Gandy Digital innovates the next generation flatbed printers using “NanoDot” Technology. A whole new concept of digital printing that has come of age to extra wide large format printing...

May 22 2019

Gandy Digital innovates the next generation flatbed printers using “NanoDot” Technology. A whole new concept of digital printing that has come of age to extra wide large format printing in Gandy Digital’s Gladi8tor True Flatbed printer.

Gandy Digital innovates the next generation flatbed printers using “NanoDot” Technology. A whole new concept of digital printing that has come of age to extra wide large format printing in Gandy Digital’s Gladi8tor True Flatbed printer. The Gladi8tor comes in two sizes, Gladi8tor “2” has a 4ft X 8ft (1.22m X 2.44m) print size or Gladi8tor “3” with a 6.5ft X 10ft (2m X 3.05m) print size both on a vacuum table. Both models can have a Roll to Roll attachment either 8ft (2.44m) Wide or 10ft (3.05m) Wide.

Gandy has been offering innovative printers for over 35 years known for their reliability and strong support. The Domin8tor and Pred8tor were the latest state of the art flatbed printers with vacuum table and special features that became the standard in the industry.

Gandy Digital has taken the best of both worlds by combining the reliable Domin8tor and Pred8tor and upgraded them with the latest “NanoDot” Technology, introducing the next generation, Gladi8tor true flatbed printer. The Gladi8tor with “NanoDot” Technology, 3 picoliter grayscale print heads gives both smooth Colour and high speed. Gandy also supplies a custom made RIP to maximise the “NanoDot” capabilities. Sharp images just got sharper, with 3 point text really readable. Incredible precision at true 1200 dpi on a Superwide format printer.

Gandy has taken this precision to a new level by creating unmatched smoothness in skin tones and even more impressive is the smooth colours on lighter shaded solid colours. This can only be achieved before with offset printing or photography. Finally a match to the quality of offset printing and photography. Everybody talks about it, Gandy has achieved it.

The Gladi8tor uses the Blade Technology, a key feature innovated by Gandy. This allows for precise prints without the need for time consuming alignment as the heads are pre-aligned by laser precision.

The best news is with all this quality, the speed has dramatically increased.

The Gladi8tor’s biggest advantage is the ability to print up to 120 (4ft X 8ft) boards an hour 3800sqft/hr (350sqm/hr). The “NanoDot” Technology coupled with our inline blade technology gives excellent sharp quality and super fast speeds. Unbelievable speed and quality that you will only believe if you witness with your own eyes.

Gandy has always kept existing customers interest and investment in mind when introducing new printers. The “NanoDot” new technology can also be upgraded on all Gandy Pred8tor and Domin8tor models.

The Gladi8tor will come with an option to take one row of print heads at half the speed or two rows at full speed. You can start with one row of print heads and upgrade to two rows and achieve full speed at a later date. The Gladi8tor will come ready for easy field upgrade.

Gandy will also offer an upgrade path to its existing Pred8tor and Domin8tor customers to start with one row of print heads and later upgrade to two rows and achieve full speed.

The Gladi8tor will have all the features from the Pred8tor and Domin8tor. Here are some of the popular features:

- Crash Sensors that stop for even small objects and save print heads from damage.

- Static Bars that really work in dry climates while keeping prints sharp.

- Automatic head cleaning and wiping station.

- Graphical User Interface simple touch and drag (GUI).

- Powerful vacuum table holds uneven materials flat.

- Automatic head height adjustment.

- Camera built in to assist remote service. Nice idea to avoid expensive visits but getting the job done.

The Gladi8tor has very powerful long lasting LED lamps that cure to perfection even at the fastest speeds and yet keeps its cool.

Gandy introduced the first “multi layer” capability many years ago. The Gladi8tor will have the same feature allowing colour, white, and colour for backlit images, and unlimited multi layer variations with as many colours as you wish.

The Gladi8tor will have the option to get double white blades to print heavier layer of white faster especially effective on darker substrates. Instead of double white you can get single white and varnish. Gandy’s varnish can also act as a very effective primer, giving a dual purpose capability.

Gandy has many years of supplying a UV ink that gives excellent adhesion to many plastics including acrylic. The Gladi8tor will continue to get the same ink formulation for its LED Lamps.

Gandy Digital’s Gladi8tor is the most advanced and groundbreaking Superwide Digital printer in the industry today.

swissQprint launched Karibu, the company's first roll to roll printer, at Fespa 2019. This sturdy Swiss product features a compelling concept and will be available from September 2019. ...

May 22 2019

swissQprint launched Karibu, the company's first roll to roll printer, at Fespa 2019. This sturdy Swiss product features a compelling concept and will be available from September 2019.

Karibu, the first swissQprint roll to roll printer, made its public debut at Fespa 2019. This is a UV inkjet printer with a maximum print width of 3.4 metres. As the Swiss manufacturer hinted in advance, Karibu incorporates ingenious features aimed at high efficiency and reliability as well as huge versatility.

Easy roll handling - The swissQprint stand at Fespa had live demonstrations of how easy and fast it is to change rolls with Karibu. Thanks to the cassette system, rolls are loaded and ready to print within minutes.

On-the-spot inspection of backlits - Karibu features a Light Box right next to the printing area, for immediate and continuous quality control of backlit prints. As a result, neither much material nor time has been lost should optimisations prove necessary. That having been said, what visitors to Fespa saw was impeccable backlit printing in typical swissQprint quality.

Ingenious mesh printing - Karibu has a Mesh Kit integrated with the print bed. This makes clean and simple work of processing permeable substrates, as well as full bleed printing. There is neither additional set-up work beforehand nor cleaning afterwards. A mouse click by the operator sends the Karibu print beam – which is movable in the X direction – from its standard position to the mesh position. Printing can then start immediately.

Printing two rolls at once - For users who regularly print in parallel, swissQprint offers a dual roll option capable of handling two rolls each up to 1.6 metres wide. This doubles Karibu's productivity. The roll holders are split into two sections with each half of the shaft driven individually, thus ensuring optimum web tension and perfect results on both rolls.

Tip Switch vacuum - Karibu has 136 keys ranged across the print bed width, rather like a piano. Each one opens or closes a vacuum channel, thus eliminating air leakage even in the gap between dual rolls. A light tap on the switches using a fingertip is all the user action required to open or close the entire vacuum area width within four seconds. This is called Tip Switch vacuum, a technical solution for which swissQprint has filed a patent application.

Status monitoring - Karibu has four beacon-like status indicators affixed to the print beam. They are observable at a distance and inform the operator about machine status and printing progress. So it is always possible to keep an eye on Karibu, even while the operator is elsewhere in the print room taking care of other equipment or tasks.

Specially developed ink set - swissQprint has developed an ink set specifically for the new Karibu roll to roll printer. The cured ink layer is flexible to ensure suitability for all imaginable roll media. The inks themselves are NVC-free and Greenguard Gold certified. Printed products are thus safe to use in critical places such as hospitals and schools, potentially broadening a print provider's range of services.

Available from September 2019 - The international swissQprint distributor network is now accepting orders for delivery starting in September 2019. Since Karibu clearly bears the hallmarks of its Swiss manufacturer, customers can look forward to the usual swissQprint quality, functionality, energy efficiency and durability. This in turn underlines the machine's combination of innovative solutions with 20 years of development experience in UV inkjet printing.

New SureColor SC-S signage printers, alongside a range of innovative applications, were all on show at the Epson FESPA stand Epson announced the launch of two new SureColor SC-S ...

May 21 2019

New SureColor SC-S signage printers, alongside a range of innovative applications, were all on show at the Epson FESPA stand

Epson announced the launch of two new SureColor SC-S signage printers, the SC-S60600L and the SC-S80600L. These 64-inch printers are an extension of the award-winning SureColor SC-S Series printer range that offer high productivity customers a lower total cost of ownership (TCO). The SC-S Series printers continue to offer customers diverse applications with access to the Epson Edge Dashboard with over 250 EMX profile downloads for a wide range of media manufacturers and media types.

“At the heart of these new industrial printers is the introduction of high capacity 1.5 litre ink pouches,” says Chris Davies, product manager – production LFP. “This means a longer running period, resulting in less user intervention and reduced downtime. The pouches are complemented by Epson’s established UltraChrome G3 eco-solvent inks which have key environmental certifications, including GreenGuard Gold and AgBB. As with all signage printers in the SureColor SC-S range, they are low maintenance, highly reliable and easy to set up.”

The SC-S60600L and SC-S80600L feature Epson PrecisionCore TFP printheads and will be supplied with Epson Edge RIP software and the LFP Accounting Tool (which will provide accurate job costing data).

Epson Edge Print software is powerful and feature-rich, easy-to-use and provides a simplified print-ready solution to get businesses up and running quickly. In addition, Epson is continuing to expand the range of available EMX files to optimise print quality on the most common, and speciality, media.

Both SureColor SC-S L version models can print on a wide range of media, from clear film and photographic paper to wallpaper, canvas and vinyl, so are suited to large scale signage and displays, point of purchase applications and billboards, back/front-lit signage and car wrapping.

“We envisage a strong take up from print service providers and sign makers who cover a wide range of business sectors and applications, providing customers with signage, point of sale, textiles, interior design and fine art products,” says Chris Davies.

“Users will be impressed by the print speeds, precision and performance of these new models and the compelling business case for adding this technology to their current portfolios. Their customers are going to be impressed by the quality and speed of turnaround.”

Other printers on the stand include the SureColor SC-S60600, SureColor SC-P20000, SureColor SC-F9300, SureColor SC-F6200 and SureColor SC-F2100.

A new LittleRed X3D-78 infrared conveyor dryer from Vastex comes w...

May 21 2019

A new LittleRed X3D-78 infrared conveyor dryer from Vastex comes with a two-metre-wide conveyor belt and can cure 185 garments/h DTG printed with digital white ink, 1080/h screen printed with plastisol ink, and 555/h screen printed with water-based ink or discharge.

“The LittleRed XD series of tunnel dryers are unique to the Australian market; offering a dryer specifically engineered to cure DTG printed digital white ink, alongside all types of screen printed inks at good turnover rates. This multi-purpose machine means that you only need one dryer to do everything.” explains Howard Debney, owner of Leapfrog Machinery, Distributor for Vastex in Australia.

The DTG-specific feature of this dryer is a high-powered pre-heating zone that boosts ink temperatures past 150°C within the first few centimeters of conveyor travel. This increases the dwell time that ink is exposed to optimum curing temperatures, allowing speed of the conveyor belt and machine output to be increased.

Previously available in a 76 cm wide model for a single row of garments and a 137 cm wide model for two rows, the new two-metre-wide X3D-78 can accommodate three rows of normal sized garments or two rows of oversized garments, yielding higher capacity than any conventional dryer in the equivalent amount of floor space, according to Vastex.

"This super-wide machine is ideal for high-production shops that need to handle the maximum output of automatic presses and/or direct-to-garment printers including shops running high capacity Kornit® DTG machines” says Mark Vasilantone, president of Vastex, adding, "No other dryer of equivalent size or cost can match its performance."

The dryer’s three 30.5 x 183 cm wide heaters output a combined 26,700 watts @240V, and are digitally-controlled and height-adjustable to maximise curing efficiency for bulky or over-sized garments. The X3D-78 also offers precision-thermal-profiling (PTP) to match curing conditions to the drying characteristics of each ink type, particularly difficult-to-cure inkjet-printed white ink.

The new dryer is 260 cm long, 226 cm wide and 137 cm high, and features a 31.2 CMM targeted exhaust system as standard to rapidly remove moisture and air contaminates from the heating chamber, while keeping exterior surfaces and controls cool.

The output of all Vastex floor-standing conveyor dryers can be increased by an order of magnitude as needs grow by adding heating chambers and lengthening the conveyor belt, with one or two additional heating chambers, allowing doubling or tripling of conveyor belt speed and drying capacity.

The conveyor belt is continuously centered by a roller belt tracking system patented by the company, and driven at precisely controlled speeds to vary dwell time.

The heaters of all Vastex dryers carry an industry-leading 15-year warranty, and feature closely spaced coils that provide high-density, medium-wavelength infrared heat for maximum cure speed without cold spots or under curing associated with conventional units.

Leapfrog Machinery distributes and supports the full range of Vastex Screen Printing Equipment throughout Australia including their Industry Leading Screen Presses, Flash Cure Units, Screen Exposing Units, Screen Drying Cabinets, Washout Booths along with complete equipment packages for entry-level to large commercial shops.

For information contact Leapfrog Machinery (0)2 9482 4999 www.leapfrogmachinery.com.au

Esko, a global provider of integrated hardware and software solutions for digital print professionals, will showcase its latest innovations at FESPA 2019. Recognising that ...

May 14 2019

Esko, a global provider of integrated hardware and software solutions for digital print professionals, will showcase its latest innovations at FESPA 2019.

Recognising that sign and display producers today require more flexibility, efficiency and accuracy in operations, Esko will present two new hardware solutions: the new Motorised Roll Feeder for soft signage applications and the Kongsberg C Edge, the upgradable digital cutting table released earlier this year. The latest version of its integrated software range Esko Software Platform 18.1 will also be on show at booth A5-G10.

ESKO-FESPARussell Weller, Esko Product Manager, stated: “These latest launches at FESPA demonstrate our commitment to innovation in hardware and software, enabling our customers to unlock long term production flexibility and profitability.”

The Motorised Roll Feeder is the only solution in the soft signage industry that delivers great cutting results on tensile materials from the very first cut through to the end of the roll. Eliminating inaccurate cuts on soft signage jobs due to wrinkles, stretch distortion or imperfectly rewound rolls, the new Motorised Roll Feeder incorporates an active material feed to avoid stretch by actively feeding the material to the Kongsberg C64 digital cutting table, rather than pulling it.

ESKO-FESPA2The new upgradable Kongsberg C Edge delivers high speed production capability of up to 75m/min at an acceleration of 1G, designed to keep up with the demands of today’s wide format digital print market. The table is complemented with a range of customisable fittings, including a conveyor feed system, a new Fast Tool Adapter to reduce downtime and maximise performance, a heavy-duty unit for high quality corrugated crease lines, and the CorruSpeed tool, a non-oscillating device for high quality cutting even at high production speeds.

Weller added: “At Esko, we believe in connecting from design to finish to boost our customers’ productivity and efficiency. At FESPA, we will demonstrate our latest hardware innovations backed by our comprehensive portfolio of software solutions including ArtiosCAD 3D constructional design software, iCut Suite for sign print finishing and true shape nesting, Device Manager for job management optimization and Automation Engine, our prepress workflow automation software. Visitors to our FESPA booth will experience first hand how Esko is investing in innovation for their success.”

To find out more and get on board with Esko innovation, visit stand A5-G10 or visit www.esko.com

HP is set to introduce the new HP Stitch S1000, a super wide dye sub production printer designed for high productivity and simplified operation, unleashing new production possibilities for interior...

May 14 2019

HP is set to introduce the new HP Stitch S1000, a super wide dye sub production printer designed for high productivity and simplified operation, unleashing new production possibilities for interior décor and soft signage.

The HP Stitch S1000 is a 3.2 meter (126-inch) dye sub printer that brings a new level of innovation to high production companies to meet deadlines more easily by enabling fast speeds, high uptime, and unattended shifts. Fully automatic maintenance ensures optimal image quality without user intervention, while saving time with easy media loading and unloading by a single operator.

The printer is making its worldwide debut the HP Stand (F30 in Hall A5) at FESPA 2019 in Munich, Germany, May 14-17. The new HP Stitch portfolio, including the 1.62 m (64 inch) HP Stitch S300 and S500 printers, removes complexity from dye sub printing.

“HP’s expansion into the textiles industry solidifies our commitment to making digital printing accessible to all. The new super wide HP Stitch S1000 removes major complexities from dye sub printing, with industry leading technology and high-quality prints at unrivalled speed,” says Santi Morera, Head of Graphics Solutions Business at HP. “The S1000 truly unlocks the power of colour for production environments through smart technology.”

HP thermal inkjet for dye sublimation ink

The HP Stich portfolio introduces dye sublimation ink into HP’s Thermal Inkjet printing technology to meet rising demand for polyester-based textiles for sportswear, fast fashion, home décor and soft signage. HP Stitch S1000 is ideal for medium and large print service providers to boost production of textile applications in the soft signage market, including backlits, frontlits, and interior décor such as curtains, upholstery, and sofas.

The HP Stitch S1000 for high-volume production offers:

• High-productivity: Meet short deadlines and seasonal peaks of production with high productivity modes, reaching a maximum production speed up to 220 m2/h and backlit speed up to 130sqm/h.

• Image quality: Sharp prints even on high density jobs printing direct to fabric using HP Drop&Dry print zone Dryer. Reliable image quality thanks to the Smart Nozzle Compensation System. The optical media advance sensor, the OMAS Plus, controls media advance, for both transfer paper and fabric materials, even when printing at highest speeds.

• Superior quality printing: HP Stitch provides 1200 native dpi in thermal inkjet printheads resulting in high quality prints, including deep blacks and vivid colours.

• High capacity: High unattended printing capability with 10 litre-capacity supplies and up to 300 kg rolls.

• Colour consistency: Distribute jobs across fleets with best-in-class colour consistency from printer to printer thanks to HP Smart Colour tools

• Maximise uptime with the first user replaceable print heads and HP Smart Services

Pricing and Availability

Information on country availability, pricing, and retail destinations for the HP Stitch S Printers Series Portfolio vary region by region.

Click here to check out the HP Stitch S1000

Intec Printing Solutions Limited, innovators in digital imaging and finishing, continues its expansion of unique solutions by introducing the ColorCut FB8000PRO as part of the ColorCut range of dig...

May 14 2019

Intec Printing Solutions Limited, innovators in digital imaging and finishing, continues its expansion of unique solutions by introducing the ColorCut FB8000PRO as part of the ColorCut range of digital cutting and creasing equipment.

Higher volume automation for flatbed cutting and creasing - improves productivity The Intec ColorCut FB8000PRO is a modular system solution, comprising the FB8000 Flatbed Cutter and ASF8000 Auto Sheet Feeder. Both devices are feature-rich and offer huge production advantages.

Whereas the FB8000 Flatbed Cutter can be purchased and used as a stand-alone device from the ASF8000 Auto Sheet Feeder – the two devices when used in unison, deliver an incredibly efficient, automated solution! Capable of cutting and creasing any shape on a typical SRA3 sheet in around 30 seconds, the dual tool head applies a class-leading 1Kg of pressure to achieve crisp cuts and deep creases on up to 600micron media.

The operator can utilise ‘productivity mode’ when manually feeding sheets – this is where the sensor seeks and reads each sheet to cut multiple sheets at a time – finished sheets are automatically moved along the table and into the collection tray.

When harnessing the productivity of the ASF8000 Auto Sheet Feeder, the operator can load the Feeder with media and leave the FB8000PRO to automatically feed, cut, crease and stack jobs - unattended. This not only offers faster production times, but it also frees-up the user to concentrate on other tasks.

QR code creation and reading. The bespoke ColorCut Pro3 software has been remastered to enhance the devices digital functionality.

Rebuilt from the ground up, ColorCut Pro3 will generate unique QR codes for placement onto vector artwork – which in turn, is read by the FB8000’s onboard video camera. This function enables instant cut file retrieval from the Job Library Server, enabling the operator to instantly view the job on screen and set the desired cutting features from the material database. This means that different aspects of the file can have different treatments applied to them and also predetermine the order they are worked on.

Check mark reading. The new style circular check marks are also read by the software. The four corner marks ensure accuracy with the artwork/cut file and compensate for any sheet placement skew or print stretch. As a bonus, the video camera provides a live view to the operator’s workstation, which also helps provide a visual confirmation of the production status. High speed sheet feeding.The ASF8000 Auto Sheet Feeder is precision-engineered specifically to partner with the FB8000 Flatbed Cutter.

It provides exceptional pneumatic efficiency and automation in material handling to deliver a solution which is perfectly synchronised with the FB8000 Flatbed Cutter.

The ASF8000 feeder enables up to 2000 sheets, (25Kg) of SRA3 printed material to be loaded into the Feeder, or a stack height of up to 22.5cm. It then uses pneumatic vacuum pressure to pick up each sheet and advance it on to the FB8000's cutting belt.

The FB8000PRO will be available to purchase, summer 2019.

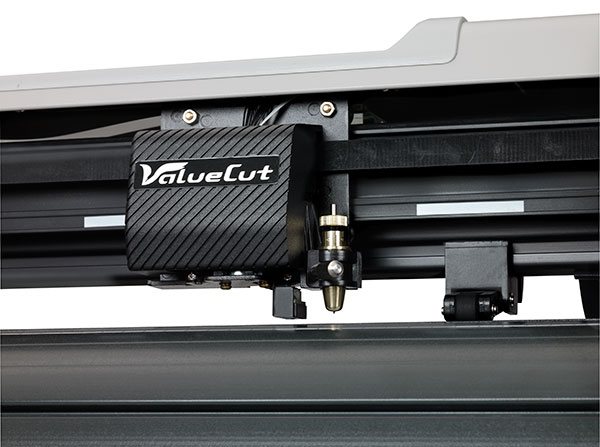

Mutoh, a leading manufacturer of wide-format inkjet printers and 3D printers, announced the launch of the new cutting plotter “ValueCut II” from the ValueCut series. The Va...

May 08 2019

Mutoh, a leading manufacturer of wide-format inkjet printers and 3D printers, announced the launch of the new cutting plotter “ValueCut II” from the ValueCut series.

The Value Cut series achieves precision cutting and high productivity. The “ValueCut II” is available in three models with different maximum cut width, and upgraded to maximise ease of use and functionality. By combining with the award winning Mutoh “ValueJet Printers”, the “ValueCut II” displays great ability as an affordable high-performance print; cut system.

Features of the ValueCut II include:

1. AASII Contour Cutting System (Automatic Alignment System II) AASII guarantees the finest cutting quality with automatic detecting registration marks.The continuous contour cutting function is added to the AASII in ValueCut II. (X axis direction only)

2. Superior cutting speed The max cutting speed is 60.2” (1,530mm)/s (at 45°direction) inherited from the current ValueCut, and enhances productivity with superior performance.

3. Optimum cutting force Selectable cutting forces range from 5g to 600g to easily cut a variety of materials.

4. 3 types of interface connection The ValueCut II supports various system environments with three available connection ports. USB, serial port (RS232C) and the newly added Ethernet port which allows users to operate multiple cutters with one PC.

5. Pen-up movement acceleration setting + contour cutting register mark detection movement speed setting The acceleration of the pen-up movement can be set in two levels according to the media. With this function, it is able to adjust the registration mark movement speed of the contour cut.

6. Function on disablement of media sensor Allows users to disable the media sensor to accommodate cutting transparent material with ease.

7. ValueCut II dedicated cutting software “FlexiSTARTER ValueCut Edition” as standard Create cut paths and print and cut paths without design software.

For more information about the new ValueCut II, please contact Russell Cavenagh, Mutoh Australia by calling 1300 468 864 or visiting www.mutoh-au.com

As the need for on-demand manufacturing increases across an ever-widening array of substrates, producers in the sign & graphic and packaging industries need a system that offers speed and versa...

April 30 2019

As the need for on-demand manufacturing increases across an ever-widening array of substrates, producers in the sign & graphic and packaging industries need a system that offers speed and versatility to meet every request that comes in. In order to remain competitive, companies must offer more material options and quicker turnaround times without diminishing the quality of their product.

As the most versatile digital cutting solution on the market, the Gerber MCT Cutter has all the tools, including laser, to complete the most challenging jobs for a wide range of substrates, while increasing productivity and delivering high-quality results. The innovative system allows users to control target registration, cut file editing and machine production from one, integrated user interface.

Six months after having acquired MCT Digital, Gerber is expanding its MCT digital cutting system worldwide into the sign & graphics and packaging markets. The highly-integrated system of hardware and software has won a number of accolades in the North America market.

“We are excited to bring such strong innovation in digital finishing to the European sign & graphics and packaging markets, and look to build on Gerber’s deep heritage of automated finishing and integrated production software,” said Gerber Technology’s Scott Schinlever, president and chief operating officer, Automation Solutions.

The most versatile cutting solution on the market, the Gerber MCT Cutter, is equipped with an industry-leading 100w laser for textiles and acrylics, as well as 11 interchangeable tools and the industry’s most integrated production and vision-guided software, TigerVision™.

“We went from doing everything by hand to having a giant digital worker who is very accurate and fast,” said Jonathan Merendlender, founder of Printed Ink (Huntingdon Valley, PA) who has been using a Gerber MCT Cutter since October 2018. “Aside from the obvious benefits of custom shapes, 3D lettering, and fabrication, the CNC router drastically cut down on labor and increased capacity almost instantly.”

The Gerber MCT Cutter will be making its European debut at FESPA, the largest international wide format professional printing exhibition that showcases the latest innovations for digital printing and laser cutting.

Esko, a global supplier of integrated hardware and software solutions for leading packaging, labels and wide format customers, has extended its Kongsberg digital cutting table range with the new Ko...

April 25 2019

Esko, a global supplier of integrated hardware and software solutions for leading packaging, labels and wide format customers, has extended its Kongsberg digital cutting table range with the new Kongsberg C Edge; a completely upgradable table design that avoids costly reinvestment for customers as business grows.

The breakthrough innovation in the Kongsberg C multifunction, digital finishing series is designed specifically for signage and corrugated packaging converters.

Russell Weller, Esko Product Manager, stated: “The new C Edge is designed to grow with our customers. Invest now and you invest for the future. Unlike other tables on the market, the C Edge is completely upgradable avoiding the impact of having to reinvest when a business expands. The C Edge evolves with a business to unlock production flexibility and profitability, and delivers exceptional cutting quality and milling accuracy at a remarkably cost-effective price.”

With high speed production capability up to 75m/min, at an acceleration of 1G, the Kongsberg C Edge enables converters to produce high quality results with fast turnaround to meet today’s dynamic market needs.

Suitable for the wide range of substrates used in the signage sector, the C Edge can be fitted with the new second Fast Tool adapter to reduce manual tool changes and minimise downtime. When two Fast Tools are utilised together, converters can achieve higher throughput with clever tool combinations and improve output quality, especially on signage materials like vinyls. The C Edge is also available with or without a conveyor.

For corrugated packaging manufacturers, the C Edge can also be fitted with a heavy duty unit with a 50kg downforce to produce high quality crease lines with a 150mm crease wheel. Efficient and high-quality creasing, even at 100% speed, is supported by CorruSpeed; a unique tool developed for cutting corrugated board at high production speeds without oscillation. The CorruSpeed tool delivers higher quality and generates significant time savings on a range of corrugated applications, even with recycled content.

Having a track record of delivering speed, precision and production power through superior engineering and build quality, Esko brings next generation innovation with the C Edge table for converters, supporting them today and in to the future.

Kongsberg C Edge is now available to the global market. For more information about the table and its complementary tools and software, please click here

HP has announced the new HP Stitch S series, a portfolio of digital textile printers that deliver fast, precise colour-matching, alongside efficient, simplified processes. It is HP’s latest i...

April 24 2019

HP has announced the new HP Stitch S series, a portfolio of digital textile printers that deliver fast, precise colour-matching, alongside efficient, simplified processes. It is HP’s latest innovation designed to accelerate commercial digital print adoption.

“Décor and fashion application trends, on demand production and personalisation are boosting digital print growth,” says Jeremy Brew, Large Format Application Specialist at HP. “The digitally printed textiles market is experiencing double-digit annual growth, forecast to reach US$5.5 billion by 2023, according to Smithers Pira. We look forward to more digital print transformations being realised with the arrival of the new HP Stitch S series.”

The portfolio of printers couple HP Thermal Inkjet technology with industry-standard dyes for superior colour durability. The first-ever built-in spectrophotometer enables Stitch’s fast and exact colour-matching. The introduction includes three new printers from 64-inch to 126-inch wide: the HP Stitch S300 64-in Printer, the HP Stitch S500 64-in Printer, and the HP Stitch S1000 126-in Printer.

The HP Stitch S300 Printer holds the first user-replaceable printhead, resulting in reduced down-times and service costs. The HP Stitch S300 Printer was designed specifically for new-to-dye sublimation professionals, prototyping departments, and growing print providers.

“Our experience with HP Stitch S300 has been much easier and faster than other dye sub printers we’ve previously used,” says Teunis Roos, Color Concepts. “Most printers require manual action in terms of head maintenance and alignment, but the HP Stitch S300 is more proactive and automated when it comes to performance.”

Highlights:

• Delivers the world’s fastest colour-matching - in the printer, in the RIP (Raster Image Processor) and in the cloud

• Features Thermal Inkjet printhead technology to help reduce time and waste, and achieve repeatable, colour consistency across customer fleets

• Offers continuous high-quality prints with transfer paper and direct-to fabric features

• Prevents downtime with HP Proactive Services offering pre-emptive support

HP Stitch S500 Printer enables predictable dye sublimation colour and less media waste for production environments. With symmetrical 2xCMYK printhead configuration and Optical Media Advance Sensor, this 64-inch printer allows for saturated and reliable one pass mode for true top speed. The HP Stitch S500 Printer was designed specifically for high production sites.

Key HP Stitch S500 Printer features include:

• Streamlined production

o Big ink supplies, larger rolls, and HP’s Tension-Sensing Winder allow unattended operations—even overnight, complete with HP Services and cloud fleet management tools.

• Colour you can rely on with HP SmartColour tools

o Confidently distribute jobs across your fleet with colour consistency from printer to printer.

• Cost savings

o Help avoid reprints and media waste with 1200 native dpi printheads and HP Smart Nozzle Compensation system, saving up to 50 percent floor space with frontal media loading and a spindle-less system.

New HP Dye Sublimation Paper

HP has also launched a set of new dye sublimation papers for the new HP Stitch S Printer series. These papers are designed and tested as a system with HP dye sublimation inks and the HP Stitch S Printer series to achieve excellent image quality and colour consistency.

The HP Stitch S300 and S500 Printer series, as well as dye sublimation paper, are available now and will be showcased at ISA 2019 in Las Vegas, Nevada from April 24-26. Visit us at Booth 1935 and 1919 for a hands-on first look at the portfolio.

The 126-inch HP Stitch S1000 Printer can be seen at ISA 2019 under exclusive invitation and will make its debut at FESPA 2019 in May.

Pricing and availability

Information on Australian availability, pricing, and retail destinations will be available in the lead-up to PrintEx 2019.

Mimaki has released the “JFX200-2513 EX”, a large flatbed UV inkjet printer. The entry level flatbed will print direct onto a range of materials including white board, tran...

April 24 2019

Mimaki has released the “JFX200-2513 EX”, a large flatbed UV inkjet printer.

The entry level flatbed will print direct onto a range of materials including white board, transparent/coloured board, wood, cardboard, and metal. Bed size is 2,500mm x 1,300mm.

“The JFX200-2513 EX is an ultimate 2.5m x 1.3m flatbed LED UV inkjet printer that combines high value-added print and high productivity," said Brad Creighton, National Marketing Manager, Mimaki Australia. "The newly developed head unit is adopted to enable production without reducing speed even in white and colour simultaneous printing. This has increased the productivity 200 per cent compared to the JFX200-2513."

“We have also added high value added printing features, including a special Emboss Print function. Most printers make the surface look bumpy with many layers of UV ink straight on top of other layers. Smoother expression is only achieved by stacking stepped layers, so there was a need to manually prepare the data for each layer. The JFX200-2513 EX allows you to create semi-stereoscopic 2.5D print data for stepped layers that are sized differently, simply by common Illustrator/Photoshop operations and RasterLink6Plus. We call this 2.5D Texture Maker, the prints look fantastic.”

The Emboss Print in the Surface Imaging is a technique that enables 2.5D expression using multiple layers of UV ink to add a three-dimensional effect to the surface.

The new 2.5D Texture Maker is a new function of Mimaki genuine rip software, RaterLink6Plus, which allows printers to easily create multi-layered gradation data.

The company says semi-stereoscopic smooth 2.5D print can be easily made, for applications such as interior materials with printed bricks and woodgrain texture, an elevation of thick ink of an oil painting, and embossed letters of signage.

The newly featured Draft mode achieves a higher-grade productivity, realising a maximum printing speed of 35sqm per hour.

Main features

1. High value-added print “2.5D Texture Maker” that enables easy creation of smooth semi-stereoscopic 2.5D data

2. High productivity

a) Print speed in white-simultaneous printing has improved 200% of the conventional model

b) Higher-grade productivity realised by adding the new print mode

3. Stability and safety

a) NCU & NRS automatically detects missing nozzles and performs recovery

b) Links with external interface allow users to meet safety standards that are different by factory

4. Upgraded usability

a) Work efficiency improved by adding the vacuum-controlling foot switch

b) Ethernet connection supported

Matrix Frame (Sydney, Australia) a pioneer of Silicone Edge Graphics, is pleased to announce the addition of four new extrusions to their range. This brings the total number of extrusions sto...

April 16 2019

Matrix Frame (Sydney, Australia) a pioneer of Silicone Edge Graphics, is pleased to announce the addition of four new extrusions to their range. This brings the total number of extrusions stocked in Australia up to twenty seven.

Two of these new extrusions enable the end user to create frames that can turn 90 degrees around an external corner, using a single fabric face. Multiple returns are possible and this effect can be achieved in both front lit and back lit applications. Stunning effects can be created – particularly around columns and other architectural features.

A new bendable extrusion has been added which can be easily rolled to create circular shapes and frames. Perfect for creating frontlit custom shapes where required.

‘Shadowbox’ is the final new extrusion to be added to the range. This extrusion allows for the addition of door and window openings into any Matrix Frame extrusion in both frontlit and backlit applications. Openings can also be created within frames for shelving and for display purposes.

Established in 2006, Matrix Frame continues to adapt and modify its products to stay at the forefront of the industry. Our aluminium frames and light boxes house eye-catching tension fabric graphics are much more convenient to ship, store, and swap out than traditional prints, which translates to huge savings on shipping costs. Each lightweight aluminium frame is engineered for both flexibility and longevity-easy to assemble, yet able to support countless graphics over its lifetime.

Matrix Frame only sell to trade customers and not to the end client. Trade customers can either purchase the system off Matrix Frame to cut and convert themselves, or Matrix Frame can cut its extrusions to size using state of the art equipment and then deliver the frame to trade customer as a ready to assemble kit.

Matrix Frame are seeking to appoint a network of Distributors and Resellers in Australia and the Pacific region.

Please contact David Cross on +61 466 892 009 or email david.cross@matrixframe.com.au for further information. Alternatively all information including a full range of videos can be found at: www.matrixframe.com.au

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters worldwide, announced today that its new TrueVIS VG2 Series eco-solvent printer cutters have won the ...

April 09 2019

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters worldwide, announced today that its new TrueVIS VG2 Series eco-solvent printer cutters have won the 2019 ISA Sign Expo® Innovation Award in the "Printer" category.

The ISA Innovation Awards recognise the most unique and outstanding product launches at ISA Sign Expo 2019. In all, there were nominees across four categories, representing the breadth of the sign, graphics and visual communications industry. The VG2-540 and VG2-640 impressed the judges – an outside panel of experts – with technological advancements, comprehensive colour choices, improved machine efficiency and increased print-and-cut accuracy.

"The ISA Innovation Award winners truly represent the most creative and innovative products available on the ISA Sign Expo floor," said Lori Anderson, ISA president and CEO. "Attendees at ISA Sign Expo have come to expect groundbreaking products and the latest solutions. These raise the bar."

Andrew Oransky, President and CEO of Roland DGA, Roland DG's US-based sales and marketing subsidiary, was quick to point out the importance of winning this coveted award. "To have ISA recognise our new TrueVIS VG2 Series as a standout product for 2019 is quite an honour, especially considering the stiff competition. The cutting-edge technologies and features of these next-generation printer cutters put them in a class by themselves," Oransky noted. "An amazing amount of research and effort went into the design and development of these machines, ensuring that every VG2 is built to exceed the needs of the most demanding graphics professional."

Kohei Tanabe, Roland DG President, Digital Printing Business Division said, "We are very pleased that the VG2 Series printer cutters, which boast the highest output quality in Roland DG history, have won this prestigious award. Roland DG is committed to providing products to help graphic providers and sign makers unleash their creative possibilities, transform their imagination into reality, and enjoy a sense of accomplishment when people react to their output graphics with ‘WOW!’

For more information on Roland DG’s award-winning TrueVIS VG2 Series wide format printer cutters, visit

www.rolanddg.com.au/vg2

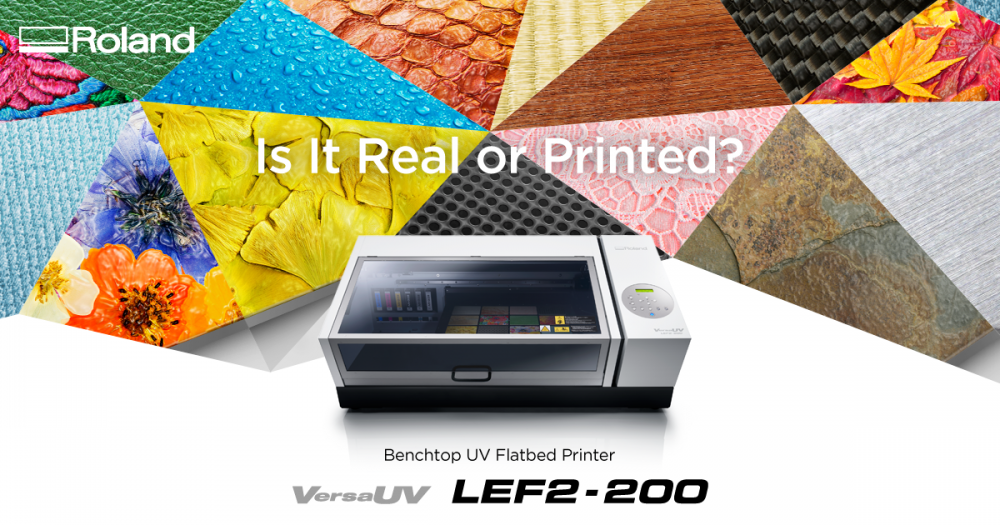

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters worldwide, today announced the launch of the VersaUV LEF2-200 20" benchtop UV flatbed printer....

March 12 2019

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters worldwide, today announced the launch of the VersaUV LEF2-200 20" benchtop UV flatbed printer.

The LEF series includes the popular desktop and benchtop versions of Roland DG’s UV flatbed inkjet printers. The latest model LEF2-200 inherits the series’ renowned ability to print amazing graphics and lifelike textures, including premium finishes such as simulated embossing, onto a vast array of materials up to 100 mm (3.94 in.) thick. New functions make the LEF2-200 even easier and more efficient to use.

"The VersaUV LEF2-200 makes it very simple to print premium-quality photographs, graphics and text on almost anything," said Kohei Tanabe, President of Roland DG’s Digital Printing Business Division. ECO-UV ink cures instantly on the surface of the material, allowing you to print directly onto PVC and plastics, canvas, wood, leather, fabric, etc. In addition to full colour printing, you can produce premium gloss and matte finishes as well as simulated 3D embossing for amazingly lifelike textures with multiple layers of Clear ink. Capable of printing on corners and curves as well as soft materials such as leather and fabric, advanced Roland ECO-UV ink formulations are designed for both flexibility and beautiful imaging.

According to Tanabe, the new LEF2-200 incorporates a host of advanced functions to simplify high quality printing. A Start Timer Function completes the setup procedures of printhead cleaning and white ink circulation automatically by your designated start time. A positioning jig makes it easy to align items on the print table. The VersaUV LEF2-200 includes the latest VersaWorks 6 RIP software, featuring an intuitive interface for easy operation and job management. The LEF2-200 also adopts a new cleaning system to increase reliability. A Head Refresh Feature removes any ink remaining on the printheads and cleans the printhead surface to maintain the health of the printer. The airtight cover protects operators from UV light and prevents dust from settling onto the surface of materials while printing.

"With the LEF2-200, now anyone can print stunningly realistic and colourful images onto many different materials that you might not think possible," Tanabe said. "To be able to offer this print capability even to people who lack training, we focused on ease of operation and bullet-proof reliability so that everyone can enjoy printing graphics and textures with confidence. This LEF2-200 adds incredible value and opportunity for business growth."

www.rolanddg.com

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters worldwide, today announced the launch of its second generation TrueVIS VG2 Series 64" and 54" wide f...

March 05 2019

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters worldwide, today announced the launch of its second generation TrueVIS VG2 Series 64" and 54" wide format eco-solvent inkjet printer cutters.

Kohei Tanabe, President, Digital Printing Business Division, stated that the company’s objective in creating the VG2 Series was to improve upon the already high standards set by the previous award-winning VG Series. "To create printer cutters that boast the highest output quality in Roland DG history, we did not stick to existing concepts, but redefined product development by focusing on dozens of little details. The result is that the new TrueVIS VG2 Series offers customers a true competitive advantage and the "power to excite."

The TrueVIS VG2 Series adopts a new generation of eco-solvent TR2 ink. In addition to the previous seven colours of CMYKLcLmLk and White, new TR2 ink supports Orange ink to greatly expand colour gamut. "Orange ink effectively leads to richer colour expression which resonates in the mind," Tanabe said. A new Multiprocess Colour Function was developed to enable using Orange ink as a process colour. In order to take full advantage of the VG2’s superior colour reproduction capability and the wide colour gamut provided by TR2 ink, a True Rich Colour preset was also created. "Now for the first time," he added, "vibrant colour can be combined with neutral grays, smooth gradations and natural skin tones to create stunning graphics."

The VG2 offers a host of technological advancements to improve both printing and cutting accuracy for reliable results during unattended operation. New middle pinch rollers raise automatically prior to starting the cutting process for unattended operation. New crop mark options for cutting laminated printed materials in combination with optimised pinch roller pressure provide more stable cutting performance. A new take-up unit supports two modes according to the type of media chosen, securing take-up stability for smooth post processes.

Tanabe said meticulous attention to details by Roland DG engineers resulted in increased performance and reliability for the VG2. Roland DG FlexFire printheads produce the precision ink firing that enables printing neutral grays, vivid colours, and smooth skin tones even at the highest speeds. TrueVIS VG2 and TR2 ink is certified for long-lasting results by the 3MTM MCSTM, providing assurance of the quality and reliability of their graphics. The VG2 with TR2 ink also supports Avery’s ICS performance guarantee and is certified GREENGUARD Gold for safe indoor graphic applications. Included VersaWorks 6 RIP software supports the latest Harlequin® RIP dual core engine with PDF 2.0 and native 64-bit processing plus new, easy-to-use capabilities that make it the most powerful RIP software ever.

Tanabe noted that the previous VG Series won the 2019 Pick Awards for Colour and Productivity from Buyers Lab. "Roland DG is committed to providing products to help graphic providers and sign makers unleash their creative possibilities, transform their imagination into reality, and enjoy a sense of accomplishment when people react to their output graphics with ‘WOW!’" he said.

For more information, please visit here

Contex has introduced two new models to the HD Ultra X scanner series. The series now includes 36- and 42-inch models, completing the range of scanning solutions for Contex’s newest line of p...

February 21 2019

Contex has introduced two new models to the HD Ultra X scanner series. The series now includes 36- and 42-inch models, completing the range of scanning solutions for Contex’s newest line of premium scanners. Introduced in 2018 to rave reviews from the scanning community, the HD Ultra X scanner series, which also includes a 60-inch model, reigns as the market’s fastest and widest scanner series available. The scanner series outperforms the competition in color matching and image scanning quality, while exceeding environmental standards. The scanner series also boasts numerous productivity-boosting capabilities to accelerate the scanning workflow, while delivering long-term value and a quick ROI. All scanners in the HD Ultra X series are immediately available from distributors worldwide.

“Our customers are thrilled with the capabilities of the HD Ultra X scanners, and the new models give them even more options to suit their requirements,” comments Jacob Bendix, CCO and VP of Global Sales and Marketing. “Productivity, improved workflow, and color matching have been the center of our attention, and our customers can instantly benefit from these advancements the HD Ultra X scanner series.”

HD Ultra X scanner series expanded

The HD Ultra X series uses CCD technology for the best quality images available in the market today. Whether scanning 36-, 42-, or 60-inches wide, customers can capture originals at an unprecedented 17.8 ips. The common platform also gives customers the same results from each scanner model.

The scanner series includes several unique features and productivity boosters, including true size detection and instant-ON capabilities, which cut valuable seconds from production time. A throttle buffer control also eliminates scanner pauses, allowing operators to continuously feed documents without waiting for scanned data to be processed.

The HD Ultra X series boasts the fastest data transfer of any scanner on the market, made possible by the GB Ethernet xDTR2.5 and USB 3.0 SuperSpeed xDTR3 data transfer technologies.

Exclusive technologies for the most advanced image quality

The advanced technology in the Contex HD Ultra X scanner series offers customers several exclusive imaging advantages, including the highest color-rendering index (CRI). The scanners are equipped with Contex Perfect Light, which uses the latest LED technology combined with specially developed diffusion filters.

Sharp scans are achieved by Contex’s exclusive lens spherical correction technology and accuracy lens enhancement (ALE), which minimizes optical distortion. Each scanner model in the the HD Ultra X series is equipped with X-Rite ICC color technology and Fujifilm camera lenses, which deliver greater depth of focus — 0.3 inches — and CCD optics of up to 1200 dpi. The depth of focus allows users to capture documents of all types — especially thick, delicate, or with irregularities — with ease.

Intuitive scanning advancements

With just the press of a lever, Contex’s Optimal Thickness Adjustment Control (OTAC) enables users to quickly adjust the HD Ultra X to the required paper thickness. Feather mode also protects delicate originals and extra-thin documents.

A speed-matched roller system ensures fast and easy document loading and eliminates skewing. Operators can choose between center and side loading, or use the adjustable paper guide for smaller documents.

The scanner’s static-free, touchless glass system and steel anti-static feed table also minimize friction, while reducing maintenance costs over time from worn scanner glass.

Exceeding environmental standards

The HD Ultra X scanner series exceeds Energy Star consumption standards and is RoHS compliant.

Additionally, the LED light source, guaranteed to last the scanner’s lifetime, saves energy by automatically turning off in between scans. Instant-ON scanning capabilities also allows operators to simply load and scan originals, without requiring the scanner to warm-up.

HD Ultra scanner series availability

The HD Ultra X scanners are available as stand-alone (Contex AIO optional) or in a ScanStation Pro configuration, which includes a stand, touchscreen monitor, and Nextimage REPRO software (Contex AIO optional). The HD Ultra X scanners can be networked to any leading printer.

For more information visit a Contex distributor, or contact info@contex.com.

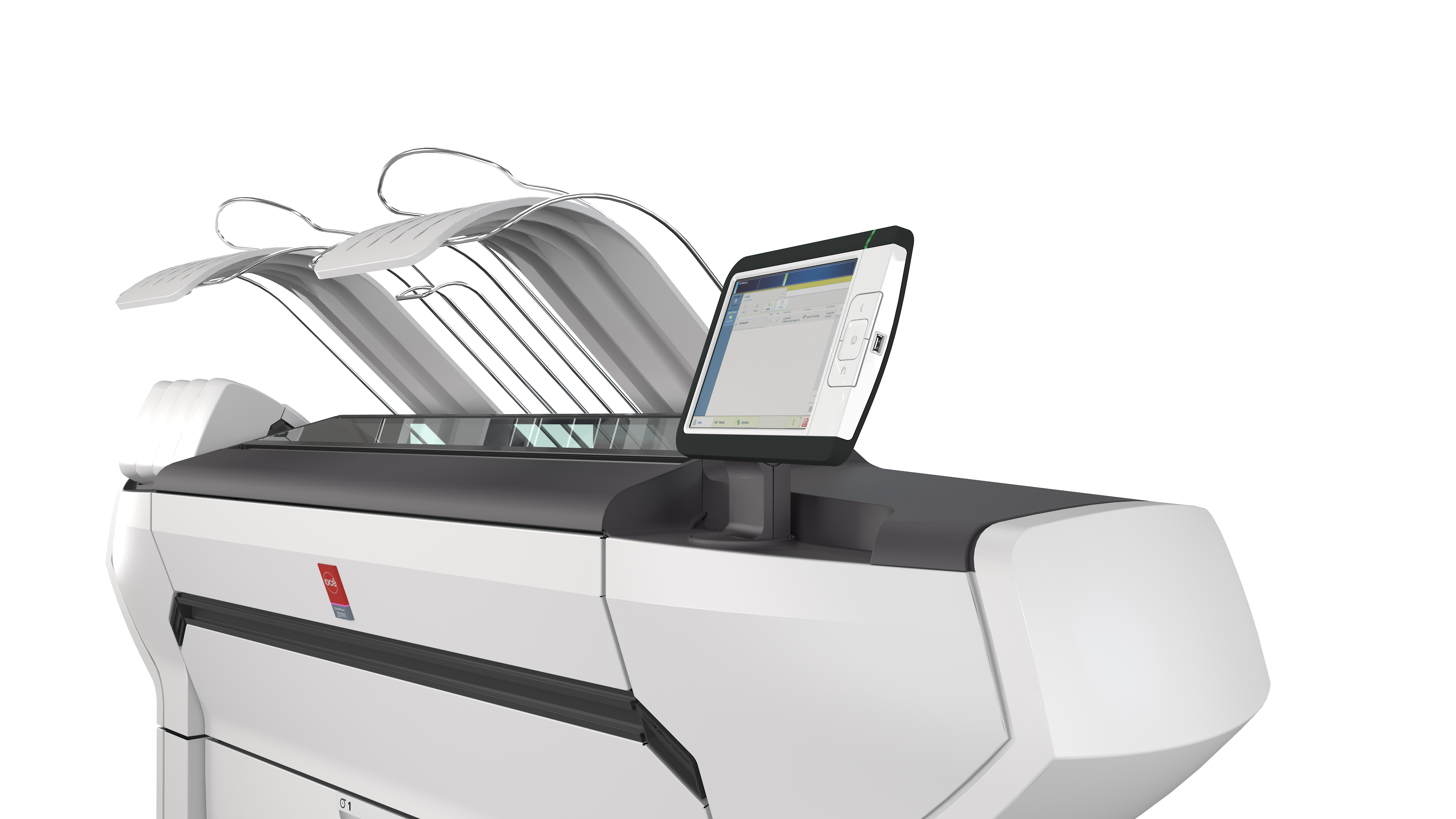

Océ Australia has today announced the launch of its new generation Océ ColorWave 3000 series, a reliable, flexible and productive large format colour printing system, which it says ha...

February 13 2019

Océ Australia has today announced the launch of its new generation Océ ColorWave 3000 series, a reliable, flexible and productive large format colour printing system, which it says has been designed specifically ‘for the creators’.

Dale Hawkins, Senior Manager – Indirect/Marketing for Océ Australia says the easy-to-use range is ideal for those looking for a productive, accurate and versatile printer that will help build business, save time…and put more money in their pockets.

The fourth generation of Océ’s CrystalPoint colour printers, the ColorWave 3000 series has a decade of proven technology behind it, providing businesses with reliable, repeatable, accurate output on a wide range of mono or colour applications where uncompromising quality is required.

“Using distinctive Océ TonerPearls, CrystalPoint brings together the best of toner and the best of inkjet to provide a versatile, precise and instantly dry print solution that is ideal for a wide range of media and applications,” Hawkins explains, saying the two models in the new series are ‘packed’ with smart, time-saving innovations and intuitive operational features.

“The ColorWave 3000 range has been designed to deliver both high productivity and unparalleled ease of use, with automated print quality settings that deliver reliable, ‘first-time-out’ quality and ‘set and forget’, intervention-free operation,” he says.

“The Océ ColorWave 3500 has been designed for worry-free, ‘walk up’ printing of CAD documents, plans, maps and the like, at the high level of precise detail required by corporates and businesses in sectors like architecture, engineering and construction.”

“Its stablemate, the Océ ColorWave 3700, provides higher media capacity and versatility, as well as superb rendering which captures every detail perfectly. This makes it the perfect choice for reprographic applications where that level of precision is a must, as well as superior, photo-quality graphics and other commercial digital print applications.”

As well as being so easy to use that even inexperienced operators can get outstanding, reliable results, both machines are exceptionally versatile, printing on a wide range of media from thin uncoated stocks like 80gsm bond to vinyls, without compromising on quality.

“CrystalPoint printing technology means that the image is totally independent of the media, so you can choose the right media for your application and be sure of getting consistent results,” Hawkins says. “Prints are delivered dry off the machine and are both robust and water resistant, giving them a certified archival lifetime of at least 100 years.”

Featuring the kind of benefits for which Océ has become renown among print service providers, Hawkins says the technical expertise and market experience of the Netherlands-based manufacturer is evident in every aspect of these machines.

“There’s Océ’s workflow software which makes job changes seamless, media capacity of up to six rolls for fast changeover between jobs without sacrificing productivity and even Océ ImageLogic scanning technology which turns imperfect originals into perfect prints using advanced image enhancement,” he says.

“On the 3700 Océ step it up even further with Océ MediaSense, which automatically adjusts the gap between the imaging device and the media, to ensure superb high quality output without manual adjustments.

“The result is a finely-tuned, beautifully engineered machine which will allow printers the ability to grow their applications volumes and expand their product range to capitalise on profitable new revenue streams while enjoying higher profit margins and faster return on investment.”

Add great environmental and OH&S credentials – CrystalPoint emits no fine dust, ozone or odour – and reliable, low-maintenance performance, backed by technical and service support from Océ Australia’s dedicated national team – and the new range ticks all the boxes.

“At the end of the day, building business success is about capitalizing on opportunities and building profitability,” Hawkins says. “With the poster printer option on the CW3700, you can move into the Graphic Arts applications while still maintaining your revenue from CAD prints using one single machine. The Océ ColorWave 3000 series, allows you to say ‘yes’ to more jobs, more often … and keep more dollars in your own pocket.”

The Océ ColorWave 3000 series are now available from Océ Australia www.oce.com.au

Canon is pleased to announce the launch of the new Océ Arizona 1300 series of high-productivity mid-volume UV true flatbed printers. With its innovations in print speed, ease-of-use and curi...

February 05 2019

Canon is pleased to announce the launch of the new Océ Arizona 1300 series of high-productivity mid-volume UV true flatbed printers. With its innovations in print speed, ease-of-use and curing technology, the Océ Arizona 1300 series is extremely versatile allowing print providers to do more, do it smarter, and do it now.

The latest in the line of Canon's award-winning Océ Arizona printers, the new Océ Arizona 1300 series is a great choice for printers in the sign and graphics industry, for whom print quality and productivity are essential. The Océ Arizona 1300 series has productive print modes, optional light and white ink support, optically clear varnish and enhanced screening to deliver outstanding print quality, print after print. It allows print providers with photographic or fine-art applications to print on a wide range of media, including odd-shaped, heavy, smooth or pre-cut media and unusual objects such as canvas, glass or wood. Customers can choose from three GT models (Océ Arizona 1340 GT, 1360 GT, 1380 GT) with a flatbed print area of 49.2 inches x 98.4 inches, or three larger 121.3 inches x 98.4 inchesXT models (Océ Arizona 1340 XT, 1360 XT, 1380 XT).

The impressive innovations in the new Océ Arizona 1300 series are the extensive application range, integrated Océ Arizona Xpert self-learning technology and instant-on capability. And for the customer who also purchases the Océ Touchstone software, users easily create textured prints, both transparent and opaque, that will even further help expand their applications capabilities and delight their customers.

Imagine … print … learn … repeat

The integrated Océ Arizona Xpert technology allows the printer to learn from what the operator does. This makes it easy and extremely productive to help reproduce complex, multi-layered projects. Just design them once with the intuitive user interface and print them. The printer will learn the recipe for the project, including transparencies and multi-sided printing, which can then be used over and over again.

Ready when you are

With instant-on printing, the Océ Arizona 1300 series printer is ready when the end-user is. The Océ Arizona 1300 series exemplifies speed and productivity, delivering sharp, high-key prints up to 568 square feet per hour and high-density prints up to 380 square feet per hour. The new LED UV curing system offers instant-on capability, allowing operators to start valuable rush jobs without waiting for the printer to warm up.

With the built in Automated Maintenance System (AMS) for hands-free printhead maintenance, nozzle function for all colours can be selectively restored in seconds.

Ready for the future

For customers with an evolving business or application range, the Océ Arizona 1300 series can be upgraded at any time such as by adding additional ink channels up to a maximum of eight, the Roll Media Option, or a Static Suppression Upgrade Kit that provides active suppression of static electricity when printing on hard plastic materials such as acrylic, polycarbonate and styrene. Also, the option to add light cyan and light magenta inks, plus our brightest white ink ever, or optically clear varnish to the ink channels helps enable even higher quality photo and fine-art and high margin applications than before.

Quick, reliable and low-maintenance

The Océ Arizona 1300 series printers are designed for the easy, reliable operation a busy print environment needs. Operators can easily make last-minute adjustments at the printer, such as nesting, batching of complex jobs, step and repeat, mirroring and re-assignment of print modes. Switching between rigid media jobs and roll to roll jobs can be done instantly at the push of a button with no extra tables to deal with. Media handling too is simple and efficient with the built in pin registration system to easily align media on the flatbed table. The new IJC357 UV inks are Greenguard Gold certified, so the prints may be used in sensitive environments such as in schools and hospitals.

https://www.youtube.com/watch?v=teVU22SLvqI&feature=youtu.be

InkTec kick off 2019 with three new JETRIX printers The New Year looks bright for South Korean company InkTec as they launch not one, but three new JETRIX printers. These newcomers wil...

January 22 2019

InkTec kick off 2019 with three new JETRIX printers

The New Year looks bright for South Korean company InkTec as they launch not one, but three new JETRIX printers. These newcomers will add to their already extensive range of roll-to-roll LED-UV flatbed printers.

Building on all the tried and tested technology of the popular KX6 and KX7, this month sees InkTec releasing the eight-channel LXi6 and LXi7 LED-UV flatbed printers. These high performance printers have been designed and developed to deliver high efficiency and will come equipped with even more advanced systems than their previous counterparts including a smarter GUI. The stronger vacuum combined with functional and vibrant ink make them extremely easy and convenient to use. The smaller LXi6 takes media up to 2.5 x 1.28m and the LXi7 extends the media size up to 2.5 x 3.06m with both offering an optional enhanced roll-to-roll option. Capable of top speeds of 78sqm/hr with a maximum resolution of 1,080 dpi; both are being pitched as the perfect mid-range LED-UV flatbed printer for print providers looking to enter the wide-format or upgrade current equipment.

Their launch will be closely followed in February, by the 1.9m wide LXiR190. This machine builds on the success of the larger LXiR320, but as its name suggests is a narrower version. InkTec have consciously taken the decision to adopt this more unusual width so that the printer can easily use two 914mm rolls at once, which will result in a doubling in the production speed of jobs. It prints at a maximum resolution of 720 x 1,440 dpi and up to speeds of 45sqm/hr, which means the printer will be perfect for many roll based applications including banners, graphics, wall coverings and textiles. The JETRIX LXiR190 is also deliberately economically priced at around £45k to again encourage demand from solvent printers wanting to move to UV.

Ben Woodruff, Head of JETRIX Sales says: “These newest machines encompass everything that is great about the introduction of LED technology. They are more environmentally friendly, more efficient to run, eliminate the need for frequent lamp replacement and more importantly create cost savings.

They will be officially launched at Sign & Digital UK, however while these printers do see InkTec venturing into new areas, initial conversations have been extremely positive. We are therefore predicting that with the introduction of these new machines, that 2019 will see a lot more JETRIX printers."