See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Antalis introduces MetaliK films for luxury detailing Antalis, the leading European distributor of paper, packaging and visual communication solutions, has introduced large format inkj...

September 06 2018

Antalis introduces MetaliK films for luxury detailing

Antalis, the leading European distributor of paper, packaging and visual communication solutions, has introduced large format inkjet metallic films to its portfolio to enable customers to combine print and cut applications for creative display.

The KernowJet MetaliK range delivers high quality metallic films for use within luxury retail settings, window displays and point of sale (POS), Christmas or seasonal campaigns and countless other applications. The films, which are available in gold, silver and rose gold finishes, provide an extremely smooth finish, giving any application a near-mirror effect.

The new offering includes KernowJet MetaliK Cut&Print; a removable metallic film ideal for double-sided displays. It is particularly suited for bright reflective lettering, logos and designs for shop windows and glass, as well as general retail settings, perfumeries, luxury boutiques and campaigns. The removable adhesive makes it specifically useful for evolving point of sale promotions. Along with being inkjet printable with Solvent, Latex and UV, the film can be easily plotted out for eye-catching lettering and decals. Kernow MetaliK Cut&Print is suitable for wet-application allowing easy application and is the same colour on both sides making it ideal for double sided window display.

Mike Collins, Product Manager for Visual Communications at Antalis UK, comments: "We are delighted to be offering a new extended offering of the brilliant KernowJet MetaliK portfolio here at Antalis. MetaliK is truly eye-catching, and the Cut&Print films in particular provide great options for many retailers and consumer-oriented companies who are looking for a smooth finish to their displays, with the luxury metallic effect providing stand-out visual aesthetics.”

Arrow Systems unveils new finishing unit Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market. The A...

September 06 2018

Arrow Systems unveils new finishing unit

Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market. The Arrow Eco 300 is a tabletop blade finisher that can diecut up to 15” wide. The system features its own cutting software, as well as inline matrix removal.

“We believe this system has a place in the digital market as it fills a need for a low cost alternative to the blade and laser finishers we offer," says Shaan Patel or Arrow Systems, Inc. “The compact design allows it to be used with any roll-to-roll digital printer, and it can also be used for prepress sampling. It is an extremely economical way to get into diecutting your own labels”

The Eco 300 allows users to switch away from pre-cut media and use continuous media to be cut after printing, which can save users of small digital roll printers a lot of money. “Pre diecut media is extremely expensive, and having an option that allows you to cut your own media without breaking the bank is a nice option for brand owners to have," adds Patel.

Canon launches Océ ColorWave 3000 wide format series Canon has launched the new Océ ColorWave 3000 series of large format printers for customers specialising in CAD, GIS ...

September 06 2018

Canon launches Océ ColorWave 3000 wide format series

Canon has launched the new Océ ColorWave 3000 series of large format printers for customers specialising in CAD, GIS and short-term graphic arts applications.

The new systems address the printing requirements in the architectural, engineering, construction and manufacturing (AEC&M) sectors, as well as corporate environments. With the Océ ColorWave 3000 series, customers have the flexibility to easily print an even wider range of applications from black and white technical documents, drawings and maps, to full colour indoor and short-term outdoor graphics such as posters and roll-up banners.

The new Océ ColorWave 3000 series comprises two different models: the Océ ColorWave 3500 and the Océ ColorWave 3700, both meeting the needs of businesses operating at mid-volumes, and both saving businesses time, resulting in a faster return on investment.

Consistent colour quality

The new printers incorporate the 10-year proven Océ CrystalPoint technology that combines the best of toner and inkjet in Océ TonerPearls, which are melted into a toner gel that crystallises onto the media. Since the introduction of the Océ CrystalPoint technology in 2008, Canon has installed more than 10,000 engines worldwide, based on this technology. Océ CrystalPoint grants customers the option to work with lower cost media without compromising on quality. Prints made with the Océ CrystalPoint technology are instantly dry, enabling handling, stacking and folding to take place immediately.

The use of Océ TonerPearls ensures strong adhesion and scratch-resistance, as well as offers sharp lines with minimal feathering for high quality documents and graphics. Océ TonerPearls prints are also waterproof, enabling businesses to produce applications for short-term outdoor use.

The Océ ColorWave 3000 series also features Océ PAINT (Piezo Acoustic Integrated Nozzle Technology) that helps to overcome nozzle failure on the fly for predictable and consistent print quality, reducing daily maintenance time.

Print-to-finish

The Océ ColorWave 3500 has a media capacity of up to four rolls and customers can automatically switch between media for faster production. The Océ ColorWave 3700 has a media capacity of up to six rolls, handling up to 1200 m, and can print up to 368m² posters per day in fast mode.

The Océ ColorWave 3000 series features the Océ ClearConnect software suite, helping businesses to manage complex print jobs and offer a more flexible and intuitive interface when submitting print files to the printer.

To avoid misprints and delays, Océ Publisher Select enables customers to automatically preview print jobs. To support this, Océ Print Assistant automatically suggests the right print mode for the job, detecting media requirements, so that the printer switches to the most appropriate media roll without the need for manual intervention.

The Océ Folder Express 3011, Océ Folder Professional 6011/6013 and Océ Stacker Select provides a compact print-to-finish solution, offering an automated folding and stacking capability for working environments in which fast production is required.

Suitable for space-constrained office environments, the Océ ColorWave 3000 series with Folder Express 3011 has a footprint of 25% less than its predecessors, the Océ ColorWave 500 and ColorWave 700, with their respective folding capabilities.

Beyond technical applications

The Océ ColorWave 3000 series is easy to use and enables customers to offer new services and applications beyond black and white technical drawings, attracting greater volumes and higher quality work.

The Océ ColorWave 3700 supports close to 40 different media types and media up to 800 μm. With Océ MediaSense technology, the print gap between the media and the print head is automatically adjusted to the optimum distance, allowing businesses to print on an even wider range of media, including uncoated paper.

The new Océ ColorWave 3000 series will be shipped from Q3 2018.

Dominic Fahy, Head of AEC&M, Industrial & Production Solutions, Canon UK comments: “Whether customers are wanting to continue to print CAD documents or looking to expand their applications capability by producing short-term graphic arts applications, the Océ ColorWave 3000 series gives them the opportunity to print both. From taking an innovative vision, turning it into a blueprint, then bringing it to life through coloured visuals, customers can use the Océ ColorWave 3000 for consistent high quality prints, time after time, print after print.”

Nazdar releases 184 Series solvent inkjet ink Nazdar Ink Technologies has announced the 184 Series, a newly developed digital imaging ink formulated specifically as a high-performance ...

September 06 2018

Nazdar releases 184 Series solvent inkjet ink

Nazdar Ink Technologies has announced the 184 Series, a newly developed digital imaging ink formulated specifically as a high-performance alternative for Mimaki JV150/300 and CJV150/300 digital printers using Mimaki BS4 ink.

Nazdar 184 Series users will benefit from low odour and enjoy the convenience of a range of packaging options, including 600ml bags and 2000ml bags compatible with MBIS.

"The new Nazdar 184 Series exhibits outstanding performance, with excellent outdoor resistance to colour fade and chemical attack caused by UV degradation or environmental pollution," said Stephen Woodall, Nazdar Ink Technologies' Global Segment Manager - Aqueous & Solvent Digital. "We've developed an ink with excellent performance and adhesion on flexible and pressure sensitive vinyl, banner material, blue back paper and backed mesh."

For more information and technical data, visit the 184 Series web page or email product questions to InkAnswers@nazdar.com

.jpg)

Konica Minolta has announced the immediate availability of the AccurioPress C83hc. This High Chroma digital press gives printers a whole new world of colour reproduction with enhanced performance.&...

September 04 2018

Konica Minolta has announced the immediate availability of the AccurioPress C83hc. This High Chroma digital press gives printers a whole new world of colour reproduction with enhanced performance.

The AccurioPress C83hc can express a much wider colour gamut than CMYK used for conventional printing. Pinks, purples, and bright greens are reproduced much more vividly and faithfully than those reproduced on a conventional CMYK toner print system.

Grant Thomas, Product Marketing Manager, Konica Minolta, said, “The wide colour gamut of the AccurioPress C83hc High Chroma toner creates new printing business opportunities. It means that colours closer to RGB can be obtained, which is great for applications like printing studio photos, photo books, photos of nature, illustrations, computer graphics (CG), web-to-print, and more.

“The printed image will be more natural and impressive when compared to an image produced on a conventional CMYK system. The expansion of spot colour reproduction is useful for printing company logos, high-impact point-of-purchase (POP), packaging, and posters.”

Key features of the AccurioPress C83hc include:

· superb colour reproduction: a unique electro-photo print system that produces colours close to sRGB; something that cannot be achieved with CMYK print systems. When in print mode, colours close to sRGB and CMYK can be obtained with the one system

· automated adjustments: automated colour and registration adjustments are possible with the Intelligent Quality Optimiser (IQ-501) enhancing quality, productivity and, ultimately, profitability

· high productivity: high productivity (81 ppm/A4), high-capacity paper handling and high-spec finishing options for high-volume printing

· excellent versatility: wide paper weight compatibility up to 350 gsm. Excellent versatility handling a variety of media with ease including envelopes, banners, and textured stocks.

· long sheet banner printing: simplex up to 1300 mm and up to 762 mm auto duplex.

The AccurioPress C83hc is equipped with Konica Minolta’s Intelligent Quality Optimiser, IQ-501. The IQ-501 maintains consistent colour reproduction and closed-loop paper registration (image-on-image, image-on-paper, and side-one/side-two registration) is measured and managed automatically in real time during printing operation.

With the IQ-501 consistent realisation of high-quality print contributes to reduced print waste and labour times for set up, reducing the need for manual intervention. It increases uptime with automated system self-correction to ensure colour reproduction remains accurate and, importantly, delivers high-quality print results time after time. The IQ-501 can deliver time savings for print operators of up to 60 per cent and can increase system print productivity by up to 20 per cent.

Konica Minolta provides exceptional service and support to keep commercial printers up and running. The new AccurioPress C83hc is available now.

Adding a new dimension to your offering is always a great way to build business and increase profitability, and that’s exactly what Océ Australia has introduced this week, both literal...

September 04 2018

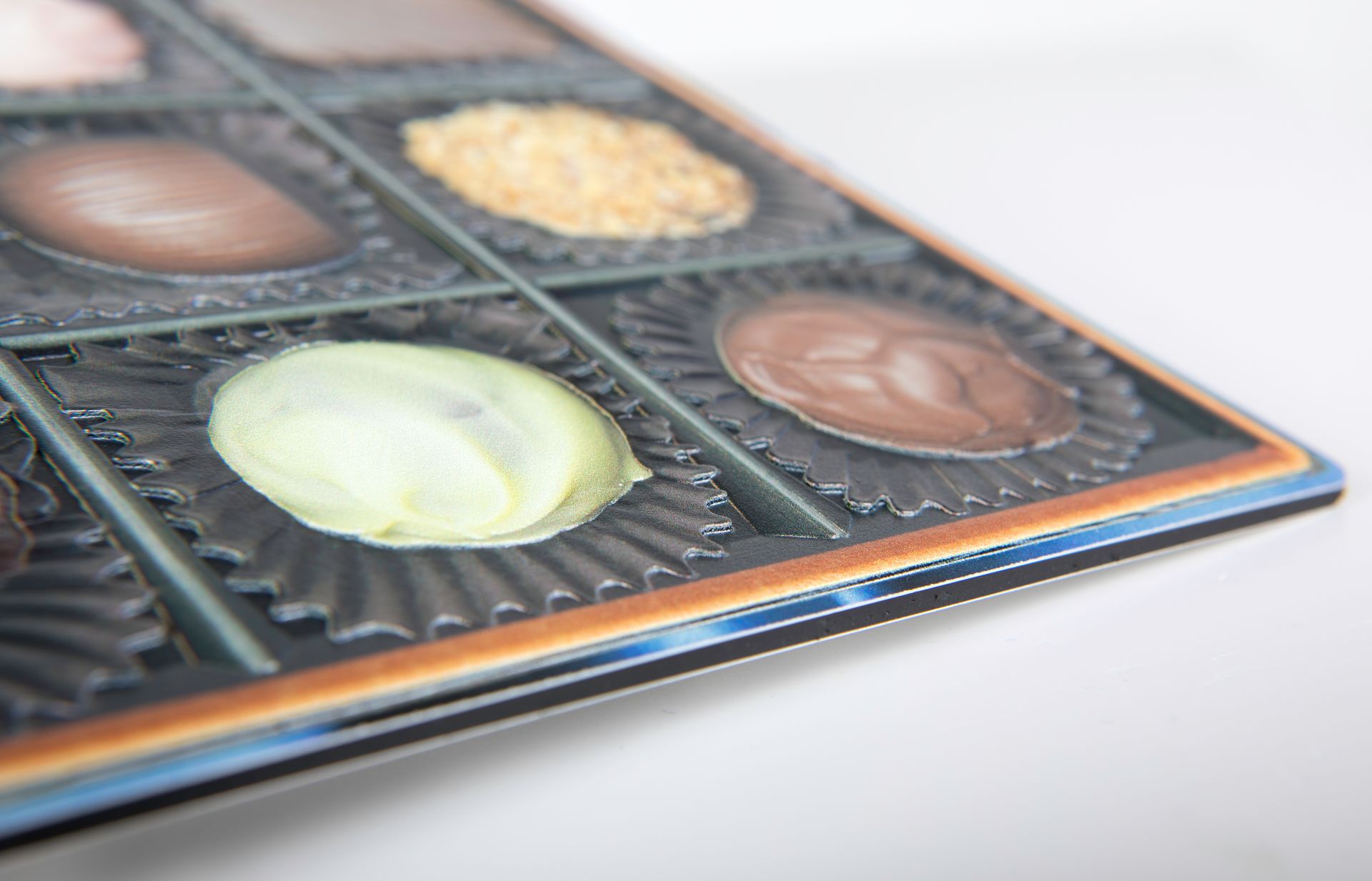

Adding a new dimension to your offering is always a great way to build business and increase profitability, and that’s exactly what Océ Australia has introduced this week, both literally and figuratively, with the launch of its new Touchstone® elevated printing technology for Océ Arizona® Series of large -format UV flatbed printers – and visitors to Visual Impact this month will be able to ‘see , touch and feel’ exactly what that will mean for their business.

Garry Muratore, Product Manager – Graphic Arts for Océ Australia, says the new workflow software has the potential to help businesses broaden their offering and build their business by creating new high-value, high-margin products using what Océ terms ‘2.5D’ print.

“We’re all aware of the advantages of normal, 2D print and it’s been interesting to see the buzz around 3D in recent years, although the ability of print service providers to integrate those technologies profitably into their business has given it limited relevance for our industry,” Muratore reflects.

“With Océ Touchstone, Arizona printers can take advantage of dimensional print in the form of commercially viable and profitable ‘2.5D’ applications, creating layered, textured prints that command significantly higher margins, without the need to invest in any additional hardware.”

Citing recent research, Muratore says print buyers expect to pay a premium for tactile prints, creating genuine opportunities to add value and improve margins for print service providers who can find a cost-effective and efficient way deliver.

“In any business, profitability is the key to success. Improving efficiency and reducing costs can help, but the real key is leveraging new technologies to establish a genuine competitive advantage,” Muratore says. “Touchstone provides the solution with a suite of new productivity tools that make it

easy to achieve high quality, repeatable results with an exciting sensory dimension.”

“Touchstone uses extensions to the Adobe toolset to allow designers to build dimensional features into print jobs at the design stage,” Muratore explains. “The design tools are free to use, but production does require Océ’s patented ALPS technology, which sits within the Onyx Thrive/ Océ

Arizona ecosystem, speciality Océ IJC257 inks and, of course, an Océ Arizona printer.”

In fact, the system offers two categories of dimensional print. Alto offering provides opaque elevation plus colour in depths of up to 1mm, while Brila offers a lower profile up to 0.5mm, with colour and varnish, opening the door to applications like metallic effects, achieved by printing on reflective media like foil.

Océ’s ALPS technology also ensures every pixel of the final ‘top layer’ – or image layer – is printed at the optimum height, exactly as if it were a 2D job, achieving outstanding quality with no softening of the image in valley.

The results are certainly impressive, with the quality, versatility and tactile appeal of Touchstone prints making it easy to appreciate how it could enhance a range of applications from wallpapers and interior products, short-run or personalised marketing, limited edition packaging, POP and signage, prototypes and moulds, and more.

“We think Touchstone will appeal particularly PSPs with a creative and entrepreneurial mindset, who understand that creating a point of difference can really help them stay ahead of the game. And, of course, those who – and also those who service ‘bespoke’ markets where print is only one component

of the finished item,” Muratore says.

“Importantly, Touchstone makes it easy for printers to achieve these dimensional enhancements, with straightforward, intuitive operation, simplified ‘real-world’ design dimensions and a high level of automation. There are no complex iterations required in the design phase and, in terms of production,

it’s pretty much ‘set and forget’.”

Those keen to “feel the difference” will have the opportunity at Visual Impact, where Océ Australia will have an entire ‘Touchstone Wall’ on display on Stand D17. If you can’t be in Sydney, but still want a preview, you can contact your local Océ business development manager to book a demo – the company has even introduced trial licenses of up to 12 months for existing Arizona users who are keen to dip a proverbial toe in the dimensional print market.

“Océ’s is committed to helping print businesses achieve success through new and profitable print technologies,” Muratore says, “and it’s fair to say that, with the introduction of Touchstone, printing has never felt so good.”

For more information, just email support.au@oce.com

Komori Announces Plans to Field Test Impremia NS40 Nanographic System Komori Corporation announced plans to initiate field testing of its new Impremia NS40, a 40˝ sheetfed Nanographic ...

September 01 2018

Komori Announces Plans to Field Test Impremia NS40 Nanographic System

Komori Corporation announced plans to initiate field testing of its new Impremia NS40, a 40˝ sheetfed Nanographic Printing System, during the spring of 2019. First shown at drupa 2016, the Komori Impremia NS40, a sheetfed inkjet press equipped with Landa Nanography technology, has been in development at Komori in Japan for more than two years.

Keeping the needs of today’s customers in mind, the NS40 is designed to combine the versatility of digital with the quality and speed of offset printing at a low cost per page. It has the capability to print on any off-the-shelf substrate, from coated and uncoated paper stocks to synthetic substrates and paperboard—up to 32 point—without the need for pre- or post-treatment of any type. Operating at an initial throughput rate of 6,500 straight sheets or 3,250 perfected sheets per hour, the NS40 will be available in multiple configurations, from a 4-7 color straight press to an 8-color perfector with in-line coating.

Based on the progress of the development of the Impremia NS40, Komori plans to carry out the first field test of the beta press in the Japanese market in the spring of 2019. This will be followed by similar plans to further test the NS40 in other countries as well.

“Komori has been working tirelessly behind the scenes to bring this game changing technology to the market so we are very excited that this product will soon be a reality,” says Scott Robertz, NS40 product manager for Komori America Corporation.

General availability of the product is planned for late December of 2019.

Epson Introduces Dye-Sublimation Solution Optimised for Rigid Photo Applications Epson today announced a new solution designed for creating dye-sublimation photo panels and other rigid...

August 29 2018

Epson Introduces Dye-Sublimation Solution Optimised for Rigid Photo Applications

Epson today announced a new solution designed for creating dye-sublimation photo panels and other rigid substrates. New Epson DS Transfer Photo Paper, a high-quality, lightweight dye-sublimation transfer paper, combined with Epson SureColor® F-Series dye-sublimation printers, inks and Wasatch RIP support, creates a complete solution designed to produce rigid photos with advanced print quality and vibrant images with minimal grain, consistency and reliability.

Universal Woods, the world’s leading manufacturer of hard surface products for sublimation, has been using the new Epson solution – DS Transfer Photo Paper with the Epson SureColor F6200 printer on its ChromaLuxe panels. “The new DS Transfer Photo Paper was manufactured with ChromaLuxe in mind, and it addresses some of our main concerns with sublimating – texture and lack of sublimation dye around the outer areas of the aluminum photo panel,” said Josh Bender, sublimation specialist, ChromaLuxe. “This complete Epson dye-sublimation solution achieved a WIR Display Permanence Rating of 65 years1, the highest we’ve seen to date with ChromaLuxe prints.”

In addition, Image Wizards, the inventors of metal prints, has been using the new Epson transfer solution to create rigid photo prints. “The new Epson DS Transfer Photo Paper is the best dye-sublimation paper for rigid applications I have used,” said Roger K. Laudy, founder and president, Image Wizards. “In particular, the ink transfer onto metal prints on aluminum is amazing, with virtually no grain, as well as high ink transfer. This is easily the paper of choice for my customers.”

The new DS Transfer Photo Paper delivers excellent color gamut and black density, with reduced grain and mottling for smoother flesh tones and cleaner, lighter colors. In addition, it offers superb handling with almost no curl and warping under the heat of a flat press. The paper offers high ink transferability with slight transparency, which helps register the printed paper to the rigid substrate. Best used with the SureColor F6200, Wasatch SoftRIP version 7.6 offers full support for the DS Transfer Photo Paper for color management, print cost estimation and color profiles.

“This new paper is especially beneficial for the SureColor F6200 user who is producing high-quality photographic prints on ChromaLuxe plates,” said Tim Check, senior product manager, Professional Imaging, Epson America, Inc. “There are a lot of multipurpose transfer paper solutions available; this is one of the first that is specifically designed for rigid photo print quality – reducing grain to provide a more dynamic range of color.”

Pricing and Availability

The new DS Transfer Photo Paper is available now through Epson authorized Professional Imaging Resellers in three roll sizes for the following MSRPs:

- 17” x 300’ – $65

- 24” x 300’ – $89

- 44” x 300’ – $165

For additional information, visit www.proimaging.epson.com

Epson launches new T-Series large format wireless technical printers SureColor T3160 and T5160 offer speed, precision and reliability in ultra-sleek, compact design

August 29 2018

Epson launches new T-Series large format wireless technical printers

SureColor T3160 and T5160 offer speed, precision and reliability in ultra-sleek, compact design

Epson Australia has launched two new high-speed, easy-to-use large-format printers – the 24-inch SureColor T3160 and the 36-inch SureColor T5160, available as desktop or floor-standing models. Marking Epson’s expansion of the T-Series product line to the low-to-mid-range CAD, AEC, GIS, POS poster and education markets, the wireless models feature a new clean and compact design coupled with the reliable printing performance inherent in Epson’s technical solutions.

Whether printing blueprints, line drawings, signage, or classroom posters, the SureColor T3160 and SureColor T5160 will assist professionals across a wider range of segments including architecture, engineering, CAD, GIS, education, corporate, home and small office users. The unique auto-switching functionality enables the printers to swap between large format roll paper and A4/A3 size paper, without users having to touch the printer, ideal for small companies that have multi-purpose print requirements in a limited workspace.

Epson Australia’s GM sales & marketing of their business division Craig Heckenberg said, “The SureColor T3160 and T5160 are designed specifically for the technical community including engineers, designers and architects who are looking for a fully functioned and compact printer that fits neatly in their office. These new printers also produce quality colour posters and displays, and they enable users to wirelessly produce accurate and vibrant prints from tablets and smartphones virtually anywhere.”

SureColor T3160

Leveraging Epson’s PrecisionCore MicroTFP printhead technology and Nozzle Verification technology to automatically detect and adjust nozzle condition, the new printers offer fast print speeds producing accurate A1 prints in 31 seconds for the SC-T5160 and 34 seconds for the SC-T3160, with precise detail and commercial-grade reliability. Featuring integrated wireless and Wi-Fi Direct connectivity, users can seamlessly print from tablets and smartphones or use the new 4.3-inch colour LCD touchscreen with simple and intuitive menu control and navigation. Next-generation high-capacity UltraChrome XD2 pigment inks deliver durable archival prints with brilliant colour and crisp lines on many paper types.

SureColor T5160

The 24-inch SureColor T3160 and the 36-inch SureColor T5160 printers deliver a range of features designed to help industry professionals increase productivity, including:

• Fast print speeds – The SC-T3160 and SC-T5160 produce accurate A1 prints in 34 and 31 seconds, respectively.

• Easy to operate – A large, intuitive 4.3-inch LCD colour touchscreen simplifies print tasks.

• Compact, clean design – Ultra small footprint and sleek, minimal design enhances workspaces.

• Replace ink less often – High-capacity cartridges, up to 50ml colour and 80ml black.

• Print from virtually anywhere in the office – Integrated wireless and Wi-Fi Direct connectivity allow for easy printing from tablets, smartphones and more.

• High-performance – PrecisionCore MicroTFP printhead offers Precision Droplet Control for outstanding clarity, and commercial-grade reliability with Nozzle Verification Technology.

• Durable, vibrant prints – Next-generation UltraChrome XD2 archival pigment ink technology produces brilliant colour, crisp lines and delivers prints that are water and scratch resistant.

• Versatile media handling – Accommodates rolls up to 24 and 36 inches and up to 50 sheets of A4 and A3 paper through the auto sheet feeder with autoswitch, as well as cut-sheet papers up to A1 (24”) or A0 (36”).

• Precise, sharp detail – Print blueprints, line drawings, posters, and more up to 2,400 dpi.

• Easy set up – Get up and running out of the box in rapid time.

Both printers come with a comprehensive 1 year on-site warranty and CoverPlus service packages are extendable up to 3 years.

The SureColor T3160 and SureColor T5160 will be available in Australia from September 2018 with RRPs beginning at $1,495 including GST.

For more information on the Epson SureColor T3160 and T5160 click here

Hop Industries Releases Hop-Syn GO Synthetic Paper Exclusively for HP Indigo Digital Presses Hop Industries, manufacturer of the durable Hop-Syn synthetic paper today announces the imm...

August 29 2018

Hop Industries Releases Hop-Syn GO Synthetic Paper Exclusively for HP Indigo Digital Presses

Hop Industries, manufacturer of the durable Hop-Syn synthetic paper today announces the immediate availability Hop-Syn GO, a new grade specifically designed for all models of the HP Indigo digital press. Environmentally-friendly and 100% recyclable, the Hop-Syn GO grade is a surface-treated, clay-coated, calendered polypropylene substrate. Its unique composition offers superb ink adhesion and high-quality graphic imaging unlike any other synthetic paper for the HP Indigo press.

Hop-Syn GO is 100% waterproof and is extremely scuff resistant, ideal for menus, identification cards, P-O-P signage, retail tags, and more. Competitively priced, Hop-Syn GO provides the durability, tear resistance, and weather resistant properties of polypropylene plastic with the print performance and efficiency of conventional paper.

“Our customers have been asking for a Hop-Syn grade made specifically for the HP Indigo press, and we delivered a substrate that outperforms all other synthetic papers in the market, both in quality output and price,” comments Jack Smith, Senior Vice President of Hop Industries. “Hop-Syn GO grade has been put through our rigorous R&D and field-tests. The feedback has been overwhelmingly positive. HP Indigo customers rave about the Hop-Syn GO’s high quality and boast about how easy it is to run.”

Hop-Syn GO synthetic paper produces vibrant imaging with 85-90% opacity. Its smooth matte finish is printable on both sides. Hop-Syn GO is UV resistant up to 3 months outdoors and can be scored and grommeted. Hop-Syn GO is available in stock sheet sizes including 12 x 18 in, 13 x 19 in, 20.5 x 29.5 in, and 55 in stock roll width.

Hop Industries stocks its full line of Hop-Syn synthetic paper in its NJ warehouse; all grades can be shipped within 24 hours. The company also offers In-house converting, slit rolls from 1-in up to 54-in, and custom sized sheets and quantities.

For questions or more information visit www.hopsyn.com

COLORTUFF EXT ® : THE NEXT WAVE IN SIGNMAKING SUBSTRATES ColorTuff EXT ® is the industry’s first 5 year exterior sublimatable aluminium sheeting. Available in sizes up to...

August 29 2018

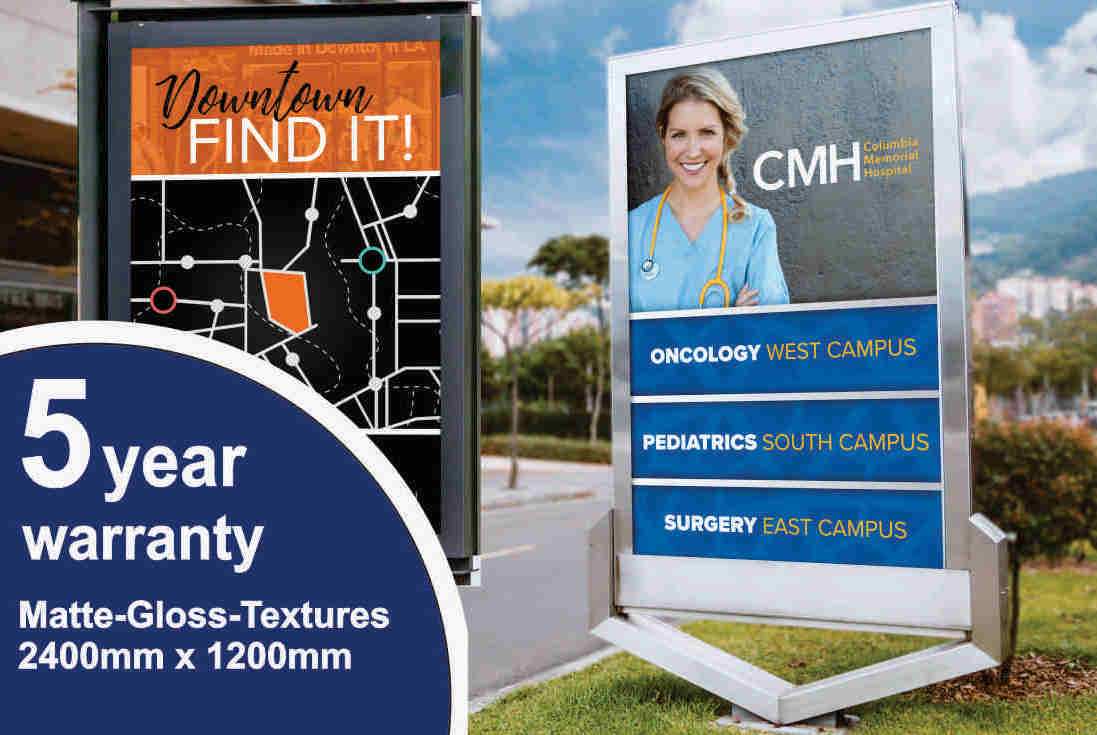

COLORTUFF EXT ® : THE NEXT WAVE IN SIGNMAKING SUBSTRATES

ColorTuff EXT ® is the industry’s first 5 year exterior sublimatable aluminium sheeting. Available in sizes up to 2400mm x 1200mm and in 3 different finishes, it will stand up to the demands of the harshest environment.

Tom Johns from Rowmark Australia stated, “Come and see our ColorTuff EXT ® display at VI Sydney. The look and feel of the Texture finish bring an authenticity to signage that will change your perception of the applications and potential of sublimation.”

With great outdoor weatherability, durability of colour and 5 year performance guarantee, ColorTuff EXT ® will open many opportunities for sign makers from Architectural, Wayfinding, Exterior Signage to Compliance Signage, Garden Art and Outdoor Informational Graphics.

Colortuff EXT ® guillotines cleanly, drills without chipping and crazing and is graffiti resistant for easy removal of spray paint and permanent markers and will provide great new option for sign makers.

For more information about ColorTuff EXT ® contact: sales@rowmark.com.au , phone 1300 023 370, see us at VI Sydney 2018 or click here for more details.

SAi Receives Software Certification for HP DesignJet Z6610 and DesignJet Z6810 Printers Salt Lake City, Utah, USA – SA International (SAi), the leading provider of softwar...

August 29 2018

SAi Receives Software Certification for HP DesignJet Z6610 and DesignJet Z6810 Printers

Salt Lake City, Utah, USA – SA International (SAi), the leading provider of software solutions for the signmaking, digital printing and CNC machining industries, today announces that its market-acclaimed SAi Flexi software solution is certified for use with both the HP DesignJet Z6610 and DesignJet Z6810 printers. The certification helps ensure print providers and sign & display companies to streamline their workflow, increase their throughput and guarantee premium quality output for their customers.

Applicable to FlexiPRINT, FlexiSIGN & PRINT, FlexiPRINT SE and HP FlexiPRINT edition v12, the certification officializes the software with HP’s stamp of approval and confirms that these Flexi solutions fully comply with its rigorous performance requirements for both DesignJet printers

Efficiency-Enhancing Tools

For users, this provides the assurance that the software will seamlessly integrate with their HP DesignJet printer without disruption to their print line.

The certification also offers those users who require advanced production tools – such as nesting, tiling and color management options – access to a catalogue of efficiency-enhancing tools. These include the ability to minimize material waste and maximize profit margins using Flexi’s new contour cut true shaping nesting tool. Users can precisely match the job spot colors with ease using Flexi’s spot color swatch tools.

Commenting on the certification, Eyal Friedman, Vice President, Technical Services at SAi, says, “As this certification demonstrates, our software solutions continue to perform at the highest level to equip print providers and sign & display companies with a multitude of business-enhancing tools.”

Designed as the world’s first and only all-in-one design, print and cut software solution, Flexi provides users with a comprehensive design-to-output workflow under one roof. Users have the choice to either purchase the software outright or via SAi’s subscription model. Subscribers have the financial flexibility to add extra licenses during peak periods as well as enjoy instant access to the latest upgrades.

SCREEN and Meccanotecnica co-operate for optimised on-demand production of premium section-sewn books SCREEN and Meccanotecnica are collaborating on optimized on-demand production of p...

August 29 2018

SCREEN and Meccanotecnica co-operate for optimised on-demand production of premium section-sewn books

SCREEN and Meccanotecnica are collaborating on optimized on-demand production of premium quality books using Screen’s EQUIOS universal workflow and roll-fed full-color high-speed inkjet press, the Truepress Jet520HD, and Meccanotecnica's automatic book folding and sewing machine, the Universe Sewing Digital print finisher.

Screen’s Australian Managing Director, Peter Scott says: “Section-sewing of bookblocks for hard cover binding is recognised as the most robust way to finish quality books for durability and appearance. By integrating Meccanotecnica’s folding and book sewing technology with EQUIOS workflow, an automated end-to end production line is possible using barcodes to carry the required information through the workflow to finishing.”

The much-awarded Truepress Jet520HD with SC inks achieves quality suited to high-end publication work and is compatible with a wide range of paper stocks including standard offset coated papers. The latest version, 3.4, of EQUIOS provides roll-to-book imposition and variable barcode output functions that support automation with Meccanotecnica's Universe Sewing Digital print finisher.

Scott adds: “Now that high-definition inkjet digital printing is possible with the Truepress Jet520HD and Screen SC inks, short-run digital printing has moved up to a new level where high-quality finishing is called for. Meccanotecnica is a leading vendor of automatic book sewing equipment, and our collaboration has enabled the automation of a process that provides exceptional durability and quality. The digital on-demand creation of books now offers quality and productivity levels that far exceed standard digital printing.”

Italy-based Meccanotecnica was founded in 1964 and is the world's leading manufacturer of automatic book sewing equipment and lines for book finishing. Globally renowned for its ASTER book sewing machines for offset print finishing, Meccanotecnica has entered the digital print finishing market by developing new solutions to allow cost-effective binding of short runs and the production of high-quality books.

www.screenaust.com.au

Konica Minolta has appointed Andrew Ward to the role of Sales Manager for Production & Strategic Sales, New South Wales. Andrew is focused on assisting commercial prin...

August 28 2018

Konica Minolta has appointed Andrew Ward to the role of Sales Manager for Production & Strategic Sales, New South Wales.

Andrew is focused on assisting commercial printers to improve their businesses and increase efficiencies through the use of Konica Minolta technology, as well as continuing to build a collaborative team that is well-trusted and respected by printers, suppliers, partners and peers.

Andrew has more than 25 years’ experience in the print industry from graphic arts to commercial print. Prior to this role he held various roles at HP and Canon.

Andrew Ward said, “Konica Minolta has a supportive, collaborative culture with a real social conscience, which is what appealed to me. With my broad experience in the industry I look forward to working with business owners to leverage their Konica Minolta technology to drive their businesses forward.”

David Procter, Director of Sales and Service, Konica Minolta, said, “Having experience in both the vendor and commercial print space means that Andrew has a depth of knowledge that will add significant value to our customers. We look forward to seeing how Andrew can motivate and coach a high-performance sales team that delivers outstanding service to our customers.”

Océ Colorado to Pop-Up at Visual Impact Sydney If you’ve been thinking about popping over to Sydney Olympic Park for the Visual Impact expo next month, there’s now a...

August 28 2018

Océ Colorado to Pop-Up at Visual Impact Sydney

If you’ve been thinking about popping over to Sydney Olympic Park for the Visual Impact expo next month, there’s now another compelling reason to attend, with Océ Australia confirming that they will bring their new ‘pop -up showroom’ featuring the revolutionary Océ Colorado 1640 64” roll -to-roll printer, to the show.

Visual Impact has a well-established reputation for bringing the very best knowledge, resources and technology to the sign, display, wide-format and digital print sectors and next month’s show in Sydney will be no exception, with market leaders like Océ Australia putting their latest and greatest on show. For Océ, VI provides the opportunity to give the Océ Colorado 1640, the first machine to feature the company’s game-changing UVgel technology, its first official show outing in the Harbour City.

Reputed to be the fastest 64” roll-to-roll machine on the market, almost five times faster than its competitors, the Océ Colorado capitalises on the gel-like structure of Océ’s unique ink technology, which allows the image to be pinned instantly to media via an LED ‘pre-cure’ process prior to full curing once the image is complete. This delivers exceptional image quality, with virtually no dot gain, and also extraordinary media versatility.

The machine’s debut at the Sydney show, where it will be teamed with an Océ Arizona 2280GT UV Flatbed Printer, follows enthusiastic feedback from Brisbane print service providers, who recently became the first in Australia to experience the ‘pop-up’ when it visited New Farm for a couple of weeks in July. According to Dale Hawkins, Senior Marketing Manager from Océ Australia, the company is hoping the same formula will be equally well received at the Sydney Showground.

“The Colorado has generated enormous interest to date, and the pop-up showroom setup is designed to allow visitors to really experience the speed, automation, quality and flexibility which allows you to print more for less – and put more money into your wallet,” he says.

“Visitors will be able to watch live demos of the Colorado producing a range of applications, learn about UVgel technology and why we believe it is the future of print, and talk to our product and technical specialists about how this technology could fit their particular business situation. Plus, we have an innovative new ROI tool which will allow visitors to crunch the numbers and see just how much of an impact the Colorado could have on their productivity and profits.”

There also seems to be plenty more attractions planned, with our spies telling us that the Océ Australia team will demonstrate plenty of ways to put more dollars in your hip pockets as well as some special VI deals for orders written at the show. For those who book a demo ahead of time (bookings can be made here), there will also be a couple of movie tickets to pop in their wallet.

Visual Impact Sydney will be held from 12 – 14 September at the Sydney Showground, Sydney Olympic Park. Click here to find out more, or register online today.

Mactac enters craft beer labelling market Officially announcing its entrance into the craft beer labeling market, Mactac Roll Label has launched a new line of all-temperature pressure-...

August 22 2018

Mactac enters craft beer labelling market

Officially announcing its entrance into the craft beer labeling market, Mactac Roll Label has launched a new line of all-temperature pressure-sensitive paper and film craft beer labels.

Designed to meet the needs of today’s craft beer brand owners, Mactac’s new craft beer labels are specially formulated with a variety of facestocks and finishes. With roughly 13 products available, Mactac offers semi-gloss, white and clear film options for bottle applications, as well as chrome films for cans.

“Craft beer packaging is all about shelf appeal, and today’s brand owners are trying to capture a certain look, with only seconds to persuade potential customers,” says Kim Hensley, marketing manager, Mactac Performance Adhesives. “Often, this means the labels on bottles and cans are just as important as the liquid inside. With a goal to stand out as much as possible at the point of sale, brand owners are seeking labels with special effects that give the perception of quality – such as varnishes, textures, the ‘no label look’ and specialty inks, in addition to vibrant, colorful labeling solutions.”

With nearly 60 years in the pressure sensitive adhesive business, Mactac has decades of experience and expertise in producing PS label solutions with a variety of specialty finishes and high-performance adhesive attributes.

Featuring the latest in Mactac’s all-temperature adhesive technology, the new craft beer label solutions are all designed with either Mactac’s industry-leading 640-AT acrylic adhesive or the company’s newest Chill AT hot-melt rubber adhesive. Both adhesives are ideal for cold and damp environments, as well as elevated temperatures. They also contain water resistance properties, maintaining adhesive integrity and aesthetic appeal if exposed to water or moisture.

Converters and printers alike will appreciate that Mactac’s craft beer label solutions allow short- and medium-run label jobs and are available under Mactac’s Precise Program, which allows customers to order less material for smaller runs – an extremely beneficial value-addition in the craft beer labelling market.

Mimaki Australia partners with Gravotech Australia. Mimaki Australia is pleased to announce that Gravotech has been appointed as a National Reseller of a selective range of Mimaki Indu...

August 21 2018

Mimaki Australia partners with Gravotech Australia.

Mimaki Australia is pleased to announce that Gravotech has been appointed as a National Reseller of a selective range of Mimaki Industrial Products.

As part of a Global Partnership Gravotech Australia will resell Mimaki’s very successful UJF Series LED UV Flatbed Printer range to complement there range of laser and engraving equipment.

As an introduction to this partnership Gravotech and Mimaki will be displaying “Print & Cut” solutions at Visual Impact Sydney exhibition on the 12th-14th September. A combination outlining the bundled benefits of the technologies.

“It is a pleasure to welcome Gravotech to the Mimaki family,” said Tomomitsu Harada - Managing Director of Mimaki Australia. “With our extensive UJF Series product range we are looking forward to bolster sales and customer focus with this partnership.”

Gravotech & Mimaki are global leading brands manufacturing premium printing & engraving machines to a wide variety of applications and Industries. “This relationship allows us to increase our product range and services that we can offer to our customers giving them access to the latest technology and products, with our combined Print & Cut solution” according to Simon Scott, Managing Director of Gravotech Australia. “It’s the perfect partnership for our business as we continue our focus on adding value to our customers’ business through service excellence – both customer and technical service alike.”

About Mimaki

Mimaki Australia are committed to support our dealer network to grow Mimaki brand awareness. Adapting new Australian initiatives which include service and warranty strategies. Regular Mini Trade show events in-conjunction with our dealer network. These events outline educational and advanced application workshops so we can provide the benefits of Mimaki products to Australian customers. Increase opportunities with IP (industrial products) TA (textiles and apparel) markets within Australia.

Mimaki is a leading manufacturer of wide-format inkjet printers and cutting machines for the sign/graphics, textile/apparel and industrial markets.

About Gravotech Australia

Gravotech is the global leader in the manufacture and supply of rotary and laser engraving machines, engraving material, consumables and extruded signage products. Through our Head Office and Manufacturing facilities in France, the Gravograph brand has been at the forefront of machine technology and quality since 1938. With offices all over Australia we are well positioned to serve and support our customers’ with the widest range of technical solutions.

Kodak to sell flexographic packaging division Kodak is to sell its flexographic packaging division, allowing it to focus on environmental plates, enterprise inkjet, workflow sof...

August 16 2018

Kodak to sell flexographic packaging division

Kodak is to sell its flexographic packaging division, allowing it to focus on environmental plates, enterprise inkjet, workflow software and brand licensing.

The division produces and markets the Flexcel NX system of flexographic imaging equipment, printing plates, consumables and related services. For the last 12 months, the division has reported revenues of US$150 million and operational EBITDA of US$33 million. During this period, it has demonstrated strong growth, achieving a nine percent increase in revenue and 18 percent operational EBITDA growth.

Kodak noted that during the sale process, it will continue to make significant investments by expanding manufacturing capacity, developing advanced technology and increasing headcount to meet customer needs.

Kodak CEO Jeff Clarke said: ‘This is a great opportunity to unlock value for shareholders given the strong interest we have received in the flexographic packaging division. The division has performed exceptionally well over the past five years and has become a significant player in the industry. This business is an excellent example of Kodak incubating and bringing disruptive innovation to the marketplace. Kodak has been evaluating monetization opportunities for the last several years in order to deleverage the company and we believe this is the right time to monetize this valuable asset.’

Clarke added: ‘Following this transaction, Kodak’s improved capital structure will allow us to increase our focus on demonstrated growth engines, while continuing to invest in and provide solutions across the commercial printing, film, and advanced materials industries.’

Post-sale, Kodak will focus on the demonstrated growth areas of Sonora environmental plates, enterprise inkjet, workflow software and brand licensing. Each of these businesses has delivered growth, profitability and strong margins, Kodak noted.

‘The company is well positioned for the future by leveraging these growth engines and continuing to maximise value in print systems, film and advanced materials,’ Kodak clarified in a statement.

Kraft Heinz aims for 100 percent recycled packaging by 2025 As part of its commitment to reduce natural resource needs and manage overall environmental footprint, The Kraft Heinz Compa...

August 16 2018

Kraft Heinz aims for 100 percent recycled packaging by 2025

As part of its commitment to reduce natural resource needs and manage overall environmental footprint, The Kraft Heinz Company has expanded its environmental strategy to include time-bound targets for achieving greater packaging sustainability and setting science-based goals to reduce greenhouse gas emissions.

Specifically, Kraft Heinz supports the move toward a circular economy and aims to make 100 percent of its packaging globally recyclable, reusable or compostable by 2025. This announcement, a complement to its ‘Growing a Better World’ strategy, supports the company’s efforts to improve the sustainability of its supply chain.

‘Our collective industry has a massive challenge ahead of us with respect to packaging recyclability, end-of-life recovery and single-use plastics,’ said Bernardo Hees, CEO at Kraft Heinz. ‘Even though we don’t yet have all the answers, we owe it to current and future generations who call this planet ‘home’ to find better packaging solutions and actively progress efforts to improve recycling rates. That’s why Kraft Heinz is placing heightened focus on this important environmental issue.’

Kraft Heinz will aggressively pursue technical alternatives while also collaborating externally to advance its commitment to deliver 100 percent recyclable, reusable or compostable packaging by 2025. The company will partner with packaging experts, organizations and coalitions to explore technical, end-of-life and infrastructure solutions, and is already collaborating with Environmental Packaging International (EPI) for consulting, tracking and other specialist services in the packaging space. The company also will work toward increasing the usage of recycled content in its packaging and decreasing the overall volume of packaging used.

While the global packaging target is new, Kraft Heinz is no stranger to advancing the sustainability of its packaging. Evidenced by previous work in this space, the company has been working for years to optimize its high-volume packaging. For example, Kraft Heinz recently exceeded its commitment to reduce the weight of its global packaging by 50,000 metric tonnes. Additionally, Kraft Heinz Europe is working to make the recyclable Heinz Tomato Ketchup PET plastic bottle fully circular by 2022, by using recycled material that can be made back into food-grade packaging.

In addition, Kraft Heinz is doing its part to accelerate the transition to a low-carbon economy by working to set science-based greenhouse gas emissions reduction goals in its supply chain. Adoption of these aggressive targets is aimed at helping avoid a global temperature increase of more than two degrees Celsius.

Added Hees: ‘We found that most of our emissions are coming from areas outside our direct operations. To truly succeed as champions of sustainability, we will look at our full value chain and determine where we can make the greatest impact for our planet.’