See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Leading printhead and inkjet technologies manufacturer, Xaar is celebrating a decade of successful collaboration with innovative decorative print mac...

October 10 2023

Leading printhead and inkjet technologies manufacturer, Xaar is celebrating a decade of successful collaboration with innovative decorative print machine manufacturer Koenig & Bauer Kammann (Kammann).

Headquartered in Loehne, Germany, Kammann is the specialist within the Koenig & Bauer Group for the high quality decoration of glass, plastic and metal containers, including spirit and soft drink bottles, drinking glasses, cosmetics and hygiene packaging, cans and containers for a variety of other industries worldwide.

The business began looking at developing a digital printing machine back in the early 2010s. Already known for its flexibility, precision and innovation, when searching for a partner in digital inkjet, Xaar’s reliable, durable and high quality printheads made it the obvious choice.

Over the last 10 years Xaar’s printheads have enabled Kammann to deliver the quality and results its customers demand from their decorative digital print applications. This continues today, with Xaar’s latest printheads, including the Xaar Nitrox, meeting the digital print needs for Kammann’s K15 and K20 product family of decorative packaging machines.

Kammann’s digital printing process allows the application of individual, personalised, and photorealistic print images on a variety of often challenging substrates and product packaging shapes, including round, oval, conical, flat and square. Articles with a diameter of up to 120 mm and a length of up to 450 mm can be decorated with a maximum print height of up to 210 mm. Beyond these standard options, Kammann also offers individual solutions for customers to expand the article size range of printability.

The contactless digital print process enables printing on many different article surfaces, which cannot be decorated with a screen-printing process. Xaar’s printheads deliver high quality results through their precise placement of ink drops, providing the very high-quality print for customers’ premium packaging applications.

Xaar’s printheads’ compatibility with inks from a wide variety of suppliers offer complete versatility to Kammann’s digital print. In addition, Xaar’s High Laydown Technology, is helping drive Kammann’s digital print innovation. This includes its digitally printed relief features, which enable the creation of embossed effects on glass bottles and other packaging at a height of up to 3 mm, all whilst maintaining the fine details of the embossing and sharp contour edges. Digital processes such as this are opening new possibilities for individual designs, which traditional printing methods cannot deliver.

Kammann’s Managing Director, Matthias Graf, said: “Our long-standing relationship with Xaar goes beyond that of customer and supplier. The past decade of innovative collaboration has allowed us to develop our digital printing solutions to achieve outstanding print quality for packaging.

“The combination of Xaar’s printheads with our machines has helped drive the innovative and revolutionary process of digital printed relief that our customers now benefit from, for the exceptional embossing of their premium packaging.”

Graham Tweedale, COO at Xaar added: “Xaar is incredibly proud to have been a trusted partner of Kammann for over 10 years. Our collaboration is pushing the boundaries of digital print technology in packaging.

“We look forward to continuing to develop our relationship, providing our world-class printheads, technologies and support as part of Kammann’s innovative digital decorative packaging solutions.”

It was a busy day for the team at Celmac and HP with the open day launch for the new HP Latex 630.

October 03 2023

It was a busy day for the team at Celmac and HP with the open day launch for the new HP Latex 630.

Jeremy Brew, HP, presenting the new HP Latex 360

Print and sign specialists gathered in Sydney to see HP’s new entry-level Latex printer be put through its paces. A roll-to-roll system, the HP Latex 360 is available in four variations including: the HP Latex 630 and HP Latex 630 W – the ‘W’ has white ink capability; and the HP Latex 630 and 630 W Print & Cut – for customers that want the option of upgrading to a dual-device solution, with print and cut functionality. HP say that print speed is 14sqm per hour. All the white ‘print modes’ can be set for different white ink densities for different levels of opacity, including spot, under-flood, over-flood, and a three-layer white ink density.

The printers come with UL Ecologo and Epeat environmental certifications, and carton-based cartridges that reduce plastic by using 100 per cent recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop process – including post-consumer beverage bottles.

Hosting the event were Celmac's Michael Boogaard and Jonny Rumney, with Jeremy Brew and Chris Bowden from HP giving presentations. Brett Williams from HP Financial Services was on hand to work through deals, with Rumney saying he is now working on quotes from the day.

Jonny Rumney, Sales Manager, Celmac said, "It was a good day. The print and sign industry has already shown a lot of interest in the new HP Latex 630 series. People here were also looking closely at some of the new online services that HP has launched at the same time as the new hardware. We have already taken a lot of enquiries."

Furthering its commitment to the environment and sustainability, Epson Australia has entered a new partnership with Botanic Gardens of Sydney to help address critical environmental challeng...

October 03 2023

Furthering its commitment to the environment and sustainability, Epson Australia has entered a new partnership with Botanic Gardens of Sydney to help address critical environmental challenges, with a specific focus on saving Australia’s vulnerable rainforest species.

Vulnerable rainforest species Sloanea woollsii. Photo credit: Botanic Gardens of Sydney

Epson Australia MD Craig Heckenberg explained, “Our partnership with Botanic Gardens of Sydney is deeply committed to playing a role in preventing the rapid loss of plants and the impending extinction of species impacted by the harmful myrtle rust fungal disease. This partnership aligns closely with Epson’s dedication to achieving sustainability and enriching communities. By emphasising the importance of progressing toward a nature-positive and climate-resilient nation, this further highlights Epson’s commitment to making a meaningful difference in both the environment and the communities we serve.”

Epson Australia MD Craig Heckenberg explained, “Our partnership with Botanic Gardens of Sydney is deeply committed to playing a role in preventing the rapid loss of plants and the impending extinction of species impacted by the harmful myrtle rust fungal disease. This partnership aligns closely with Epson’s dedication to achieving sustainability and enriching communities. By emphasising the importance of progressing toward a nature-positive and climate-resilient nation, this further highlights Epson’s commitment to making a meaningful difference in both the environment and the communities we serve.”

The Epson Australia team inside the award-winning Australian PlantBank conservation and research facility at the Australian Botanic Garden Mount Annan, with Dr Cathy Offord, Head of Australian PlantBank Research

Australian rainforest plant species face numerous threats, including habitat fragmentation, invasive species, diseases and the impacts of climate change. At present, there are at least 16 rainforest species that are likely to become extinct within one generation, and there are over 350 other species that are also affected by myrtle rust - a significant proportion of our unique Australian flora.

Through the partnership, Epson will be supporting the Botanic Gardens of Sydney’s research and conservation efforts, with a primary focus on the Rainforest Seed Conservation Program. This program propels innovative conservation methods for storing seeds and plant material of rainforest species, many of which cannot be conserved by traditional seedbank storage methods, making them more vulnerable to the risk of becoming threatened or extinct.

Epson’s partnership with the Botanic Gardens of Sydney will support the team at the Australian PlantBank to continue advancing the development of alternative conservation techniques, including tissue culture, cryogenic storage and living plant collections. This crucial ‘protective custody’ provides an ongoing source of material for research and enables plants to be returned to the wild as part of rewilding or restoration programs.

Amanda Rollason, Botanic Gardens of Sydney's Technical Officer, prepares plant specimens for storage in sterile tissue culture at the Australian PlantBank, an alternative to traditional seed banking. Picture credit: Botanic Gardens of Sydney.

Botanic Gardens of Sydney Chief Executive, Denise Ora, said Botanic Gardens of Sydney is a purpose driven organisation that relies on support from partners such as Epson to help achieve positive environmental outcomes through shared values in sustainability and conservation.

Epson volunteer planting session at the Australian Botanic Garden Mount Annan.

“Native Guava is a critically endangered rainforest species and with Epson’s support, our scientists will conduct critical work in developing a genetically diverse collection in tissue culture at the Australian PlantBank. This will help to secure this species in our living collections and enable a range of research outcomes aimed at eventually restoring this species in the wild to help build more resilient ecosystems for generations to come,” Ms Ora said.

Epson Australia Environment & Sustainability Manager, Fatida Un, added, “This partnership not only underscores the importance of conservation and biodiversity but also aligns seamlessly with the United Nation’s Sustainable Development Goals by promoting community education and advancing climate action.”

To celebrate the partnership, Epson employees recently joined the Botanic Gardens of Sydney’s horticulture team to help restore habitats with understorey plant species such as shrubs and grasses, which play a vital role in the natural landscape by protecting the soil and providing food and shelter for insects and animals.

Craig Heckenberg concluded, “As we collaborate with the Botanic Gardens of Sydney, we are inspired by the diverse range of initiatives they advocate for as their iconic botanic gardens, cutting-edge research facilities, powerful community engagement programs and youth education initiatives open doors for our partnership to thrive. Our new partnership will truly help Epson and the Botanic Gardens of Sydney to co-create meaningful value within our local communities.”

More about The Rainforest Seed Conservation Program

The Rainforest Seed Conservation Program aims to increase the Australian and global capacity to conserve rainforest species by improving our understanding of their biology, developing best-practice methods of conservation, and working with other conservation agencies to prevent future loss of plant species in the wild.

Follow Epson on social media:LinkedIn: @Epson-AustraliaFacebook: @EpsonAustraliaFacebook: @Epson New ZealandTwitter: @EpsonAustYouTube: @EpsonAustraliaInstagram: @EpsonAust

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and printer/cutters worldwide, is pleased to announce today the start of a collaborative project for cu...

October 03 2023

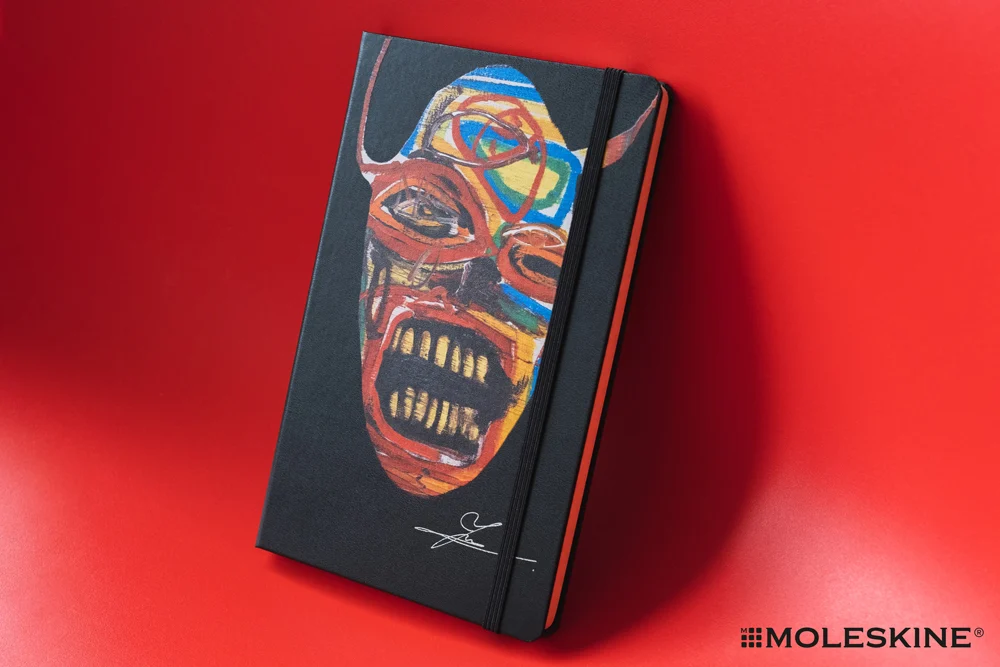

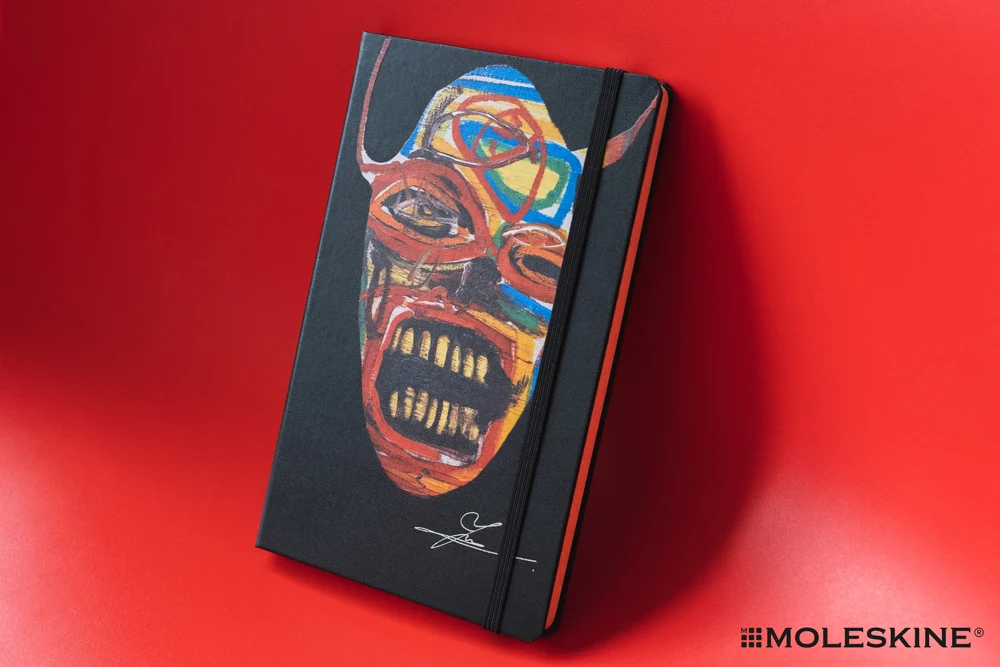

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and printer/cutters worldwide, is pleased to announce today the start of a collaborative project for customised notebooks with MOLESKINE Japan.

MOLESKINE was created as a brand in 1997, bringing back to life the nameless black notebooks used by writers and artists like Vincent van Gogh, Pablo Picasso, Ernest Hemingway, and Bruce Chatwin that had long gone out of print. Today, the Moleskine brand encompasses a family of objects that enhance productivity and creativity including notebooks, diaries, and planners, journals, bags, writing instruments, reading accessories, publishing, and digital tools.

Roland DG is collaborating with MOLESKINE Japan on two projects

The first is a customisation service at MOLESKINE's directly managed store, which will open on Wednesday, September 27 in the Kobe Hankyu Department Store. The LEF2-200 benchtop UV printer will be used for in-store printing.

The second is the production of premium notebooks to be sold at the "Panta Rhei – For as long as the world turns," a museum exhibition of Yukimasa Ida to be held at the Kyocera Museum of Art in Kyoto from Saturday, September 30. The uniquely energetic artwork by Mr. Ida will be reproduced with our large-format VersaOBJECT CO-series UV printer.

Mr. Toru Kimeda, General Manager of Moleskine Japan, said, "The Moleskine Store in Kobe will be the first directly managed store in the Kansai region of Japan. We decided to run the in-store customisation service in order to provide our customers with an experience of unparalleled excitement. Customers will be able to freely design and combine multiple motifs taken from artworks by Yukimasa Ida, one of Japan's leading up-and-coming artists today, and have their notebooks printed right in front of them. In addition, at the Kyocera Museum of Art exhibition, End of today - 2/21/2023 Mask – (2023) and End of today - 1/16/2022 African Mask - (2022), the End of Today series will be printed on notebooks and sold in limited quantities."

“This project required a printer that could meet various requirements, such as a wide colour gamut, highly detailed expression, direct printing on thick notebooks, and ease of operation in stores," Mr. Kimeda continued. “We felt that a partnership with Roland DG was the perfect fit."

Mr. Yukimasa Ida said, "When I first saw the printed samples, I was impressed by the vividness that exceeded my imagination. I’m very happy that more people can enjoy my work by using this kind of digital technology.”

Tony Miller, General Manager of Roland DG Global Sales and Marketing Division, said, "MOLESKINE offers tools and services that help people be more creative, and we feel this collaboration has special significance because we have so much in common with a company that values people's creativity in the same way we do. It is also a great honour for us to work with an artist who is leading the Japanese contemporary art scene with his unique artwork. We are proud that our UV printers have been chosen by people who have a strict eye for expression. We hope that many people will visit the MOLESKINE shop and art exhibition to experience the excitement.”

CorelDRAW Graphics Suite, the fully loaded professional design toolkit for delivering vector illustration, layout, photo editing, typography, and real-time collaboration, introduce...

September 26 2023

CorelDRAW Graphics Suite, the fully loaded professional design toolkit for delivering vector illustration, layout, photo editing, typography, and real-time collaboration, introduces updates today that empower designers to achieve amazing results quickly and more efficiently. Available with a subscription, the newest productivity-powered features and enhancements boost creativity and simplify the graphic design workflow.

“Thanks to the latest updates, designers can enjoy creating more in less time,” said Klaus Vossen, Senior Product Manager for CorelDRAW. “We want to accelerate designers’ success by enabling them to unleash their creative potential and bring their artistic visions to life, whether they’re at the office, home, or on the go.”

Here’s what’s new for CorelDRAW Graphics Suite subscribers and maintenance customers:

In addition to the popular budget-friendly subscription, designers have the opportunity to purchase a perpetual version of the software, CorelDRAW Graphics Suite 2023. This one-time purchase option includes several updates that were previously released for subscription customers since CorelDRAW Graphics Suite 2021, plus some all-new features and refinements introduced in March 2023 and September 2023. Many of the new features and enhancements, apps, and workflows are available exclusively to subscribers and maintenance customers and are not available in the one-time purchase version of CorelDRAW Graphics Suite 2023.

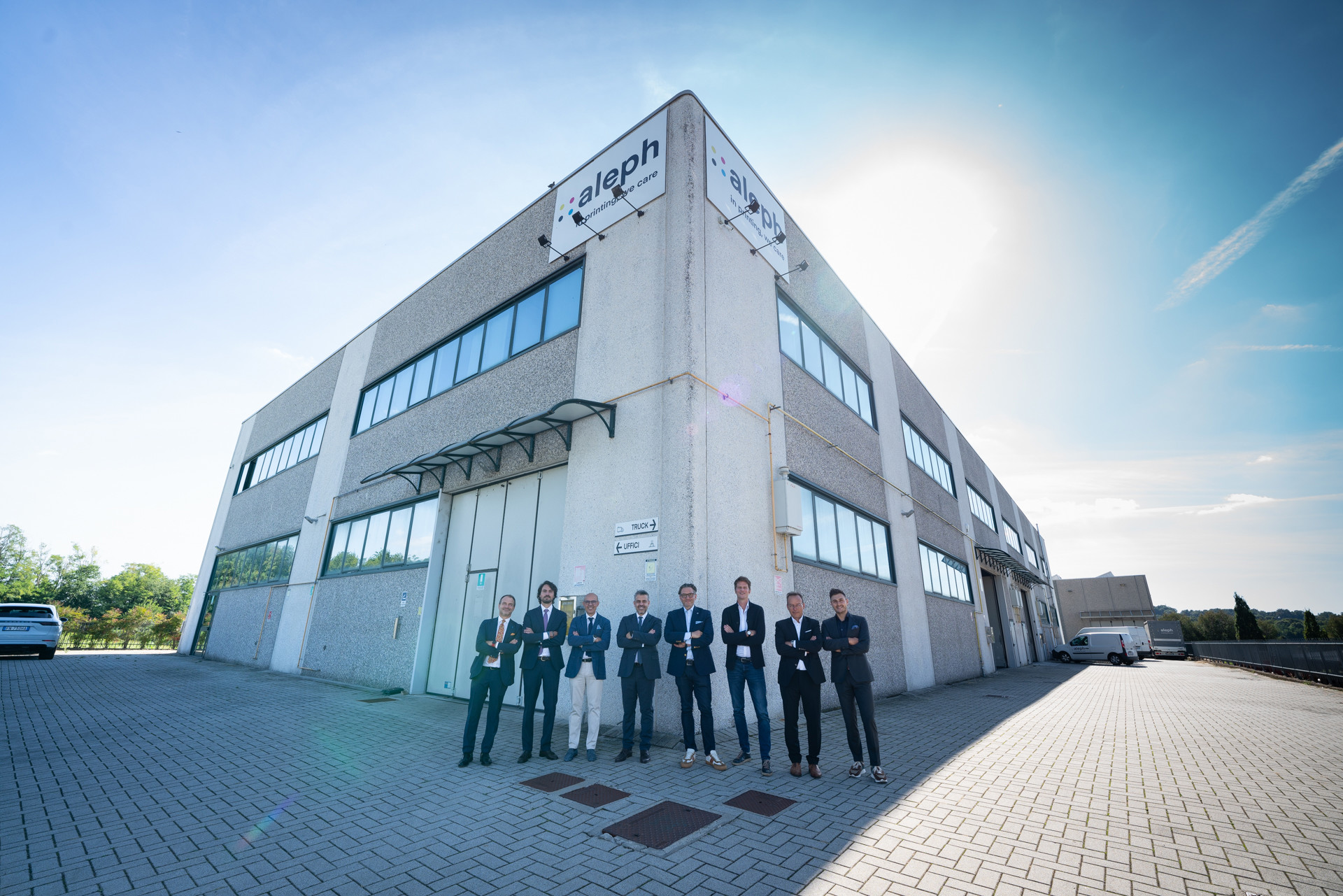

Durst Group, manufacturer of advanced digital printing and production solutions, has acquired Aleph SrL, a pioneer in sustainable digital solutions for textiles and interior and ex...

September 26 2023

Durst Group, manufacturer of advanced digital printing and production solutions, has acquired Aleph SrL, a pioneer in sustainable digital solutions for textiles and interior and exterior decorations. With this strategic move, Durst Group further enhances its position in water-based and sustainable printing technologies. For Durst Group, the acquisition also serves as a bridge to Como, Italy, the center for textile design and high-quality applications.

Established in 2000 in Lurate Caccivio (Como), over the last 20 years, Aleph has transitioned from a software house and distributor of textile consumables to an independent manufacturer of innovative machines for digital water-based printing.In 2017, Wise Equity entered Aleph's capital with the Wisequity IV fund, alongside the three historical entrepreneurs Alessandro Manes, Roberto Manes, and Roberto Temperini, to support the progressive internationalization journey, with the goal of positioning itself in special applications in both the textile industry and adjacent sectors such as billboard printing. Today, the company generates over 60% of its revenue abroad in more than 20 countries.

"We are delighted to welcome Aleph into the Durst family," said Christoph Gamper, CEO and co-owner of Durst Group. "Their expertise in sustainable, water-based applications, their software for high-end textiles, and their creative solutions for water-based poster printing align perfectly with our vision of pushing the boundaries of digital printing technology. Together, we will strengthen our market position, expand our product portfolio, and enhance value for our global customers."

In recent years, markets for digital printing technologies with water-based ink applications have experienced rapid growth, driven by increasing demand for environmentally friendly and customizable products. To meet this market trend, not only high-performance printing systems with eco-friendly ink systems are necessary but also extensive process knowledge and integrated software solutions, which both companies aim to combine optimally through this merger.

"Collaborating with Durst Group marks an exciting new chapter for Aleph," said Alessandro Manes, CEO of Aleph SrL. "Our shared passion for technological innovation, the pursuit of excellence, and the commitment to true sustainability define this collaboration. Together, we have the opportunity to make significant advancements in the digital textiles, exterior, and interior decoration sectors."

"We are very proud to have accompanied Aleph during these years of transformation from a distributor to a machinery manufacturer,” says Valentina Franceschini, Senior Partner at Wise Equity. “today among the leaders in sustainable innovation, Aleph has achieved significant goals in terms of organization, product range, and technological development, and we are confident that Durst represents the ideal partner to continue the growth journey."

The strategic acquisition aims to leverage synergies between the two companies by combining Durst Group's global presence and extensive procurement network with Aleph's expertise in sustainable digital solutions – both machines and software – for textiles and decoration. This seamlessly aligns with Durst Group's strategy to diversify its portfolio and meet the evolving needs of its customers across various industries.

Both Durst Group and Aleph are committed to ensuring a smooth transition for their customers, partners, and employees during the integration process.

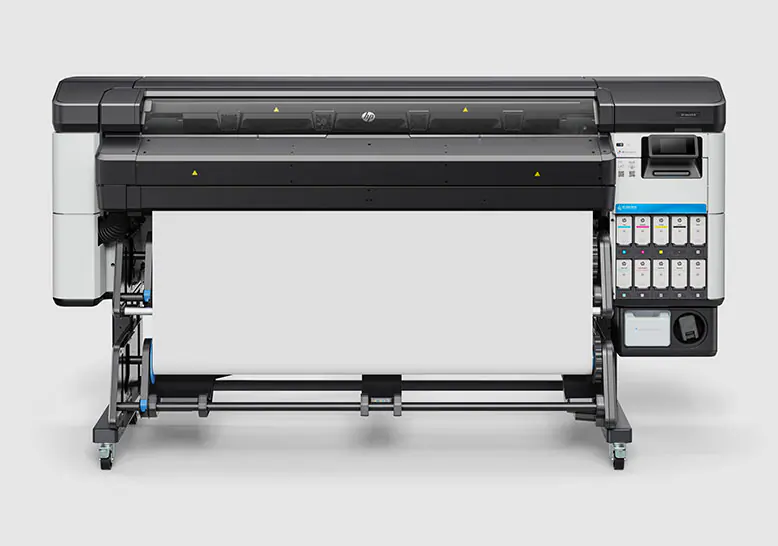

Due to the popularity of HP Recycled Removable Adhesive Fabric for aqueous printers, HP now introduces HP Recycled Removable Adhesive Fabric, 3-in Core (Latex/solvent), made with r...

September 26 2023

Due to the popularity of HP Recycled Removable Adhesive Fabric for aqueous printers, HP now introduces HP Recycled Removable Adhesive Fabric, 3-in Core (Latex/solvent), made with recycled water bottles* and coating materials for Original HP Latex, solvent, low-solvent, and UV-curable inks.

HP Recycled Removable Adhesive Fabric, 3-in Core (Latex/solvent) has the same remarkable water-based, repositionable adhesive that doesn’t harden over time and can be mounted on indoor and outdoor surfaces without leaving a residue.

“HP Recycled Removable Adhesive Fabric, 3-in Core (Latex/solvent) is the ideal solution for a variety of applications and is offered at a comparable price to traditional non-post-consumer recycled products,” says Michelle Oczkowski, BMG Product Manager for HP Large Format Media.

This non-PVC product meets environmental and safety standards, can help to reduce the environmental impact of printing and is certified slip-resistant for floor graphics. It can be contour cut and applied without stretching.

HP Recycled* Removable Adhesive Fabric, 3-in Core (Latex/solvent):

September 20 2023

HP Australia launched the new HP Latex 630 printer series, completing HP’s Latex range and making white ink technology available to Print Service Providers (PSPs) of all sizes. White ink allows users to produce a more impactful range of signage and décor jobs with stunning image quality and colors that jump off the page, creating attention grabbing campaigns for end-customers.

The HP Latex 630-series, as with the rest of HP’s Latex portfolio, allows firms to offer more sustainable printing services: with water-based latex inks that give off negligible chemicals or odors; UL ECOLOGO® and EPEAT® environmental certifications;[[iii]] and carton-based cartridges that reduce plastic by using 100% recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop process - including post-consumer beverage bottles.[iv]

“The new HP Latex 630-series packs our leading latex features, such as white ink, into a more compact and affordable form factor - allowing even the smallest of print businesses to effortlessly deliver high impact signage and décor applications, boosting margins,” Craig Hardman, ANZ Large Format Country Manager. “Beyond the hardware, we have continued to innovate when it comes to services and solutions, with new cloud-based HP Print OS functionalities giving time-pressed users the ability to process and monitor jobs from virtually anywhere.”

The HP Latex 630 family provides a number of options and features, including:

Win business online and simplify operations

As part of a continued focus on helping PSPs improve productivity and grow their business, HP has also announced HP PrintOS Design & eCommerce – an intuitive web-to-print solution that saves valuable time with simplified print application design capabilities, efficient production paths, and step-by-step guidance on how PSPs can integrate it with an existing e-commerce store.

"We spend a lot of time listening to print providers about what they need to grow, and one key area was evolving their e-commerce capabilities and better connecting the front and back-ends of their business," added Craig Hardman. “HP Print OS Design & eCommerce is our response, giving PSPs a quick and easy way to enhance their online shop, as well as new ways to process orders and automate jobs.”

The Design & eCommerce solution will be made available in select countries within HP’s PrintOS suite to subscribers of the HP Professional Print Service Plan (PPSP) ‘Plus’ tier, making the PPSP offering more appealing to small and medium sized PSPs. HP’s Professional Print Service Plans are designed to enable business agility, maximize uptime, and to provide learning opportunities and support.

For further information about HP Print OS Design & eCommerce and HP Professional Print Service Plans, please visit the website here.

Availability

The HP Latex 630, HP Latex 630 W, HP Latex 630 Print & Cut Plus, and HP Latex 630 W Print & Cut Plus are expected to be available from September 19th, 2023, in major markets globally.

The HP Print OS Design & eCommerce solution is expected to be available from November in the UK, Spain, Australia and New Zealand. For further information, please contact a local sales representative.

For further information about HP Print OS Design & eCommerce and HP Professional Print Service Plans, please visit the website here.

Durst Group has today unveiled full details of a new innovative technology that utilizes computer vision and artificial intelligence to take high qua...

September 19 2023

Durst Group has today unveiled full details of a new innovative technology that utilizes computer vision and artificial intelligence to take high quality label production to another level. On its stand C45 in Hall 7 at Labelexpo in Brussels, Belgium, the manufacturer of digital printing and production technologies is demonstrating the Durst Hawk Eye system that is designed to assist operators and automate the print quality. In addition, it significantly reduces set-up time and waste, resulting in enhanced efficiency and a more competitive total cost of ownership (TCO) for the Tau RSC platform printers.

Durst Hawk Eye includes a scanner system, workstation and touch screen monitor. It corrects print mistakes, such as missing nozzles, inline and in real time. In the rare event of a printhead nozzle malfunctioning, in-built artificial intelligence (AI) systems automatically detect and localise any problems without any speed reduction. Neighbouring nozzles then compensate with larger drops to ensure that outstanding print quality is maintained. Operators do not need to complete any set-up and there is no need to print a special test pattern.

Other announcements by Durst at Labelexpo include important ink developments. It is expanding the Tau RSC ink portfolio with the new Tau RSC LED inks. The new ink set, available in CMYK, with optional orange, violet, green and white, is increasing the attractiveness of the Tau RSC press portfolio. By significantly reducing the energy consumption during the operation and by eliminating frequent UV bulb and reflector changes, the overall TCO of the Tau RSC presses becomes even more attractive. The new Tau RSC LED ink combines the excellent print quality and performance of the existing Tau RSC UV ink with Durst Group’s roadmap towards a more sustainable printing industry. It provides reduced energy consumption and a reduction in consumable cost and maintenance time. This results in economic benefits for customers and a reduced ecological footprint. The vivid inks create a huge color space allowing to precisely reproduce important brand colours.

Durst has also unveiled the new Tau RSC UV Ink 3 high speed UV inks, formulated without the need for TPO photoinitiator.

Durst’s software label ecosystem also features prominently on the Durst stand. Tau printers are equipped with Durst Workflow Label, prepress and production software, and Durst Analytics, the analytics and monitoring tool, to make the printer a production unit from day one. All Durst software solutions are modular and can be easily managed through a web-based user interface. A browser based VDP editor for creating and managing variable data is available in the workflow.

The show also provides the platform for Durst Group to show live running of the Tau 510 RSCi single pass press, which is equipped with new automation features. The press on its stand is equipped with the powerful double white feature, allowing excellent opacity white ink printing at 80m/min.

“Our team of experts are on hand at Labelexpo to provide personalised demonstrations, answer questions and discuss how our solutions can revolutionize customers’ printing operations,” said Martin Leitner, Product Manager of Durst Group. “The Durst Hawk Eye is a game-changer for the digital printing industry. This technology will greatly increase productivity and efficiency, but, more importantly, it will reduce waste and the carbon footprint of our customers. We are thrilled to introduce this innovative solution to the market and provide exclusive information during Labelexpo.”

Grant Thornton has released its 2023 Manufacturing Benchmarking Report, analysing the financial data from 100 Australian mid-sized manufac...

September 19 2023

Grant Thornton has released its 2023 Manufacturing Benchmarking Report, analysing the financial data from 100 Australian mid-sized manufacturers and tracking their performance during FY23 to provide a unique view of the Australian Manufacturing sector.

The Report has revealed positive trends in 2023, with a 6.7 per cent year-on-year average sales growth. This is attributable to increased capital expenditure and investing into emerging technologies, particularly for businesses with revenue over $100m whose scale has supported ongoing growth and success.

“While Australia’s manufacturing sector is still navigating disruption and will be for some time, opportunities for growth and development are on the horizon,” said Michael Climpson, National Head of Manufacturing at Grant Thornton.

“While this is positive, there is still much work to be done and the Government’s continued support in the sector with initiatives such as the National Reconstruction Fund, R&D Tax incentive, and state-driven programs will continue to empower mid-sized manufacturers to deliver on growth ambitions and strengthen our domestic capabilities,” continued Michael Climpson.

According to the data, the financial impact of the initial COVID-19 outbreak has been fully recovered in the sector, highlighting that we’re witnessing the first emerging results of both government investment in sovereign manufacturing, the resilience of the industry and a willingness to do things differently.

The data shows an increase in all market sizes, with the greatest increase in the $40m-$100m category, which was the manufacturing category impacted the most by COVID-19.

Like other industries, inflation is easing but remains at elevated levels, suggesting ongoing high sales growth for 2023/2024 could be expected.

However, headwinds including rising costs, inflationary pressures, and disruptions in supply chains have impacted cash flows, mainly for manufacturers with a turnover under $40m. To manage this, the Report highlights affected manufacturers have turned to new and emerging technologies and invested in sustainability measures to remain profitable.

** Research methodology of the Grant Thornton 2022 Manufacturing Benchmarking Report

Grant Thornton used a sample of 100 Australian mid-sized manufacturers to create the 2022 Manufacturing Benchmarking Report. The data is largely extracted from audited financial statements, the majority being Grant Thornton clients. The analysis can include an element of judgement applied, including normalising out of the averages any major outliers. For the purposes of this report, mid-sized manufacturers generally have an annual turnover of $20 million - $600 million.

For further details on the findings please see our media release attached and click here to access the 2023 Manufacturing Benchmarking Report.

Well respected Adelaide based Graphic Arts Supplies will represent Mutoh products in SA and the NT.Graph...

September 19 2023

Well respected Adelaide based Graphic Arts Supplies will represent Mutoh products in SA and the NT.

Graphic Arts Supplies Sales Director Steve Murphy commented. “We recently spent 2 days with the Mutoh Australia team learning their product range. Over those days it became apparent that our two businesses share the same values with a customer focussed attitude and quality in all points of customer contact. We look forward to representing the extensive range of Mutoh’s Japanese made printers and cutters in SA and the NT.”

Russell Cavenagh, Mutoh Australia Managing director agrees. “Japanese companies play the long game. With Mutoh’s 70 years of manufacturing experience, what matters to us is delivering an exceptional customer experience through reliability, quality, and value. With the appointment of Graphic Arts Supplies, we know our customers, both old and new, can now experience those same values”.

For more information, please contact Mutoh Australia on 02-9437 1366 or sales@mutoh-au.com or Graphic Arts Supplies on 1300 939 854 or sa@graphicarts.com.au

Hasler Cutting Systems have launched a groundbreaking development for large format cutting operations, int...

September 19 2023

Hasler Cutting Systems have launched a groundbreaking development for large format cutting operations, introducing the world's first 5-meter wide digital flatbed XY cutter, equipped with the latest Optiscout software, delivering unparalleled quality, versatility, and affordability.

Hasler's commitment to delivering cutting-edge solutions with exceptional value has led to the creation of 15 different table configurations, including the remarkable 5-meter wide cutting table, setting a new industry standard. Unlike any other offering on the market, our product combines European craftsmanship, state-of-the-art technology, and affordability, making it the perfect digital cutting solution for a wide range of industries.

Key Highlights of the Hasler Digital Flatbed Cutters:

Optiscout Software: The industry standard Optiscout software empowers users with advanced capabilities for precision cutting, ensuring optimal results for a diverse range of materials and applications.

Competitive Pricing: Hasler's 5-meter wide cutting table and other flatbed XY digital cutters are available at the highest quality and lowest cost on the market.

Experienced Team: Hasler's team of large format digital cutting table specialists boasts over 50 years of combined experience, ready to assist your company in optimizing production operations.

Versatile Tool Options: Hasler tables offers a complete selection of tool options, from routing to knife cutting to crease and kiss-cut tools, ensuring a tailored solution for your specific cutting needs.

Transparent Pricing: Hasler's upfront pricing and table configurator provide clear and straightforward price information, allowing you to make informed decisions without the need for negotiations.

Customisation:

Choose from fifteen distinct configurations based on five standard cutting table widths, or personalize the length with table extensions. Add features like roll-off/sheet fed systems, full conveyors, and various tool heads and up to 5kW router and accessories to meet your unique cutting demands.

Exceptional Warranty Package:

Every Hasler table is backed by an industry-leading 2-year full warranty, giving our customers peace of mind and confidence in their investment. In addition to a 5-year limited warranty that includes remote technical support, and a 10% discount on consumables and labor costs.

"Hasler is committed to pushing the boundaries of what's possible in large format cutting technology while maintaining affordability," said Melody Thompson, Sales & Marketing Manager for North America at Hasler Solutions USA. "The new 5-meter wide digital flatbed cutter with Optiscout software is perfectly paired to any 5-meter wide format printer on the market today, and represents the culmination of Hasler’s dedication to innovation and customer satisfaction. Hasler cutting tables are built for 24/7 production. Whether you are a small, medium, or large business, Hasler has the solution you need to enhance your cutting capabilities, increase productivity, and drive success."

LIA Victoria has achieved a major coup, announcing that its next Technical Event on the evening of 12 October will be held at one of the most tightly...

September 19 2023

LIA Victoria has achieved a major coup, announcing that its next Technical Event on the evening of 12 October will be held at one of the most tightly-guarded print sites in Australia, Note Printing Australia in Craigieburn.

The high-security plant, which produces bank notes for Australia and a host of other countries, as well as passports and certificates for births, deaths and marriages, is opening its doors to LIA Members for a tour and presentation.

Tickets to the event are expected to be highly sought-after, with LIA Members entitled to attend completely free of charge, and those yet to join being asked to contribute just $30 for the once-in-a-lifetime opportunity. Numbers will be strictly limited, so those interested are encouraged to enquire or reserve your place without delay by contacting Jenny Berry at vic@lia.com.au.

It’s just the latest move by the state chapter of LIA, which continues to grow from strength to strength since it relaunched post-COVID.

Since 2022, it has held a regular program of events including technical evenings at Southern Impact, Fujifilm Business Innovation and Ball & Doggett, conducted the industry’s Graduate of the Year program with one of the State finalists taking out national honours, and has participated in PacPrint in Melbourne last year and Visual Impact Sydney earlier in 2023.

Robert Black, President of LIA Victoria, says it’s been an exciting time for the association’s committee – but now, they are calling for ‘all people in print’ to show their support by renewing their membership.

“We have been very fortunate to have received seed funding to reestablish LIA Victoria after a pandemic-induced hiatus,” Black says, “but to be sustainable into the future, we need the people of the print and wider graphic communications sector to show their support by joining as members and, if possible, by considering sponsoring our activities.

“Membership to the association is very cost-effective at just $45 per annum for individuals and $120 for companies, and the funds raised through memberships and sponsorships will be invested back into the industry to provide these technical and networking events, and to support the leaders of the future.”

Those interested in joining LIA Victoria should fill out the LIA Membership form here and return to vic@lia.com.au or to find out more about membership and sponsorship opportunities, download a full Membership & Sponsorship Brochure here

New AutoSet Digital reduces waste and delivers efficiency gains for digital label printers

September 11 2023

New AutoSet Digital reduces waste and delivers efficiency gains for digital label printers

Esko has today (11 September) launched a new complete print inspection solution for digitally printed label production, delivering unparalleled quality control to reduce waste and boost efficiency.

With AutoSet Digital, Esko has introduced an end-to-end solution that automates AVT print inspection of digitally printed labels from prepress through to on-press and finishing.

“The labels market is in a period of considerable change,” said Guy Yogev, Senior Director of Product Marketing at Esko. “Volume-wise, there has been around a 15% growth in digital label printing and around 40-to-50% of all label presses sold today are digital or hybrid, so it’s clear the market is growing significantly.

“But in this volatile market, the overall macro-economic climate of crisis and economic recession is driving increased pressure on margins, forcing label converters to look for ways to improve operational efficiencies and reduce waste,” said Guy. “Businesses are looking for ways to reduce the volumes of material they use, which means reducing defects, over-runs and waste, all while dealing with the added pressure of on-time deliveries and quality expectations. Operators might sometimes still be able to visually identify errors on presses running at 30m per minute, but as speeds increase, so does the risk of error. With digital presses getting faster, now is not the time to be loose with quality. The cost implications of such errors can be huge, which is why we have created a complete end-to-end automation solution based on connectivity between prepress to production and all the way to finishing.

“Historically, many businesses have been put off investing in print inspection on digital lines because of perceived product limitations,” said Guy. “For example, an inspection system needs to be set up for every run, and digital printers will typically have multiple SKUs in the printed roll and in many cases the design and job can change on the fly with no press stop. With inspection you might have had to stop and reset the system for each SKU, which created a real-time barrier with integrating inspection. But now, AutoSet Digital takes information for each SKU from Esko Automation Engine and relays it directly to the print inspection system.”

AutoSet Digital is now covering all of the digital workflow - whether the inspection is done on the digital printing press, on a hybrid press or on a digital finishing line.

The innovative inspection workflow for digitally printed labels combines the accuracy and speed of the AVT Helios 100% print inspection systems with the automation of AVT AutoSet Digital, empowering operators to automatically upload and switch between jobs, enabling the AVT WorkFlow Link to record, scan and edit multiple jobs on the same roll. “The system on the press records defects, and after production the physical roll is uploaded to the finisher together with the virtual roll,” explained Guy. “This virtual roll includes the recorded defects mapped on the entire roll and either the operator or a dedicated QC editor can review and edit the virtual roll. Once edited, the mapped virtual roll will automatically signal the rewinder/doctor machine where the physical roll should stop at the identified point to remove the defect.

“It could be a single label due to an isolated defect, or an entire segment if there has been an issue,” said Guy. “Either way, the operator can immediately clean up the roll and rectify the error, it also brings operator efficiencies, freeing up their time to work on other value-adding tasks during a run.”

Guy explained that AutoSet Digital brings these same efficiency and productivity benefits to hybrid presses and digital finishing lines. “Our 100% inspection platforms can be installed at any production workflow with AutoSet Digital, providing complete hands-free inspection setup and continuous non-stop inspection when job and job design changes.

“With the Digital Workflow, unique barcodes are used to identify the job automatically,” he said. “When these barcodes are identified between jobs (‘lead-in/lead-out’ area), or within the print job design, they automatically set up the inspection parameters for the job that has already been created in prepress. That way, jobs can now be printed or finished with no manual setup and no production stop or slow down,” he said. “The system automatically loads up inspection parameters between jobs, keeping the line running and saving the business time and money, while ensuring accuracy and reducing waste.”

Entirely automated workflow

One of France’s leading label producers, AG3M has been using Esko AVT print inspection systems since 2020. As a member of the Esko pre-release community, the company was among the first to integrate AutoSet Digital into its prepress and production.

Sylvain Marchal, Président Directeur Général AG3M, said that one of the main benefits of the new system is that the company now has direct control over the print quality for multiple runs. “We can check as many as ten files simultaneously,” he said. “We can immediately link to the master PDF and view the inspection report which tells us if the job ran ok or not. The counter on the digital press tells us that we have printed a sufficient number of labels to move the job to the rewinder.

“Having such an entirely automated workflow has been a major development,” he said. “Before we integrated the print inspection system with the production floor, errors would lead to a bad print run and cause regular press stoppages or even, in the worst cases, a return of the artwork to prepress.

“Today, with this digital inspection workflow, there is inline Delta E colour measurement which ensures us a stable print run from start to finish. We have increased production by about 30%, reduced paper waste, unnecessary reprints, lost time, and machine stoppages. Now we ended up with 99.9% of all faulty prints being removed from the rolls supplied to the customer,” he said.

Guy Yogev said the speed and scale of results experienced by AG3M are common amongst users of AutoSet for Digital. “We have created a true end-to-end solution for print inspection for digital labels print inspection, and we are delighted to be making it available to customers,” he said.

For more on AutoSet for Digital and the complete range of Esko AVT print inspection solutions, visit www.esko.com/en/products/print-inspection

at Labelexpo Europe, Brussels, Fujifilm launches LuXtreme, a new LED UV curing system that allows any traditional flexographic press to be converted to LED UV curing, resulting in ...

September 11 2023

at Labelexpo Europe, Brussels, Fujifilm launches LuXtreme, a new LED UV curing system that allows any traditional flexographic press to be converted to LED UV curing, resulting in enhanced label production on a narrow web press.

LuXtreme offers high speeds of up to 200m/min, along with better substrate stability, resulting in enhanced productivity for printers. Additionally, the system offers 30-50% higher radiant intensity than competitive LED curing systems, up to 25W/cm².

The system uses 30-60% fewer LED lamps to achieve the same radiant intensity as other comparable systems. This results in better registration and less material distortion. improving the overall quality of printed materials. The energy savings this offers compared to conventional UV systems, as well as competitive LED curing systems, are significant, with both material usage and waste also significantly reduced, enhancing overall productivity and making the system a highly sustainable mercury-free solution.

Due to the reductions in power required for the LED UV lamps, cost savings can be made across the production process. Additionally, the lower maintenance, downtime and make-ready times required to support the system also lead to a lower number of replacement parts required over its lifecycle, and lower associated labour costs.

The working environment for operators is also improved, with many undesirable factors eliminated or reduced, including heat from conventional UV and air cooled LED lamps, ambient noise and odours.

The system offers up to 50,000 hours LED life and up to a 720mm lamp length, scalable in 24mm steps. An LED adaptor allows easy integration on to existing mountings.

Manuel Schrutt, Head of Packaging, Fujifilm EMEA comments: “We are excited to be bringing such an innovative and unique solution, alongside other innovations such as LED IFDC inks, to the labelling market. Sustainability is at the forefront of our processes and product development, and this launch demonstrates our commitment to providing high quality solutions that are beneficial for the environment, while providing customers with improved efficiency and productivity and a pleasant work environment. Labelexpo provides the ideal opportunity to launch this to the market and we look forward to showcasing the product to existing and potential customers.”

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters is pleased to announce major moves to bolster its service and support offering to its...

September 11 2023

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters is pleased to announce major moves to bolster its service and support offering to its customers in Western Australia, today.

After extensive training at Roland DG's Head Office, Stephen Jones has been appointed to the position of Service Technician, Western Australia. Stephen’s appointment signifies the first direct employee Roland DG has posted in WA and reflects the company’s growing focus on serving customers through its Roland DG Care initiatives in the state.For more information on Roland DG Care and to contact the Service and Support Team, visit www.rolanddg.com.au/support.

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and printer/cutters worldwide, today announced the addition of the BN2-20 and BN2-20A desktop inkjet printer/cutters to ...

September 11 2023

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and printer/cutters worldwide, today announced the addition of the BN2-20 and BN2-20A desktop inkjet printer/cutters to its VersaSTUDIO product lineup.

"Since our founding in 1981, we have been providing digital solutions that enable anyone to easily do what could only be achieved previously by people with special skills and experience," said Tony Miller, President of Roland DG’s Global Sales and Marketing Division. "Today, our compact, easy-to-use, and affordable desktop products are marketed under the brand name VersaSTUDIO and include a broad range of popular desktop solutions, such as inkjet printers, cutters, engravers, metal printers, and foil transfer laser decorators."

The new BN2 series offers a choice of two powerful eco-solvent desktop devices that use the same high-definition print heads, eco-solvent inks, and cutting technology as our wide-format printers for outstanding print quality and precision contour cutting. In addition to their compact size, printing speed for the new BN2 series is approximately 4 times greater than previous models, allowing users to produce a wide variety of high-value-added items, from original T-shirts, posters, stickers and labels, to displays; quickly and easily from their workspace.

According to Miller, the BN2 series was designed to offer excellent usability, even for novices, who can begin producing professional print quality items straight from set-up. This simplicity extends from installation to usability through multi-colour LED lights which indicate printer status at a glance.

The included Utility software supports intuitive operation through easy-to-understand icons for quick access to menu items, while the functional bundled software can be used for everything from design creation to output. Also, the innovative Frontal Access Structure allows media setup and maintenance to be performed from the front of the printer for a more efficient use of space.

Incorporating the Roland DG Connect App, which virtually connects the BN2 series printer production and creative output, users get an in-depth view of their printer’s operating status to keep their device/s running at optimum print performance.

Customers can choose from two models, the CMYK plus White 5-colour BN2-20 and the CMYK 4-colour BN2-20A. Each model includes design and output software and comprehensive manufacturer’s warranties as standard, which present an attractive value proposition for first-time users.

"Since the first model was introduced, over 25,000 units of the BN Series have been sold worldwide, with broad applications including start-ups, shifting out-sourced production in-house, and educational settings" Miller said. "With further advances in productivity and usability, the BN2 series opens the door to greater creativity and business success for even more people. We will continue to expand our VersaSTUDIO series lineup to meet the creative needs of desktop professionals around the world."

Learn more about the new VersaSTUDIO BN2 Series desktop printer/cutters at www.rolanddg.com.au/products/printers/versastudio-bn2-series-printer-cutter.

The Summa S Class 3 is a state-of-the-art device designed for professional users who demand top performance in their cutting applications and want to explore new opportunities....

September 11 2023

The Summa S Class 3 is a state-of-the-art device designed for professional users who demand top performance in their cutting applications and want to explore new opportunities.

At the heart of the S Class 3 is its unique True Tangential Cutting Technology, ensuring top-notch performance. The addition of the all-new OPOS Camera with onboard image processing provides ultra-fast mark recognition and processing, making print&cut workflows smoother and more efficient. The performance head is the most advanced in the vinyl cutter series and can now automatically switch between cutting and creasing, perfect for short-run packaging jobs, and setting a new standard in the industry.

High-Precision & Unrivalled Performance

The S Class 2, a proven performer, has been on the market for ten years. It is not only unmatched (still!) by its competition, it is also very much valued by its customers. "For the S Class 3, we kept the good and proven. And while they may look similar under the hood at first sight, a lot has been upgraded. The latest electronics made it possible to achieve faster responsiveness, better data processing, and more precise motor control, resulting in a smoother, faster, and more reliable result.", says Randi Kerkaert, product manager.

Reliable & Versatile Cutting

Nowadays, vinyl cutting is probably not the hottest topic in the Sign & Display industry. "The long lifetime of every Summa vinyl cutter allows sign shops to avoid the need for further investments in vinyl cutting equipment. On the other hand, having a premium cutting plotter available on the work floor remains essential and critical for many businesses", states Christof Van Driessche, CCO at Summa. "A reliable cutting plotter is much appreciated even in an industrial environment. With the introduction of the S Class 3, we aim to provide new opportunities for sign shops to expand their current vinyl cutting businesses and explore new territories, like cardboard cutting and creasing."

The S Class 3 will be available in our partners' showrooms as of September 2023. Check out all the details of this amazing product, including the barcode workflow with enhanced roll-up system, its Performance Head and the all-new OPOS Camera.

Currie Group and Canon Production Printing Australia have announced a new partnership which will see the well-known supplier add the Canon Arizona and Colorado M-Series printer ran...

September 06 2023

Currie Group and Canon Production Printing Australia have announced a new partnership which will see the well-known supplier add the Canon Arizona and Colorado M-Series printer ranges to its growing portfolio of solutions for the commercial print, and sign and display print sectors.

The announcement, made this morning, expands Canon Production Printing’s reach in the market to keep up with demand for the popular printers, while ideally complementing Currie Group’s existing range of products for these sectors.

Rob Mesaros, CEO of Currie Group, says the new partnership is just the latest step in the company’s ongoing process of modernisation, as it continues to grow and meet customer needs with new solutions that help drive success in evolving market sectors.

“Currie Group has a long history of transformation which has kept us one step ahead of market trends, and we’ve continued to transition in recent times based on the same principles which have served the company so well over more than 70 years – agility and an appetite for pragmatic risk taking, based on strong market knowledge and careful planning,” Mesaros says.

“Channel partnerships with Tier 1 OEMs have been a cornerstone of our strategy, and we are delighted to announce this new partnership with Canon Production Printing, who are such a well-respected market leader, and to add these innovative technologies to our sign and display product portfolio.”

Craig Nethercott, Managing Director, Canon Production Printing Oceania, says “Currie Group is a recognised leader across the print industry and we are excited to welcome them onboard as our latest strategic partner in the region.’’

“This new partnership is aimed at supporting our growth ambitions within the large-format graphics sector by expanding our reach in the market.”

“The award-winning Canon Arizona flatbed and Colorado M-Series product ranges have been hugely successful in both global and local markets. The innovative technology incorporated into the Canon Large Format Graphics product portfolio will enable Currie Group to offer a diverse range of application possibilities to their customers.”

Paul Whitehead, Business Unit Manager – Sign & Display for Currie Group, says his company is in a unique position in the market, with strong reach not only into the large format sign and display sector, but also into general commercial print. The new additions to the company’s product range, he says, will benefit both.

“Market demand across both those sectors is constantly evolving, with diversification driving new applications for print service providers of all kinds. With the addition of the Canon Production Printing products to our portfolio, we are now well-placed to meet all those requirements,” he points out.

“The new Colorado M-series opens up the 1.6m space for roll-to-roll applications, providing segment leading productivity thanks to its market-leading UVgel technology, and the award-winning Arizona family which is the most sold range of mid-volume UV flatbed printers – fills another gap in our portfolio by providing us with dedicated solutions for rigid media.”

“Combining this with our existing portfolio now gives us the broadest, most complete portfolio of large format solutions for the production and industrial space in the market – backed, of course, by the expertise from both the Canon team and our own product specialists, and our extensive national service and support network.”

Both printer ranges will be available to order from Currie Group with immediate effect, confirms Josh Konrad, GM Customer Support Services, Canon Production Printing Oceania.

“The onboarding of Currie Group as a partner has commenced, given the existing skills and experience of both service and support organisations, the learning curve is expected to be minimal and will see Currie Group operational quickly,” he says.

“We are looking forward to supporting them as they continue to grow in the Large Format Graphics market.”

While improving access for these market-leading products is the ultimate purpose of the partnership, the fundamentals behind the match actually goes deeper, with both organisations noting that they share the same philosophy and principles when it comes to delivering exceptional service to customers.

“Both Currie Group and Canon Production Printing have enviable relationships with our customers, based on product innovation and excellence, and a real commitment to strong services support. That shared ethos and approach provides a strong foundation for our partnership going forward,” Mesaros says.

“This partnership with Canon Production Printing adds value to both our businesses, and should give our customers even greater confidence in the ability of our people, and our products, to help them drive success as the market continues to evolve.”

Global printing industry leader Inkcups announces the global launch of the XJET Switch, a groundbreaking digital printer for direct-to-bag and hard goods applications.This s...

September 05 2023

Global printing industry leader Inkcups announces the global launch of the XJET Switch, a groundbreaking digital printer for direct-to-bag and hard goods applications.

This state-of-the-art addition to the esteemed XJET line is the first UV flatbed printing machine formulated with high-quality bag decoration in mind. As the ‘Switch’ title indicates, the new machine boasts flexible capabilities for both pliable and hard goods, manual load and automated load and index - either 180 or 90 degrees if some pretreatment is required.

The XJET Switch sets a new standard in swift and high-quality UV flatbed printing, producing high-quality, full CMYKWW (highly opaque white) images directly onto a variety of bags and hard goods. Its exceptional capabilities make it an ideal solution for decorating reusable bags made from a wide range of materials and colors, and it is capable of handling even the most challenging substrates such as clear and thin bags.

XJET Switch Feature Overview

The four rotating platens of the XJET Switch are a standard feature that optimizes print productivity with two setups simultaneously. Additionally, the system provides customization options that allow for the configuration of platens to meet specific customer requirements. For instance, it is feasible to have three-up, four-up, or more within the printable area. Additionally, the industrial design allows for integrated pre-treatment.

This industrial printer is specifically designed for a 3-shift production setup, enabling rapid prints with exceptional quality. It incorporates cutting-edge functionalities including automated purging, wiping, and caping stations, white recirculating system, servo control indexer, two 16-watt adjustable UV lamps, and numerous additional features that contribute to swift production while ensuring high-resolution images for a premium finished product.

Paired with the highly flexible XFLEXX UV Ink series, the XJET Switch highlights its versatility by decorating an extensive range of reusable bags, eliminating the risk of cracking or distorting as the bag naturally moves with use. Furthermore, among the ink series, the Vivid White ink stands out, delivering a brighter and more opaque white, rivaling the printed white achieved through competing processes.

Benjamin Adner, CEO, remarks, “The XJET Switch made its trade show debut at PRINTING United in 2022, and we were thrilled to witness its immediate success. This direct-to-bag printer generated a tremendous amount of excitement among our customers, who have been eagerly seeking a consistent and sustainable way to decorate reusable bags. This innovative machine serves as the perfect solution to their needs, for tote bags and beyond, and we hope to exceed their expectations.

We enthusiastically anticipate the creative possibilities that our customers will bring to life with the XJET Switch.”