Epson Australia will exhibit at PacPrint 22 with not only its biggest product offering ever, but also having cemented its position of Number 1* in terms of market share for Large Format’ and Direct to Shape printers across Australia and New Zealand for the last two years (2020-2021). Epson’s Number 1 position in these market areas is based on data from research specialists, IDC.

Taking with them the philosophies of “Be limitless” and “Expand your business possibilities” Epson is exhibiting a veritable armada of printing solutions, with many of the products that helped Epson achieve their Number 1 status also on their stand at PacPrint 2022.

In the Fabric area Epson will feature their large 76” SureColor F10060 aimed at soft signage and just-in-time manufacturing. The SC-F10060 achieves an outstanding gamut using just four inks. It combines advanced Epson Precision Dot Technology with UltraChrome DS HDk ink to achieve high image quality with intense and accurate colour. Alongside the SureColor F10060 will be the SureColor F6360 - 44” which suits a wide range of production applications including customised garments and fabrics, hard and soft signage, décor and merchandise.

Then there’s the Epson SureColor F9460H - 64” which represents the fourth generation of Epson’s proven 64” platform and combines Epson Precision Dot Technology, with advanced media management and UltraChrome DS HDk ink to enable outstanding image quality at high speed.

Finally in fabric will be the Epson SureColor F3000 – DTG which has scaled up to suit to needs of high-volume producers. The SC-F3000 combines advanced Epson UltraChrome® DG ink with Epson’s latest PrecisionCore™ head technology and an upgraded print engine. Staggered 2.6" print heads enable high-speed, single-pass, five-colour production.

The next area on the stand is Signage where you will see Epson’s latest solvent models as well as their new resin range featuring the SureColor R5000L, which offers a low running cost and accurate and repeatable colour on a platform that enables rapid job turnaround.

You will also see the Epson SureColor V7000 - UV Flatbed. The SureColor V7000 is designed to produce durable images on a wide range of substrates, with superior colour and print quality. The SC-V7000 combines Epson precision imaging and print head technology with new UltraChrome UV ink. The printer supports flexible production with four separate print zones and support for media up to 80mm thick. This is a printer designed to provide durable and worry-free operation backed by a comprehensive service program that can be extended up to five years.

Also on display in signage will be the Epson SureColor S80660L - 64” CISS which is designed to produce durable images with maximum impact and format flexibility, quickly, easily and at minimum cost. Prints dry quickly to enable ad-hoc, same-day job turnaround, while the high-capacity media and ink supply systems enable efficient roll-to-roll production with remote status monitoring and reporting.

Then there’s the Epson SureColor S60660L - 64” CISS which also features Epson's latest PrecisionCore print head and UltraChrome Eco-Solvent ink technology. It produces images that are brighter and glossier than competitors with an outstanding colour gamut.

Epson is known as a leader in the commercial and professional photo printing space with models such as the SureColor P9560. That said, Epson are also a major player in small format photo printing and on the stand they will display in both key areas. This includes the new SureLab D1060 dry-film minilab which is designed for low-medium volume production. It can be operated as a standalone machine or in multiples for heightened production. It incorporates a high precision Epson Micro Piezo™ Thin Film Print™ (TFP) head that enables accurate and consistent output in resolutions up to 1440 x 720 dpi. Staying true to the SureLab series, the D1060 is compact, lightweight, and requires minimal operational space.

Epson has launched a huge range of models in the Technical & Poster segment over the last two years you will see a number of these at PacPrint along with the SureColor T7760D. This newly redesigned model combines high-speed production with flexible media handling in an extremely compact footprint and a clever new six-colour ink set.

Epson will also have the SureColor T5460M - 36” MFP on display. The SC-T5460M features Epson's latest PrecisionCore™ print head and aqueous UltraChrome® XD2 pigment ink. It will print an A1 image in as little as 22 seconds with output that dries almost instantly to be water and rub resistant. The SC-T5460M is Epson’s first wide format printer to include an integrated scanner. Developed for engineers and architects, it also provides the perfect solution for corporate, government, retail and education users.

If it’s colour and proofing you’re after then Epson’s unique SD-10 Spectrophotometer will also be demonstrated. The SD-10 is an ultra-compact high-precision spectrophotometer. Small in size but big in features, it is designed to be your constant print companion. It lets you determine the exact colour of a test item and compare it with another or with a known standard such as Pantone®. Most importantly the readings you take are accurate and consistent.

The industrial and commercial labels is where you will see Epson’s latest SurePress AQ ink industrial label press, the L-4733AW, as well as the ColorWorks CW-C4010, both on display for the first time in Australia.

The SurePress L-4733AW digital label press incorporates Epson’s acclaimed MicroPiezo® inkjet printhead and uses industrial grade Epson SurePress AQ ink. It is designed for converters who wish to produce general purpose and specialised labels in short and ultra-short print runs on mainly paper based stocks. It produces output on coated and uncoated substrates with a high colour gamut, high colour accuracy and outstanding print resolution and precision. Jobs are quick to set up and easy to complete with the absolute minimum in consumption, wastage and labour.

Bringing comprehensive connectivity and dynamic image quality together in a compact design, the ColorWorks C4010 label printer enables your business to harness the power of communication through colour. This versatile label printer features high-performance PrecisionCore® technology and is engineered for reliability. It delivers crisp, photo-quality colour labels on demand at up to 1200 dpi resolution.

Alongside is the Epson ColorWorks C6510A, the highly dependable 8” commercial inkjet label printer covering the full spectrum of label sizes for enhanced productivity and versatility.

The final area in this formidable library of printing offerings comes in the form of Epson’s Document Solutions and Business Printers that are designed to increase efficiencies and productivity while helping SMBs and SMEs to lower their impact on the environment. This important area will feature and demonstrate Epson’s WorkForce Pro WF-C579R network MFP, WF-C879RTC workgroup printer and the Epson WorkForce Enterprise WF-C20600.

On stand G20, Epson will present applications printed on the ML-8000, the new standard in textile image qualityFor the first time in Australia at PacPrint 2022 on stand ...

June 14 2022

On stand G20, Epson will present applications printed on the ML-8000, the new standard in textile image quality

For the first time in Australia at PacPrint 2022 on stand G20, Epson Australia will present applications and samples on its new Monna Lisa ML-8000 direct-to-fabric textile printer - the new standard in textile image quality.

Monna Lisa ML-8000 textile printer

The ML-8000 is the new entry model in the Monna Lisa series with eight of the latest PrecisionCore printheads. The ML-8000 packs the power and performance of the latest world-class Epson inkjet printing and manufacturing technologies into a single package.

The Monna Lisa series combines performance and usability to meet the needs of the digital textile market for flexibility and sustainability. With its eight PrecisionCore printheads, the ML-8000 reaches typical print speed of 155 square metres per hour (600x600 dpi – 2 pass*1).

Monna Lisa ML-8000 textile printer

The ML-8000 is a next-generation digital textile printer with high print quality,

productivity, stable operation with minimal downtime, and allows easy operation for an affordable price, making it the ideal printer for companies looking to move into local, onshore digital printing and production.

Digital printing has become increasingly popular with fashion and textile designers as they strive meet the increased demands for short runs and fast fashion while under pressure from public criticism to ease environmental burdens. The ability to deliver digital designs for digital print on demand enables businesses to offer their customers a faster turnaround without having to rely on mass shipments of stock crossing continents, much of which result in higher waste streams due to analogue printing.

The Monna Lisa ML-8000 is symbolic of the all-round quality of Epson’s digital print technology, blended with the uncompromising standards of fashion inspired by Epson’s print partner Robustelli and its rich history of textile design and manufacturing in Italy’s Como province.

The ML-8000’s superior image quality is enabled by Epson’s high quality printheads. Epson’s exclusive Microweave and lookup table (LUT) technologies reduce banding and graininess and advanced new Multi-Layer Halftone Technology (MLHT), which randomises the halftone dot pattern on each layer, reduces image degradation caused by dot misalignment. Dynamic Alignment Stabiliser (DAS) technology also ensures stable print quality by controlling waveforms on each printhead chip for higher dot placement accuracy and more uniform dot density on each pass.

The ML-8000 also features symmetrical colour alignment for consistent colour overlap order during bidirectional low pass printing, and Accurate Belt Position Control (ABPC) technology automatically detects the belt feeding distance to ensure highly precise fabric feeding. The result is optimal quality and speed, with superb reproduction of colour gradations, fine details and complex geometric patterns.

Stable operation with unprecedented usability is realised with the advanced cleaning mechanisms and automated adjustment functions. A fluff blower system removes fluff from the fabric surface before it enters the printing area and an ink mist extraction system helps prevent ink mist from adhering to the nozzle surface.

Nozzle verification technology (NVT) detects missing dots that indicate nozzle clogging and adjusts ink delivery to maintain image quality and reduce printing errors. An easy-to-replace fabric wiper roll continuously wipes the printhead nozzles clean automatically, reducing daily manual maintenance work. High accuracy of printhead alignment technology allows the user to replace the head quickly.

Thanks to an automatic calibration function by an RGB camera, operators can carry out printhead replacement including adjustments in as little as 30 minutes.

Epson’s Remote Monitoring System (24/7 monitoring) enables a quick response to potential problems, reducing downtime and service calls.

Ease of use is enhanced by a 9-inch LCD touch panel that displays current printer status, operating instructions, and regular maintenance procedures, and by hot-swappable, dual 10-litre or 3-litre high-capacity ink cartridges that allow uninterrupted production.

Epson GENESTA inks are available in Acid, Reactive, Disperse, and Pigment formulations in a degassed vacuum-pack. They are ECO PASSPORT certified to meet globally recognised standards for environmentally friendly textile printing. In addition, the Acid ink is bluesign® approved and the Reactive and Pigment inks are GOTS approved by ECOCERT.

ML-8000 Key Features:

- Printheads: eight Epson PrecisionCore printheads. The latest generation MicroTFP print chip combines quality, accuracy and speed.

- Productivity: typical print speed of 155 m2/hr (600x600 dpi – 2 pass*1)

- Maximum print speed: up to 250 m2/hr (300x600 dpi; 1 pass*2)

- Resolution: up to 1200 dpi.

- Width: 180 cm

- Ink colours: eight

- Ink types: Genesta Acid, Reactive, Disperse and Pigment. Genesta water-based inks allow precision and colour fastness in fabric prints. Genesta inks obtain the highest quality on any fabric type.

- Ink capacity: three or ten litres.

About F.lli Robustelli and For.Tex

The Monna Lisa project is the result of partnership between F.lli Robustelli for product engineering, For.Tex for inks development and Epson for Epson print technology.

Founded in Villa Guardia (Como, Italy) in the 1950s, F.lli Robustelli is a company100% owned by Epson Italia. They engineered the first digital textile printing machine on Epson print technology.

Established in Fino Mornasco, (Como, Italy), For.Tex is a company 100% owned by Epson Italia. For.Tex was chosen to develop the inks for Monna Lisa project and Genesta ink.

On stand G56, the SureColor V7000 will demonstrate how it combines superior image quality with enhanced production flexibility

For sign makers looking to produce UV output, Epson Australia will display its first-ever flatbed printer, the SureColor V7000, at PacPrint 2022 on stand G56.

SureColor V7000

The SureColor V7000 builds on the success of Epson’s award-winning SureColor S-Series range of signage printers, delivering flexible production with truly outstanding image quality and a reduced running cost.

Key features of the SC-V7000

The SC-V7000 has been designed to meet the needs of today’s signage businesses with flexible high-quality production and a reduced total cost of ownership (TCO). It will print on a wide range of substrates including paper, film, CorefluteTM, vinyl, canvas, aluminium and acrylic. It produces image quality to suit the most exacting applications including signage, POS/POP, premium packaging, décor, custom cabinetry and even fine art.

This robust and versatile printer incorporates eight Epson MicroPiezo printheads. Each head features 1,440 microfine nozzles with variable size dots as small as 4 pl. Working in conjunction with a new 10 colour Ultrachrome UV ink set, it will produce images with a very wide gamut and surprisingly fine gradation, sufficient to satisfy the most demanding customers. White and Varnish can even be applied as spot colours for enhanced detail and finish.

SureColor V7000

The SC-V7000 offers a 1.25 m x 2.5 m print area that supports media up to 80 mm thick and 50 kg/m2. It features a vacuum system with four independently adjustable zones for flexible operation. Integrated layout pins and a height sensor on the head carriage enable easy media setting while an ioniser ensures reliable and consistent output. The print heads are mounted in a staggered array that enables up to three layers to be applied in a single pass (White + Colour + Varnish) for fast and efficient production.

Epson has ensured that the SureColor V7000 is cost-effective to install and efficient to run. It is supplied complete with Epson Edge Print RIP software and Flatbed Controller software. It can be managed from the desktop using Epson Edge Dashboard and supports Epson’s new Cloud Solution PORT service. Installation is included in the purchase price and it ships with on-site CoverPlus that can be extended out to five years. Unlike many printers of its type, Epson even includes periodic maintenance.[1]

The SureColor V7000 is available for purchase via authorised Epson resellers in Australia and New Zealand now.

June 07 2022

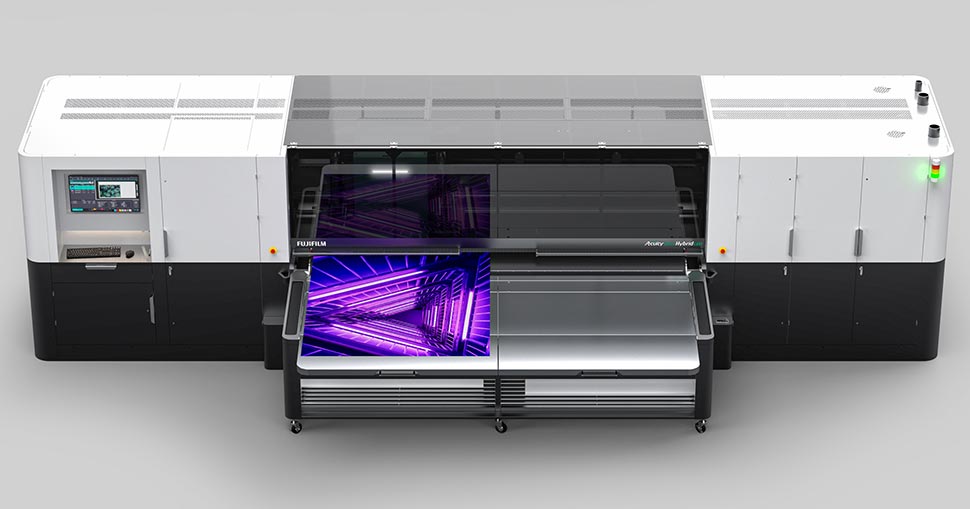

Fujifilm announces its entry into the high-end wide format hybrid market with the unveiling of the Acuity Ultra Hybrid LED at FESPA 2022. The machine, which will be commercially available from the autumn, is making its first public appearance on the Fujifilm stand (C30, Hall 2.2) at FESPA 2022.

Part of Fujifilm’s ‘Blueprint’ concept, the Acuity Ultra Hybrid LED is a 3.3m high-end printer that offers superb, high quality printing to both rigid and flexible substrates. Printing at speeds of up to 218 m²/hr (RTR), and delivering a print resolution of up to 1200 x 1200 dpi, the Acuity Ultra Hybrid LED is unique in being able to combine ultra-high quality and a competitive return on investment, for both rigid and flexible applications, all in one platform.

It is engineered with the operator in mind and designed with specialist inks to support the printing of exceptional near-photographic interior graphics and the high-speed printing of banners and PVC signage.

Along with media loading and unloading tables, the Acuity Ultra Hybrid LED also features a dimpled table surface to support all media types while allowing easy media positioning. A robust catch mechanism protects against accidental damage, and secure locking allows for media feed accuracy throughout every print run.

The GUI features the same exceptional design features found on the Acuity Ultra R2 and includes additional functionality to handle rigid media production – up to six sheets simultaneously.

An intelligent vacuum control system automatically turns on the correct vacuum zones needed for any print job based on the width of the media, and the vacuum motor power constantly adjusts to maintain optimal media hold down, regardless of media type and size, ensuring an accurate and high quality print finish.

For maximum flexibility when printing roll-to-roll, a bespoke designed airshaft allows dual roll functionality, so two media rolls of different diameters (each up to 36cm) can run at the same time.

Fujifilm has created an entirely new ink range, Uvijet UH, especially for the new machine, with six colours (CMYK, Lm, Lc) available as standard and white ink also available as an optional extra. The new ink has both Greenguard Gold and AgBB certification.

Uvijet UH has been carefully designed to adhere to a broad range of rigid and flexible substrates, while also matching the exceptionally high quality of the Uvijet GS and AU inks used in the Acuity Ultra R2. The machine and the ink have both been designed by Fujifilm and they work together to maximise quality while also minimising ink usage, helping to keep running costs down and boosting ROI.

Kevin Jenner, European Marketing Manager, Fujifilm Wide format Inkjet Systems says: “Our ‘new blueprint for wide format’, announced last year is our answer to industry demand for greater flexibility, ease-of-use and better ROI. Our all-new Fujifilm Acuity range, built to that new blueprint concept, has been designed to offer exceptional performance and unbeatable value, and the Acuity Ultra Hybrid LED is the latest evidence of Fujifilm’s commitment to the continued development of this range to meet changing market needs. Fujifilm has combined its expertise, built up over decades developing exceptional flatbed and roll-to-roll platforms, to design a new wide format hybrid platform that will set a new standard in price and performance and offer exceptional versatility and ROI.”

June 07 2022

At Fespa 2022 in Berlin, swissQprint dropped a surprise by unveiling a completely new model: the Kudu high-end flatbed printer, featuring an impressive combination of high productivity and first-class output quality.

Kudu high-end flatbed printer swissQprint

In a totally unexpected move, swissQprint unveiled a new printer model at Fespa 2022 in Berlin: Kudu is a 3.2×2 metre high-end UV LED printer that complements the existing flatbed range – Nyala, Impala and Oryx. Like the 4th generation of this trio, which swissQprint launched only six months ago, Kudu operates at a redefined standard of quality. It is also highly productive and offers ten colour channels (nine on the other models).

Top-rank output and quality

At its maximum productivity of 300 square metres per hour, the UV printer delivers convincingly high output quality. Carmen Eicher, Chief of Sales and Marketing Officer at swissQprint, explains: “Kudu incorporates the latest print head technology, with an addressable resolution of up to 1350 dpi.”

New mechanics and software

The flatbed printer stands on a newly designed mechanical foundation and operates using the latest linear drives. “This ensures precise droplet placement at such high speeds”, adds Carmen Eicher. Kudu features the Tip Switch vacuum, like the other flatbed and roll to roll printers from swissQprint. In the case of Kudu, it is divided into 260 zones, which gives the operator very simple and selective control of the vacuum. And speaking of control: Lory, the output software developed in-house by swissQprint, is the Kudu operator’s cockpit. The graphical user interface with its virtual flatbed is designed for intuitive and safe operation.

3.2 m roll to roll option and ten colour channels

Kudu, like all swissQprint flatbed printers, is expandable with a roll to roll option. It is the first swissQprint model to feature ten colour channels, which further increases application diversity. Users configure the channels according to their needs, and may adapt the configuration at any time later. The newly developed universal ink (Greenguard Gold certified) is available in CMYK, light cyan, light magenta, light black, white, effect varnish and primer as well as the spot colours orange and neon yellow and pink – a swissQprint exclusive.

June 07 2022

swissQprint presents a new total solution for UV flatbed printing on glass, comprising the glass option and an adhesion-optimised ink set.

Individually printed glass elements are all the rage in interior design: for kitchen splashbacks, shower and room partitions, glass doors, lift cabin panelling, wall art, etc. For those already providing such services – and others with plans to do so – swissQprint has put together an interesting package: a mechanical solution for an efficient, clean process, supplemented by an ink set for optimum adhesion.

Glass option for an efficient and clean process

A pivoting alignment edge with five stepless adjustable horizontal stops ensures precise positioning of glass panels on the print bed. The latter is covered by special protective paper that is air-permeable. So the vacuum holds down the media but the paper retains ink printed in the bleed margin. The print bed stays clean, and with the roll to roll option the operator advances the paper at the touch of a button. This means short set-up times between jobs.

Inks that adhere without primer

The ink set optimised for glass printing includes process and light colours, as well as white and effect varnish. A bonding agent is unnecessary, which eliminates one process step. The varnish is used for finishing, for example to produce partial frosted glass or gloss effects.

With the new solution, both newcomers and existing swissQprint users can pick up on the trend and specialise in direct printing on glass. The glass option and inks are retrofittable to swissQprint LED printers. Thus, swissQprint once again delivers on its promise to continue offering users new perspectives. Without major new investment.

Further information: T +41 71 727 05 05 office@swissqprint.com www.swissqprint.com

Epson will be debuting their new production-class, SureColor T7760D dual-roll technical printer for the first time, alongside their latest large-format and document printers, on stand G3...

May 31 2022

Epson will be debuting their new production-class, SureColor T7760D dual-roll technical printer for the first time, alongside their latest large-format and document printers, on stand G34 at Sydney Build 2022 - Australia's leading construction, architecture and infrastructure expo.

New SureColor T7760D dual-roll printer

The SureColor T7760D combines an extremely compact footprint with flexible media handling and a high print speed. It is designed for companies who want to produce large-format colour drawings and posters in moderate to high volume. The SureColor T7760D is particularly suited to construction, retail and print-4-pay applications. It uses 6 inks that come in large cost-effective cartridges with an additional red to enhance the colour gamut. Integrated high-speed hardware-based Postscript® enables fast and accurate image reproduction via drag-n-drop from the desktop or direct from a USB device. The SureColor T7760D features dual-roll support with the second roll also able to be used as an auto take up. There is also an integrated pull-out media bin and an optional flat sheet stacker.

The T7760D is targeted to be released in Australia in July, so visitors to Sydney Build will be the first to see this new generation production-class SureColor T-Series printer in the flesh.

Also on display will be the SureColor T5460M and the T3160M. Developed from the ground up, the SureColor T-Series models include Epson’s latest PrecisionCore printhead which provides outstanding image quality while enabling higher-speed performance than previous generation models. The SureColor T3160M compact industrial design provides a small footprint for space-constrained production environments.

SureColor T5460M

Attendees to the Epson stand at Sydney Build will also be able to see the Epson WorkForce Pro WF-C879R workgroup printer in action on the stand. The WF-C879R enables offices to benefit from increased productivity of a local distributed fleet that required minimal intervention, while providing predictable print costs.

WorkForce Pro WF-C879R

The WF-C879R uses up to 94 percent1 less power than comparable colour laser printers thanks to Epson’s Heat-Free Technology. It not only lowers electricity costs but also requires fewer supplies to reduce the environmental impact.The simple printing process and high page yield ink reduces downtime, making businesses more efficient and productive.

1Epson saves up to 94% energy used while printing comparing the Epson WorkForce Pro WF-C878RTC model with 64 competitive laser devices in the Australian 21 to 44ppm A3 colour MFD segment as at 1 July 2021.

HP is delighted to announce the launch of The Print Hub, an interactive platform specifically developed to support HP Latex users and help them get the best out of their printers.

The Print Hub offers personalised content covering all topics related to HP Latex, allowing users to explore a wide range of exclusive and specialist information dedicated to the HP Latex range of print technology.

Customers – both existing and potential – can explore insightful and informative content such as webinars, videos and expertly written articles, as well as access in-depth technical information about HP Latex printers and the applications they can be used for.

Visitors will enjoy a personalised experience when browsing content on The Print Hub based on their navigation history and asset clicks. The ‘Recommended for You’ feature suggests content that may be of interest to each individual visitor, while the ‘Continue Watching’ option allows users to pick up from their last visit.

Another stand-out feature on the interactive platform is the ‘Printer Selection Tool’, whereby users can select certain criteria to help them identify the most suitable printer for their business and proposed applications.

In addition, visitors will have the opportunity to sign up for live broadcasting experiences of certain events that are happening – such as the upcoming FESPA Global Print Expo in Berlin – allowing those who cannot attend in person to access key information from the comfort of their office.

“From its beginnings, when it was branded ‘Possibility City’ and used as a means to replace physical shows during the pandemic, the interactive site showed great promise. The HP Large Format team soon realised that the platform was fast becoming an essential – and 24/7 accessible – resource for customers wanting to research and explore content and learn about HP’s offerings in the Latex technology space,” says Isabella Jelinek, Large Format Marketing Manager UK&I at HP.

“Subsequently, we optimised and improved the platform’s functionality. We added more content to offer customers a rich, personalised experience, curated with exactly what they want to read, see and do – all in one place – and The Print Hub was born.”

April 11 2022

Kornit Digital Ltd. (“Kornit”), a worldwide market leader in sustainable, on-demand digital fashionx and textile production, introduced its distinctive Kornit Atlas MAX Poly system – an industry-first direct-to-garment (DTG) solution delivering superior-quality digital decoration for vibrant, colourful design on polyester and poly-blended apparel.

Kornit’s Atlas MAX Poly capitalises on the demand for fashionable, unique sportswear and apparel. As the industry emerges from a post-pandemic environment in which athletic and leisurewear became mainstream, there is increasing demand for apparel combining polyester and poly-blends with vivid designs across a range of colours. Atlas MAX Poly can transform the multi-billion-dollar professional and recreational sports apparel and teamwear markets, limited today by limitations in mass customisation of polyester.

“Kornit Atlas MAX Poly is a game-changer,” said Omer Kulka, Chief Marketing Officer at Kornit Digital. “As fashion and sports apparel merge, there’s new opportunity for innovative fashion on polyester, currently the fastest-growing textile vertical. For the first time, recreational sportswear, promotional, and sports brands can embrace vibrant and colourful design with Kornit’s proven MAX technology – setting superior quality standards for on-demand production previously not possible.”

Unveiled during Kornit Fashion Week Tel Aviv 2022, Atlas MAX Poly incorporates Kornit’s field-proven MAX technology for high-quality premium decoration, process automation, and smart autonomous quality control. With Kornit’s XDi decorative applications, Atlas MAX Poly enables endless designs and creativity on polyester, and empowers new styles for multiple effects and unlimited combinations such as emulating threadless embroidery, high-density vinyl, screen transfer emulations, and 3D effects.

The solution is compatible with mesh and plain fabrics, including brushed polyester, while maintaining durability and breathability. It brings the highest throughput for on-demand polyester decoration, reducing total cost of ownership to drive profitability. Customers gain competitive advantage via Pantone colour-matching and a wide colour gamut including neon colours for bright and vibrant impressions, using single-step mechanisms minimising production footprints while maximising versatility.

Beyond superior quality, graphics, colour, and application variety, Kornit Atlas MAX Poly offers efficient, reliable, profitable end-to-end polyester production via:

Kornit Atlas MAX Poly is successfully deployed across four global beta customer sites with expected availability in 2Q22. Click here to view Kornit MAX technology in action.

Mutoh Industries announced the launch of their new 54”/1,371mm wide water-based inkjet printer, “XpertJet 1341WR Pro” from the MUTOH XpertJet series which delivers excellent print quality and high productivity. In a compact body with a space-saving design that’s easy to handle, equipped with MUTOH’s latest unique technologies, the XpertJet 1341WR Pro is designed for high image quality and user convenience.

Dye-sublimation transfer ink to be paired with is MUTOH original "DH 21" ink, which provides superior media transfer and achieves high-density colours with less ink consumption. The fast ink drying enables printings on thinner/lighter transfer papers, and excellent jetting performance and colour stability provide high-quality output.

The XpertJet 1341WR Pro is an ideal printer for trade show graphics, flags, banners, custom interior design, apparel, custom merchandise and more.

The XpertJet Pro series achieves both high image quality and high productivity by combining the newly developed "AccuFine" print head and the new print effect "i-screen".

The “AccuFine” extra wide and high-density piezo print head delivers the best-in-class ink drop placement accuracy and achieves both high-speed printing and high image quality. The “AccuFine” can produce high-quality solid printing with less banding, even at high speed.

The new print effect “i-screen”, created from MUTOH’s "Intelligent Interweave" printing technology, optimises the new print head "AccuFine", reducing banding for smoother print images.

Other key features of the XpertJet 1341WR Pro are as follows:

Bi-Directional adjustment “DropMaster2”, a built-in sensor on the carriage which automatically calibrates bi-directional alignments, saving time and reduces validation in adjustment among different operators.

The Media feed adjustment “FEED MASTER”, which automatically performs paper feed correction by printing a pattern that is read with a sensor.

Nozzle selection function “Nozzle Area Select”, which temporarily prints using selected areas of active nozzles when clogged nozzles fail to recover.

Media roll balance management “Media tracker”, that manages the remaining media by printing barcodes before removing roll in use. It will read the barcode when reloading that roll and streamlines management of remaining capacity for multiple media.

Three head height settings, allowing the optimal print head height to be selected from 3 stages depending on the media being used. This reduces the risk of contact, and also provides stable print quality.

Partial pressure cancel mechanism, In order to prevent cockling, the pressure rollers can be individually cancelled to finely adjust the pressure applied to the media. A wide range of media types can be fed under optimal conditions.

MUTOH Status Monitor (MSM) enables checking the printer’s operation status in real time.

Paired with MUTOH original dye-sublimation ink “DH21” : Ink cartridges of 220ml and ink bags of 1,000ml are available for each colour of CMYK. Selection can be made according to the application and business situation.

March 15 2022

Xante is pleased to announce the latest addition to its UV flatbed printer lineup, the Xante X-98. The X-98 takes Xante’s proven UV print technology to the next level with a larger bed size (55″ x 98″), doubling the size of their other flatbed UV products. Utilizing up to four Epson i3200 four-channel printheads, the CMYKW X-98 prints in bold, vibrant color on virtually any rigid media including wood, glass, stone, metal, acrylic, coroplast, and more. This new offering is powered by the award winning iQueue Adobe PostScript/PDF workflow software.

The X-98 UV flatbed printer will quickly produce full-color 4’x 8′ signage, decorative items, personalized awards, or unique promotional items in minutes. With a bed size of 55″ x 98″, customers will be able to simultaneously print up to 12 18″x24″ signs, dramatically increasing speed and efficiency of production. With Xante’s iQueue Adobe PostScript/PDF workflow, customers can now achieve magnificent multi-panel wall art, accurately manage spot colors, control print quality, create multi-up imposed layouts, and much more.

With adjustable print head height up to three inches, and resolutions up to 2880 DPI, the X-98 will allow for printing on a wide array of media with amazing speed and image quality. Printing on dark substrates, or clear material, is also simple using the white option controls embedded within iQueue Workflow. Users have the option where, when, and how white ink is applied. The standard X-98 configuration will contain two Epson i3200 printheads at an economical price of $74,995 and a four-printhead configuration is $79,995 for environments where high speed and production are critical.

“The Xante X-98 demonstrates our commitment to the continued expansion of our outstanding flatbed UV printer lineup. The world of print has changed and Xante is investing in the new reality of print.” stated Robert Ross, CEO and President at Xante. Xante UV High-Density inks for the X-98, and for all Xante UV printers, are sold in economical half-liter bottles. These inks provide incredible outdoor durability and amazing color quality.

The Xante X-98 is currently in full production and ready to ship.

Mimaki announced the simultaneous worldwide release of large format inkjet printers,

March 01 2022

Mimaki announced the simultaneous worldwide release of large format inkjet printers, "330 Series".

Since the world's first eco-solvent inkjet printer, "JV3-130S/160" was introduced to the market in 2002, we have been leading the industry by introducing printers with new values, always focusing on "something New, something Different" to meet customers' needs for high image quality and quick delivery.

With the catch copy, "Give your creativity a Glow up", in pursuit of new value, we designed and developed the casing of these products from the ground up, with bringing together the technological expertise we have accumulated over the past 20 years for the newly announcing " JV330-130/160" and "CJV330-130/160" of large format inkjet printer. And the "330 Series" will make an appearance in the market as new models bearing the "3", which has been really loved from the customers engaged in sign graphic industry.

JV330-130/-160 and CJV330-130/-160 are added to the line-up of the entry model "100 Series" and the standard model "300 Series" as middle and high-end models to meet the needs of customers. In addition to its impressive image quality and high productivity, the high value-added functions are mounted to assist customers in saving work and labor.

The 330 Series have newly the "Mimaki Weaving Dot Technology (MWDT)", a printing technology that changes the order of ink droplet placement depending on the printing conditions. It suppresses unexpected occurrence of streaks or unevenness of printing caused by slight individual differences in the print head or subtle deviations in adjustment.

We have also released a new input profile "Deep Colour Natural", a standard format for colour management. It makes full use of the wide colour gamut of the market-proven "SS21", our eco-solvent ink and reproduces fully vivid solid colour*1 expression, natural gray tone, and natural skin tone, which were difficult to coexist in the past.

Printing speed is 21.0m2/h in standard mode with 4 colour (C, M, Y, K), and 13.2m2/h with 8 colours (C, M, Y, K, Lc, Lm, Lk, Or), of high productivity. As befits our flagship model, it promotes work efficiency with high image quality and high productivity.

The "XY slitter" and the "Media changer" are two high value-added functions that assist in your saving work and labor. The XY slitter has an in-line function that cuts all sides of the media after printing, enabling automatic slit processing without the need of taking-out media. This will significantly shorten the post-process work and reduce the space required for the cutting work that used to be done manually.

And the Media Changer accommodates up to three rolls of media to be able to change by simply turning the handle with light force. The Media changer reduces the time and effort required to change media, contributing to a more efficient work environment.

In addition, these new models are compatible with "Mimaki Remote Access (MRA)", which allows you to remotely operate the machine and check its operation status from your smart phone*2 or PC, if inside a LAN environment of the same segment. Operation of the printer without worry even from a remote location provides you with a desirable work environment.

As the other new mechanism, there are an ink supply unit that enables agitation of large-capacity 2L ink packs without removing them from the unit, and the drive motor, which was conventionally mounted on only one side, is now mounted on both the left and right sides of the media winder for more stable winding. These new designs ensure uninterrupted long-hour operation.

Furthermore, Mimaki Advanced Pass System 4 (MAPS4)*3, Nozzle Check Unit (NCU)*4, Nozzle Recovery System (NRS)*5, and Dot Adjustment System (DAS)*6 have inherited our printing functions for supporting a stable operation. Focusing large indoor and outdoor signage and graphic market, the new models are equipped with "JV330 Series" only for printing function and "CJV330 Series" having print & cut functions each with the lineup of -130 (maximum media width of 1,361 mm) and -160 (maximum media width of 1,610 mm) to be released in April 2022.

With "something New, something Different" as our management vision, Mimaki Engineering will continue to pursue new technological innovations constantly and to realise the "beauty and speed" that our customers demand.

Mimaki announced the release of large format inkjet printers

March 01 2022

Mimaki announced the release of large format inkjet printers TS330-1600 sublimation transfer inkjet printer

We have been leading the industry by introducing printers with new values, always focusing on "something New, something Different" to meet customers' needs for high image quality and quick delivery.

With the catch copy, "Give your creativity a Glow up", "TS330-1600" is our newly releasing large format inkjet printer of which casing was designed and developed from the ground up, by bringing together the technological expertise of Mimaki’s accumulation over the past 20 years.

TS330-1600 is a sublimation transfer inkjet printer that enables high production with high image quality suitable for a flagship model and is equipped with new functions to improve stable operation and pursues work and labor saving for customers.

The "Mimaki Weaving Dot Technology (MWDT)" a printing technology is newly installed, and it changes the order of ink droplet placement depending on printing conditions. This new technology suppresses unexpected occurrence of streaks or unevenness of printing caused by slight individual differences in the print head or subtle deviations in adjustment to produce both the best solid print*1 quality in our company's history and the beautiful printing quality.

Printing speed of 69m2/h in Draft mode (600x600 dpi, 2Pass) with 4-colour ink set (Bl,M,Y,K) is achieved,

which is increased to about 138% of speed compared to our conventional model*2. In addition, MAPS4 (Mimaki Advanced Pass System 4) *3 reduces banding (horizontal stripes) during low passes.

Two optional units of the "10 kg ink tank unit" and the "Mini jumbo roll unit" that have been popular with our other models*4 are customised to be able to attach to TS330-1600.

The 10kg ink tank*5 of large capacity type can be installed to the "10kg ink tank supply unit"*6 to be able to significantly reduce running costs compared to the standard 2L ink pack apply. The "Mini jumbo roll unit "*6 is a feeding option that can be equipped with Mimaki VisionTM Jet-X Mini-162, our genuine transfer paper of approximately 2,500m length roll that have achieved low running costs.

With the lower running costs, these two optional units contribute to reducing downtime of ink and media replacement, as well as reduced workload for customers.

TS330-1600 adopts a new function to prevent conveyance misalignment in long length media winding. The drive motor for winding, which used to be mounted only on one side, is now mounted on both the left and right sides to distribute the load and strengthen the winding force. The "V-shape cut function" cuts the media into a V-shape, allowing the tape to be fixed at a single point straight against the paper core is added. Moreover the "Media edge guide" for assisting in media winding is downsized to make it easier for customers to attach and remove it by themselves.

Those new additional three functions and item can reduce human error and prevent media feeding misalignment.

Mimaki’s printing functions such as, NCU (Nozzle Check Unit)*7 , NRS (Nozzle Recovery System) *8, DAS (Dot Adjustment System)*9 are taken over to ensure stable operation for long-time printing.

New features to improve usability

As a new cleaning mechanism, a "cloth wiper" has been adopted to increase the removal rate of unwanted ink droplets adhering to the nozzle surface.

Compared to conventional "rubber wipers", the new wiper reduces ink splattering on the head station and improves maintainability and cleanliness. The maintenance space has been expanded, and LED lighting has been installed inside the main unit as standard, making it even easier to view and use.

"Mimaki Remote Access (MRA)", which allows you to operate the machine panel and confirm the operating status like error-check from a smartphone*10 or PC within the same segment LAN environment is applied to the new model. The operability of printer from a remote location without worry provides the work environment that customers require.

"Sb411" and "Sb410"*11 inks proven in the market are applied to TS330-1600

All colours of these environmentally friendly inks have acquired "ECO PASSPORT"*12, as an international certification of safety and security against chemical substances for dyes, pigments, auxiliaries, and finishing agents, that are used in the production of textile products.

Ink sets are available in 4, 6, 7, and 8 colours. Besides the basic colour of blue, magenta, yellow, and black for 4 colour ink set, there are light blue, light magenta, light black, fluorescent pink, and fluorescent yellow that are selectable among 6/7/8 colour ink sets to suit your work.

The print width corresponds to 1,600mm, which is frequently used in textile and apparel applications. TS330-1600 is compatible with two types of RIP software for printing,"RasterLink7", which is both easy to use and highly functional and,"TxLink4 Lite", which is suitable for textile printing, and either can be selected at the time of purchase.

With "something New, something Different" as our management vision, Mimaki Engineering will continue to strive as an innovator company to provide products that are close to our customers.

Mimaki announced the release of new cutting plotters in three sizes with different cuttable areas: "CG-60AR (cut...

March 01 2022

Mimaki announced the release of new cutting plotters in three sizes with different cuttable areas: "CG-60AR (cuttable area: 606 mm width)", "CG-100AR (cuttable area: 1,070 mm width)", and "CG-130AR (cuttable area: 1,370 mm width)".

For more than 30 years since 1988 of the release of the CG Series of high-accuracy cutting plotters for the signage industry we have been highly evaluated by customers around the world. As more jobs require shorter delivery times, we have received various requests such as speedy and accurate cutting of more diversified materials and beginner-friendly operability.

The "CG-AR series" to be released this time are the reasonably-priced latest cutting plotters of entry-model with improved usability, combining more advanced cutting performance and the ability to handle a wide range of cutting materials.

The highest cutting pressure in its class of 550g and a cutting speed 105% compared with our conventional product*1 have been achieved as the basic performance. By the increasing of 50 g of cutting pressure allowing the cutting of a wider range of materials, including PVC, fluorescent and reflective sheets, and rubber sheets. Also, CG-AR series are now capable of full cutting of cardboard. Using the dedicated optional products*2, they can produce high-quality cutouts from plain paper to cardboard, and an additional line-marking gauge enables a fold line making. These features help to create paper crafts and packages that could not be produced with the conventional models and expand not only the range of processable materials but also the range of applications.

We have also added a function that focuses on "usability" so that a variety of customers can use these products. Now that they support Windows plotter drivers, it will be easy to output data to the cutting plotter. You can send data directly from Microsoft Word, for example, without using design software such as Adobe Illustrator*3, to perform cutting. This allows you to cut and plot text and graphics easily, just like outputting them with a general office printer.*4

Moreover, support for "Mimaki Remote Access (MRA)" allows the operator to remotely use the machine and check its operation status. It would be possible through smartphone*5 or PC in the same segment network environment to operate the machine's panel, check errors, and operational status of cutting progress etc. By running a cutting plotter from a distance without worry, the customer is provided with their desired working environment.

Also, a feature "ID Cut function" newly applied in the entry-level model further improves usability. *6 This function is used to perform Print & Cut efficiently by cooperation with Mimaki printers. By reading the printed register mark with ID, the data contained in the ID is automatically cut. Data transmission from the PC is completed with one-time operation, and once you set the printed sheet on the cutting plotter, cutting is completed automatically. Though being an entry-level model, it has achieved a cost performance that even enables unattended operation.

This selectable "usability" not available in the previous series allows a wide range of customers to build an efficient output system.

This "CG-AR series" cutting plotter delivers overwhelming cost performance to further support your business as an entry-level model that is easy to use by both existing and new users of cutting plotters and goes beyond the normal functional limits. The product suitable for a wide range of applications such as car wrapping, wall decoration, paper crafting, and packaging, in addition to signage applications such as stickers, labels, POP, and signs will be released worldwide in April 2022.

With "Newness & Difference" as our management vision, Mimaki Engineering will continue to push forward as an innovative company creating new value for our customers.

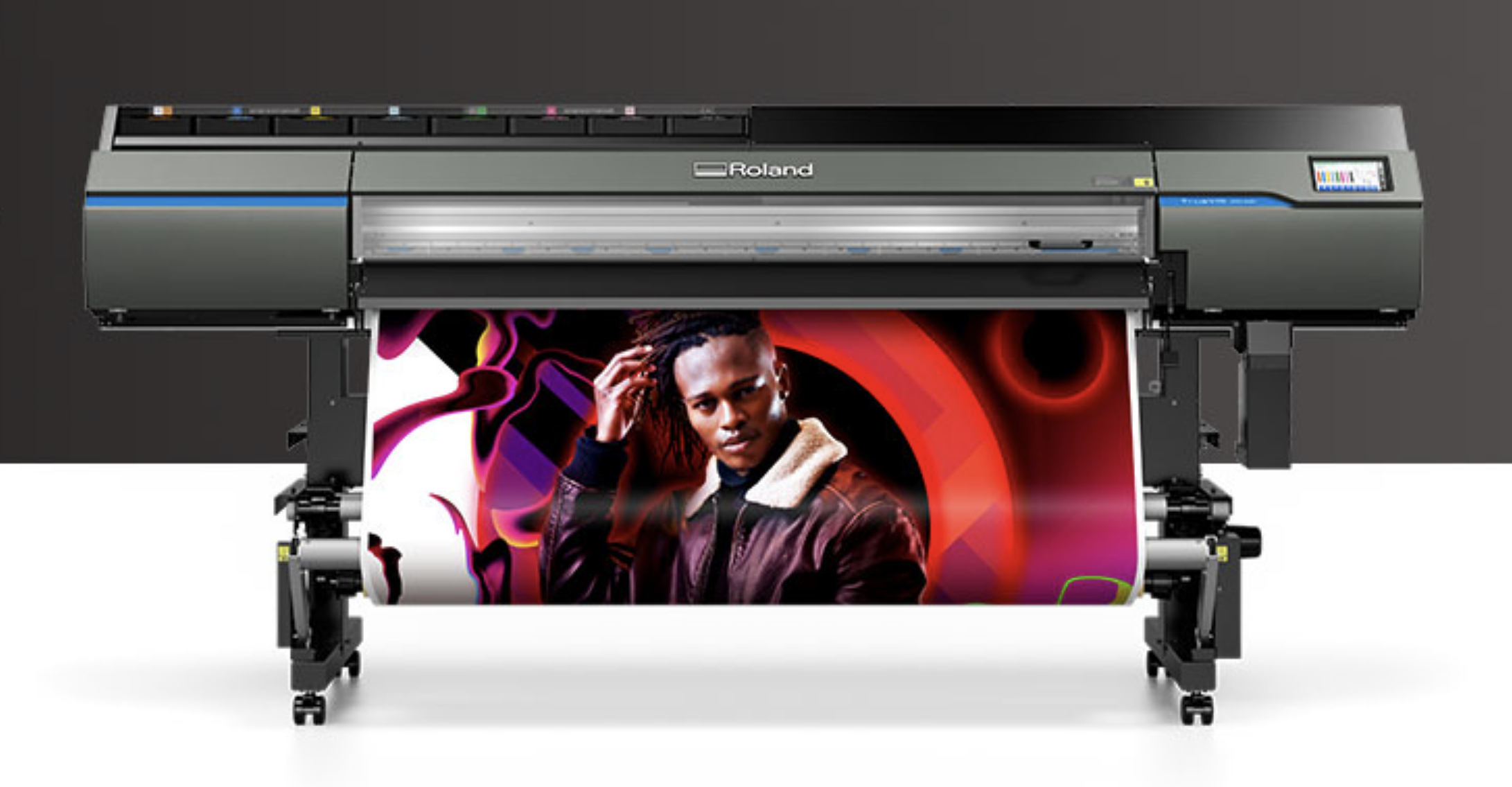

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, announced today the launch of its third generation of TrueVIS wide format inkjet printer cutters, including the professional flagship VG3-640 and VG3-540 models with up to eight ink colours and the value-packed SG3-540 and SG3-300 with four ink colours.

"Since its launch in 2016, we have focused on building upon our award-winning TrueVIS brand, to produce durable graphics with the extraordinary power to excite hearts and minds," said Tony Miller, President of Roland DG’s Global Sales and Marketing Division. "The combination of unparalleled colour, durability and ease of use has appealed to large numbers of digital print business owners, resulting in sales of more than 23,000 units." "Our exciting new products were developed based on user feedback, with the goal of making the performance of the next instalment of the renowned TrueVIS brand even more intelligent and user-friendly than before," Miller said. "After thoroughly reviewing the previous hardware design, we developed a new platform from scratch. The rigidity of the body has been increased by four times, and the dot shape and position of the ink droplets can be controlled more accurately and consistently than ever before. Taking TrueVIS' best image quality to the next level has resulted in the next generation standard of excellence for Roland DG." The flagship VG3 Series adopts a new eight-colour ink set of CMYKLcLmOrGr for unequalled colour matching and visual expression with a wider colour gamut using special Orange and Green inks, and smoother colours with reduced graininess using Light Cyan and Light Magenta. The new True Rich Color 3 preset optimises the potential of both superior colour reproduction of the printer and the wide colour gamut of TR2 inks to achieve a unique combination of vividness and natural appearance in a single graphic. According to Miller, the new TrueVIS was also designed to offer excellent usability without relying on operator proficiency. The new TrueVIS features an easy-to-read colour LCD touch panel for quick and easy access to check settings, get a real-time view of ink levels and media, and perform device commands. Both VG3 and SG3 models include a new media setting support function that reduces media skew for easier and more accurate media loading. TrueVIS also supports automatic media gap and feed compensation for a more stable, unattended workflow. The newly developed centre and side pinch rollers further optimise the pressure to hold the media in place, resulting in improved print and cut quality. For increased productivity and profitability, TrueVIS inkjets are designed to work with Roland DG Connect, a cloud-based app that provides numerous helpful functions by connecting your devices and sharing information. For example, based on the shared product information, you can achieve faster, more proactive support, view the status of various functions and machine up-time, easily calculate profitability, and quickly download media output profiles. This helps customers to reduce downtime, improve work efficiency and realise more efficient business operations. "The world is changing dramatically," Miller added. "We live in an era where special experiences are required to excite people so print producers are challenged to work more efficiently and creatively than ever. The VG3 and SG3 Series has been developed to create exceptional value for the future of the printing business and provide the finest image quality to as many customers as possible. Through the new TrueVIS, we are passionate about working together with our customers to open up new possibilities in the printing business." To find out more about the VG3 Series, go to: https://www.rolanddg.com.au/products/printers/truevis-vg3-series-printer-cutter To find out more about the SG3 Series, go to: https://www.rolanddg.com.au/products/printers/truevis-sg3-series-printer-cutter |

MUTOH Australia has released the new XpertJet 1341SR ‘Pro’ series printer. Based on the former long running VJ-1324X model, the new XpertJet 1341SR ‘Pro’ series has significant speed increases (up to 200%) plus the integration of 3 new key Mutoh technologies to enhance quality and production.

The new, larger ‘AccuFine’ print head, ‘i-screen’ and Mutoh’s new genuine rip software ‘VerteLith’ all combine to deliver high printing speeds, extremely accurate dot placement, smooth gradations, and an intuitive workflow via the simple to use, but powerful Mutoh VerteLith rip (which recently won the European Digital Press Association for workflow technology)

The MUTOH XpertJet series, which delivers excellent print quality and high productivity, now has a 54”/1.3m wide eco-solvent printer model perfectly balancing cost and performance. In a compact body that’s easy to handle, equipped with MUTOH's latest unique technologies, the XpertJet 1341SR Pro is paired with MUTOH's new eco-solvent ink "VJ-MS31" that excels in colour reproduction, weather resistance, and ease of maintenance. The ink has been certified UL GREENGUARD Gold, making it environmentally and operator friendly.

The XpertJet 1341SR Pro brings the best "Made in Japan Quality" to various markets such as banners, trade show graphics, indoor and outdoor signs, POP displays, vehicle wrap and more.

Stock is available in Australia now. For more information, please contact Mutoh Australia sales@mutoh-au.com or 02-9437 1366. To learn more about all of Mutoh’s award-winning products visit www.mutoh-au.com

February 08 2022

The new MUTOH ValueJet 1628MH hybrid printer combines upgraded features and new technologies designed to produce vibrant output with smoother gradations and a wide color gamut using MUTOH’s own VerteLith RIP software.

The VJ-1628MH is the most versatile printer on the market and offers the flexibility of printing on roll or rigid media using MP31 multi-purpose inks in up to 8 colors, including CMYKx2 and CMYKWhWh. A new built-in circulation system for white and magenta inks provides improved color stability and consistency while a new custom roller selection function offers diverse media compatibility and the ability to set each pressure roller independently for various types of substrates.

MUTOH’s new VerteLith RIP software is bundled with FlexiDESIGNER MUTOH Edition 21, a $2,199.00 value. VerteLith includes MUTOH Clear Tone and CMYK technologies, two preview functions and auto-generation of named Pantone spot colors. The VJ-1628MH outputs packaging prototypes, indoor/outdoor signage, banners, posters, and thermoforming prints easily and efficiently with high heat and stretch tolerance, and produces a smooth and natural finish, preserving the texture of the print substrates.

The VJ-1628MH is a direct replacement for the VJ-1627MH. Other model features include:

January 27 2022

The latest addition to Xante's UV flatbed printer lineup, the Xante X-55, takes Xante's proven UV print technology to the next level with a larger bed size (50x55”), and doubles the production speeds of its flatbed UV products. Based on up to four Epson i3200 four-channel printheads, the CMYKW X-55 prints in bold vibrant colour on virtually any rigid media including wood, glass, stone, metal, acrylic, coroplast and is powered by the award-winning iQueue Adobe Postscript/PDF workflow software.

The X-55 UV flatbed printer will quickly produce full colour signage, decorative items, personalised awards, or unique promotional items in minutes. With a bed size of 55x50” customers will be able to print up to six 18x24” signs simultaneously, dramatically increasing speed and efficiency of production. With Xante’s iQueue Adobe PDF workflow customers can now achieve magnificent multi-panel wall art, accurately manage spot colours, control print quality, create multi-up imposed layouts and much more.

With adjustable print head height up to 3” and resolutions up to 2,880 DPI, the X-55 will allow for printing on a wide array of media with amazing speed and image quality. Printing on dark substrates or clear material is also simple using the white option controls embedded within iQueue Workflow. Users have the option where, when and how white ink is applied. While the bed size and imaging area are large, the footprint is still compact with a footprint of only 7.5’x7.5’ allowing shops of almost any size to add X-55. The standard X-55 configuration will contain two Epson i3200 Printheads at a economical price of $59,995 and a four printhead configuration is $64,995 for environments where high speed and production are critical.

“The Xante X-55 demonstrates our commitment to the continued expansion of our outstanding flatbed UV Printer lineup. The world of print is changing and Xante is investing in that future,” stated Robert Ross, CEO and president of Xante.

Xante UV High Density inks for the X-55 and all of our UV printers are sold in economical 1/2 litre bottles. These inks provide outdoor durability and impressive colour quality. The Xante X-55 is currently in full production and customer installs begin in January 2022.

October 25 2021

Kornit Digital Ltd., a worldwide market leader in sustainable, on-demand, digital textile production technologies, announced today the release of its Kornit Presto MAX system for sustainable on-demand production of apparel and other textile goods.

The new system will make its live debut at Kornit Fashion Week Los Angeles + Industry 4.0 Event, which the company is hosting November 2-5 to showcase technology innovations, partnerships, and proven strategies driving the business case for sustainable, on-demand production of fashion and textile goods worldwide.

“Presto MAX will change the textile industry forever, transforming digital into the catalyst for modernizing the business, breaking the barriers between imagination and physical applications, connecting consumers and fulfillers on a global scale, and truly capitalizing on digital’s promise for delivering both sustainability and profitability, free of waste,” said Ronen Samuel, Kornit Digital Chief Executive Officer. “Whether your business is finished goods or ready-to-use custom fabrics, growing your own brand or supplying the world’s retailers and entrepreneurs, this technology represents the cutting edge of on-demand, unconstrained textile production, in terms of both capability, accessibility, and sustainability. Kornit empowers producers to create more with less, shrink their carbon footprint, and deliver unlimited expression while creating new opportunities and growth.”

Kornit launched its MAX technology in April, and is already field-proven via the Kornit Atlas MAX system, which is today supplying demanding global brands with the high retail quality and application variety needed to grow their product offerings and answer evolving consumers’ needs.

Kornit Presto MAX reflects the company’s commitment to expanding groundbreaking capabilities to all segments of the marketplace, building upon its continuously improving portfolio of technologies to accelerate and empower the industry’s transformation into a more responsive and responsible model.

Introducing never-before-seen capabilities to transform virtual concepts into brilliant custom fabrics for fashion, home décor, and other textile applications, Kornit Presto MAX is the first digital print system to offer white printing on colored fabrics, enhancing decoration capabilities for dark colored fabrics more broadly. It is the only single-step solution—and the most sustainable solution available—for direct-to-fabric printing, delivering the highest quality and softest feel with brilliant whites and brighter neon colors. The system is ready to incorporate future iterations and evolutions of XDi technology—3D decorative applications to produce threadless embroidery, high-density, vinyl, screen transfer, and other innovative effects.

Kornit Presto MAX is compatible with natural fabrics, synthetics, and blends, and includes advanced algorithms for smart autonomous calibration, to deliver high-quality results with short cycle times and minimal manual interruptions or defects. The system was devised for compatibility with the KornitX global fulfillment ecosystem to enable anywhere, anytime production, supporting a true distributed production model that fulfills nearer the end consumer, eliminating time and logistical waste from the experience while empowering brands to ensure quality and consistency across all systems and production sites.

Kornit Presto MAX provides the cornerstone of a smart, efficient, sustainable EcoFactory that empowers producers to cover and integrate more parts of the process, from design to finished product, to decrease their carbon footprint, use minimum manpower, and generate less waste. This means eliminating excessive time, labor, and shipping throughout the value chain, enabling proximity production to meet the accelerated demands of a web-driven global marketplace—revealing new sales channels and clever business models to grow the business long-term.

Efficient, high-quality, versatile digital inkjet solutions can be key to helping display graphics providers drive profitability and capture new growth opportunities. Electronics For Imaging, Inc. is working closely with those providers, presenting them innovative solutions that can drive their display graphics business forward faster in an economic recovery. This week, dozens of EFI™ customers, prospects and industry media and analysts are attending a series of EFI Ignition open house events that deliver a more-comprehensive view of growth opportunities display graphics providers can capture.

The events – one-day invitation-only presentations and demonstrations at the EFI Global Inkjet Innovation Center in Londonderry, New Hampshire – highlight the ways print providers can take their businesses to new heights by leveraging leading-edge production solutions.

“The pandemic has understandably forced the cancellation or postponement of several large tradeshows that would have served as launch events for these products, but that does not diminish our customers’ need for continued advancement and innovation,” said Ken Hanulec, vice president of Worldwide Marketing, EFI. “Our conversations with customers at this week’s Ignition event will give a strong representation of the market opportunities display graphics businesses have for success in a recovering market using our leading portfolio of innovative solutions.”

This week’s events highlight new product launches and a range of topic areas that address specific display graphics challenges and opportunities. New product launches and presentation topics include: