See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Alfex Laser will run live demonstrations of a number of its industry leading laser systems for cutting, marking and engraving at PacPrint 2021, providing a variety of solutions for signage and disp...

July 06 2021

Alfex Laser will run live demonstrations of a number of its industry leading laser systems for cutting, marking and engraving at PacPrint 2021, providing a variety of solutions for signage and display, branding, name plating, graphics, tracking & traceability applications and business.

Today, the company confirmed its largest display to date will include the KERN LaserCELL and EcoFlex systems, EPILOG Fusion PRO and Fusion EDGE series, Lotus High Speed Laser Marking Systems, BOFA Filtered Extraction Systems and Vision Engraving & Routing Systems’ 1642R CNC engraver/router.

The Alfex stand is sure to be a drawcard for visitors to the PacPrint and Visual Impact expos, with many business owners now recognising the value and versatility of adding an Alfex Laser solution to improve production efficiencies and expand their capabilities and in turn increase profitability.

“By integrating a laser into your workflow, you can offer products from dimensional letters, to image cut outs, engraved ADA, point-of-purchase displays, 3D models and more, using a wide range of materials ranging from acrylic and plastics, to wood and even metal,” Christian Buhagiar, Business Development Manager, explains.

Leading the PacPrint showcase will be two new models of the EPILOG Fusion Pro series – the Fusion Pro 24 and 36 – which expands the choice of work area sizes in this high-performance range to four, ranging from 610 x 610mm up to 1219 x 914mm.

“The Fusion Pro Series from EPILOG Laser has unquestionably paved the way for the future of the laser engraving and cutting industry, with never-before-seen technologies including live camera positioning right on your computer screen and the fastest engraving speeds on the market today just to name a few.” Christian says, “so businesses can easily create or re-create custom artwork for their clients.”

“The EPILOG Software Suite makes for fast, easy set-up and allows operators to provide unique names for each job process if they wish, while the EPILOG’s IRISTM camera positioning system saves production and design set-up time and ensures precision results every time, by providing the operator with a ‘live feed' of the artwork position from inside the system,” he says.

Also featured will be the new Fusion EDGE 12, 24 & 36 laser systems also featuring live IRIS™ camera positioning technology and 5G acceleration. The addition of these new models further expands the company’s portfolio to include mid-range options ranging in size from 610 x 305mm up to 914 x 610mm.

“The feature-packed EDGE series is fast and easy to set up using programs like Illustrator, CorelDRAW and AutoCAD,” Christian explains. “It also features IRIS™ CAMERA POSITIONING Technology, plus a 7” touch-screen display panel, SAFEGUARD™ protection package upgrade and job trace functionality to improve workflow and production times.”

For those requiring a more industrial solution for heavy applications such as cutting acrylic and plastics up to 25mm thick, Alfex Laser will demonstrate the high-performance, US-designed and manufactured KERN EcoFlex laser system. Available in two sizes – 1270 x 1320mm and 2540 x 1320mm – and laser power options up to 250 watts, high-speed motors and KCAM Laser Software providing users with a competitive edge over other laser system options.

“Alongside the EcoFlex, we’ll also be demonstrating the high-performance, flagship KERN LaserCELL laser cutting and engraving system, which answers the demand for systems that blend safety and performance, with the ability to cut 25mm acrylic with a flame polished edge as well as stainless steel, aluminium and most other metallics” Christian says.

“The LaserCELL can accommodate laser power options from 50W – 400W to cut both metal and non-metal materials in a completely enclosed, Class 1 Safety Enclosure which makes it ideal for high-traffic areas like factory floors and classrooms.”

Finally, Christian says the Vision 1624R CNC engraver/router will demonstrate how easy it is for businesses to offer customisation using milling, drilling, contouring, routing and more on materials from metal, to wood and sign foam.

“The 1624R is a medium-format machine with a work area of 609 x 406 mm, and a maximum path height of 178 mm on the z axis, but it has huge potential to expand options and boost production time on everything from deep metal engravings, to routed wood signs, cut-out letters and 1.5 or 3D signs,” he says.

“We’re excited to showcase and demonstrate Alfex Laser’s expansive product portfolio live on-stand at PacPrint in September and look forward to helping you and your business diversify and expand into the future.”

PacPrint 2021 will co-locate with the Visual Impact Expo and the Label & Packaging Expo at the Melbourne Convention & Exhibition Centre from 28 September to 1 October this year. Click here to register for the show, or go to www.pacprint.com.au for more information. To find out more about the Alfex Laser range, go to www.alfexlaser.com.au

Esko has announced the launch of a free downloadable e-book, ‘Trends in the Beverage Packaging Industry: Ingredients for Success’, which outlines key industry trends and the tools brand...

July 06 2021

Esko has announced the launch of a free downloadable e-book, ‘Trends in the Beverage Packaging Industry: Ingredients for Success’, which outlines key industry trends and the tools brands can adopt to capitalize on them for commercial success.

The global market for alcoholic beverages amounted to over 1.49 trillion US dollars in 2020 and is expected to grow to 2.2 trillion USD by 2025, according to Statista. Changing consumer habits during the pandemic have led to a plethora of new behavioral trends, which equates to a host of opportunities for brands hoping to capture new market share in the sector.

“Almost a third of consumers would like to continue working from home and coupled this, over half of consumers are actively looking for tips on personal health and wellbeing. In catering to this, brands can expand into whole new categories. For example, alcoholic flavoured water known as Hard Seltzer,” says, Matthew Haws vice president global marketing at Esko Brand Solutions.

“When creating whole new product lines with multiple SKUs, smart brands are using digital tools to help streamline the journey and make the transition from ideation to new product launch pain-free. With digital asset management (DAM) tools like MediaBeacon, external assets can be approved and made available to marketing teams to ensure promotion is extremely agile.

The latest free resource from the Esko team covers market trends and offers deeper insight into categories such as spirits and cocktails. Packaging trends are also on the agenda with a look at digital tools for success.

As brands and retailers strive to keep ahead of the competition, technologies such as MediaBeacon and web-based collaborative workflow management system, WebCenter, help them to cut to the chase quicker by streamlining packaging design projects and taking away common stumbling blocks that slow the process down.

“The beverage industry is extremely competitive in terms of packaging design. Speed to market with new and different designs is paramount to influencing the purchasing decision ahead of rival brands. Teams that have control of their assets through digitalization are much more likely to turn concepts into actual product ranges quickly – and more cost-effectively.”

Download the Esko Trends in the Beverage Packaging Industry: Ingredients for Success e-book no

GJS today announced it has secured the first Australia sale of the new Brother GTXpro Bulk garment printer with Sydney-based printing business T-Shirt Magic. It will use the printer to increase pro...

July 06 2021

GJS today announced it has secured the first Australia sale of the new Brother GTXpro Bulk garment printer with Sydney-based printing business T-Shirt Magic. It will use the printer to increase production volume while simultaneously increasing its eco-friendliness thanks to the capabilities of the printer.

Andrew Sprason and Lily Yang, the husband-and-wife owners of T-Shirt Magic took ownership of their first Brother garment printer back in 2011, and since then they have moved through all subsequent Brother DTG models including the GT-3 series, and the GTX, having multiple units of each.

T-Shirt Magic is one of Australia’s premier DTG printers. Founded in 1998, T-Shirt Magic designs, prints, and supplies garments to clubs, businesses, corporations, and charities.

The investment in the new Brother GTXpro Bulk will allow T-Shirt Magic to scale its production capabilities as the business continues to grow, while also allowing faster production. The GTXpro Bulk will also increase cost efficiency for the business, thanks to the new bulk ink delivery system.

“The Brother GTXpro Bulk will allow us to offer even better quality and faster turnarounds, and at a lower cost for bulk printing,” said Sprason.

The purchase and install of the Brother GTXpro Bulk will also allow for improved production reliability.

“With our other Brother GTX printers, the addition of the Bulk means that we will always be able to fulfil customer orders. If for some reason one of the GTX’s is unavailable or requires maintenance or servicing, we will still have two others as redundancy,” Sprason added.

Continuing Brother's legacy of creating industrial-grade garment printers, the GTXpro Bulk features a proprietary bulk-feed system for its specially formulated inks. Meticulous attention to every detail means that every component is up to the rigours and demands of high-production garment decoration.

The bolder, brighter Innobella Textile Inks are water-based pigment inks and are ECO PASSPORT by OKEO-TEX certified and CPSIA compliant. The bulk packaging uses less plastic thanks to the new reusable tanks so there is less waste and less impact on the environment.

GJS

Following the successful February online training course, Idealliance Australasia, the global standards developer and certifying body for ISO and G7 colour specification, will hold another G7 Exper...

July 06 2021

Following the successful February online training course, Idealliance Australasia, the global standards developer and certifying body for ISO and G7 colour specification, will hold another G7 Expert 5-day course commencing on July 19th. David Crowther of Colour Graphic Services will once again conduct the course for four hours each day, Monday-Friday, 19th – 23rd July.

G7 is Idealliance’s global industry-leading set of specifications for achieving visual similarity across all print processes currently being drafted into ISO 12647-2. Crowther says: “G7 Certification is a valuable qualification fior anyone involved in graphic reproduction where colour is critical. It is the leading colour initiative in print consistency and near neutral appearance, and the G7 methodology specifies how to align any 4-colour CMYK print output to align all print technologies, regardless of where or how a product is printed. Lockdown time and home office isolation are ideal times to learn – and add the colour skills and certification that are increasingly recognised as essential by printers and brand managers.”

The July interactive online training, using Zoom, takes place over five consecutive days, but only 4 hours per day – so you still have time to attend to work, production and/or personal matters. Training consists of a variety of components, including shared slides, video, whiteboard illustrations of critical concepts, press runs and print calibration simulations, plus hands-on activities and analysis.

A very experienced trainer, Crowther’s qualifications include:

G7 Expert trainer, BrandQ Manager certified, G7 Process Control Expert certified, Colour Management Professional Master certified, G7 Expert certified, Member – (EX-004) Australian ISO Technical Committee for Graphic Technology TC 130, Mellow Colour Certified Partner, Techkon Certified Service Partner, Colour and Print Consultant

Schedule, costs and resources

Delegates on the course will receive a library of print resources, enabling participation in the instructor-led hands-on activities. Downloadable production resource materials such as G7 test forms help in learning how to implement G7 in workplace facilities, to obtain G7 Master qualification.

“Participants will also receive access to the extensive online training library including on-demand training recordings to view to support your continued growth as a G7 Expert. Participants are strongly encouraged to participate in hands-on activities utilizing their own colour management tools and solutions," says Crowther.

Seats are kept to a low number to ensure direct support by Idealliance’s certified G7 Expert trainer & technical staff. Seats are currently still available.

The July schedule is as follows:

Monday July 19, 2021: 10:00am – 2:00pm AEST

Tuesday July 20, 2021: 10:00am – 2:00pm AEST

Wednesday July 21, 2021: 10:00am – 2:00pm AEST

Thursday July 22, 2021: 10:00am – 2:00pm AEST

Friday July 23, 2021: 10:00am – 2:00pm AEST

Pricing (in US dollars) for the 5-day course is:

G7 Expert - Idealliance Members USD$2,149.00 / Non-members USD$2,619.00

G7 Professional - Idealliance Members USD$1,799.00 / Non-members USD$2,009.00

Bookings and further information can be obtained by emailing:

David Crowther on Email: david@idealliance.org.au

Roland DG Corporation, a leading manufacturer of wide- format inkjet printers and printer cutters, today announced the addition of EUV5 Orange and Red UV-curable inks for use in the VersaUV LEC2 se...

July 06 2021

Roland DG Corporation, a leading manufacturer of wide- format inkjet printers and printer cutters, today announced the addition of EUV5 Orange and Red UV-curable inks for use in the VersaUV LEC2 series of UV-LED printer cutters.

With integrated printing and cutting, diverse media support and ease of use, the LEC2 series UV printer cutters are ideal for the quick turnaround of numerous applications, including adhesive decals, labels and stickers, signs, POP, backlit panels, interior décor and packaging prototypes. In addition to CMYK, Clear, White and Primer, EUV5 UV ink now supports new Orange and Red inks as process colours. CMYK + Orange + Red expands the colour gamut by approximately 20%, thereby increasing the number of Pantone colours reproduced by approximately 200 colours*² compared to four-colour CMYK. Combined with Roland DG’s True Rich Color print settings that maximise the potential of hardware and inks to produce stunningly vibrant graphics with neutral greys, smooth gradations and natural skin tones, it is now possible to more accurately reproduce brand colours that were previously difficult, if not impossible.

Tony Miller, Division President of Global Sales & Marketing Division, said, "The LEC2 series is characterised by its versatility, quick turnaround, and unique special printing capabilities for high value-added expression on a wide range of compatible media. We are confident that the addition of Orange and Red UV inks will bring even more value and competitiveness to our customers' businesses. Roland DG will continue to contribute to the development of the printing and manufacturing industry by providing products and services that expand the creative possibilities of our customers."

To find out more, go to: www.rolanddg.com.au

Durst, manufacturer of innovative digital printing systems and software solutions, has presented in its online event, “All you need is RSC”, the extended Tau RSC printer portfolio in it...

June 28 2021

Durst, manufacturer of innovative digital printing systems and software solutions, has presented in its online event, “All you need is RSC”, the extended Tau RSC printer portfolio in its new cross-platform design. New features for highly flexible, high-quality yet cost-effective digital label printing from short to long runs were introduced on the updated Tau 330 RSC and a Tau 510 RSCi with integrated flexo stations at the Durst Customer Experience Center in Brixen, Italy.

The coronavirus pandemic has changed the needs of consumers worldwide and the demands on label production. On the one hand, label converters must be able to deliver long runs in the shortest possible time to keep the entire supply chain running. On the other, they must cope with many more short runs. In addition, an increasing number of brands and end customers are demanding environmentally friendly label production. As a result, label converters need tools and processes that allow them to quickly adapt to these changes. They need operator-friendly digital presses that produce reliably, fast and cost-effectively short to long runs and allow to minimise waste, ink and power consumption.

To address these market demands Durst has updated its Tau RSC platform and further improved the successful Tau 330 RSC and Tau 330 RSC E presses for short and medium runs. Even various Tau RSCi solutions for hybrid printing and inline processing can be offered now, thanks to the expansion of the product range with various partners.

As shown in the online presentation, the Durst Tau RSCi can be configured with optional flexo stations – before and/or after the digital print unit. Therefore, challenging materials can be used by adding a primer or combination printing between flexo and UV Inkjet. By printing white over with the post-press flexo station more applications can be added to the press. The user-friendly flexo stations fit to the available printing widths of 330, 420 or 510 mm of the Tau RSCi and are equipped with a slide in/out carriage to aid loading and unloading of the ink pan, pick-up and anilox roller. With the new flexo stations, Durst again unlocks potential new profitable business scenarios for its customers.

A new Ink Save Mode allows Tau RSC platform users to reduce ink costs by an average of 12% on a CMYK press. This cost-effectiveness boost will enable more jobs to be shifted to digital production. The operator can choose if he wants to print either in best match mode or with the special save ink mode. Then, the Durst Workflow Label software utilises image analysis to analyse the print job and replaces the original colour combination with an alternative one, with the goal of less ink consumption and minimal visual change in the label appearance.

The intelligent software now also includes a new automatic maintenance feature to avoid downtime and reduce service costs. Automatic cleaning of the print heads is carried out contact-free by the integrated maintenance unit, which also prevents possible damage. The process is intelligently controlled and smoothly integrated into the ongoing print operation. With this new function, availability increases, an overall better and stable print quality is achieved due to the overall better printhead condition, and less ink is wasted because almost no more purging cycles are needed. Last, but not least, Durst equips every new Tau RSC / RSCi printer model with additional IT security hardware. The operator needs to actively turn a safety key to allow access from outside of the machine.

These new developments are also available as a retrofit for existing Tau 330 RSC and RSC E customers, providing additional value to already-installed presses.

Helmuth Munter, in his last official engagement as Durst Group Label & Flexible Packaging Segment Manager, said: “Today, we count over 250 Durst Tau installations, of which close to 130 are Tau RSC installations, with many clients owning multiple machines that print in an industrial environment 24/7 in 3 shifts per day. So, we can proudly say: We at Durst have advanced the digital transformation with our Tau single pass inkjet technology in the Label & Flexible Package Printing market. Single pass inkjet has evolved to a mainstream label printing technology, with a market share of 25% + globally.”

Thomas Macina, Durst Group’s new Global Sales Manager for Labels & Flexible Packaging, added: “Many Durst customers have successfully walked this path with the Durst Label & Flexible Packaging team. Durst grew with them, and they grew with our solutions. Therefore, we will continue to have our eyes open and our ears very close to the market to be able to understand and support our customers future needs. Our product portfolio has all the key capabilities and is well positioned to cover the requirements of the different print runs. The RSC E and RSC for short and medium runs, and the RSCi for medium and long runs. All our customers can count on Durst’s innovation and the continuous development of RSC technology as a platform for continued successful growth in the label and packaging printing industry.”

Domino & Paragon Inks Join Forces and Create Fully Compliant Suite of UV Varnishes for Global Use Available for global use, these UV curable varnishes have been fully validated for compli...

June 28 2021

Domino & Paragon Inks Join Forces and Create Fully Compliant Suite of UV Varnishes for Global Use

Available for global use, these UV curable varnishes have been fully validated for compliance meeting multiple legislations.

Domino Digital Printing Solutions, one of the most successful leading players in the digital printing industry, and global inks specialist, Paragon Inks, have developed a full suite of varnishes specifically for overprinting on Domino's UV95 and UV90 ink sets for use with their N-series digital inkjet label presses. Available for global use, these UV curable varnishes have been fully validated for compliance meeting multiple legislations.

Julie Cross, Technical Director for Domino's Digital Printing Solutions division said, "After listening to the challenges faced by some of our customers, we wanted to help them by providing a varnish optimised for overprinting UV95 printed output. We therefore set about finding a solution, ultimately deciding to work in partnership with Paragon Inks. And after 18 months of great collaboration between the two teams, we have developed a range of varnishes fully validated for compliance, and suitable for global use."

Varnishes are used on labels for three reasons: to provide enhanced protection from sunlight, wear or abrasion to extend the life of the labels; for aesthetic reasons to enhance label designs and colours, add value and increase shelf presence; and to enable labels to be overprinted with variable information later in the packaging production process.

The first set of varnishes (matt and gloss including TTO over-printable), for use with Domino's UV95 food packaging compliant UV digital ink set, are optimised such that the output does not need to be corona treated before the varnish is applied. Not only does this reduce the complexity of the hybrid printing line, but in addition, it provides a solution for medias that are unable to be corona treated, such as some metallic foils. During testing, it was also identified that the gloss varnish can be used as a lamination adhesive enabling further simplification, as one varnish can be used for two applications.

These varnishes have been formulated for many non-direct food packaging applications and, under the right conditions, are migration compliant. They are suitable for global use, being fully compliant with Nestlé, EuPIA, Swiss Ordinance Annex 10 and the North American TSCA (Toxic Substances Control Act).

To compliment these, there is a second suite of varnishes suitable for use with Domino's general purpose UV90 ink set.

Amanda Jones, Business Development and Marketing Director at Paragon Inks, concludes, "At Paragon Inks, we are committed to continuous improvement and customer service. We recognised that label converters were experiencing challenges applying varnishes to digitally printed labels. This partnership with Domino highlights how we have worked together as a team to develop a mutually beneficial solution for both organisation's customers. We look forward to continuing to work with Domino in the future."

For more information about Paragon Inks, visit: www.paragoninks.co.uk

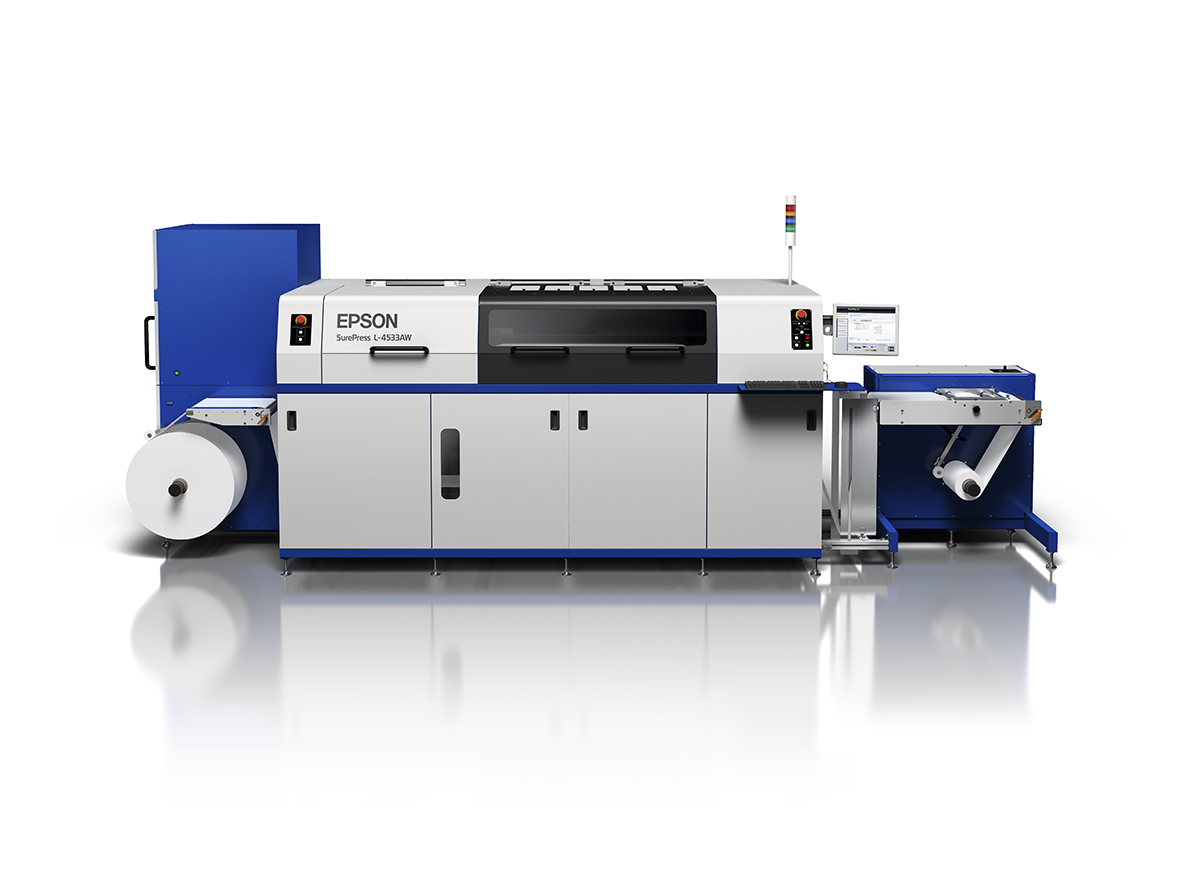

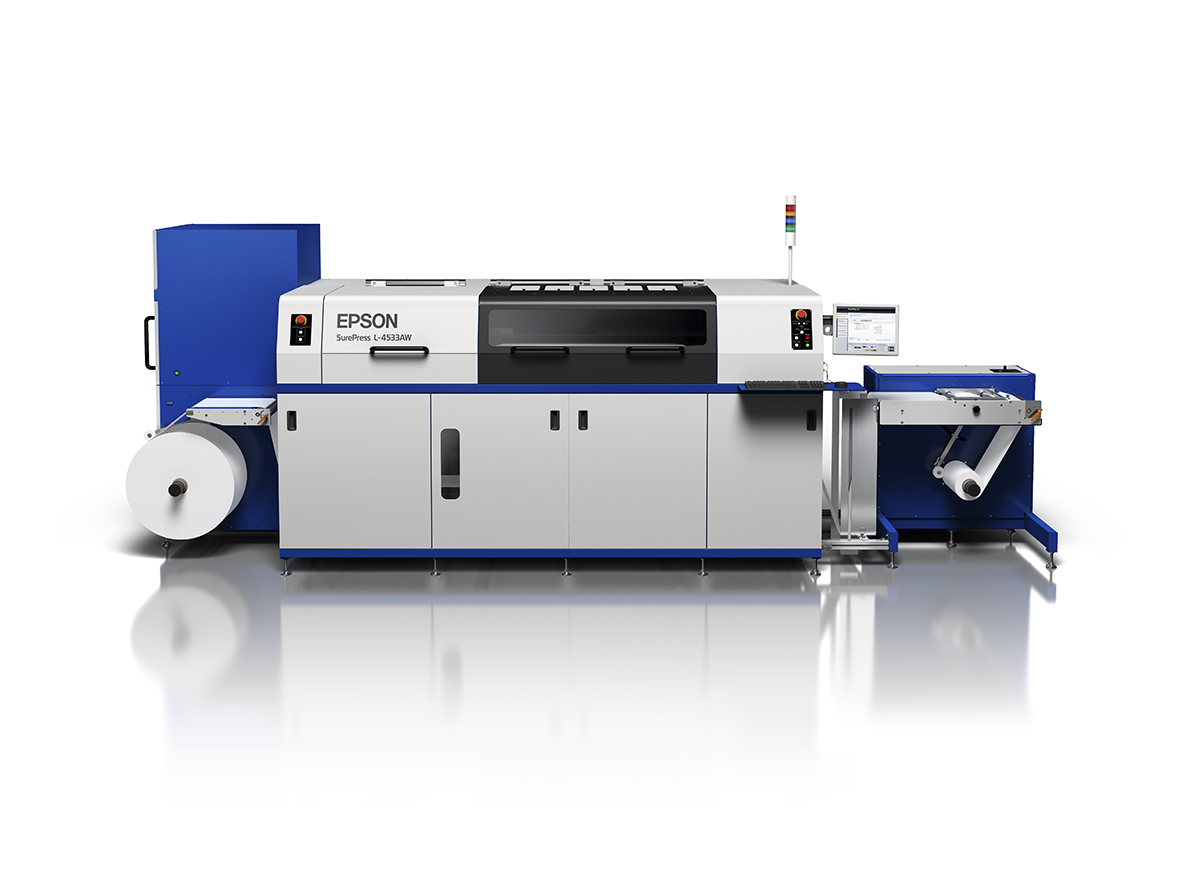

Epson has appointed FUJIFILM Business Innovation Australia (FUJIFILM BI) to sell and service their SurePress resin-based industrial label presses into the commercial print space, specifically targe...

June 28 2021

Epson has appointed FUJIFILM Business Innovation Australia (FUJIFILM BI) to sell and service their SurePress resin-based industrial label presses into the commercial print space, specifically targeting commercial printers. FUJIFILM Business Innovation Australia are now the exclusive reseller partner of Epson SurePress resin products in Australia and given the company’s existing, longstanding, successful relationship with Epson in the wide format category, the new partnership is a natural fit with many benefits for the market.

FUJIFILM Business Innovation Australia General Manager, Graphic Communication Services, Chris Lynch, said “We are very excited to be able to offer our existing clients including commercial printers an opportunity to broaden their own market reach with the addition of these Epson SurePress devices. In particular, for those looking to diversify and extend upon their current print offer to their own customers. The label market provides a perfect opportunity for this as demand continues to grow year on year.”

As Lynch mentioned, in their new role FUJIFILM BI will address the growing demands of commercial printing companies wanting to enter into the label market and the trend of commercial printing companies needing to expand their service offerings to their customers. Label production has proven to be recession proof during the COVID-19 pandemic and FUJIFILM BI, with its extensive sales and service team is well positioned to market and maintain SurePress to the commercial print market in Australia.

Epson Australia Managing Director, Craig Heckenberg said, “Label production is currently one of the strongest printing businesses maintaining stable demand in Australia and worldwide. Commercial printers in Australia looking for diversification can address the label market far more efficiently with SurePress products and this means more local production, a faster response to the supply chain, variable data, customisation and versioning and better security. As a leader in digital printing solutions, FUJIFILM BI brings a unique perspective to the label market. They are also able to offer the extensive service and support coverage for Epson SurePress products that the market requires.”

The Epson SurePress range has been designed for printers seeking to move into the digital age, either for the first time or as an expansion, with enhanced customer service, marketability and operational profit.

SurePress devices combine digital image processing with the latest ink and drop-on-demand print technologies to facilitate flexible production with outstanding print quality. They produce labels with exceptional colour and resolution on a wide range of industry standard substrates, without the need for special coatings or pre-treatment.

The SurePress machines are easy to operate, simple to install, and support a wide range of industry standard finishing equipment. They are particularly suited to short and ultra-short length jobs where they offer rapid and cost-effective turnaround. They deliver a precise, premium product with low running costs, minimum maintenance and low downtime.

For more information on Epson’s SurePress range go to: www.epson.com.au/surepress

Böttcher Systems will show off its full range of solutions on its stand at PacPrint 2021, with a display it says will support all ‘four pillars’ of its business - carton packaging,...

June 28 2021

Böttcher Systems will show off its full range of solutions on its stand at PacPrint 2021, with a display it says will support all ‘four pillars’ of its business - carton packaging, printing with hybrid UV and Light Emitting Diode inks (HUV-LED), flexible packaging and commercial print. The result is a showcase which will be a real drawcard for visitors not only to PacPrint, but to the co-located Label & Packaging Expo.

A focus of the show for Böttcher will be innovative solutions aimed at helping businesses reduce makeready times while also improving their sustainability record, says Managing Director, Mitch Mulligan.

“Böttcher’s ECS ‘Easy Cleaning System’, for instance, was designed with this in mind,” he says. “These easy-to-clean inking rollers incorporate special polymers and additives in the rubber to reduce the adhesion of the ink to the roller surface, effectively improving ink transfer whilst also enhancing the washability of the roller train.

“This not only saves time, but means you can significantly reduce your wash consumption, typically by 30-50%. These ECS rollers are available for all drying technologies and in a range of durometers to accommodate printers’ and press manufacturers’ preferences.”

As well as the special roller coverings, the ECS system now also includes washes with enhanced cleaning power, including the Mistral ECS which will be launched at PacPrint.

“To make this product, we took our highest-quality conventional wash and made it even better,” Mulligan says. “New materials not only improve its ability to dissolve and remove ink from rollers and blankets, but increase the proportion of biological components in the wash, helping businesses reduce their environmental impact.

“With businesses in this region among the most eco-conscious in the world, we believe PacPrint is a fitting place to launch the best wash Böttcher has ever made!”

Tailor-made solutions for flexographic and rotogravure printing will also feature on the company’s PacPrint stand, with the proven CAMBIUM sleeve for plate mounting among them.

“Valued by independent printers and packaging groups for their geometric and mechanical stability and low weight, CAMBIUM sleeves are now available internationally through the Böttcher Group with our worldwide production and sales companies,” Mulligan advises.

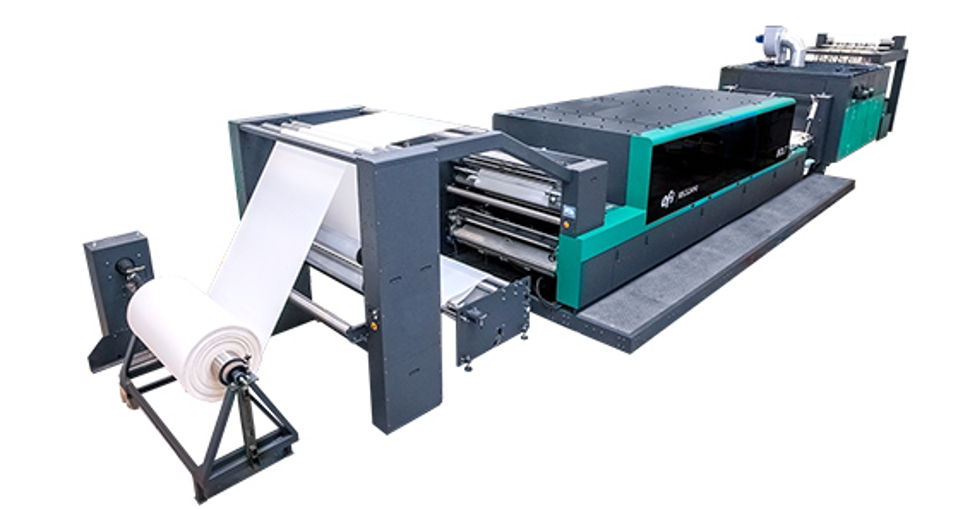

Electronics For Imaging, Inc. has enhanced the world’s fastest digital textile printer, the EFI Reggiani BOLT. The upgrade is a combination of hardware and software enhancements ...

June 28 2021

Electronics For Imaging, Inc. has enhanced the world’s fastest digital textile printer, the EFI Reggiani BOLT.

The upgrade is a combination of hardware and software enhancements that will minimise artefacts, compensating for missing nozzles that may occur over time and enhancing uniformity to deliver smoother solid colours. The upgrade also delivers improved quality and smoother gradients, plus it enables faster printhead replacement and drastically increases file processing speed by up to 200% for large, complex files.

Dedicated colour profile creation on the newest-version EFI Fiery BT-1000 digital front end driving the printer delivers better, more-intense tones and improves capabilities for matching existing colour profiles commonly used in digital textile printing.

The enhancements are an important step in further enhancing digital printing’s presence in the industry, bringing greener, more-sustainable inkjet technologies to the fore as a replacement for analogue dyeing procedures that make textile manufacturing the world’s second-largest polluting industry.

“With the industry’s top speed and now the delivery of even higher print quality, the EFI Reggiani BOLT can help spur a revolution in textile printing, migrating more production to digital technology, ensuring the fastest return on investment on high-volume work thanks to superior throughput and unmatched reliability and uptime,” said EFI Reggiani Senior Vice President and General Manager Adele Genoni. “With the BOLT’s new enhancements – and its ability to print extremely high quality on a variety of designs and fabric types at record-breaking speeds up to 90 metres per minute – the economic cross-over point between analogue and digital printing of fabrics is lower than ever before. The time for single-pass technology is now with this best-in-class, sustainable, high-quality and high-throughput digital textile print solution.”

This 1.8-metre-wide single-pass printer – the first digital textile printer to receive the Printing United Alliance InterTech Award for advanced print technology innovations – is well-positioned to have a major transformational impact on the industry. With its current installed base, the EFI Reggiani BOLT is already responsible for printing more than 50 million linear metres of fabric worldwide.

Faster processing and higher-quality print

Now available globally, the EFI Reggiani BOLT upgrade features hardware and software enhancements for improved overall performance, printing quality, uniformity, and increased user friendliness including:

Focused on the current market needs of production-class print providers, Epson today introduced a new line of SureColor P-Series photographic and graphic art wide-format printers. The new SureColor...

June 22 2021

Focused on the current market needs of production-class print providers, Epson today introduced a new line of SureColor P-Series photographic and graphic art wide-format printers. The new SureColor P-Series models are designed specifically for high-volume photo fulfilment, retail photo labs, poster and graphic art production. The new production-class SureColor P-Series 24- and 44-inch models are slated to launch this year, with the initial SureColor P8560D 44-inch dual roll printer available first.

Leveraging Epson’s latest 2.64-inch PrecisionCore printhead and six-colour UltraChrome PRO6 pigment inks, Epson’s new photographic printer line enables higher-speed performance than previous generation models while providing outstanding image quality. The innovative, space-saving design provides a small footprint for space-constrained production environments. In addition, the latest models include several new features that improve workflow and media handling, including Adobe Embedded Print Engine as standard, dual roll, built-in take-up reel for roll-to-roll printing, complete front operation, easy automatic roll loading, and optional, adjustable production stackers.

“As the demand for more personalised photo products, decor and graphic art continues to rise, print service providers are demanding higher quality and higher productivity at lower costs,” said Epson GM marketing Bruce Bealby. “These new P-Series production-class printers deliver on all those fronts. The first available model in this new line, the SureColor P8560D is engineered to achieve high speed with innovative media handling, all with the high quality and reliability synonymous with Epson.”

More about the new SureColor P-Series

The new line contains a range of features designed to meet the needs of demanding print service providers, including:

Epson today introduced a new generation of production-class, SureColor T-Series wide-format printing solutions with an innovative, compact design. Five new SureColor T-Series 24-, 36- and 44-inch d...

June 22 2021

Epson today introduced a new generation of production-class, SureColor T-Series wide-format printing solutions with an innovative, compact design. Five new SureColor T-Series 24-, 36- and 44-inch dual roll models are slated to launch later this year. The SureColor T7760D 44-inch dual-roll printer will be available first.

Developed from the ground up, the all new SureColor T-Series models include Epson’s latest 2.64-inch PrecisionCore print head which provides outstanding image quality while enabling higher-speed performance than previous generation models. The new, compact industrial design provides a small footprint for space-constrained production environments. The latest models also incorporate a number of new features that improve usability and streamline workflow and media handling, including Adobe Embedded Print Engine standard on most models, dual rolls, built-in take-up reel for roll-to-roll printing, complete front operation, easy automatic roll loading and optional, foldable production stackers.

“Not only do these new T-Series printers deliver significant speed and functionality enhancements over the previous generation and compared to competitor models, a tremendous amount of development work has gone into making them as compact as possible. They sport a truly innovative design that fits into any shop or office space, even when space is limited,” said Epson GM marketing Bruce Bealby. “The T-Series line of printers is a focus for Epson with nine models in the family already. Built on decades of imaging expertise, these new additions deliver production-class performance in a compact form factor and come with powerful software to help modern businesses improve workflows and streamline project delivery.”

The first available SureColor T7760D delivers posters and POP displays at speeds over 28 m2/h and CAD and technical drawings at production-class speeds over 130 m2/h, making it the fastest in its class1.

More about the new SureColor T-Series

The new line delivers a range of features designed to revolutionise business productivity, including:

Fujifilm’s stylishly designed new Acuity Prime flatbed prints at exceptionally high quality to a range of rigid and flexible media. Optimising price/performance was at the heart ...

June 22 2021

Fujifilm’s stylishly designed new Acuity Prime flatbed prints at exceptionally high quality to a range of rigid and flexible media.

Optimising price/performance was at the heart of the design of the Acuity Prime. For example, it features a high quality LED curing system which is air-cooled, meaning there is no requirement for an expensive water-cooling system. And the Prime is so power efficient that it only requires a single-phase 25-amp supply, helping to keep running costs to a minimum.

A new ink system – Uvijet HM – has been formulated to provide excellent adhesion to a broad range of substrates while also producing a wide colour gamut. The new ink range is optimised to produce high quality, vibrant images day in day out.

A new jetting primer meanwhile, improves adhesion still further for particularly challenging substrates. This removes the need for offline pre-treatment of substrates before printing, saving time and money. The machine also features a printable area of 2.54m x 1.27m and can accommodate media up to a thickness of 51mm.

Available in CMYK formats with white, with additional clear and jetting primer, the Acuity Prime with Uvijet HM offers the ultimate versatility and value by providing the flexibility for print businesses to customise it to their own needs.

Careful consideration has also been given to operational ease-of-use. Multiple practical benefits for both operators and service engineers have been built into the design, making the day-to-day operation of the printer as straightforward as possible.

One such feature is the media loading pins, which can be operated with the touch of a button, allowing for pinpoint media placement precision and exceptionally accurate print registration from job-to-job.

The five-part media zone system, based on common media sizes, vastly reduces the amount of masking required. This means job set-up times can be sped up considerably.

The machine’s splash-free ink pouch system is designed for easy pouch changeover and incorporates an LED light system to quickly and effectively alert the operator to low ink levels.

Alongside all the new technical features, the Prime also includes practical benefits, such as an integrated shelf for operator tools, which allows them to be kept close to hand but safely away from moving parts of the machine. There is also a handy cabinet built into the space underneath the front of the machine for convenient storage of PPE, personal items or first aid kits, helping to keep the area around the machine clear.

The software and user interface have also been carefully considered with the software completely redesigned to give all the tools required in the most straightforward way possible.

Anda Baboi, Marketing Manager, Fujifilm WFIJ says: “The Acuity Prime represents both a ‘next step’ and a new start for Fujifilm. It’s built on our knowledge and expertise, but at the same time it’s something fundamentally new – the new blueprint for wide format. The thing that really sets it apart from anything we have brought to market before is the extent of the creative freedom we have had over every aspect of its design and development. Having this level of control has given us the opportunity to address a huge number of practical and technical issues, ensuring that the end product offers unbeatable standards of performance; exceptional value, versatility and ease-of-use, and the best ROI available on the market.”

Following several years of successful Acuity Ultra installations since its launch in 2018, and as part of Fujifilm’s strategy to create the new blueprint for wide format, Fujifilm today annou...

June 22 2021

Following several years of successful Acuity Ultra installations since its launch in 2018, and as part of Fujifilm’s strategy to create the new blueprint for wide format, Fujifilm today announces the launch of the Acuity Ultra R2.

Available in 5m or 3.2m versions, the new machine features the same high levels of quality and reliability as its predecessor, but offers a huge number of design improvements to benefit both ease-of-use and overall productivity.

The new, stylish enclosed design eliminates stray UV light, removing the need for a light curtain, while from a functional point of view the machine is designed with both maintenance and ink supply on the same side, giving operators easier access and more room in which to work when performing routine tasks. An external visual light also quickly alerts operators to low ink levels without the need to look inside the machine.

The Acuity Ultra R2 also features larger ink tanks. This simple change ensures that all the ink from a standard can is used when refilling, eliminating the clutter and mess of opened, half-used ink cans that are often a feature of print workplaces. The ink tanks have also been designed for easy access for refills.

Maintenance-free ink pumps have also been integrated into the new machines to increase up-time, and a unique new print viewing window allows the operator to check on the progress of a job without leaving the workstation. The workstation itself has also been redesigned, now featuring desktop space, a handy drawer for tools or personal items, integrated lighting, and a larger monitor for ease-of-use and better display of print jobs.

Another significant design benefit is that the separate chiller unit that accompanied the original Acuity Ultra has now been fully integrated into the design of the new machine. This frees up considerable workspace and reduces clutter.

The Acuity Ultra R2 also features a crash detector with increased sensitivity and dual way activation, helping to identify and address potential problems early. Furthermore, it also features a new low scratch surface platen and new automated meniscus control, offering even greater precision and consistency in ink droplet placement.

Like the original Acuity Ultra, the R2 is available in various colour configurations up to eight channels, but recognising the fact that modern print businesses are all unique – with often very different needs and priorities – the Acuity Ultra R2 is available with conventional UV curing as standard, or with an LED UV curing system for six colour and white configurations. This gives customers the option to choose either the ultra-high productivity of conventional UV, or the comparatively lower operating costs and lower energy use of LED. Both the 5m and 3.2m versions of the machine also feature an improved roller design to prevent media wrinkles.

Kevin Rhodes, Marketing Manager, Fujifilm WFIJ says: “The original Acuity Ultra set a new standard for combined quality, performance and price when it was launched in 2018. Three years later, the Acuity Ultra R2 is taking that up another level as part of our brand new Acuity range and our ‘new blueprint’ for wide format.”

The new Avinci CX3200 is a dye-sublimation roll-to-roll printer that can print either directly to textile or on transfer paper. It delivers high productivity and a consistently vibrant print qualit...

June 22 2021

The new Avinci CX3200 is a dye-sublimation roll-to-roll printer that can print either directly to textile or on transfer paper. It delivers high productivity and a consistently vibrant print quality on a wide range of polyester-based fabrics.

The Avinci CX3200 engine enables sign printing companies to create textile prints of up to 3.2 m wide at a production speed of up to 270 m²/h. The engine uses eco-friendly, odourless water-based dye sublimation inks to print either directly to fabric or to transfer paper.

Being able to print directly to fabric is easy and ideally suited for fast handling of soft signage applications such as banner displays, wall graphics and point-of-sales or trade show displays, as well as for special applications requiring print-through, such as flags. Transfer paper, in turn, allows for super sharp prints, eliminates any set-off, and limits media waste to a minimum. In addition, it extends the application scope to sportswear and fashion garments, as well as home décor prints on non-coated polyester fabrics.

The Avinci CX3200 guarantees a wide and vibrant colour gamut, outstanding tonal rendering and fine detail reproduction. The dedicated dye-sub inks stand out through their flexibility, and outdoor resistance. They deliver a stable jetting performance and the same first-rate quality batch after batch. An offline calendering unit effectively fixes the colours after printing.

Philip Van der Auwera, Wide-Format Marketing Manager at Agfa, states: “The market demand for soft signage keeps growing, as it is lightweight, resistant to wrinkles and folding, and easy to transport and reuse. The Avinci CX3200 will meet the needs of existing textile printing companies, as well as enable sign & display printers to diverge into textile printing and bring in new business. We designed it to be fit for high productivity and maximum uptime. It is extremely robust and reliable, as well as easy to operate.”

Reliability and convenience guarantee high productivity

The new Avinci CX3200 is a solidly built, reliable engine that can handle any job from a single print to sizeable runs in a 24/7 setup. It is equipped with Kyocera water-based print heads that will cover the printer’s entire life cycle. The strong pre-heater limits drying time and reduces set-off, while the vacuum make sure that thin transfer papers are kept perfectly wrinkle-free.

Changeover between jobs is fast and easy. Loading a new roll can be done in less than seven minutes by a single operator, thanks to the automatic media transport with pinch rollers.

Asanti warrants colour consistency and low ink consumption

The Avinci CX3200 is driven by Agfa’s intuitive Asanti workflow software, which streamlines all preparation, production and finishing steps of the printing process. Its smart algorithms guarantee high print quality and colour consistency, as well as low ink consumption.

In addition, Asanti features a number of options that facilitate soft signage production, such as the automated positioning of cutting marks and grommets, and the easy design of canvas extensions for the creation of flag pole pockets. It also lets printers nest and tile artwork to optimise media use.

With Asanti StoreFront, Agfa’s web-to-print software solution, soft signage printing companies can automatically manage incoming web orders or set up online stores.

New film and overlaminate provides exceptional performance and ease of use, resulting in faster installs with less rework Sydney Australia, Auckland New Zealand – ...

June 08 2021

New film and overlaminate provides exceptional performance and ease of use, resulting in faster installs with less rework

Sydney Australia, Auckland New Zealand – June 1, 2021 – In a fast-paced industry that demands creative ideas, bold designs and flawless installations, graphic manufacturers and installers need to have access to best-in-class tools that can exceed expectations and ensure customer satisfaction, while still achieving maximum return-on-investment. With more than 30 years in the graphics industry, 3M recognises the importance of designing films that not only look impressive on the road, but are easier to install, offer exceptional conformability and lift less. That’s why 3M is proud to introduce 3M™ Print Wrap Film IJ280 with 3M™ Gloss Wrap Overlaminate 8428G – their newest print film and overlaminate for commercial vehicles to the market.

Created to make an impact in both installation and performance, the combination of 3M™ Print Wrap Film IJ280 and 3M™ Gloss Wrap Overlaminate 8428G delivers exceptional ease of use, leading to faster installations with less rework. As a result, installers can wrap commercial vehicles confidently and with less effort, so every installation can be completed quickly and correctly.

“At 3M, we’re committed to developing innovative graphic solutions that provide outstanding aesthetics, are easy to work with and exceed industry expectations,” said Scott Wheaton, 3M Global Portfolio Leader – Digital Print Films. “Our new 3M™ Print Wrap Film IJ280 not only delivers on print quality, durability and conformability, but also reduces labor costs by minimising rework, contributing to a stronger bottom line for our customers.”

The new 3M™ Print Wrap Film IJ280 with 3M™ Gloss Wrap Overlaminate 8428G not only helps graphics manufacturers achieve faster installs, it helps them do it fearlessly.

Benefits of the new products include:

• Preferred by installers globally*

• Up to 20 percent faster to install^

• Proven to lift 2x less*

• Conforms with less heat*

• Outstanding print quality

• 3M™ Comply™ v4 Air Release designed for max airflow and smooth results

• Proprietary adhesive offers optimised initial tack, slide and repositionability

• Removes cleanly at end of life with heat

• Backed globally by the 3M™ MSC™ Warranty

For more information on 3M graphic films and to request a sample, visit 3M.com.au/IJ280 and 3M.co.nz/IJ280.

*when compared to Avery Dennison® 1105EZRS/1460Z, Arlon SLX®/3210, & 3M™ IJ180Cv3/mC/8518 with experienced installers applying 3M™ IJ280/8428G for the first time.

^when compared to Avery Dennison® 1105EZRS/1460Z, Arlon SLX®/3210, & 3M™ IJ180Cv3/mC/8518.

Durst, manufacturer of innovative digital printing systems and software solutions, and All4Labels Global Packaging Group, a world-class one-stop converter servicing local and multinational clients,...

June 08 2021

Durst, manufacturer of innovative digital printing systems and software solutions, and All4Labels Global Packaging Group, a world-class one-stop converter servicing local and multinational clients, announce successful beta testing of Durst’s new Tau 510 RSCi at All4Labels in Gebesee - Germany.

All4Labels, which has 29 production sites across the world and more than 3,000 employees, specialises in the home and personal care markets, as well as food and beverage. The group is recognised by its customers as a preferred provider of pressure sensitive, shrink sleeve and security labels as well as flexible packaging solutions and identification.

The Tau 510 RSCi was installed at the All4Labels plant Gebesee in mid 2020 and was since then tested under real production conditions for a dedicated range of label & package printing applications. Thanks to the positive performance of the beta machine, another machine has meanwhile been installed in the same press room to further increase production capacity needs in Gebesee, followed by multiple installations in other All4Label plants across Europe.

Christian Kraft, Plant Manager at All4Labels Gebesee, said: “This investment in Durst’s RSCi printing technology, software and service represents a further step up in what we offer for customers demanding the very best, who include internationally renowned brands and local companies. Optimisation of production processes has become All4Label’s main priority in a market where we see a high level of customisation, premiumisation and personalisation. Digital printing and the associated technologies have allowed us to offer greater flexibility and faster response to the marketplace. Now, with the new Tau 510 RSCi, Durst has moved to yet another level and will be providing us with industrial performance for medium and long print runs with outstanding quality.”

Helmuth Munter, Durst’s Segment Manager, Labels & Flexible Packaging, said: “We are delighted to be a business partner of All4Labels and we are proud and happy about the successful beta test of our new Tau 510 RSCi. This strategic alignment is a perfect endorsement for our strategy and the strong emphasis that we place on customer care, quality and innovation, thus in partnership helping our clients be increasingly successful in their chosen business, and we’re looking forward to a future successful growth with All4Labels.”

The Epson International Pano Awards is dedicated to the craft and art of panoramic photography and is the world’s largest competition devoted to the genre. It’s also a competition that ...

June 08 2021

The Epson International Pano Awards is dedicated to the craft and art of panoramic photography and is the world’s largest competition devoted to the genre. It’s also a competition that with Epson’s help has grown larger every year and the 2021 awards are no exception. With that in mind Epson and The Pano Awards have launched this year’s call for entries.

Curator David Evans explained, “It’s that exciting time again where we call for entries to win a US$40,000 prize pool, including $13,500 cash and an array of prizes including an Epson SureColor P7070 printer, an Epson SureColor P5070 printer and an Epson EB-1781W ultra-slim projector. I’m delighted to officially announce that professional and amateur photographers around the world are now invited to enter the 12th Epson International Pano Awards and that early-bird entries are open from today until Monday 2 August, 2021.”

The 2020 competition saw 5859 images submitted from 1452 photographers in 96 countries and these numbers are expected to be exceeded again this year.

Epson GM marketing Bruce Bealby said, “For the twelfth year Epson is delighted that we are able to support these amazing awards and the wonderful photographers who embrace them in challenging times. Not only does Epson enjoy a long, rich and successful history in the photographic industry with photographers of all levels, we also are very committed to the industry. As a result, we are very much looking forward to seeing the entries and how vibrant they look when printed out on Epson’s dedicated photo printers.”

The Epson SureColor-P7070 is a 24" (610mm) large format printer and the SureColor P5070 is a 17" (432mm) large format printer both of which are designed for premium photo, fine art, proofing and packaging design. They support a wide range of standard and specialist media in roll and sheet formats and feature a PrecisionCore® Thin Film (TFP) head with Variable Sized Droplet Technology™ that enables the output of images in high resolution with superior fidelity and tonal gradation.

Both printers use Epson’s latest UltraChrome® HDX all-pigment aqueous ink for accurate colour with an enhanced gamut, Dmax and image durability. The printers also use a 10-colour ink configuration with two levels of black, a choice of a third black or alternative Violet ink for outstanding colour and black and white prints with up to 99% PANTONE® coverage.

Its ultra-slim design, radiant widescreen performance and easy wireless connectivity make the Epson EB-1781W the ultimate choice in portable projectors. It delivers value, convenience and performance and easily delivers brilliant content from any widescreen notebook with native WXGA (1280 x 800) resolution. Couple that with 3200 lumens colour and white light output and the results are truly amazing.

David Evans concluded, “It’s no secret that Epson's photo and fine art printers lead the way and set the standard for colour and black and white image reproduction. We are delighted by the degree that the photographic community gets behind the awards and equally by what an amazing support and sponsor Epson is.”

The judging panel for the 2021 Pano Awards includes some of the world's top photographers and industry professionals – Lucie Debelkova, Ignacio Palacios, Isabella Tabacchi, Bill Bailey, Aaron Spence, Paul Marcellini, Perri K Schelat, Justin Majeczky, Anna Gibiskys, Andreas Paehge, Jason Denning, Thomas Erh and Juan Pablo de Miguel.

Early bird entries for The Pano awards are open now. To enter go to: www.thepanoawards.com/enter-2021-awards/

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, today announced the appointment of Jonathan Cate to the position of Service Technician in Melbourne....

June 08 2021

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, today announced the appointment of Jonathan Cate to the position of Service Technician in Melbourne.

Bringing with him a wealth of knowledge and experience, Jonathan has previously worked as a technician in the engineering, copier, and wide format printing industries. Jonathan is looking forward to commencing his new role, and is keen to hit the ground running in Melbourne and regional Victoria.

"Jonathan’s knowledge, experience and enthusiasm for helping customers, aligns perfectly with the company," says Roland DG Australia Service Manager, Duncan Gillespie. "We are excited to welcome Jonathan to the Roland DG family, and look forward to the value he will add to the Roland DG Care program".

Based in Melbourne, Jonathan will be responsible for direct service to regional and metro customers, as well as assisting current dealers and agents in the region. Given the current lockdown in Victoria, it is hoped that his appointment will help our customers get their businesses back up and running as soon as restrictions ease across the state.

Roland DG Care includes a complete range of premium services to help customers throughout the lifecycle of their experience with Roland DG. The program includes: fixed travel costs for scheduled preventative maintenance services for Roland DG wide format printers under Fixed Price Scheduled Servicing; installation and training solutions under Roland DG Engage; training courses and clinics under Roland Academy; and industry-leading warranties.

For more information on Roland DG Care and to contact the Service and Support Team, visit www.rolanddg.com.au/support

Spandex, the one-stop supplier of innovative solutions to the sign, graphics and display industries, has appointed Andrew Coulsen to the role of Chief Executive Officer, effective from 3rd May 2021...

June 01 2021

Spandex, the one-stop supplier of innovative solutions to the sign, graphics and display industries, has appointed Andrew Coulsen to the role of Chief Executive Officer, effective from 3rd May 2021. He succeeds Rod Larson, who has served as CEO for 14 years and remains with the business as Executive Chairman.

An Australian born, Andrew Coulsen has served since 2009 as CEO of NTT Ltd. – Europe, a technology service company. He is also a Non-Executive Board member of Tungsten Networks, a publicly-listed UK entity. His career to date has been focused in the technology distribution sector, with experience across go-to-market, finance and operations. He has worked in Australia, USA, Germany, the UK and Switzerland for organisations including Dimension Data, subsequently acquired by NTT, Comtech and Optus. He holds a degree in Accountancy with Marketing from the University of Sydney.

Andrew will be based at Spandex’s headquarters in Zurich, Switzerland.

Rod Larson comments: “It has been my privilege and pleasure to serve Spandex as CEO for the last 14 years, during which time our team has driven significant growth, expanding into diverse new vertical markets, extending our presence to 20 countries, building our portfolio of brands, and optimising our distribution and service infrastructure to give the best possible choice and support to our customers around the world. The time has come to transition to a new CEO who can take Spandex forward and meet our ambitious objectives for the business. Andrew is an exceptional commercial leader who is the perfect choice to lead the overall strategic direction and development of the company in the years to come.”

Andrew Coulsen adds: “It’s my pleasure to join Spandex and to have the opportunity to head up a growing business with such a strong track record and an outstanding team. Our focus now is to grow our European, Australian and North American operations as well as to expand in new geographies, bringing our exceptional brand portfolio and service excellence to even more customers worldwide. I’m excited to lead Spandex on the next stage of its successful journey.”