October 19 2021

Direct To Film (DTF) printing has been around for longer than you might think, although it’s only very recently that it’s started to gather more traction and pique the interest of garment producers both in the UK & Ireland as well as further afield.

For a long time, Direct To Garment (DTG) has been the ‘go to’ solution for those looking to print onto a wide variety of garment types and colours, but now there’s a viable alternative. Utilising white ink technology, without the need for pre-treatment, DTF offers users the capability to print onto almost any fabric type or colour with ease. Furthermore, the durable ink technology means that there’s no cracking, even on stretch materials, with high wash and rub resistance. All of that in an affordable package with ultra-low running costs.

At R A Smart (CAD & Machinery) our reputation as suppliers of premium quality textile printing solutions is supported by our selection of industry leading equipment. We take our product selection very seriously and only partner with the best manufacturers that produce high-quality machines and our DTF solution is no different.

Following extensive in-house testing we’ve partnered with a pioneering producer of the entire DTF package, with patented ink and application technology developed over the past 4 years. We’re excited to bring this revolutionary solution into the market as the exclusive distributor for the UK & Ireland. Our demo unit is fully up & running at our Cheshire based facility for customers to visit, produce samples and see this amazing technology firsthand.

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, today announced the BN-20A, a new, lower-cost addition to its VersaSTUDIO series of desktop inkjet printer cutters.

October 12 2021

swissQprint is launching a new series of models this October. The core of the new flatbed printers is cutting-edge print head technology along with advanced mechanical features that promise a quantum leap for users – especially when it comes to output quality.

swissQprint large format printers are renowned for their top quality – in terms of design as well as printing results. The Swiss manufacturer has redefined its standards and is now launching its flatbed generation 4.

Enhanced quality, increased productivity

New print heads are the centrepiece of the new generation. Maximum resolution of 1350 dpi and ultra-high-precision droplet placement significantly boost the print quality of the Impala and Nyala models. Both printers also benefit from an impressive increase in output for certain production print modes. The Oryx model is almost 40 percent faster than its predecessor, making it a truly outstanding entry-level printer.

Improved comfort and efficiency

swissQprint has incorporated various mechanical improvements into generation 4, singling out the Tip Switch Vacuum (patent pending) as a highlight. The table is divided into as many as 256 segments that users can quickly and easily switch on or off at the touch of a finger. This eliminates tedious and time-consuming masking – also in the gap between boards and dual rolls. Because there is no air leakage, the vacuum develops its full force and reliably holds down hard-to-handle media.

Modular configuration

The new range offers a host of options for individual configuration. Users can have their printer assembled exactly in line with what they require today. If their needs or requirements change, they can add a diverse range of options to the printer at any time.

The new flatbed generation from swissQprint is available for delivery via the company's worldwide distribution network as of now. Demonstrations can be arranged either face-to-face or via live streaming. swissQprint also offers a sampling service.

Further information:

swissQprint AG

Schützenwiese 8

CH-9451 Kriessern

T +41 71 727 05 05

F +41 71 727 05 06

office@swissqprint.com

October 12 2021

Xante’ is pleased to announce the introduction of its new Heavy White UV Ink for its X series of UV printers.

Current and future Xante’ X16/X33 users will be able to enjoy the new heavy pigment-loaded white ink for greater coverage, printing fewer layers and increasing production speed. For existing customers this change in white ink will be seamless and new customers will be able to take advantage of the increased production speeds.

Mark R. Priede, Vice President of Sales and Marketing, stated "Our customers are demanding greater production and flexibility. We are continuing to design new functionality for our current customers; the Heavy White ink will allow the customer to have greater coverage in a single pass. This will make them more efficient and increase overall productivity. We are always working hard to provide this for our current and future customers."

Xante’s Heavy White UV Ink is currently shipping and available. From a pricing standpoint, there will be no increase of price for this new ink technology. For more information on Xante’s Heavy White Ink or the X16/X33 please call 251-473-6502 or visit our website at www.xante.com.

Kornit’s first-ever impact report codifies brand vision of transforming the fashion industry with uncompromising eco-friendly production on demand: “These KPIs reflect Kornit’s co...

September 21 2021

Kornit’s first-ever impact report codifies brand vision of transforming the fashion industry with uncompromising eco-friendly production on demand: “These KPIs reflect Kornit’s core values, embedded into every aspect of our business,” says CEO Ronen Samuel.

Kornit Digital Ltd., a worldwide market leader in digital textile production technologies, today released its 2020 Impact and Environmental, Social, and Governance (“ESG”) Report. This inaugural report affirms Kornit’s commitment to achieving specific ESG goals. This includes the way Kornit conducts business, creates meaningful impact in local communities, and achieves environmental sustainability, in addition to how Kornit will continue to build a diverse and inclusive company culture, foster employee growth and development, and empower fair and safe labor practices globally.

“Our vision is to boldly transform the world of fashion and textiles for a better, more sustainable planet,” said Ronen Samuel, Kornit Digital’s Chief Executive Officer. “This report serves as our roadmap to achieving this vision.”

Mr. Samuel continued, “The fashion industry is unfortunately responsible for severe ecological damage, producing nearly 20% of global wastewater each year and over-producing an average of 30% as an integral part of its ‘normal’ course of doing business. We are laser-focused on changing that trajectory. Sustainability is top of mind at Kornit, in our spirit and in practice, every single day.”

In addition to enabling eco-friendly production processes with technology and consumables that use less water, reduce waste, and minimize the carbon footprint, Kornit technology solutions enable sustainable production on demand, which eliminates overproduction of apparel and other textile goods. A 2021 Life Cycle Assessment conducted on two flagship products, the Kornit Atlas MAX and Kornit Presto S, demonstrated that relative to traditional analog processes, Kornit’s digital production systems used up to 95% less water and 94% less energy, and produced up to 83% less greenhouse gas (GHG) emissions for the Presto S system and up to 93% less water and 66% less energy, and produced up to 82% less greenhouse gas (GHG) emissions for the Atlas MAX system.

Based on this study, in addition to past sustainability performance results and strategic projections for business growth and market expansion, by 2026 Kornit Digital’s sustainable on-demand solutions are expected to enable the production of approximately 2.5 billion apparel items in a responsible manner to deliver:

HP Inc. has introduced a range of DesignJet and PageWide XL Pro devices to equip large format print users with the technology to navigate and thrive in the new normal. The portfolios a...

September 21 2021

HP Inc. has introduced a range of DesignJet and PageWide XL Pro devices to equip large format print users with the technology to navigate and thrive in the new normal.

The portfolios also deliver advanced photo and colour quality, enhanced precision, and new graphics application potential - all while driving improvements in sustainability.

With the two new HP DesignJet Z Pro devices, HP is offering print service providers (PSPs) and Geographic Information System (GIS) analysts the latest solutions to produce professional photo-quality prints and high precision colourful GIS-generated maps. Meanwhile, the three new HP PageWide XL Pro printers equip PSPs and reprohouses with the ability to respond faster to customer demands and diversify their existing capabilities.

“As our customers continue to grapple with uncertain business conditions following a uniquely challenging past couple of years, we know that expanding their print application reach, an ability to move fast, and outstanding colour and graphics performance define their large format printing needs”, said Daniel Martinez, General Manager, Large Format Business, HP. “This is why we’re introducing the new HP DesignJet Z Pro and HP PageWide XL Pro series. Both portfolios are designed to help users navigate uncertain demand, respond to tighter deadlines and unlock untapped potential in their own offerings.”

Highest colour quality with HP DesignJet

Marking the 30-year anniversary of the very first DesignJet product, the new HP DesignJet Z6 Pro and Z9+ Pro offer PSPs and GIS analysts respectively the highest professional photo quality and precision, along with leading security features.

Thanks to the chromatic RGB HP Vivid Photo Inks, HP DesignJet Z Pro users can now achieve 93% pantone coverage – 26% more gamut compared to the previous generation – and produce prints with the image quality of a 12-ink printer with just nine inks. Additional features such as the High-Definition Nozzle Architecture (HDNA) printheads and dual drop technology, which reduces visible grain and eliminates the need for light coloured inks, promise prints with clear details and dazzling-contrasts.

The HP DesignJet Z9+ Pro, which offers the widest colour gamut in its category, is the perfect choice for PSPs looking for a professional photo quality printer. Users can customise ICC profiles for their print jobs and achieve desired colour accuracy and consistency. PSPs also have the option to include the HP Gloss Enhancer Upgrade Kit to produce superior gloss uniformity.

Additionally, the HP PrintOS mobile app lets PSPs take more control of their print operations – from monitoring performance and reacting to issues, to sharing media pre-sets remotely. For the first time, the new HP DesignJet Z Pro printer series also incorporates the HP PrintOS Service Center application. This smart cloud-based solution enables users to gain a single, real-time view of all ongoing service cases, with updates that are accessible anytime, anywhere.

For GIS analysts looking to produce very precise maps, print sharp contour lines and text with close attention to keeping data secure, the new HP DesignJet Z6 Pro is the ideal printer. The Adobe PDF Print Engine enables excellent transparencies and layer reproductions - while HP’s HDNA printheads and HP Pixel Control deliver the highest precision, as well as smooth gradients and distinct shades of colour that are particularly needed for printing complex maps.

HP DesignJet Z6 Pro is the world's most secure large-format printer, promising the best data protection through encrypted communications and Access Control List. Features such as HP Connection Inspector, HP Secure Boot, and Whitelisting ensure the best network protection, putting all worries about data security to rest.

Both the HP DesignJet Z6 Pro and Z9+ Pro also enhance efficiency with the fastest media handling, spindle-less and automatic roll feed. The HP DesignJet Z6 Pro prints twice as fast on plain paper at the same quality while the HP DesignJet Z9+ Pro allows users to print up to 18% faster, with better quality, on satin photo media - and 46% faster on canvas.

Maximise productivity with HP PageWide XL Pro

HP has also announced three new HP PageWide XL Pro printers that enable retail PSPs and reprohouses to respond faster to customer demands, meeting tighter deadlines. Additionally, users will also be able to leverage new short-term applications including the potential to print on boards, cardstock, and paper from A2 to B1, and thickness up to 10mm.

The new HP PageWide XL Pro 5200 and HP PageWide XL Pro 8200 offer print speeds up to 20 D/A1 pages/min, and 4300 ft2/hr (400 m2/hr) and 30 D/A1 pages/min, and 5300 ft2/hr (500 m2/hr) respectively, enabling users to meet short turnaround time. With the PageWide XL Pro 8200 able to print mixed outputs of both CAD drawings and presentation boards, both printers are also capable of delivering full projects two to three times faster than before. With the new HP PageWide XL Pro 5200 and HP PageWide XL Pro 8200, users can also expand their print applications into two-sided, short-term retail posters, which can be easily managed with HP SmartStream.

Designed to help boost profits and cut costs, both the HP PageWide XL Pro 5200 and the HP PageWide XL Pro 8200 enable users to save up to 50% preparation and finishing costs. Using up to three-litre Original HP Eco-Carton ink cartridges, both printers ensure low running costs for CAD drawings and posters. Features such as the versatile stacker, inline folders and auto switch free up operation time, giving reprohouses the power to say yes to more print jobs.

The compact HP PageWide XL Pro 10000 boosts productivity with fast printing speeds of up to 700 m2 (7500 ft2) or 1,000 B1 posters per hour, and can print on different sizes materials, including paper and boards to cardstock and cutsheets. It also provides PSPs with the capability to deliver quick results with instant-dry prints on compatible substrates. With HP PrintOS, PSPs can easily control the operations of their fleet anywhere, anytime – while also enjoying simplified maintenance and fast start-up. The HP PageWide XL Pro 10000 also features the first HP large-format auto sheet feeder and versatile stacker, providing seamless end-to-end cut-sheet workflow.

HP – a partner in sustainability

The new HP DesignJet portfolio and HP PageWide XL Pro 10000 printer are all rated as ENERGY STAR 3.0 compliant and EPEAT registered, meaning they use less energy and are certified as environmentally preferred products.

The new HP DesignJet Z Pro printers are made of 30% recycled plastic, using over eight 16.9-oz (0.5-L) bottles worth of ocean-bound plastic, and are fully compatible with large format FSC-certified papers, a range of recyclable HP media and free, convenient take-back program for certain HP media.

Both new portfolios are fully compatible with HP Eco Carton Cartridges, achieving up to 80% reduction in plastic. The outer carton of Eco-Carton cartridges can be disposed of through local cardboard recycling

Inks for the HP PageWide XL Pro 10000 printer are UL ECOLOGO Certified and verified for Nordic Swan Ecolabel printing companies.

HP PageWide XL and DesignJet prints are recyclable, returnable, or non-hazardous and safe for disposal.

The new HP PageWide XL Pro series is expected to be available in all major markets starting September 15th, and the new HP DesignJet Z6 Pro and Z9+ Pro on October 1st, 2021. Pricing information available locally.

Part of Xaar’s ImagineX platform, Ultra High Viscosity technology ensures Xaar’s printheads deliver high impact, productive and efficient results for volume digital label and packaging ...

September 14 2021

Part of Xaar’s ImagineX platform, Ultra High Viscosity technology ensures Xaar’s printheads deliver high impact, productive and efficient results for volume digital label and packaging printing applications.

Xaar, the leading inkjet printing technology group, says the advanced capabilities of its Ultra High Viscosity technology demonstrates the significant difference that inkjet printing can make to labels and packaging.

Part of Xaar’s ImagineX platform, Ultra High Viscosity technology ensures Xaar’s printheads deliver high impact, productive and efficient results for volume digital label and packaging printing applications.

By enabling an extended high colour gamut and fluids with larger particles and more pigment, colours are more vibrant and whites and blacks stronger – this unbeatable capability to print high opacity, especially whites, in a single pass is extremely useful for delivering impact on many labels and direct-to-shape packaging printing applications.

In addition, fluids, and inks with viscosities of up to 100 centipoises (cP) can be jetted in a single pass, further opening up opportunities for label and packaging printers to deliver new and exciting finishes for clients across a wider variety of packaging materials, with a high degree of efficiency and productivity.

Energy is also saved because UV fluids, which previously required heating to 45 degrees C before jetting, can now be laid down at room temperature. Overall, less fluid is required as well, making the process even more sustainable.

Further, high-build varnish embellishments can be achieved more easily, to add texture, visual impact, and functionality (such as ink that resists cracking on flexible surfaces) to labels and packaging. From braille and tactile warning triangles on labels, to the latest haptic effects for a high-end look and real shelf presence for rigid and flexible packaging, with Xaar’s Ultra High Viscosity technology results can be achieved that have traditionally only been possible by using screen printing.

Graham Tweedale, General Manager of Xaar’s printhead business unit, said; “We are already seeing how Ultra High Viscosity technology is opening up new possibilities for Xaar in a number of applications, particularly label and packaging.

“Whereas previously inkjet printheads have typically been only able to jet fluids of around 8 to 12 cP, our technologies enable printers to jet much higher viscosities, achieving a wider colour gamut and unparalleled opacity, and can be used to print an extensive range of special effects.

“In addition, after many years of requests from clients to be able to print higher molecular weight photopolymers to increase resistance and flexibility for printed materials, our Ultra High Viscosity technology has realised this capability, truly unleashing the power of inkjet.”

Ultra High Viscosity technology is available across many of Xaar’s printheads including the Xaar Nitrox, the 50x series, and Xaar 2002.

Mutoh Japan unveiled the XPJ-1642WR water based CMYK 64” (162 cm) digital inkjet printer. Manufactured and engineered in Japan and based on Mutoh’s new XpertJet printer pla...

September 07 2021

Mutoh Japan unveiled the XPJ-1642WR water based CMYK 64” (162 cm) digital inkjet printer.

Manufactured and engineered in Japan and based on Mutoh’s new XpertJet printer platform, the XpertJet 1642WR incorporates two new generation extra wide 1600 nozzle AccuFine print heads, installed in a staggered setup. The new heads will offer best-in-class drop placement accuracy. Combined with Mutoh’s new proprietary i-screen weaving technology – Mutoh’s fourth generation weaving algorithms - the new print heads will deliver exceptional print quality at high production speeds. The XpertJet 1642WR will deliver sellable high quality production speeds up to 61 m²/h. Top engine speed of the machine is 98 m²/h.

Targeted at the sublimation transfer market, the XpertJet 1642WR dye sublimation printer will deliver high quality graphics for transfer onto all possible flexible and rigid polyester materials: in-store textile décor graphics and displays, soft signage and graphics for events and trade shows, home decoration, flags and pennants, sports goods (snowboards, helmets), gadgets (mugs, umbrellas, mouse mats) and apparel (fast fashion, blouses, sportswear, outdoor jackets, T-shirts). The printer will also print directly onto closed coated polyester fabrics or mixed fibres.

To accommodate the widest range of dye sublimation papers, the printer has pressure rollers with adaptable pressure which can also be individually disabled. Four different head heights can be used, from 1.5 mm to 4 mm.

To facilitate uninterrupted volume production, the new 1642WR integrates an automatic nozzle check unit which will automatically detect missing nozzles and clean them. The machine can also be equipped with three different motorised take up systems of 30 kg, 40 kg and 100 kg. There is a front media drying unit and replaceable mist collection filters.

The new XpertJet 1642WR comes with Mutoh’s new generation DS3-series HC dye sublimation ink. HC stands for ‘Increased Colourant’ which means reduced ink consumption, faster drying and compatibility with lightweight papers.

The new inks come in degassed 1 kg pouches for reliable jetting, excellent image definition and sharpness.

The XPJ-1642WR integrates all known Mutoh XpertJet features, i.e. illuminated print platform, re-usable ink cases as well as an enhanced roll off system with new media feed flanges.

The new 1642WR combines existing and brand new Mutoh core technologies :

Following the lead of their international counterparts, Canon Production Printing Australia today announces the launch of the new Arizona 135 GT flatbed printer to the Australian market.

August 31 2021

Following the lead of their international counterparts, Canon Production Printing Australia today announces the launch of the new Arizona 135 GT flatbed printer to the Australian market.

The Arizona 135 GT provides an investment solution to assist lower volume print service providers to fulfil new business opportunities whilst accessing the proven benefits of the award-winning Arizona series.

Designed for outstanding productivity and application versatility, the easy-to-use Arizona 135 GT produces exceptional image quality. This is thanks to The Arizona VariaDot greyscale printing technology, which uses advanced drop size selection techniques to deliver photo-realistic images. With the ability to handle substrates of up to 125 x 250 cm in size and up to 50.8 mm thick and to print at speeds of up to 34.2 m2/hour, the Arizona 135 GT is a smart investment for new opportunities or as the second printer.

Craig Nethercott , Managing Director, Canon Production Printing Australia, comments, “The Arizona flatbed family has become renowned for its image quality, productivity, reliability and application versatility, winning multiple awards and resulting in over 7,500 installations worldwide. In bringing the Arizona 135 GT to market, we’re looking to make the ideal flatbed platform for printing multiple applications on both rigid and flexible media available the Display Graphics & Signage market. As the latest member of the fifth generation of Arizona printers, the Arizona 135 GT offers users the same core technology and benefits of its mid-volume siblings at an attractive investment level and we’re confident that it will again prove to be as popular as its predecessors.”

The productivity of the Arizona 135 GT is enhanced by its easy-to-use functionality, including nesting, batching of complex jobs, step and repeat, mirroring and re-assignment of print modes. Accurate print registration avoids errors and the ability to make last-minute adjustments at the printer saves valuable time. With uptime being crucial to any print operation, the Arizona 135 GT incorporates a number of service features to maximise availability: Automated Maintenance System provides hands-free printhead maintenance and selectively restores nozzle function in seconds, while On Remote Service allows the user to authorise remote assistance by experienced service technicians, ensuring the highest possible uptime.

Access high-margin applications on huge media range

Thanks to Arizona flatbed technology and its UV-LED curing, a vast range of durable applications are achievable on rigid or flexible media with standard or porous surfaces, including glass, aluminium and other metals, canvas, wood, MDF, cardstock, ceramic tiles and plastics. The Arizona Static Suppression Kit also enables the Arizona 135 GT to print on hard plastic materials, such as acrylic, polycarbonate and styrene, while the Arizona Classic high-pressure vacuum system provides extremely reliable media hold- down during printing, even for warped rigid media. More opportunities are accessible with the flatbed printer’s field-upgradeable Roll Media Option. This allows users to produce flexible media applications up to 2.2m wide, including thin and heat-sensitive media, and to run roll-to-roll jobs unattended overnight.

Access new levels of creativity with Arizona Xpert prepress software

The Arizona 135 GT supports the Arizona Xpert prepress software, enabling the design and production of high-value applications with ease. Including ready-made recipes for easy-to-create applications, the software allows users to exchange recipes directly with customers, so that designers can preview the end product with a 3D view in the Arizona Xpert Extensions, minimising design errors. The Arizona approach to first-time-right printing leads to less waste and fewer costly mistakes which, in turn, leads to better overall margins and faster turnaround times. Arizona Xpert also offers further high-margin opportunities for textured surface prints – the ability to print applications with multiple ink layers.

Access a sustainable flatbed printing solution

The Arizona 135 GT’s VariaDot technology uses variable drop sizes from 6 to 30 picolitres. Not only does this produce pin-sharp images but it also means that the Arizona printing process consumes as much as 50% less ink than regular flatbed printers, making the Arizona 135 GT environmentally and economically attractive. The device’s environmental credentials also include the use of UL GREENGUARD Gold certified inks for any indoor applications, such as in schools, hospitals and retail stores – and the low emissions make for a healthier printing environment too. Additionally, the Arizona 135 GT features low-energy consumption as a result of its Instant-On functionality and minimal warm-up time thanks to its LED lamps. Other energy saving features include its standard voltage power supply, energy-efficient curing process and power-efficient vacuum pumps.

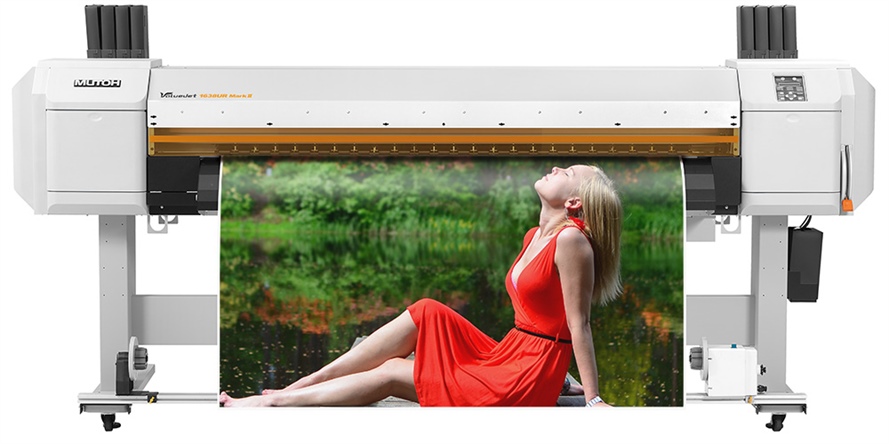

MUTOH has released the next generation of UV-LED printers, the hybrid VJ-1638UH Mark II and the roll-to-roll VJ-1638UR Mark II. MUTOH’s new VerteLith RIP comes as standard with t...

August 24 2021

MUTOH has released the next generation of UV-LED printers, the hybrid VJ-1638UH Mark II and the roll-to-roll VJ-1638UR Mark II.

MUTOH’s new VerteLith RIP comes as standard with the Mark II series to create dynamic output, producing the best-possible gradients, skin tones and vivid colours. Featuring i-WeaveUVEX 2 Intelligent Interweave Print Technology, MUTOH Clear Tone half tone technology, MUTOH CMYK wide colour gamut ICC profile and auto-generation of Pantone© coated/uncoated spot colours. Smart MUTOH technologies streamline workflow, increase productivity, and deliver high-quality output at faster production speeds

The VJ-1638UH/VJ-1638UR Mark II printers include:

- Staggered dual print heads with UV-LED lamps on both sides.

- MUTOH UV-LED inks, which allow printing on transparent/coloured media with a 6-colour CMYK+White+Varnish configuration or 2 x CMYK for faster output.

- Multi-layer printing capability

The VJ-1638UH Mark II is a hybrid printer with the capability to print on rigid substrates (up to 15mm thick) as well as roll media, while the VJ-1638UR Mark II prints on roll media only. A 30kg take-up system is standard on the VJ-1638UR Mark II. A 40kg take-up system is optional, as is a heavy-duty 100kg take-up. An optional 30kg take-up is available for the VJ-1638UH Mark II which can handle rigid media up to 15kg.

VerteLith includes several useful workflow tools which enhance the use of the Mark II series UV-LED printers. Features include auto-layout and print multi-page PDF functions at the click of a button and supports auto-generation of white and varnish inks to create rich, textured prints without complicated steps. Additionally, auto-generation of Pantone© coated/uncoated spot colours is a standard feature of VerteLith.

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, today launched Roland DG Connect, an app that allows users to gain a detailed understanding of their overa...

July 27 2021

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, today launched Roland DG Connect, an app that allows users to gain a detailed understanding of their overall print operations and access essential data for keeping their devices running at their optimum performance. Free to new and existing Roland DG owners, the new app is currently available for use with all TrueVIS™ series printers and printer cutters.

Roland DG Connect provides instant access to key performance data, and allows the user to monitor device activity and increase print production efficiency. The app features an easy-to-understand colour-coded dashboard that provides an instant view of statistics like ink usage per cartridge, while also showing a printing volume timeline for periods of up to 30 days. Additionally, it displays crucial information for optimising the health of your printer, such as print head manual cleaning frequency, wiper life status, and levels of liquid waste – data that helps keep your printer running in top condition, minimising downtime and maintenance. In addition, Roland DG Connect provides instant alerts that help you avoid any costly productivity issues, as well as notifications that let you know when firmware updates are needed or if inks are in need of replenishment. Colour-coded views make it simple to monitor ink consumption per cartridge, so you can effectively plan your ink usage and budget.

Users will also appreciate the helpful reporting and accessibility information the Roland DG Connect App offers. A built-in Job Log lets you review up to 30 days of print production on one or more connected devices, while an Error Log delivers machine alerts, including instant notifications on "feed motor errors" or "print finish activity."

Other Roland DG Connect features include easy access to product documentation, user guides, and support materials for Roland DG printers, plus a function that allows users to instantly view their device warranties and expiration dates for added peace of mind.

"At Roland DG Australia, we want to ensure that our customers not only have the highest quality printers available for their specific needs, but also cutting-edge tools that maximise performance and extend the life of their machines," said Greg Stone, Product and Marketing Manager at Roland DG Australia. "The new Roland DG Connect App allows Roland DG end users to monitor their printers in real time, keep them operating at the highest level, and take their production with them wherever they go."

Greg also points out that the Roland DG Connect App is dynamic and will grow more robust over time. "We will be enhancing the app continuously, incorporating additional features and functionality that will make life increasingly easier for users," he added.

TrueVIS owners can get started with Roland DG Connect by first registering online at the Roland DG Connect page, and then downloading the app, at the following link: https://www.rolanddg.com.au/products/software/roland-dg-connect-app

Following its recent launch of neon inks for UV printing, swissQprint now highlights the scope that these fluorescent colours open up. With just two inks, four striking colour variants are possible...

July 27 2021

Following its recent launch of neon inks for UV printing, swissQprint now highlights the scope that these fluorescent colours open up. With just two inks, four striking colour variants are possible – Yellow, Pink, Green and Orange.

Following its recent launch of neon inks for UV printing, swissQprint now highlights the scope that these fluorescent colours open up. With just two inks, four striking colour variants are possible – Yellow, Pink, Green and Orange – as well as countless applications.

Neon inks for UV printing are the latest craze in the swissQprint ink portfolio. The colours available: Neon Pink and Neon Yellow. They glow in daylight and are fluorescent in black light. And yet more colour variants are possible in the mix: Neon Green and Neon Orange. No matter what the message is, people are bound to notice it.

Theme worlds with a difference

swissQprint describes the application areas as follows: "Neon is ideal for event, exhibition, art and theme worlds, and it's the key to truly dazzling promotions." The range of potential indoor applications includes posters, ceiling hangers and POS displays, information and guidance systems, trade fair and event concepts including wristbands, safety notices or campaign signage, and more besides.

Can be retrofitted

Neon inks are available for all swissQprint flatbed and roll to roll printer models with UV-LED curing. They can be retrofitted at any time, especially as swissQprint systems have nine freely configurable colour channels. Advice and sales via the worldwide network of swissQprint dealers.

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, today announced the addition of the new GR2-640 and GR2-540 64” and 54” vinyl cutters t...

July 20 2021

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, today announced the addition of the new GR2-640 and GR2-540 64” and 54” vinyl cutters to its CAMM-1 series.

The CAMM-1 series is capable of cutting almost any shape quickly and cleanly from a broad range of sheet and film materials that range from thin automotive window films and heat-transfer sheets to thick reflective sheets and sandblast masks. Applications include signs, automotive window film, vehicle wraps, sports apparel and more. According to Kevin Shigenoya, Vice President, Digital Printing Business Division, “Our vinyl cutters are often used in combination with our large format inkjet printers for printing and then cutting colourful graphics into unique shapes for stickers, labels and various store decorations and, more recently, for making social distancing signs to assist with preventing the spread of COVID-19.”

The newly announced GR2-640 and GR2-540 are an ideal balance between affordable pricing and superior cutting performance, and are designed to integrate seamlessly with large format inkjet printers. With a maximum cutting speed of 1,530 mm/s, a maximum downforce of 600 gf and smooth media feeding, the GR2 Series achieves the precision cutting quality and high-volume productivity required by professional users.

One of the key features of the GR2 Series, according to Shigenoya, is that the cutters pair smoothly with Roland DG’s large format inkjet printers and use the same VersaWorks 6 RIP software for seamless Print-then-Cut production. Contour lines can be added and crop marks generated automatically to imported printing data in VersaWorks 6, to ensure the outlines of graphics are cut accurately, eliminating the need for users to switch back to Adobe® Illustrator®, CorelDRAW® or other graphics software to complete production. The GR2 Series features a multi-crop mark function for more accurate contour cutting of large print and cut jobs after lamination. It also includes the Roland DG AAS II plug-in software for pairing with other large format inkjet printers.

Shigenoya said, The GR2 Series combines quality and accuracy making it possible to produce unique and attractive applications efficiently and cost effectively.”

“There is fierce competition among sign making shops,” he added. “Roland DG is committed to contributing to the development of digital solutions and services aimed at helping our customers explore the bounds of their creativity.”

To find out more about the GR2 Series, click here.

Epson is expanding its range of PrecisionCore printheads to meet the accelerated shift towards digital printing in the commercial and industrial sectors. The D3000-A1R is the first in ...

July 13 2021

Epson is expanding its range of PrecisionCore printheads to meet the accelerated shift towards digital printing in the commercial and industrial sectors.

The D3000-A1R is the first in Epson’s new range of printheads that support ink circulation at nozzle level, which increases reliability by reducing nozzle cleaning and capping requirements.

The printhead can be used either in single colour 1200dpi mode or with two colours at 600-dpi resolution. This combined with high-frequency driving technology enables the D3000-A1R to deliver outstanding image quality and high print speeds comparable to those of existing analogue printers.

With a 67mm print swathe, the DC300-A1R is easily scalable for wide, high-quality applications such as flexible packaging, labels and décor. Its robust, industrial design means it can be safely handled without causing damage to the printhead nozzles.

The demand for digital printing with water-based ink has risen in recent years due to a growing requirement to mitigate the environmental impact of printing. The D3000-A1R is well-placed to offer a competitive edge to equipment manufacturers who are keen to address environmental and sustainability concerns.

Paddy O’Hara, Business Development Manager at Epson Europe, says: “Our new series of water-based ink, nozzle level recirculation printheads demonstrates our commitment to developing technology that contributes to low environmental impact digital printing and the acceleration of inkjet innovation.

The D3000-A1R builds on the quality and reliability of our industry-leading PrecisionCore technology, adding ultimate flexibility for a wide variety of industrial printing applications. The width and design of the printhead is unique within the industry, allowing for highly scalable configurations in multi-head arrays.”

Key Features of the D3000-A1R include:

• 1200-dpi resolution and high-frequency driving

• Nozzle level recirculation inkjet printheads at 1200 nozzles per inch. Printheads do not require regular ink ejection and head cleaning

• The printhead can be used either in single colour 1200npi mode or with 2 colours at 600npi per colour

• 67mm print swathe and robust modular design allows print chips to be easily arrayed in both moving serial printhead and fixed line head configurations

• Reduced environmental impact

The D3000-A1R will be available later this year.

Roland DG Corporation, a leading manufacturer of wide- format inkjet printers and printer cutters, today announced the addition of EUV5 Orange and Red UV-curable inks for use in the VersaUV LEC2 se...

July 06 2021

Roland DG Corporation, a leading manufacturer of wide- format inkjet printers and printer cutters, today announced the addition of EUV5 Orange and Red UV-curable inks for use in the VersaUV LEC2 series of UV-LED printer cutters.

With integrated printing and cutting, diverse media support and ease of use, the LEC2 series UV printer cutters are ideal for the quick turnaround of numerous applications, including adhesive decals, labels and stickers, signs, POP, backlit panels, interior décor and packaging prototypes. In addition to CMYK, Clear, White and Primer, EUV5 UV ink now supports new Orange and Red inks as process colours. CMYK + Orange + Red expands the colour gamut by approximately 20%, thereby increasing the number of Pantone colours reproduced by approximately 200 colours*² compared to four-colour CMYK. Combined with Roland DG’s True Rich Color print settings that maximise the potential of hardware and inks to produce stunningly vibrant graphics with neutral greys, smooth gradations and natural skin tones, it is now possible to more accurately reproduce brand colours that were previously difficult, if not impossible.

Tony Miller, Division President of Global Sales & Marketing Division, said, "The LEC2 series is characterised by its versatility, quick turnaround, and unique special printing capabilities for high value-added expression on a wide range of compatible media. We are confident that the addition of Orange and Red UV inks will bring even more value and competitiveness to our customers' businesses. Roland DG will continue to contribute to the development of the printing and manufacturing industry by providing products and services that expand the creative possibilities of our customers."

To find out more, go to: www.rolanddg.com.au

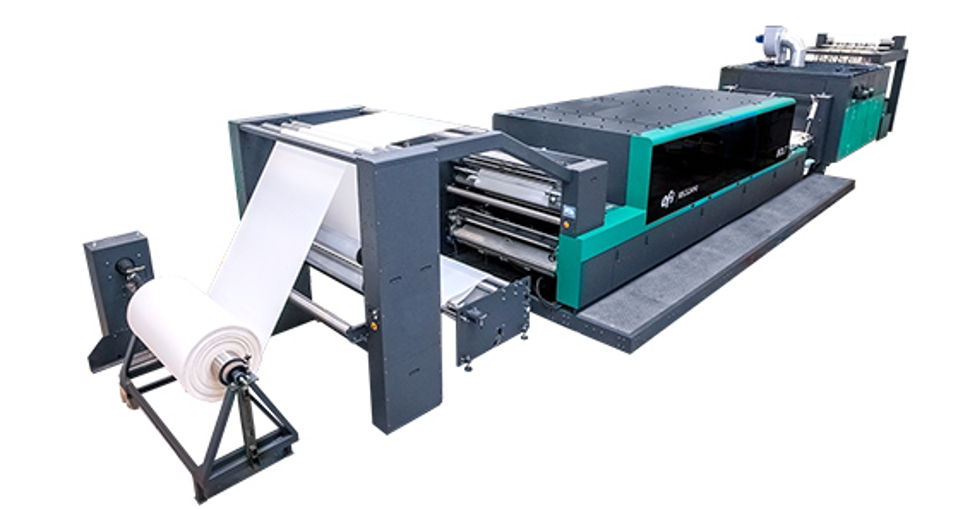

Electronics For Imaging, Inc. has enhanced the world’s fastest digital textile printer, the EFI Reggiani BOLT. The upgrade is a combination of hardware and software enhancements ...

June 28 2021

Electronics For Imaging, Inc. has enhanced the world’s fastest digital textile printer, the EFI Reggiani BOLT.

The upgrade is a combination of hardware and software enhancements that will minimise artefacts, compensating for missing nozzles that may occur over time and enhancing uniformity to deliver smoother solid colours. The upgrade also delivers improved quality and smoother gradients, plus it enables faster printhead replacement and drastically increases file processing speed by up to 200% for large, complex files.

Dedicated colour profile creation on the newest-version EFI Fiery BT-1000 digital front end driving the printer delivers better, more-intense tones and improves capabilities for matching existing colour profiles commonly used in digital textile printing.

The enhancements are an important step in further enhancing digital printing’s presence in the industry, bringing greener, more-sustainable inkjet technologies to the fore as a replacement for analogue dyeing procedures that make textile manufacturing the world’s second-largest polluting industry.

“With the industry’s top speed and now the delivery of even higher print quality, the EFI Reggiani BOLT can help spur a revolution in textile printing, migrating more production to digital technology, ensuring the fastest return on investment on high-volume work thanks to superior throughput and unmatched reliability and uptime,” said EFI Reggiani Senior Vice President and General Manager Adele Genoni. “With the BOLT’s new enhancements – and its ability to print extremely high quality on a variety of designs and fabric types at record-breaking speeds up to 90 metres per minute – the economic cross-over point between analogue and digital printing of fabrics is lower than ever before. The time for single-pass technology is now with this best-in-class, sustainable, high-quality and high-throughput digital textile print solution.”

This 1.8-metre-wide single-pass printer – the first digital textile printer to receive the Printing United Alliance InterTech Award for advanced print technology innovations – is well-positioned to have a major transformational impact on the industry. With its current installed base, the EFI Reggiani BOLT is already responsible for printing more than 50 million linear metres of fabric worldwide.

Faster processing and higher-quality print

Now available globally, the EFI Reggiani BOLT upgrade features hardware and software enhancements for improved overall performance, printing quality, uniformity, and increased user friendliness including:

Focused on the current market needs of production-class print providers, Epson today introduced a new line of SureColor P-Series photographic and graphic art wide-format printers. The new SureColor...

June 22 2021

Focused on the current market needs of production-class print providers, Epson today introduced a new line of SureColor P-Series photographic and graphic art wide-format printers. The new SureColor P-Series models are designed specifically for high-volume photo fulfilment, retail photo labs, poster and graphic art production. The new production-class SureColor P-Series 24- and 44-inch models are slated to launch this year, with the initial SureColor P8560D 44-inch dual roll printer available first.

Leveraging Epson’s latest 2.64-inch PrecisionCore printhead and six-colour UltraChrome PRO6 pigment inks, Epson’s new photographic printer line enables higher-speed performance than previous generation models while providing outstanding image quality. The innovative, space-saving design provides a small footprint for space-constrained production environments. In addition, the latest models include several new features that improve workflow and media handling, including Adobe Embedded Print Engine as standard, dual roll, built-in take-up reel for roll-to-roll printing, complete front operation, easy automatic roll loading, and optional, adjustable production stackers.

“As the demand for more personalised photo products, decor and graphic art continues to rise, print service providers are demanding higher quality and higher productivity at lower costs,” said Epson GM marketing Bruce Bealby. “These new P-Series production-class printers deliver on all those fronts. The first available model in this new line, the SureColor P8560D is engineered to achieve high speed with innovative media handling, all with the high quality and reliability synonymous with Epson.”

More about the new SureColor P-Series

The new line contains a range of features designed to meet the needs of demanding print service providers, including:

Epson today introduced a new generation of production-class, SureColor T-Series wide-format printing solutions with an innovative, compact design. Five new SureColor T-Series 24-, 36- and 44-inch d...

June 22 2021

Epson today introduced a new generation of production-class, SureColor T-Series wide-format printing solutions with an innovative, compact design. Five new SureColor T-Series 24-, 36- and 44-inch dual roll models are slated to launch later this year. The SureColor T7760D 44-inch dual-roll printer will be available first.

Developed from the ground up, the all new SureColor T-Series models include Epson’s latest 2.64-inch PrecisionCore print head which provides outstanding image quality while enabling higher-speed performance than previous generation models. The new, compact industrial design provides a small footprint for space-constrained production environments. The latest models also incorporate a number of new features that improve usability and streamline workflow and media handling, including Adobe Embedded Print Engine standard on most models, dual rolls, built-in take-up reel for roll-to-roll printing, complete front operation, easy automatic roll loading and optional, foldable production stackers.

“Not only do these new T-Series printers deliver significant speed and functionality enhancements over the previous generation and compared to competitor models, a tremendous amount of development work has gone into making them as compact as possible. They sport a truly innovative design that fits into any shop or office space, even when space is limited,” said Epson GM marketing Bruce Bealby. “The T-Series line of printers is a focus for Epson with nine models in the family already. Built on decades of imaging expertise, these new additions deliver production-class performance in a compact form factor and come with powerful software to help modern businesses improve workflows and streamline project delivery.”

The first available SureColor T7760D delivers posters and POP displays at speeds over 28 m2/h and CAD and technical drawings at production-class speeds over 130 m2/h, making it the fastest in its class1.

More about the new SureColor T-Series

The new line delivers a range of features designed to revolutionise business productivity, including:

Fujifilm’s stylishly designed new Acuity Prime flatbed prints at exceptionally high quality to a range of rigid and flexible media. Optimising price/performance was at the heart ...

June 22 2021

Fujifilm’s stylishly designed new Acuity Prime flatbed prints at exceptionally high quality to a range of rigid and flexible media.

Optimising price/performance was at the heart of the design of the Acuity Prime. For example, it features a high quality LED curing system which is air-cooled, meaning there is no requirement for an expensive water-cooling system. And the Prime is so power efficient that it only requires a single-phase 25-amp supply, helping to keep running costs to a minimum.

A new ink system – Uvijet HM – has been formulated to provide excellent adhesion to a broad range of substrates while also producing a wide colour gamut. The new ink range is optimised to produce high quality, vibrant images day in day out.

A new jetting primer meanwhile, improves adhesion still further for particularly challenging substrates. This removes the need for offline pre-treatment of substrates before printing, saving time and money. The machine also features a printable area of 2.54m x 1.27m and can accommodate media up to a thickness of 51mm.

Available in CMYK formats with white, with additional clear and jetting primer, the Acuity Prime with Uvijet HM offers the ultimate versatility and value by providing the flexibility for print businesses to customise it to their own needs.

Careful consideration has also been given to operational ease-of-use. Multiple practical benefits for both operators and service engineers have been built into the design, making the day-to-day operation of the printer as straightforward as possible.

One such feature is the media loading pins, which can be operated with the touch of a button, allowing for pinpoint media placement precision and exceptionally accurate print registration from job-to-job.

The five-part media zone system, based on common media sizes, vastly reduces the amount of masking required. This means job set-up times can be sped up considerably.

The machine’s splash-free ink pouch system is designed for easy pouch changeover and incorporates an LED light system to quickly and effectively alert the operator to low ink levels.

Alongside all the new technical features, the Prime also includes practical benefits, such as an integrated shelf for operator tools, which allows them to be kept close to hand but safely away from moving parts of the machine. There is also a handy cabinet built into the space underneath the front of the machine for convenient storage of PPE, personal items or first aid kits, helping to keep the area around the machine clear.

The software and user interface have also been carefully considered with the software completely redesigned to give all the tools required in the most straightforward way possible.

Anda Baboi, Marketing Manager, Fujifilm WFIJ says: “The Acuity Prime represents both a ‘next step’ and a new start for Fujifilm. It’s built on our knowledge and expertise, but at the same time it’s something fundamentally new – the new blueprint for wide format. The thing that really sets it apart from anything we have brought to market before is the extent of the creative freedom we have had over every aspect of its design and development. Having this level of control has given us the opportunity to address a huge number of practical and technical issues, ensuring that the end product offers unbeatable standards of performance; exceptional value, versatility and ease-of-use, and the best ROI available on the market.”

Following several years of successful Acuity Ultra installations since its launch in 2018, and as part of Fujifilm’s strategy to create the new blueprint for wide format, Fujifilm today annou...

June 22 2021

Following several years of successful Acuity Ultra installations since its launch in 2018, and as part of Fujifilm’s strategy to create the new blueprint for wide format, Fujifilm today announces the launch of the Acuity Ultra R2.

Available in 5m or 3.2m versions, the new machine features the same high levels of quality and reliability as its predecessor, but offers a huge number of design improvements to benefit both ease-of-use and overall productivity.

The new, stylish enclosed design eliminates stray UV light, removing the need for a light curtain, while from a functional point of view the machine is designed with both maintenance and ink supply on the same side, giving operators easier access and more room in which to work when performing routine tasks. An external visual light also quickly alerts operators to low ink levels without the need to look inside the machine.

The Acuity Ultra R2 also features larger ink tanks. This simple change ensures that all the ink from a standard can is used when refilling, eliminating the clutter and mess of opened, half-used ink cans that are often a feature of print workplaces. The ink tanks have also been designed for easy access for refills.

Maintenance-free ink pumps have also been integrated into the new machines to increase up-time, and a unique new print viewing window allows the operator to check on the progress of a job without leaving the workstation. The workstation itself has also been redesigned, now featuring desktop space, a handy drawer for tools or personal items, integrated lighting, and a larger monitor for ease-of-use and better display of print jobs.

Another significant design benefit is that the separate chiller unit that accompanied the original Acuity Ultra has now been fully integrated into the design of the new machine. This frees up considerable workspace and reduces clutter.

The Acuity Ultra R2 also features a crash detector with increased sensitivity and dual way activation, helping to identify and address potential problems early. Furthermore, it also features a new low scratch surface platen and new automated meniscus control, offering even greater precision and consistency in ink droplet placement.

Like the original Acuity Ultra, the R2 is available in various colour configurations up to eight channels, but recognising the fact that modern print businesses are all unique – with often very different needs and priorities – the Acuity Ultra R2 is available with conventional UV curing as standard, or with an LED UV curing system for six colour and white configurations. This gives customers the option to choose either the ultra-high productivity of conventional UV, or the comparatively lower operating costs and lower energy use of LED. Both the 5m and 3.2m versions of the machine also feature an improved roller design to prevent media wrinkles.

Kevin Rhodes, Marketing Manager, Fujifilm WFIJ says: “The original Acuity Ultra set a new standard for combined quality, performance and price when it was launched in 2018. Three years later, the Acuity Ultra R2 is taking that up another level as part of our brand new Acuity range and our ‘new blueprint’ for wide format.”