See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Global manufacturing leader of graphic films Arlon Graphics has announced 3 new virtual application demos launching May 18 running through July 29, 2021. These demo events allow vehicle wrap instal...

May 11 2021

Global manufacturing leader of graphic films Arlon Graphics has announced 3 new virtual application demos launching May 18 running through July 29, 2021. These demo events allow vehicle wrap installers to get hands-on with Arlon’s FLITE Technology films and interface with our Technical Experts conveniently and safely. The 3 demo topics are:

The ultimate range in flatbed production printing is now even faster, with the introduction of robotics technology for the automatic loading and unloading of media. Following the succe...

May 11 2021

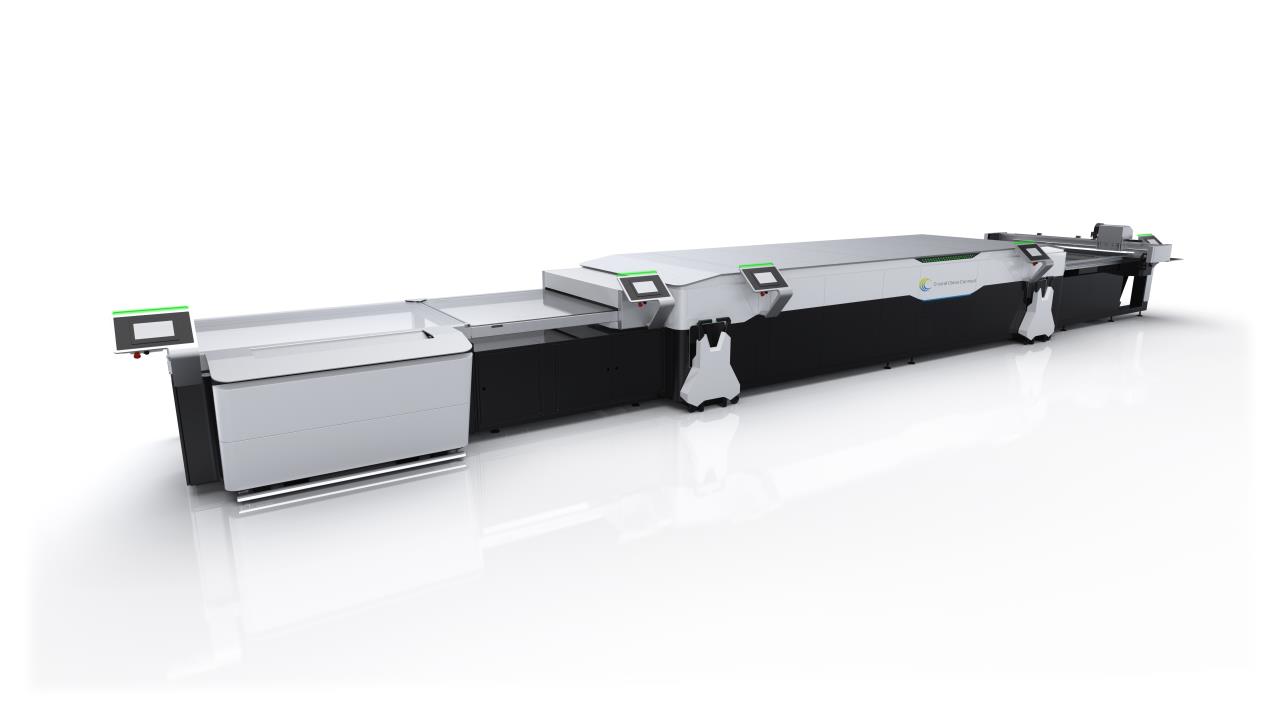

The ultimate range in flatbed production printing is now even faster, with the introduction of robotics technology for the automatic loading and unloading of media.

Following the success of Fujifilm and Inca Digital’s Onset X HS range, the ultra-high productivity large format series now comes with automated technology to assist with long run production. It also slashes job changeover times and reduces the need for manual intervention between runs.

Utilising Dual Flex and High Five robotics, the range includes a semi-automatic (manual load and automatic take-off) configuration and a fully automatic loading, take-off and stacking system, designed specifically to handle flexible and difficult materials, such as unconditioned corrugated board.

“The new automation options available with the Onset X HS range are the result of close collaboration with our current Onset X customers,” says Matt Brooks, Head of Products & Solutions at Inca Digital “Longer run, full automation is becoming more and more common, and with the introduction of highly sophisticated robotic arms from ABB and Inca’s uniquely designed sheet pick-up technology, our Onset X customers can now produce extremely high volume, high quality print work in even less time. The ultra-high productivity and rapid job changeovers optimise production levels like never before.”

There are four automation options for the Onset X HS range – the 3/4 semi-automatic system, a fully automatic material loading system, a fully automatic handling system for unconditioned corrugated board, and a fully automatic handling system with integrated flexible loading.

The 3/4 automation system allows for single sheet, multiple sheets or double-sided print in registration. The operator loads sheets onto a preload table and the system takes over the rest, stacking it on a pallet for simple removal of the printed media. What’s more, the system allows the operator immediate, direct access to the bed and registration points for quick switch between manual and semi-automatic work.

The fully automatic material loading system is designed to handle conditioned and dimensionally stable sheets. It works in conjunction with the 3/4 handling unit to provide full automation, handling multiple sheets with highly accurate registration. The loader can be moved away from the machine to allow access to the print bed.

The corrugated board solution incorporates a fully automatic handling system, specially designed to handle difficult materials like unconditioned corrugated board. Vacuum-to-vacuum transfer ensures precision handling, from the robotic arm pickup to placement on the print bed and stacking of the printed board.

Dual Flex – this unique fully automatic solution with integrated flexible loading enables printers to transition seamlessly between lay table loading and dual robot automation. This solution provides full capability to load and unload flexible, semi-rigid and rigid sheets with a seamless switch from one operation to the other. In full automation mode, the dual robots also offer an optional “flip to print” mode – High 5 – for front to back, double sided print requirements without manual intervention.

“A fast and powerful handling system is vital for the Onset X to perform to its full capacity, helping to maximise job turnaround speeds and job changeovers for longer runs,” continues Brooks “We’re delighted to be launching these advanced automation solutions to the market, helping our customers to achieve optimum productivity and print quality, and we have already seen a great deal of interest in these new types of automation solutions”.

“Fujifilm has enjoyed a long and successful partnership with Inca Digital since the two companies together pioneered the world’s first wide format UV inkjet printers in 1999,” says Kevin Jenner, European Marketing Manager, Fujifilm Wide Format Inkjet Systems. “The Onset X range has been setting the standard for quality and productivity in the sector for some years now and we’re delighted to be able to offer our customers yet another step up in speed and efficiency.”

HP Inc. announced the latest addition to its HP Stitch portfolio to help print service providers (PSPs) diversify their soft signage and interior décor offerings, as well as meet more challe...

May 11 2021

HP Inc. announced the latest addition to its HP Stitch portfolio to help print service providers (PSPs) diversify their soft signage and interior décor offerings, as well as meet more challenging customer needs. The updated 126-inch HP Stitch S1000 is designed to offer high quality with greater versatility and smooth operation.

"The new HP Stitch S1000 will allow PSPs to expand their dye-sub production versatility even further and say yes to ambitious projects, as well as demanding and innovative applications,” said Oscar Vidal, Large Format Global Business Strategy Director, HP. "With the large format industry set for a progressive year, HP’s latest Stitch device ensures soft signage and interior decoration professionals are able to handle a diverse range of customer needs, safe in the knowledge they have the technology to deliver.”

Take on more

The highly versatile new HP Stitch S1000 gives users the option to print directly to fabric or onto transfer paper, simplifying workflows without compromising on results - while 1200 native dpi printheads and HP’s Drop & Dry system ensure deep blacks, vivid colours and extreme resolution to deliver work of the highest-quality.

A newly incorporated contact heater offers enhanced backlit saturation performance on direct-to-fabric jobs, meaning colours appear brighter and more vivid than ever before.

Work faster

HP Stitch S1000 is designed to provide rapid turnaround production start-up times and speeds of up to 2370 ft²/hr (220 m²/hr). Additionally, it also offers the possibility to double the through put on substrates of up to 63 inches (1.6m) with dual roll accessory.

The Smart Nozzle Compensation system and Optical Media Advance Sensor Plus work together to ensure reliable image quality while operating at pace. With an additional integrated aerosol and vapour extraction system, meeting tight deadlines has never been easier.

User-replaceable printheads and HP preventative maintenance support helps increase uptime, while spreader rollers, 10-litre ink supplies and rolls up to 600lb (300kg) allow print professionals to confidently leave the device to print unattended.

Take control

Combined with the HP PrintOS app, print operations are easily controlled anywhere, anytime – while also allowing PSPs to make data-driven decisions . If working with a fleet, the HP Configuration Center ensures jobs are distributed efficiently for maximum productivity, with a built-in spectrophotometer providing colour consistency across fleet.

Tests show that in 40% less time, a single operator can easily load both transfer and textile rolls - enabled by features including automatic media tension adjustment, simple media path, automatic and optimised printhead cleaning, and a device warm-up process that occurs in parallel with loading.

Gain a sustainability edge

The updated HP Stitch S1000 uses ECO PASSPORT certified dye sublimation inks, a standard that verifies the safety of chemical products used in the textile and leather industry. The device also benefits from HP’s free and convenient printhead recycling scheme, via the HP Planet Partners initiative. Meanwhile, the outer carton of a S1000 ink cartridge is made from cardboard and can be recycled locally - part of HP’s goal of creating a more circular, low-carbon economy.

Pricing and Availability

Information on country availability, pricing, and retail destinations for the HP Stitch S Printers Series Portfolio vary region by region.

A first-look at the product can be found via this video

Durst, manufacturer of innovative digital printing systems and software solutions, is setting a milestone in the field of sublimation printing with the launch of the P5 TEX iSUB. The a...

May 04 2021

Durst, manufacturer of innovative digital printing systems and software solutions, is setting a milestone in the field of sublimation printing with the launch of the P5 TEX iSUB.

The abbreviation iSUB stands for "inline sublimation." This eliminates individual work steps, resulting in a significant increase in quality and efficiency for the user.

The soft signage market is experiencing enormous growth rates in all areas of application - from visual communication and decor to textile clothing. In the period from 2017 to 2023, the sales volume will increase by more than 60 percent, according to a forecast by Keypoint Intelligence. Converted to absolute figures, the market will grow globally from around $19.2 billion in 2019 to $31.4 billion (2023).

A number of trends can be pinpointed for this continued growth, which clearly speak in favour of the soft signage market. These include environmental friendliness through the use of water-based, odourless inks. Other user benefits include cost efficiency in logistics and low ink consumption, as well as fast project implementation and a wide range of applications. "Durst has been active in the soft signage market since 2010, and we have been able to place over 250 systems from the Rhotex series on the market worldwide," emphasises Christian Harder, Vice President Sales, Durst Group AG.

Integrated inline fixation

In tune with these trends in the soft signage market, Durst has developed the P5 TEX iSUB, which is based on the successful P5 platform with a maximum print width of 3.3 meters. At the heart of the Durst P5 TEX iSUB is the integrated inline fusing for direct printing on polyester fabrics. The advantages of this one-step process are obvious, explains Andrea Riccardi, Head of Product Management, Durst Group AG: "No investment and no floor space is required for a calendar. The Durst P5 TEX iSUB is operated by only one operator, and the process acceleration also increases our customers' ability to deliver." Whereby the P5 TEX iSUB is not limited to direct printing, but transfer papers can also be printed and further processed in the usual way. It is precisely the combination of both processes in one system that gives users enormous flexibility.

Innovation iSUB - contactless fixing technology

The Sublifix dye sublimation ink developed by Durst delivers vivid colours, even on difficult media such as blackback or backlit for light boxes or flags. A unique feature of the P5 Text iSUB is its innovative contactless fusing. The iSUB contactless technology ensures excellent colour consistency as well as extreme sharpness of detail in images and text, also blurring or bleeding of colour is virtually eliminated.

A wide range of applications can be implemented with the P5 TEX iSUB. One example is decorative fabrics with strong, brilliant colours and exact reproduction of details. Another are flags that show good print on both sides of the material even without external calendaring. Blackback applications as well as colourful light boxes round out the spectrum while retaining the soft-touch feel. In all these applications, the Durst RIP plays a central role, ensuring consistent colour across all media.

The maximum print speed is 383 m2/hour when the 330 cm print format is fully utilised, inspiring the efficient implementation of all these application examples. Access to two rolls via the Multi-roll option makes changing materials much easier in practice. In addition, the dual-roll option allows two rolls with a width of 1.6 meters to be printed. Another outstanding feature of the Durst P5 TEX is the integrated finishing unit, which can be used to sew and stitch media.

Test under practical conditions

The Durst P5 TEX iSUB is currently undergoing field testing at the Italian ABS Group, which has a long-standing partnership with the Durst Group and has been working with a Rhotex 500 and Rhotex 325 for many years. In conjunction with the Durst P5 TEX iSUB, ABS Group benefits from the flexibility and significant process acceleration. "The Durst P5 TEX iSUB will also prove its reliability in 24/7 operation and deliver a significant increase in quality to our customers," said Andrea Riccardi. The ABS Group management also gives a very positive assessment of the Durst Analytics tool, the data from which is used to network the P5 TEX iSUB with the ERP software developed in-house and thus optimise production planning and individual processes.

"The P5 TEX iSUB combines efficiency, quality and productivity at the highest level. At Durst, we are convinced that our solution will give a significant boost to the soft signage market," assures Christian Harder, Vice President Sales, Durst Group AG.

Xaar, has launched its latest printhead – the Xaar Nitrox – that provides users with greater print speeds and uniformity to deliver unparalleled performance across a wide variety of pri...

May 04 2021

Xaar, has launched its latest printhead – the Xaar Nitrox – that provides users with greater print speeds and uniformity to deliver unparalleled performance across a wide variety of print applications.

The new Xaar Nitrox is the next printhead to come from ImagineX which sets the roadmap for Xaar’s bulk inkjet innovations and printhead developments.

Speed is integral to the Xaar Nitrox, with firing frequencies of up to 48kHz enabling print at up to 100 metres per minute. Set-up time and installation are also fast, with drop in printhead alignment and Xaar’s AcuChp Technology allowing for a more automated process that is quick, easy, and reliable.

With its ‘plug and print’ capability, printer uptime is maximised, and superb print uniformity also delivered. Xaar’s TF Technology recirculation minimises any temperature changes within the printhead, virtually eliminating print density variations and controlling viscosity to provide consistent printing across the swathe throughout each job.

Maintaining a constant flow of fluids directly past the back of the printhead nozzles enables instant priming of the Xaar Nitrox and avoids the need for costly and wasteful purging before printing can start. The very high flow rate also prevents sedimentation and nozzle blockages, particularly in heavily pigmented inks, radically improving reliability in even the harshest printing environment.

The Xaar Nitrox supports the widest range of applications and handles the broadest range of fluids. Its open printhead architecture and TF Technology facilitate printing in multiple orientations. Consequently, the Xaar Nitrox prints extremely reliably, whether in vertical or horizontal mode, or even when being positioned by a robotic arm with accelerating and decelerating speeds.

High Laydown Technology delivers very high volumes of ink in a single pass and combined with Xaar’s TF Technology allows fluids with higher particle loading and sizes, even those with viscosities of up to 100 centipoise, to be used. This enables the Xaar Nitrox to print an increased colour gamut and special effects for applications in the ceramic, glass and packaging sectors as well as jetting higher molecular weight materials for Advanced Manufacturing and 3D printing.

Backwards compatible with the Xaar 1003, the three variants of the Xaar Nitrox – Core, Pro and Elite – provide customer choice and flexibility for a range of print needs.

The Nitrox Core is designed for applications using oil-based inks, such as in ceramic tile decoration, while the Nitrox Pro can handle more demanding fluids including soluble salts and frit used for printing glass. The Nitrox Elite delivers printing at up to 48kHz and its exceptional drop placement and accuracy make it perfect for functional fluids and 3D applications, alongside more traditional display graphics and label printing solutions.

Graham Tweedale, General Manager of Xaar’s printhead business unit said: “We are delighted to be launching the next printhead from our ImagineX platform.

“Whether using the latest highly viscous fluids for 3D printing or High Laydown for packaging and labels, the speed, performance and productivity of the Xaar Nitrox means you can use it to print right the first time and every time.”

HP introduces HP Durable Foldable Document Material, 3-in Core — a uniquely strong, yet flexible material that has amazing holding power. Once folded, documents lay flat and stay tightly fold...

May 04 2021

HP introduces HP Durable Foldable Document Material, 3-in Core — a uniquely strong, yet flexible material that has amazing holding power. Once folded, documents lay flat and stay tightly folded with little expansion.

HP Durable Foldable Document Material, 3-in Core (DFDM) can be easily transported due to its thin, lightweight construction. This remarkably tough printing substrate was designed and tested to resist jamming in commercial folding machines. Engineered with DuPont Tyvek material, it produces tear- and water-resistant, lay-flat, foldable maps, banners, and posters that can be grommeted and stitched.

Compatible with HP PageWide XL and HP DesignJet printers, it is perfect for applications where durability and tear resistance are required. And this trouble-free material has the unique “Fold n’ Hold“ properties.

hplfmedia.com

Massivit 3D Printing Technologies, will unveil the industrial-grade Massivit 5000 at the AMUG 2021 Conference in Orlando, FL (May 2nd-6th, 2021) as well as at two live Webinars showcasing the new c...

May 04 2021

Massivit 3D Printing Technologies, will unveil the industrial-grade Massivit 5000 at the AMUG 2021 Conference in Orlando, FL (May 2nd-6th, 2021) as well as at two live Webinars showcasing the new capabilities, features, and applications.

The Massivit 5000 will enable manufacturers and service providers across a range of industries to expedite their lead times for manufacturing large parts, prototypes, and tooling by up to 30 times the production speed of existing technologies.

To book a live demonstration of the Massivit 5000 at AMUG 2021 (2nd-6th May), please click here.

Based on the company’s unique, patented Gel Dispensing Printing (GDP) technology – already adopted across 40 countries for fast, cost-effective production of large parts – the new Massivit 5000 introduces to the market new resolutions, materials, and automation capabilities that address industry 4.0 needs, enabling production of large-scale parts within hours instead of weeks.

A new printing material, DIMENGEL 110, now available with the Massivit 5000, facilitates high-definition printing and greater fidelity to CAD designs. Two new resolutions enable print optimization according to layer thickness and speed requirements. The Massivit 5000 offers a Dual Material System that allows operators to print simultaneously with a different material on each head. New software automation features also allow operators to improve workflow efficiencies and enable easy monitoring and operations.

This latest addition to the Massivit 3D portfolio of large-scale 3D printers facilitates complex, large parts up to 145cm x 111cm x 180cm (57” x 44” x 70”) that instantly cure during the printing process, enabling ready-made parts straight off the printer without the need for post-processing and with almost no required support structures.

During two launch Webinars, attendees will experience a virtual, live tour of the Massivit 5000 and will see a broad range of applications available across the automotive, marine, rail, and scenic fabrication sectors.

A keen, lively, and enthusiastic group of members of Australia’s specialty printing industry attended the FESPA Australia Annual Golf Tournament on Friday 23 April 2021 at Sandhurst Golf Club...

April 28 2021

A keen, lively, and enthusiastic group of members of Australia’s specialty printing industry attended the FESPA Australia Annual Golf Tournament on Friday 23 April 2021 at Sandhurst Golf Club, in Melbourne.

Conducted in a fun and good-natured competitive spirit the players enjoyed a round of golf at one of Victoria’s key championship Golf Courses, they also had a chance to takeout prizes from a range of categories, including Overall Winner of the FESPA 2021 Tournament, Nearest To Pin, Longest Drive, and the coveted Hole-In-One with a cash prize of $20,000.

“The FESPA Annual Golf Tournament is an enjoyable day out and offers a great way for members to develop relationships with clients and suppliers as well as spending time in a fun environment with industry colleagues,” said Nigel Davies, President of FESPA Australia.

Sponsored by HVG Graphics, Ancyn Screen Printers, Imagebox, and SMIB, with key prizes supplied by Drummond Golf and Callaway, the Annual Golf Tournament offered all a chance to practice their swing, hit a few balls and catch up for a post-game lunch.

“I thoroughly enjoyed the day, more so, when it was announced that our team were the overall winners! Bonus!”, said Ewen Donaldson, captain of the VIVAD team.

The day concluded, as is the tradition, at the 19th hole!

Esko and Asahi Photoproducts have showcased their fully automated flexo platemaking line CrystalCleanConnect at this year’s virtual.drupa event. “With CrystalCleanConnect w...

April 27 2021

Esko and Asahi Photoproducts have showcased their fully automated flexo platemaking line CrystalCleanConnect at this year’s virtual.drupa event.

“With CrystalCleanConnect we have brought together key hardware and software technologies from both organizations to deliver a number of breakthrough advantages from design to print,” said Pascal Thomas, Director of Flexo Business with Esko. “CrystalCleanConnect delivers a cleaner, more environmentally balanced operation that simplifies the flexo platemaking process, improves safety and boosts print quality consistency.”

Esko, the global developer of integrated software and hardware solutions for the packaging and labels markets, has collaborated with Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, on the innovative flexo platemaking solution. CrystalCleanConnect fully automates the entire platemaking process, from imaging and exposure through to plate production, reducing the number of steps in the flexo platemaking process from 12 to just one. This equates to a reduction from 36 minutes in platemaking and plate cutting to just 2.5 minutes of operator time to complete all processing steps.

“With CrystalCleanConnect, the operational benefits to businesses are as pronounced as the environmental benefits,” said Pascal. “With the removal of so many process steps, there’s an immediate 90% reduction in required operator time, which not only eliminates the potential for human error but also delivers immediate efficiency gains. Quality is assured through Asahi and Esko technologies working in complete harmony, and the combination of improved efficiency and quality delivers an average increase of 25% in press OEE.”

A holistic approach to connecting technologies

Dieter Niederstadt, Technical Marketing Manager for Asahi Photoproducts said: “Flexo needs to simplify processes while improving quality, consistency and profitability. In doing so, flexo can create new business opportunities and positively transform into a printing technology in balance with the environment.

Esko_Asahi_CCC_Logo“This breakthrough innovation is different in many ways to other solutions on the market,” Dieter said. “It is not just an assembly of available plate making processes delivered inline, but rather a holistic approach to connecting technologies, up and downstream of the prepress value chain, using an intelligent automation hub as the backbone and heart of the solution. CCC is truly pushing boundaries to the current scope of plate automation delivering a mount-ready plate as well as being the first automated production solution without the need for VOC-based washout solvents in in the platemaking process.”

Pascal Thomas added: “At Esko, we have long been dedicated to improving the platemaking experience, in terms of quality, productivity and connectivity. Together with Asahi Photoproducts, we are taking the flexo platemaking process to a brand-new level, enabling our customers to be even more competitive while also ensuring they can meet today’s demands for flexible and sustainable supply.

“With CrystalCleanConnect, our ultimate objective is to improve our customers’ overall business performance and profitability,” said Pascal.

For more information, visit www.asahi-photoproducts.com/en/CCC

FUJIFILM Corporation (President: Kenji Sukeno) today announces the Jet Press 750S High Speed Model, featuring the industry’s fastest* output speeds of 5,400 B2 sheets per hour for a sheet-fed...

April 27 2021

FUJIFILM Corporation (President: Kenji Sukeno) today announces the Jet Press 750S High Speed Model, featuring the industry’s fastest* output speeds of 5,400 B2 sheets per hour for a sheet-fed digital inkjet press.

This new model retains all the features of the current Jet Press 750S for commercial and folding carton package printing applications:

(1) High image quality outperforming that of offset printing

Utilising advanced ultra-high-density and high-precision “SAMBA” printheads and aqueous pigment “VIVIDIA” ink, the Jet Press 750S High Speed Model is able to produce ultra-high quality print equal to or even better than offset.

(2) High-speed output of 5,400 sheets per hour

The Jet Press 750S High Speed Model has the highest productivity available* for a sheet-fed inkjet press, 1.5x faster than that of the current Jet Press 750S.

(3) Flexible

According to the type of job being run, high quality mode (3,600sph) and high performance mode (5,400sph) can be switched for maximum flexibility.

(4) Improved total cost of ownership

The High Speed Model makes it possible to transfer a wider range of offset jobs to digital to reduce the total cost of ownership.

(5) Upgradeable

On site upgrade is available for new and current Jet Press 750S owners.

The Jet Press 750S High Speed Model is being showcased at virtual.drupa (April 20th to 23rd) via a concept video, and is also being featured on Fujifilm’s new website, https://believinginprint.fujifilm.com

The Jet Press 750S High Speed Model is scheduled to be available in Autumn 2021.

Fujifilm will continue to contribute to the development of the world’s printing industry by developing and providing innovative products for the digital printing market, the popularity of which is ever increasing.

*As of April 2021, in B2 inkjet digital machines.

A new B1-size digital press to pioneer new business fields Komori has launched the 40" Sheetfed Nanographic Printing® System Impremia NS40 sales. The machine confi...

April 27 2021

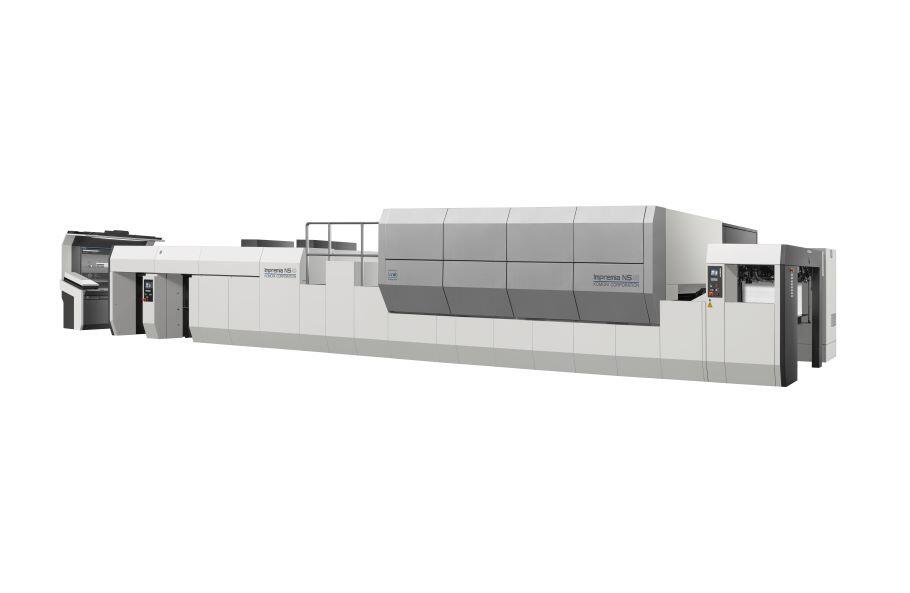

A new B1-size digital press to pioneer new business fields

Komori has launched the 40" Sheetfed Nanographic Printing® System Impremia NS40 sales. The machine configurations are available in two models: 4-colour + coater and 7-colour + coater.

Komori presented this model at the Komori Web Session* at virtual.drupa,

Introducing a new digital press, with the impressive productivity and profitability needed to expand customers' businesses by meeting growing demand for short and medium runs including variable printing and versioning for immediate turnaround on jobs such as packages, displays and point of purchase. Supported by Komori's previously amassed technologies, and with unique designs such as use of image transfer blankets, the press achieves B1 print speeds of 6,500 sph. As a "digital offset" press, the NS40 is the peak of digital presses and is made possible only by Komori.

■Features

B1 printing speeds of 6,500 sph

With standard aqueous inkjet printers, the ink is ejected directly onto the substrate, allowing moisture from the ink to soak into the substrate. This, in turn, requires a large amount of energy to dry the printed sheets, and prevents high-speed printing.

With the Impremia NS40, however, printheads instead eject aqueous Nanoink® onto an image transferring blanket, which forms a thin layer. The ink then dries on the blanket and is transferred after the inner moisture has dissipated, preventing moisture from penetrating into the substrate as deeply and allowing for high-speed drying. This unique innovation is what allows for top-class printing speeds of 6,500 revolutions.

Helps achieve impressive productivity and profitability for small to medium runs

Able to print at speeds of 6,500 revolutions with no need to change plates or ink, the Impremia NS40 is perfect not only for short packaging but also for jobs demanding short turnarounds, and heavy use of special colours, such as point of purchase. In terms of both productivity and profitability, the NS40 greatly excels at jobs such as short and medium runs where standard offset presses fall short.

Reduces time spent for corrections and on-site confirmations

The Impremia NS40 can produce acceptable sheets from the first sheet, with no need to change plates or ink. Compared to offset presses, this can greatly reduce the time spent, from corrections to final printing and on-site confirmations, even for short to medium runs of many different printed items.

Excellent post-press compatibility

Allows for the same post-press processing as with offset presses, such as offline aqueous press coating, PP lamination, board lamination, punching and folding.

Reduces costs, environmentally friendly

-Productivity

Costs remain unchanged even when producing only the necessary amount, eliminating the need for inventory, for more effective use of space.

-Costs

Efficient paper use, even for package and display printing.

-Environment

Conforms to strict European and American foodgrade safety standards such as for Nestle and the FDA.

For more information, please visit www.komori.com

Konica Minolta has received a Red Dot Award: Product Design 2021 for its flagship AccurioPress C14000 Series of production presses from a record number of entries. Launched in Oc...

April 27 2021

Konica Minolta has received a Red Dot Award: Product Design 2021 for its flagship AccurioPress C14000 Series of production presses from a record number of entries.

Launched in October 2019, the award-winning presses, which also include the AccurioPress C12000, are supporting Konica Minolta’s mission to help its customers transform. Konica Minolta is doing this by predicting potential trends and challenges and creating solutions that address these.

An international jury remarked on the outstanding design of the AccurioPress C14000 Series. The AccurioPress C14000 prints at 140 pages per minute (ppm) in A4 and is 40 per cent faster than any other toner-based machine from Konica Minolta. The AccurioPress C12000 provides the same high print quality and a similarly fast speed of 120 ppm.

The AccurioPress C14000 Series also offers the new TU-510 versatile trimmer unit for advanced operational efficiency. The TU-510 is a truly unique inline, four-edge trimmer and creaser that allows full bleed finishing support for banners, booklets, direct mail, and a dedicated business card cutting option. In addition, the AccurioPress C14000 Series is equipped with the Intelligent Quality Optimiser (IQ-501) as standard, which can also improve labour efficiency by as much as 30 per cent.

Professor Dr Peter Zec, founder and CEO of Red Dot, said, “Never before in the 60-year history of our design competition have so many companies and design studios faced the professional judgement of our international jury as this year. Products from 60 countries reached us, and their design quality and degree of innovation were evaluated in a process lasting several days. The fact that Konica Minolta claimed its place in a strong field speaks for the excellent quality of its products. The international jury only awards this sought-after seal of quality to products that feature an outstanding design.”

Sue Threlfo, general manager, production and industrial print, Konica Minolta, said, “The AccurioPress C14000 really is a game-changer for the industry. It provides value for commercial printers in high-volume environments where deadlines are tight, quality is key, and efficiencies are needed. Konica Minolta is proud to have received this global award, which recognises its commitment to setting new standards in product design, while incorporating automation technology that boosts quality, reliability, and productivity. We look forward to helping our Australian customers leverage the benefits afforded by the C14000.”

For more information visit: konicaminolta.com.au/home

Kornit Digital, worldwide market leader in digital textile printing technology, announced today the release of its new MAX technology, establishing a new standard for on-demand fashion and apparel ...

April 27 2021

Kornit Digital, worldwide market leader in digital textile printing technology, announced today the release of its new MAX technology, establishing a new standard for on-demand fashion and apparel production.

One technology, highest quality, endless design possibilities – all waste-free

MAX technology surpasses industry norms for retail quality on multiple fabric types and breaks new grounds of versatility with previously unattainable print applications, significantly expanding the reach of digital on-demand textile production into the centre of mainstream fashion and apparel.

A key feature of Kornit’s MAX technology is XDi, which delivers revolutionary 3D capabilities for new, high-density graphic decoration that can simulate embroidery, vinyl, and heat transfer in a single, waste-free digital process. The new XDi, which is based on Kornit’s patents, allows fulfillers and brands to expand their offerings to include new-to-market, innovative decorations without the inefficiencies and cost of operating analog technologies.

Introducing Kornit Atlas MAX and ActiveLoad Automation

Kornit also debuted the ActiveLoad Automation technology, a new robotic system to significantly ease the burden of manual and labor-intensive media handling in the textile decoration industry. This increases total output per shift while ensuring minimal downtime and exceptional reliability. The new patent pending ActiveLoad Automation technology ensures continuous production and consistency, while decreasing human error and fatigue, regardless of employee experience and training, for ultimate results and best operational efficiency.

The first product with MAX technology is now commercially available in the Kornit Atlas MAX, a carbon-neutral, industrial-scale DTG production system, providing unsurpassed retail quality, exceptional colour-matching capabilities, and a wide, vivid colour gamut, with exceptional durability. The Atlas MAX is delivered with the new XDi technology built in, for 3D printing capabilities. An upgrade to the Kornit Atlas systems will be available during the first quarter of 2022.

“Kornit’s new MAX capabilities bring sustainable on-demand production to the mainstream. We plan to roll out the MAX technology to additional lucrative market segments such as team sports, athleisure, diverse categories of fashion, and home décor applications,” said Omer Kulka, Kornit Digital CMO. “Kornit innovation arrives at just the right moment to match supply to demand – demand that requires freedom of design for self-expression, quality, and sustainable practices; and supply that expands on-demand capabilities enabling the direct-to-consumer vision.”

Delivering on the promise of digital production

“There’s a growing realisation and acceptance that on-demand production is the answer to meet the demands of today’s consumer,” said Ronen Samuel, Kornit Digital CEO. “Kornit’s MAX technology defines the future of on-demand, sustainable textile production, and the future is here now. MAX offers a rare sustainable symbiosis, more creativity, less waste. I am excited to experience what’s possible once the collective brilliance of our industry begins to create digitally, without limits. A world of opportunity awaits us.”

“Our customers have a strong, growing need for retail quality and additional applications, and we are confident the Kornit Atlas MAX will equip us to meet that demand,” added Scott Valancy, COO, Monster Digital, which beta-tested the new system.

To learn more please join a special industry event hosted in partnership with FESPA on April 28-29, 2021. More details can be found on the Kornit website.

BOBST has updated the design of its digital label press to improve convenience and usability, helping to make this highly productive machine even more efficient. Design updates include...

April 20 2021

BOBST has updated the design of its digital label press to improve convenience and usability, helping to make this highly productive machine even more efficient.

Design updates include a more ergonomic and easier-to-access ink cabinet, the possibility to fit rolls up to 600mm for ultimate substrate versatility and a flexible / movable screen for an even more convenient management and control of the machine from every angle.

“One of the hallmarks of BOBST is we never sit still, we are always thinking of ways we can improve the customer experience,” said Erik van Sloten, Head of Sales, Labels. “And the way we do that is by first and foremost listening to our customers. The changes we have made to the Mouvent LB701-UV have come from speaking to printers and converters, understanding their needs, and acting on them.”

The Mouvent LB701-UV enables digital label production for ultra-short and medium run label jobs, with no trade-offs. It is associated with very high productivity, with a speed of up to 70m/min, exceptional print quality (1,200 x 1,200 dpi), and the widest color gamut in its category – printing with up to 6 colors plus optional white with 70% opacity, at 45m/min.

The machine already had a compact and ergonomic design, but this has been enhanced further ensuring one operator only is able to run the press.

“It’s by watching that you design optimal efficiency,” explained van Sloten. “By making the design as user-friendly as possible, we provide the operator the means to complete the tasks at hand.”

The machine provides the best TCO (Total Cost of Ownership) in its category. Elements contributing to its excellent TCO include low initial investment, ongoing operational costs, quick set-up time and high productivity, allowing for higher profitability.

Konica Minolta Australia has launched a new line of versatile colour digital production presses. The AccurioPress C4080 Series high-speed digital press offers robust and user-friendly production. I...

April 20 2021

Konica Minolta Australia has launched a new line of versatile colour digital production presses. The AccurioPress C4080 Series high-speed digital press offers robust and user-friendly production. It’s the perfect fit for businesses looking to expand their production capabilities with advanced automation and ease of use for various applications. The AccurioPress C4080 Series will help power business growth through intelligent automation, outstanding image quality, and print application diversity. It supersedes the C3080 Series and also includes the AccurioPress C4070 and AccurioPrint C4065, lighter versions of the C4080 that can bridge the gap between an office and production printer with the same image quality at a more affordable price point.

The AccurioPress C4080 Series is built on the same engine as the AccurioPress C14000 Series launched last year. It is highly versatile, delivers outstanding quality and performance, and is packed with an array of advanced automation features to boost productivity and expand capability.

The AccurioPress C4080 runs at 81 ppm (A4) colour while the AccurioPress C4070 runs at 71 ppm (A4) colour, and the AccurioPrint C4065 runs at 66 ppm (A4) colour.

Tatjana Ferguson, product marketing manager, Konica Minolta, said, “The C4080 Series is another important step in enhancing Konica Minolta’s line of colour production printers, providing an easy transition into digital printing with inline finishing options allowing prints to be boxed and shipped right off the press. The advanced automation, high quality and productivity, and a myriad of finishing options provide endless opportunities for printers to expand into new markets and develop new revenue streams.”

Outstanding media versatility for ready-made print products means the C4080 Series can print on thin to thick stocks (62 to 360 gsm), banner stocks up to 1300mm (simplex) and up to 900mm (duplex) at full rated speed. The AccurioPress C4080 expands application possibilities and offers envelope printing without the need for an additional fuser. It also offers an array of versatile inline finishing options for unmatched productivity.

One of these options is the unique, TU-510 Inline Trimmer Unit, which can trim, crease, and perforate inline. With this Inline trimmer Unit, it is now possible to produce fully finished output inline with additional options for inline creasing, business cards (up to 130 business cards per minute), postcard cutting and perforation (vertical and horizontal).

Other inline finishing options enable booklet making, perfect binding, punching, stapling, inline trimming, and stacking to meet customers’ needs and tap into new revenue streams.

The AccurioPress C4080 Series can be equipped with Konica Minolta’s IQ-501 Intelligent Quality Optimiser option. This is a fully automated, closed-loop quality management tool that performs automatic density correction and front-to-back registration prior to printing.

New to the AccurioPress C4080 Series is the external media detection sensor, an optional sensor for measuring and identifying media, ensuring the correct media settings are selected. Together, the Inline Trimmer Unit, external media detection sensor, and Intelligent Quality Optimiser make it possible to produce fully finished, high-quality, ready-to-be-boxed output quickly and easily without the need for skilled operators. For customers, this means increased uptime, productivity, quality, and ultimately profit.

The AccurioPress C4080 provides outstanding image quality with 3600 (equivalent) x 2400 dpi resolution. The Line Stacker option supports long sheet bypass and offers operators the advantage of offloading while the machine is still running.

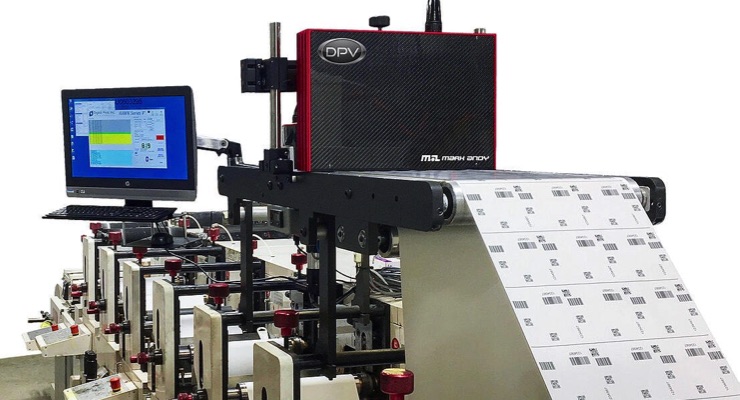

Mark Andy, Inc. has launched Digital Plus Variable (DPV), an inkjet module designed to simply and cost-effectively adds single-colour variable data to any new or existing digital, flexo, or finishi...

April 20 2021

Mark Andy, Inc. has launched Digital Plus Variable (DPV), an inkjet module designed to simply and cost-effectively adds single-colour variable data to any new or existing digital, flexo, or finishing machine without compromising speed.

With advanced printhead technology and a robust design, Mark Andy says DPV is the ideal variable data solution for a broad range of industrial and commercial printing applications, such as labels, forms, direct mail, tickets, gaming, promotions, tags, and pharmaceutical packaging.

“Digital Plus Variable is flexible, durable, and operator-friendly. The system utilises the latest 30 & 40 kHz print module for high-speed data transfer and high-quality inkjet printheads that deliver 600 dpi cross-web print resolution and 300 to 600 dpi in process direction, with speeds up to 500 fpm,” says Scott Warhover, VP engineering, Mark Andy.

The monochrome digital print bar offers adjustable drop size and shaving to ensure premier barcode readability, while internal heaters minimise the impact of external temperature changes to guarantee superior printing. An integrated head cap and automated service mode reduce printhead maintenance, increasing pressroom efficiency.

“The DPV is a straightforward press upgrade that is a benefit to any pressroom because it is an inexpensive low-risk solution with high return. Total cost of production is nearly 90% less than the standard cartridge-based offerings in the market, and the system is also highly dependable, allowing converters to integrate fast variable data to their production for a fraction of the cost,” concludes Warhover.

Available for immediate order, DPV joins Mark Andy’s digital portfolio, including the new Digital Series iQ, Digital Pro and Digital Series HD.

Mimaki Engineering Co. Ltd. (Headquartered in Nagano Prefecture, Tomi City; President / Kazuaki IKEDA), manufacturer of industrial inkjet printers, cutting plotters and 3D printers, announced the r...

April 20 2021

Mimaki Engineering Co. Ltd. (Headquartered in Nagano Prefecture, Tomi City; President / Kazuaki IKEDA), manufacturer of industrial inkjet printers, cutting plotters and 3D printers, announced the release of “JFX600-2513” and “JFX550-2513”, large flatbed UV inkjet printers.

The JFX600-2513 and JFX550-2513 are successor models of JFX500-2131, a large flatbed UV inkjet printer on sale from 2012.

Equipped with drastically increased number of print heads, the JFX600-2513 and JFX550-2513 enable highly efficient printing and can improve productivity by approximately 300% for the JFX600-2513 and 150% for the JFX550-2513 compared to the JFX500-2131. In addition, the number of colours that can be installed has been increased from 4 colours in the previous JFX500-2131 to 6 colours, and a wide variety of ink sets can be selected to lead printing with vivid colours and higher expressive power. It really creates to print more eye-catchy signage graphics at higher speeds than ever before.

The maximum printable size is 2,500 mm x 1,300 mm, with a thickness of up to 60 mm. It supports 4'×8’ boards (1,220 mm x 2,440 mm), which are often used for signboard production. Since direct printing on media is possible, they can print on a variety of media such as resin, glass, and metal, not to mention large sign boards, which makes them perfect printers for a wide range of applications such as large decorations, sign displays, and interior materials. Enable of direct printing on media up to 60mm thick, the printers are capable of 2.5D printing (Emboss print), which creates an uneven surface by printing with multiple layers of UV ink, offering high value-added printing applications.

Mimaki in-house developed UV inks used in JFX600-2513 and JFX550-2513 are environmentally harmonised product with extremely low VOC content that are friendly to humans and the environment. They have been certified as “GREENGUARD Gold” because they meet the world's most stringent standards for volatile organic compound (VOC) emission measurement tests specified by UL, a U.S. third-party safety science organisation, which guarantees their safety to the environment.

Mimaki Engineering is developing “Connected Digital Printing,” a system that connects inkjet printers to peripheral devices such as robots, conveyor belts, inspection equipment, various sensors, and pre- and post- processing systems through intercommunication to enable integration into production lines, unattended on-demand production, and mass customisation.

The new models JFX600-2513 and JFX550-2513 support our original “MDL command” that allows users to control the printers from their production system or peripheral devices. By utilising MDL commands, it is possible to acquire information such as the amount of ink remaining in the printer and error information, as well as possible to control the table position and height where the print media is set, and printer operations such as the start of printing to deliver the unmanned, labor-saving, and automated printing of workpiece transfer. It contributes to the realisation of digital transformation (DX) including pre and post processes of print and provides digital on-demand printing solutions for a new added value.

The JFX600-2513 and JFX550-2513 are scheduled to start sales in the summer of 2021 and will be targeted at sign graphics applications including large indoor and outdoor signs and advertisements.

"Mimaki Australia is really excited to launch these 2 NEW LED UV Flatbed printers by July this year," says Btad Creighton, National Marketing Manager, Mimaki Australia. "The JFX550 and JFX600 performs a significant increase in productivity which is up 300% (JFX600 model) compared to our previous JFX500 production model. These 2 NEW models are perfect for 8x4 boards (1,220 mm x 2,440 mm) with a thickness of up to 60mm. With features including 2.5D printing (Emboss Print), Greenguard Gold certified inks and “MDL command” that allows users to control the printers from their production system or peripheral devices. The JFX500 and JFX600 is a must view for Australian sign and print producers looking for their next investment."

Overview

1. Up to 300% faster print speed than JFX500 for improved productivity

2. The UV inks for the both models are certified as GREENGUARD Gold due to their environmental friendliness.

3. High value-added printing available, such as 2.5D print by UV printing

4. “MDL command” for printer control to support automation of workpiece transfer

*Specifications, designs, dimensions, and other information described in this document are subject to change without notice due to technical improvement etc.

Digital ink manufacturer, NUtec reports an expanding water-based dye sublimation ink range with the latest addition of fluorescent options. Customers can now experience a wider, brighter colour pal...

April 20 2021

Digital ink manufacturer, NUtec reports an expanding water-based dye sublimation ink range with the latest addition of fluorescent options. Customers can now experience a wider, brighter colour palette in the company’s Aquamarine water-based offering with the addition of both fluorescent yellow and fluorescent pink.

The Aquamarine AQ10-DST-HC ink is a dye sublimation range developed for use on Epson DX4, DX5, DX6, DX7, 5113, PrecisionCore TFP, XP600 & EPS3200 printheads, and is optimised for transfer printing on coated and uncoated transfer paper.

High density colour leads to reduced ink consumption with faster print speeds for increased productivity and vibrant images, keeping costs down and output up. Recommended applications include activewear, interior décor textiles, graphic arts and soft signage using substrates with a minimum 60% polyester content.

NUtec sales and marketing director, Neil Green notes: “We are seeing an exponential increase in demand for digital textile printing as companies look for more sustainable and waste-reducing ways to do business into the future. The shift from traditional to digital printing in the textile industry allows for rapid small sample testing, short runs with quick turnaround times and less stock-piling at warehouses. This is preferred in the fashion and interior décor industries as it will result in general waste reduction, while time to market is improved. This trend is encouraging for NUtec as we choose to invest in new products and innovations for this sector, the latest being our fluorescent specialty inks offering.”

nutecdigital.com

Trotec Laser Pty Ltd has recently expanded its very popular range of TroGlass laserable acrylics to include TroGlitter Chunky Glitter acrylic. Available in 14 different colours a...

April 20 2021

Trotec Laser Pty Ltd has recently expanded its very popular range of TroGlass laserable acrylics to include TroGlitter Chunky Glitter acrylic.

Available in 14 different colours and at 3mm and 4mm, this Chunky Glitter cast acrylic provides exciting opportunities for creative minds and designers to explore many different and interesting new visual effects and can be used for a variety of applications including jewellery, signage, decorative items and point-of-purchase displays, to name a few.

Like all TroGlass products, TroGlitter Chunky Glitter acrylic comes standard with a plastic laserable mask. This feature protects the acrylic from scratching, which reduces scrap and rework, and improves processing results. These products require little or no post-processing and depending on the laser settings, laser engraving the material surface can result in a prominent or subtle engraved image.

Reece Moore, managing director of Trotec Laser Pty Ltd, says that the new products were added to the product portfolio with the company's driving mission in mind: To make customers more profitable.

"Our growing range of laser and rotary materials allows us to provide our customers with new opportunities to broaden product offerings, meet a wider range of application needs, and get the most out of a laser investment," Moore says. "When we can empower our customers to grow business and increase profits, everyone wins."

Find more information on our materials product line on our website at: www.engraving-supplies.com.au.

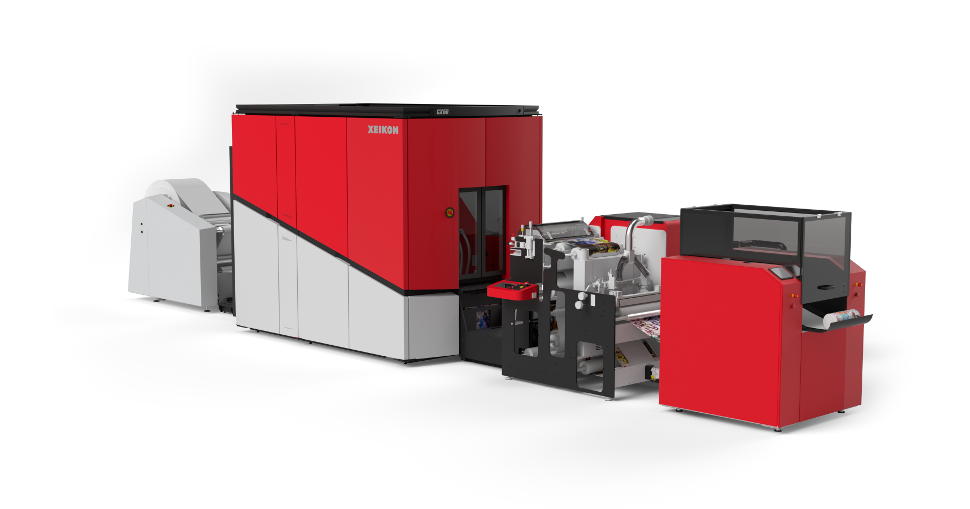

Xeikon announces an eco-friendly, cost-effective digital answer to today’s wallpaper production challenges. As a key part of Xeikon’s Wall Deco Suite and with Xeikon’s bespoke and...

April 20 2021

Xeikon announces an eco-friendly, cost-effective digital answer to today’s wallpaper production challenges. As a key part of Xeikon’s Wall Deco Suite and with Xeikon’s bespoke and environmentally friendly dry toner technology with extended colour gamut, the new Xeikon CX50 is introduced.

The Xeikon Wall Deco Suite is an all-in-one streamlined solution including inline finishing – all developed to cost effectively produce creative wall decorations including custom illustrations and photomurals in short runs. Meeting today’s consumer demand for individualised home interiors, the Xeikon CX50 digital press offers unlimited creative freedom across a wide range of substrates where every printed product can be unique.

Dimitri Van Gaever, Market Segment Director for Graphic Arts, states, “Xeikon has once again led the way in bringing to market a complete end-to-end solution for wall decoration production. What we have put together is a complete automated Wall Deco factory coming together to produce a quality finished coreless roll. The Xeikon CX50 digital press fits perfectly into our portfolio for wallcovering applications, midway between the Xeikon 3050 REX entry level option and our high-end Xeikon CX500 digital press. For higher speeds the Xeikon CX50 can be upgraded from 20mpm (65ft/min) to 30mpm (98ft/min). With Xeikon’s dry toner technology and advanced colour management capability with new generation interfaces and cloud connection, the Xeikon CX50 simplex digital press is designed to offer maximum OEE and TCO.”

The wall decoration business has huge potential, however online ordering, stricter environmental controls and consumer demand for unique products is presenting a number of challenges for conventional wallpaper companies. Xeikon is dedicated to helping its customers improve business profitability and drive growth through our creative solutions. Xeikon has designed and developed its Wall Deco Suite to give businesses an all-in-one cost-effective solution which can give them every advantage in the marketplace.

Like all of its presses, the Xeikon CX50 is driven by Xeikon’s powerful and intelligent X-800 digital front end for full automation and integration. Xeikon’s Digital Front End (DFE) workflow is a true differentiator and enabler and can be integrated with common ERP and MIS systems. The X-800 workflow, which is the same across all Xeikon dry toner solutions, features a ‘poster layout’ function for murals and wallcoverings to ensure spot-on registration for seamless installation. Accuracy of colour reproduction is guaranteed by an integrated on-press inline spectrometer and an optional registration camera. The Xeikon CX50 press provides superior colour consistency and an extended colour gamut. Xeikon’s developed dry toner is available in CMYK, Red, Blue, Green, Orange and Magenta, plus additional colours such as one-pass opaque white and colours produced on customer request. Inline finishing equipment has been specifically designed to work within Xeikon’s Wall Deco Production Suite and includes inline water-based varnishing, slitting, waste removal and coreless rewinding, providing a fully finished wallpaper roll, ready-to ship, in one operation.

Van Gaever concludes, “Part of Xeikon’s ongoing value proposition is to offer the market choices to help customers drive business growth. We believe a successful and cost-effective investment in a digital production solution works best when it is based on expected and realistic print volumes. The Xeikon CX50 press is ideal for those working in wall decoration production with flexible orders and shorter runs. With its capability to upgrade to higher speeds, an investment in this press ensures and secures future business growth. With Xeikon’s long standing expertise, we can help our customers make relevant and appropriate choices. We are recognised as a ‘go to’ trusted advisor and solutions provider. With the introduction of our Xeikon CX50 digital press for Wall Decoration, we strengthen our comprehensive portfolio so that our customers can find everything they need from Xeikon.”