, textile producers will benefit from a truly remarkable production solution that builds on EFI Reggiani’s many years of experience and innovation in textile printing.”

The EFI Reggiani HYPER printer features:

72 recirculating print heads with 600-dots per inch (dpi) native resolution and full variable drop size;

Recirculation up to the nozzle plate and an innovative printhead maintenance system featuring contactless wiping to help ensure that printheads are ready to print;

Enhanced, proprietary auto-calibrating continuous ink recirculation system to reduce maintenance at start up and during production;

A double bridge that provides maximum stability and accuracy, while ensuring easy carriage access for smooth maintenance on all the printheads;

A wide range of printing modes, including EFI Reggiani’s legacy high uniformity printing modes, to ensure outstanding quality and extreme design versatility. Users gain much more capability and versatility, eliminating the limits faced with printing solid colours, geometric patterns, fine lines, deep blacks, smooth gradients and more, while satisfying their need for speed;

EFI Reggiani proprietary electronics and software with real-time image processing and no image pre-calculation time prior to printing. This enables production of design changes on the fly with a complete WYSIWYG (what you see is what you get) experience to maximise throughput and productivity;

A precision Kevlar® conveyor belt with an embedded magnetic device for adhesive application, along with EFI Reggiani’s original longitudinal belt movement control to ensure optimal and accurate belt movement, even when running at high speed;

Longitudinal belt movement control for extreme belt precision during high-speed printing;

Several fabric feed and take-up options, including an oscillating brace for folding, a small roll winder up to 400 mm, or a big roll winder up to 1,600 mm;

An industrial dryer with symmetrical ventilation and high-efficiency exhaust capacity powered by gas, electricity, oil or steam;

The new printer is commercially available worldwide as of this month.

For more information about EFI Reggiani and other products and solutions from EFI, visit www.efi.com.