US$200 million innovation investment will power both digital and sustainable print transformation in corrugated packaging and textiles. HP announced a significant investment in the nex...

October 29 2019

US$200 million innovation investment will power both digital and sustainable print transformation in corrugated packaging and textiles.

HP announced a significant investment in the next generation of water-based ink solutions, ahead of PRINTING United 2019. The company has committed US$200 million over five or more years to develop water-based ink technologies for printing digitally on corrugated packaging and textiles.

The company’s commitment complements ongoing HP investments in other printing technologies and markets aimed at creating sustainable digital print solutions. Traditional textile coloration makes use of technologies that can be problematic from a water emissions perspective. World Resources Institute estimates that about 20% of industrial water pollution comes from garment manufacturing.[1]

“Investing in water-based solutions that meet market needs and the increasing sustainability requirements of graphics customers is expected to propel business growth for HP,” says Santi Morera, general manager and global head of graphics solutions, HP Inc. “We will be dedicating resources toward continued innovation and industry disruption to accelerate safer, simpler and more sustainable water-based printing technologies that meet the quality, performance and economics needed by these markets.”

Future of the market

HP’s true water-based inks for corrugated packaging have already shown leadership for sensitive applications such as food packaging. The company is committing resources to enable the next major generation of ink, printhead and press technology, with improved quality, performance and sustainability in our solutions out of a belief that water-based solutions are the long-term future of this market.

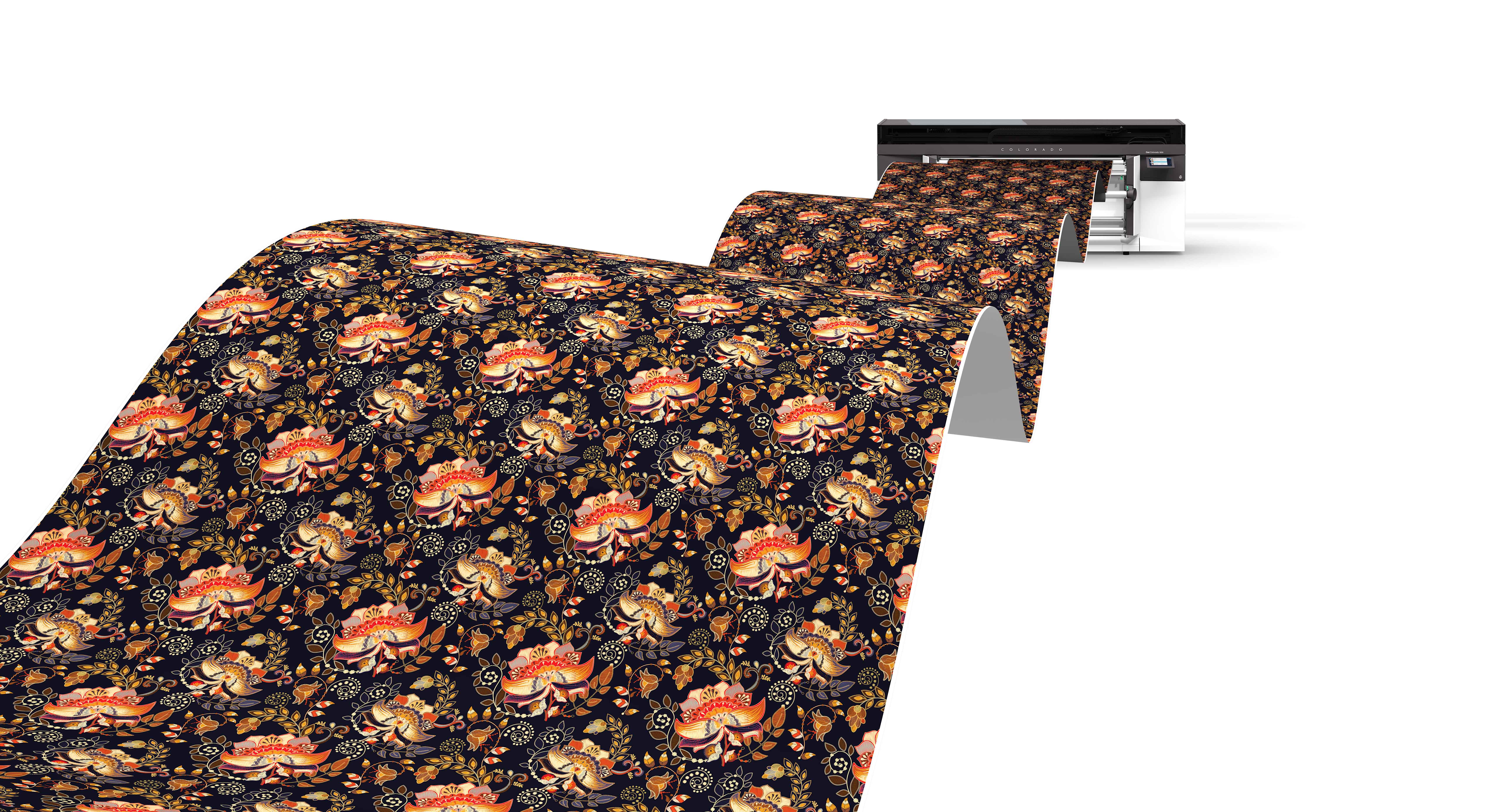

While executing plans for transforming the textiles market, HP is mindful of the technology options from both the traditional analog and digital perspectives. As such, HP is collaborating with the textile industry in order to make the right choices for water-based digital platforms.

This announcement builds on HP’s existing innovation in water-based ink technology, such as for the sign and display market. Water-based HP Latex Inks, for example, established a durable, versatile and safer alternative for existing inks used for signage and displays. Additional sustainability achievements across HP’s graphics business allow brands to reduce waste and minimise their environmental impact.

“HP’s continuing investment in advancing water-based ink technology gives DS Smith confidence that we will meet the health and safety demands of our customers, along with our own high standards for the work environment of our employees,” said Ruediger Lindner, general manager, DS Smith.

Robert Seay, general manager, Georgia-Pacific Hummingbird said, “Water-based inkjet inks are a technology differentiator in corrugated packaging, enabling us to confidently address a broader range of applications from food and beverage to personal care products.”

HP believes that investing in water-based ink solutions for the corrugate and textile printing markets will have beneficial effects along the entire product lifecycle, for the people who operate our printing systems, for the end users of the printed product, and ultimately for the final reuse, recycling, or disposal of that product.

Mutoh Industries, a leading manufacturer of wide-format inkjet printers, is pleased to announce their new generation, MS41 EcoSolvent ink, has been certified for ‘Wallcovering’ - the hi...

October 29 2019

Mutoh Industries, a leading manufacturer of wide-format inkjet printers, is pleased to announce their new generation, MS41 EcoSolvent ink, has been certified for ‘Wallcovering’ - the highest-level category possible. Mutoh Australia General Manager, Russell Cavenagh commented: “Recently developed in conjunction with our new range of XpertJet printers, this latest Greenguard Gold certification further demonstrates Mutoh’s ongoing commitment to the environment and better workplaces”.

UL’s GREENGUARD Certification Program is a widely used standard for design professionals, consumers and others to find low emitting interior products that promote better indoor air quality. Products that achieve GREENGUARD and GREENGUARD Gold Certification have demonstrated low chemical emissions during normal use.

The GREENGUARD test method includes standardised room exposure models for both an office and classroom environment developed by the California Department of Public Health. The stringency of these models is directly related to the surface area of product that will be used in the room. For products that may be used in many applications, UL considers all potential applications and awards certification for the highest surface area loading for which the products meet the GREENGUARD and/or GREENGUARD Gold Certification criteria.

MUTOH continuously takes steps to ensure our company and our products are environmentally responsible. MUTOH has been committed to provide customers safe, environmentally- friendly and high-quality products by following industry standards in our product development process.

About MUTOH’s original eco-solvent MS41 ink

The MUTOH MS41 ink is their 4th generation of eco-solvent ink, which has featured a wide colour gamut that delivers vibrant, high density prints, with excellent dot gain. It is capable of printing on a wide range of coated and uncoated substrates and suited for long term outdoor and indoor applications with excellent weather resistance, abrasion and chemical resistance. The outdoor durability without lamination is up to 3 years. The MS41 ink has less nozzle clogging due to high ink resolvability so that it provides easy maintenance.

Area of Application – printer compatibility:

- MUTOH MS41 ink is currently applicable to the MUTOH new eco-solvent printers; XpertJet 1682SR/1641SR.

- XpertJet 1682SR – 2 print heads / 7colours (CMYK+Lc, Lm, Lk) or 4 colours (CMYK) x2

- XpertJet 1641SR – 1 print head / 4 colours (CMYK)

- It will be applicable to their ValueJet eco-solvent printers soon.

Mutoh Australia

Phone: 02-9437 1366

E-mail: sales@mutoh-au.com

Fresh from its successful introduction at PrintEx19 in August, the new Colorado 1650 roll-to-roll production printer is about to start rolling out across the country, with new stock on the water an...

October 29 2019

Fresh from its successful introduction at PrintEx19 in August, the new Colorado 1650 roll-to-roll production printer is about to start rolling out across the country, with new stock on the water and technical training underway to meet demand generated at the Sydney show.

The Colorado 1650 – the second machine to use Océ’s patented UVgel technology – was released to the world at FESPA in June, and debuted in Australia at PrintEx19 in Sydney, where Océ Australia’s Product Manager for Graphic Arts, Garry Muratore, says it was a ‘show stopper’.

“When the Colorado 1650 was launched at FESPA earlier this year, our intention was to introduce it to Australia as soon as practical. PrintEx gave us that opportunity,” Muratore explains.

“The machine we had on stand was one of the first to be released outside of Europe, and those who took the opportunity to see it in action immediately appreciated its advantages. In fact, several business owners indicated to us that they came to the show specifically to see the 1650, keen to find out if the hype was justified – and they weren’t disappointed.”

While it’s not the company’s practice to give out hard numbers on sales or leads, Muratore is happy to report that the machine generated significant interest at the show, with deals well into the double-digits expected to be contracted before Christmas, many more to follow in 2020, and installations set to commence from mid-October.

“We’ve probably had as much interest in this machine as any we’ve ever released, so we’ve been working hard to ensure we have adequate stock and to ensure we are well prepared to support the new model,” he says.

One printer. One set of inks. One roll of media. Two distinct finishes.

So, why the excitement? Muratore says it’s largely due to two new advances which further enhance the applications versatility, productivity and profitability of Océ’s UVgel technology - a newly-formulated, more flexible UVgel 460 ink range, and Océ’s innovative FLXfinish technology.

“Océ UVgel technology, as many will remember, centres around a gel-based ink that ‘pins’ instantly to media, and two-stage LED curing,” Muratore recaps. “First released in the Colorado 1640 in 2017, it offered- Print Service Providers the advantages of existing wide-format technologies like Latex and eco-solvent, without the ‘quality versus productivity’ compromises so often seen with these legacy technologies.

“The Colorado 1650 takes this further, with a new, more ‘stretchable’ ink formulation which provides perfect image stability, even when folded, bent or wrapped, and the ingenious Océ FLXfinish technology which allows printers to choose between high gloss or deep matte finishes, without changing inks or media.”

Add high speeds, to easily manage peak periods in the industrial print environment, reduced ink usage and premium print quality on even basic media, and high levels of automation which remove or minimise routine tasks like media loading and daily maintenance, and Muratore says the new printer is not only more versatile, but also demonstrably more profitable than its competitors.

Installations to Commence from Mid-October

With the first installations of the Colorado 1650 commencing this month, Océ Australia have been busy building on the already vast expertise and knowledge of its team, and its understanding of the local roll-to-roll market. This commenced with collaborative media and applications testing at a couple of launch customer sites – the Colorado 1650 has passed with ‘flying colours’, Muratore reports – and with extensive training of the Australian-based service, technical and sales support teams at our Customer Experience Centre in Melbourne.

“In addition, we have installed one of the new machines in both our Melbourne and Sydney technical centres, to facilitate on-going customer support and application demonstrations across Australia.

“Obviously technical support is crucial when rolling out a product of such importance, and we can now confidently say we are ready to go…and genuinely excited to see this revolutionary product start to roll out to the market this month,” Muratore says.

For 20 years now, Note Printing Australia (NPA), as a close partner of KBA-NotaSys, has been using one of its security presses to produce not only banknotes, but also the inner pages of passports. ...

October 22 2019

For 20 years now, Note Printing Australia (NPA), as a close partner of KBA-NotaSys, has been using one of its security presses to produce not only banknotes, but also the inner pages of passports. To date, they have been printed in a combination of conventional and waterless offset. With the desire for greater design freedom and the ability to test new ideas on short-turnaround times, the company has switched to an exclusively wet offset process with a half-format sheetfed offset press. The project was completed right on schedule and to the full satisfaction of the customer.

A Rapida 76 with four printing units, a drying tower, a perfecting unit and four further printing units went into production in Craigieburn in April. This modern, high-performance sheetfed offset press enables NPA to introduce numerous innovative technologies. Numbering, rainbow printing and many other applications which are today standard in security printing can all be realised on the B2 press, thanks to the incorporation of a whole raft of special and newly developed features. Special accessories for the handling of lightweight substrates and plastic films round off the configuration.

Technological sophistication

The Rapida 76 lays the foundations for even better exploitation of the manifold design and pre-press possibilities which today exist in document printing. NPA is now able to print photorealistic images, for example. In other words, the illustration quality is comparable to that of real photographs. To achieve this, parts of the image are printed in their full photographic resolution, while others are “softened”.

In addition, the press allows mixed UV operation, which means that certain security features can be incorporated into conventionally printed documents via a UV process. These features remain invisible under normal light. If the image is held under a UV lamp, on the other hand, the security feature is revealed – for example, native fauna might appear in the depicted landscape. Such effects represent significant improvements in the security standards for documents.

High quality and fast makeready

The Rapida 76 with perfecting unit for 4/4 production offers NPA all these possibilities. At the same time, a broad spectrum of automation functions serves quality monitoring and makeready savings. These functions include a facility to disengage unused inking units, fully automatic FAPC plate changers, CleanTronic Synchro for parallel washing of the blankets, impression cylinders and rollers in production with conventional and UV inks, non-stop pile changing at the feeder and delivery, and colour control on both sides of the sheet.

The Rapida 76 is an ideal solution for demanding projects in security printing.

Neil Taylor, NPA’s Capital Engineering Manager, puts it this way: “We’ve only had the press for a short time, but it’s clear the Rapida is providing NPA with a printing capability where there's a lot more control in colour management and visual inspection.”

NPA is thus well equipped to tackle passport projects in which it can empower customer decision-making as it enables the examination of initial print quality with trial material.

p.p1 {margin: 0.0px 0.0px 0.0px 0.0px; font: 14.0px Helvetica} Melanie Fergin is the first woman to be crowned Continental Winner for Australia an...

October 07 2019

Melanie Fergin is the first woman to be crowned Continental Winner for Australia and New Zealand

Avery Dennison has named five continental winning vehicle graphics installers in the “Wrap Like A King” 2019 Challenge. These winners, who showed their prowess with a variety of Avery Dennison® films including Supreme Wrapping™ Film, the Conform Chrome™ Series and MPI 1105™ Supercast Digital film, come from Australia and New Zealand, South Africa, North America, Europe and North Asia.

- Australia and New Zealand - 2014 Porsche 911 Turbo S TECHART GT street R by Winguard Paint Protection Specialists

- South Africa - Eric The Viking – Sharpline drift car wrap by Sharpline Signs and Graphics

- North America - Creature from the Wrap Lagoon by MetroWrapz

- Europe - BMW M135i / / / Artist by WrapStyle s.r.o.

- North Asia - Wrap Like A King 2019 – SLS AMG by Shanghai DC Town Auto Service Co., Ltd.

“Congratulations to Melanie Fergin and her team at Winguard Paint Protect Specialists for taking home the Continental crown for Australia and New Zealand!” said Jordan Leach, Senior Business Manager, Avery Dennison Graphics Solutions Australia & New Zealand. “It is an outstanding entry and we wish Melanie the very best as she heads to Las Vegas for the finals of “Wrap Like A King” Challenge!”

Since the Challenge opened on 3 June 2019, wrap installers from 55 countries across the globe had submitted their wrap projects to be judged by a panel of judges from around the world including Justin Pate, co-owner of The Wrap Institute and Peter Wright, technical marketing manager for Avery Dennison Graphics Solutions Australia & New Zealand.

The judges evaluated the submissions based on the following criteria: visual transformation based on the difference between the before and after pictures submitted (35%), quality and skill level of installation (30%), overall public look and appeal (25%), and uniqueness of the

design (10%). “I’m honoured to be recognised as the Continental Winner for Australia and New Zealand,” said Melanie Fergin, Winguard Paint Protection Specialists based in Adelaide. “This wrap installation for the Porsche GT Street R is one of the most complex yet rewarding wraps I’ve ever done. A big thank you to the incredible effort and dedication of the Winguard team who made this car look so good and achieve a paint-like finish! I also want to thank the car’s

owner, Scott Bormann, for his vision and trust in our team, and massive thanks to Avery Dennison for organising this global challenge, giving us vehicle wrappers something extra to work towards!”

Melanie’s prize consists of return airfares to Las Vegas, a four-night stay in Las Vegas during SEMA between November 4 and 8, 2019 as well as a large banner stand display, continental winner’s trophy, exposure on Avery Dennison Graphic Solutions’ Facebook, USD$500 gift vouchers and SEMA passes.

At the 2019 SEMA Show, the overall winner will be chosen by the judges as the best in show and crowned the “King of the Wrap World”. The winner’s grand prize package is worth almost USD$5,000, with additional gift vouchers and exposure via the Avery Dennison website, social media and web advertisements.

Wishing Melanie Good Luck at the grand final in Las Vegas in November!

With an already impressive range of 3D Systems’ printers in its portfolio Konica Minolta Australia, a leading supplier of 3D printing equipment and services in Australia, has announced a part...

October 07 2019

With an already impressive range of 3D Systems’ printers in its portfolio Konica Minolta Australia, a leading supplier of 3D printing equipment and services in Australia, has announced a partnership with Markforged, a leading provider of atomic diffusion metal printers and composite carbon fibre 3D printers. This rounds out an impressive portfolio that lets Konica Minolta address any industry application requirements and budget.

Markforged offers an end-to-end 3D printing system with a wide range of manufacturing-ready materials. The Markforged solutions rival traditional manufacturing processes in speed, quality, and cost, and expand the applications for additive manufacturing with purpose-built industrial technologies.

In today’s global market, Australian manufacturers and designers are rapidly becoming leaders with the next generation of additive technologies. They’re bringing composite and metal materials to market that are easy to implement and operate and are backed up by uncompromising service and support.

Eric Holtsmark, general manager – strategy, transformation and technology, Konica Minolta Australia, said, “There is now a real shift in the industry from prototyping to end-use applications. With Markforged 3D printers the ability to produce affordable, strong parts in a range of exciting new materials will accelerate manufacturers speed-to-market in way never seen before, giving them a massive competitive advantage.”

Adding Markforged to Konica Minolta’s 3D line-up extends its industry-leading capability in delivering high-performance, advanced 3D printing solutions to Australian innovators in many industries including: manufacturing, aerospace, engineering, automotive, medical, and universities. These industries will have unprecedented access to both groundbreaking technology and essential fundamental infrastructure.

Ved Narayan, Vice President, APAC, Markforged, said, “We’re thrilled to be partnering with Konica Minolta to provide Australian manufacturers with the essential tools to unlock their manufacturing potential and to help build the factory of the future. Konica Minolta has the experience and skills to help Markforged provide unprecedented levels of access and support to the world’s leading manufacturing providers.”

Neopost, a global supplier of digital, mailing, graphics and shipping solutions and an Australian distributor of HP and Epson wide format presses, has changed its corporate name to Quadient. ...

October 01 2019

Neopost, a global supplier of digital, mailing, graphics and shipping solutions and an Australian distributor of HP and Epson wide format presses, has changed its corporate name to Quadient.

The new branding strategy is designed to integrate the organisation with an aligned corporate brand platform so clients can better leverage the full range of solutions on offer and simplify and solidify customer interactions, a company statement about the name change says.

Quadient Australia managing director Stuart Macdonald released the statement to local customers in Australia, advising that an account manager will “be in touch soon” regarding the name change.

“As customer expectations continue to evolve to meet and match their always-on existence, building a strong connection with customers requires a focus beyond physical channels. The connected customer expects immediacy and simplicity. They want experiences that are personalised, readily-available, consistent, meaningful, convenient, and secure — regardless of the channel,” the statement from Macdonald said.

“Over the past 18 months, we have worked to unite our industry leading solutions – Quadient Customer Experience Management, Neopost Mail-Related Solutions, Business Process Automation, Parcel Locker Solutions and Graphics Solutions – under a unified brand. We are focused on delivering solutions that create relevant and personalised interactions. On Monday, September 23, 2019, we announced our new brand to the market.

“Your account manager will be in contact with you soon regarding this exciting change and to answer any questions you may have. ”

Quadient CEO Geoffrey Godot said the change represents the realisation of the new organisation announced in January 2019.

“In January 2019, we unveiled our new strategy aimed at growing our company and moving away from being a holding company to a focused, integrated organisation,” Godet said in a statement.

“It was critical to align our corporate brand platform with this new strategy, using a purpose-driven brand to help businesses leverage our entire portfolio of solutions to simplify and solidify interactions with their customers. This change comes at a defining moment in our company’s history and is instrumental in unifying our global organisation around a common aspirational brand.”

Together with Canon Inc., Océ has announced that it is changing the trading name of its Océ businesses globally to Canon Production Printing, effective January 1, 2020. F...

October 01 2019

Together with Canon Inc., Océ has announced that it is changing the trading name of its Océ businesses globally to Canon Production Printing, effective January 1, 2020.

From next year, Océ – the production printing operation of the well-regarded Canon Group – will also integrate its products under the Canon brand name. For both organisations, the change creates brand unity across all areas of our printing business. By combining Océ’s legacy of excellence in unique printing technologies for over 140 years, with the power of the innovative Canon brand, it establishes a clear end-to-end, go-to-market approach.

Océ and Canon will continue servicing their respective ends of the printing market, and the transition ensures a congruous, ‘end-to-end’ capability across the companies’ entire print portfolio. This enables both brands to continue servicing a broad range of clients’ evolving needs, with industry-leading printing hardware and software that is customised for a range of industries.

Leading the companies in the region are Dave Yoshida, Managing Director of Canon Oceania and Craig Nethercott, Managing Director of Océ Oceania (soon to be Canon Production Printing Australia).

Commenting on the name change, Craig Nethercott shares: “Océ Australia has always been a proud part of the Canon family, so it’s great to see that the Océ brand has been brought in line with the global Canon Group. This is testament to our demonstrated success in the production printing space in a dynamic environment.

Nethercott acknowledges that the change may surprise some here in Australia, as it comes after a 22-month period of strong focus and the creation of a unique market approach, under the Océ Australia brand. Over this time, Océ has established a strong consultative relationship with its customers across Australia and New Zealand, based around accessibility, understanding and meeting each business’ unique requirements with effective technologies. In light of this, he emphasises that the change is in name only.

“Apart from the name change, it’s really business as usual. We’ve built a solid workforce, culture and operations, so none of this changes. The continuing development of the innovative technologies Océ is renowned for, coupled with the strength and market leadership of the Canon brand, puts us in an even stronger position to deliver some of the best customer solutions on the market,” confirms Nethercott.

Commenting on the collaboration with Océ, Dave Yoshida shares: “This advancement signals a strong message globally about Canon’s long-term commitment to the production printing market. Our customers have always been at the heart of everything we do, so we welcome the opportunity to work closely with Craig and his teams to deliver impactful solutions that accelerate the growth of our customers and Canon in the region.”

Konica Minolta has announced the 450th global installation of its AccurioLabel presses at Labelexpo Europe. Providing excellent local service and support, along with delivery of parts ...

September 30 2019

Konica Minolta has announced the 450th global installation of its AccurioLabel presses at Labelexpo Europe.

Providing excellent local service and support, along with delivery of parts and consumables, Konica Minolta’s digital toner-based technology has reached another label printing milestone after beginning successful trials less than four years ago.

The 450th installation milestone has been marked by live demonstrations of the AccurioLabel 230, the newest model in the toner label press family from Konica Minolta, which is a central feature on its stand.. Important enhancements include a 73% speed increase, improved productivity, an option for overprinting, no warm-up required between jobs, less waste and more accurate print registration.

Konica Minolta is showing one of its AccurioLabel 230s with a flexo station for printing white inline for the first time, as well. Offered by Grafisk Maskinfabrik (GM), its development and manufacturing partner in Europe, this option will be available in the near future. Existing users can also have their systems retrofitted to enable inline white printing.

Konica Minolta is also highlighting software enhancements using augmented reality (AR), as well as displays of embellishment and finishing workflow with MGI technology on the joint stand. A special focus is on the MGI JETVarnish 3D WEB Color+ embellishment for label and flexible packaging.

Konica Minolta visitors have the chance to win personal fitness trackers by guessing how many meters will be printed on the two Konica Minolta AccurioLabel presses at Labelexpo over the four days of the show.

Konica Minolta’s overall theme for Labelexpo Europe 2019 is “Around the world, around the clock.” This underlines how Konica Minolta AccurioLabel presses help print providers around the world to move their business forward.

Edoardo Cotichini, team manager, Industrial Printing, Konica Minolta Business Solutions Europe, says, “Labelexpo is a perfect opportunity for us to involve customers in industry-first insights and synergies to inkjet printing and AR solutions, as well as demonstrating practical ways of growing business opportunities.

“In a true collaborative approach as a relationship-oriented company, we actively source expertise from customers and partners for inkjet and toner-based printing solutions. This enables us to develop with our customers, using their inputs for future developments of our world-class technology, not just pushing out what we think is best for the markets. One example is how we work with IIJ (Industrial Inkjet Ltd), which has developed its print engine concept further to include a range of standard press-adaptors for common flexo label presses,” he adds.

Sabre Graphics is a privately owned and operated Australian company, directed by Ryan Collins, that supplies and installs signage and graphics for marketing companies, architectural fit-outs, retai...

September 30 2019

Sabre Graphics is a privately owned and operated Australian company, directed by Ryan Collins, that supplies and installs signage and graphics for marketing companies, architectural fit-outs, retailers, builders and many other types of event activations. Recently, after securing contracts with multiple, high-end, international retail brands, Sabre purchased two Epson SureColor S80600 high-quality signage printers.

Sabre Graphics GM Peter Briard explained, “After Sabre secured the contracts the main requirement our new clients had was that their brands’ colour profiling and colour management on all printable roll-to-roll media was not to be compromised in any way. It had to be of the very highest quality. Thus, it became an easy choice for Sabre to purchase the Epson SC-S80600 printers as they were the best fit for our customers’ needs, offering a superior print and more consistent quality than competitive printers. They are also very easy to operate and maintain.”

In the signage and printing world, cost efficiency and workflow reliability has never been more important as Briard added, “The SC-S80600 printers offered low ink costs, allowing us to provide competitive pricing to our clients. They also have special functions like remote status and error reports and attachments like auto take-up and drying units. These attachments were a mandatory purchase as they increase the machines run speeds, whilst still maintaining the superior print quality - saving everyone involved time and money.”

Epson SureColor S80600 printers being used at Sabre Graphics

The benefits of the SureColor S80600 printers’ unique additional features didn’t stop there for Sabre Graphics.

Briard continued, “These additional features are a huge benefit to Sabre Graphics as they enable us to work remotely, whilst issuing reports advising the printers’ status. This, in turn, further enables us to print around the clock and guarantees our installers will receive the prints and install them on time for our clients’ launch dates.”

The prints generated from Sabre’s new Epson SureColor S80600 printers provide indoor and outdoor graphics and signage for windows, awnings, the tops and sides of buildings, lightboxes and many other works in a variety of environments, such as commercial office and retail fit-outs.

The versatility and functionality of their new printers is not lost on Peter Briard as he concluded, “The SureColor S80600 printers ensure Sabre can provide our clients with a fast turnaround and the peace of mind that the print quality is superior to all others. This makes them easy for our installation team to work with. Sabre will continue to purchase Epson products and, in particular, the SureColor S80600, moving forward because these excellent printers are durable, efficient and easy to operate. Absolutely critical are the SureColor S80600’s low ink costs and the one-year warranty, with the option to extend to five years, which simply can’t be beaten.”

www.epson.com.au

Sydney based John Fisher printing have recently installed the latest Anapurna H1650 LED Hybrid printer. This long established Business provides quality printed products with high...

September 24 2019

Sydney based John Fisher printing have recently installed the latest Anapurna H1650 LED Hybrid printer.

This long established Business provides quality printed products with high levels of service & flexibility, to support & achieve creative solutions for their clients. John Fisher Printing specialisation is within the POS, Packaging and short term signage sectors.

Managing Director Tony Fisher said – “At John Fisher Printing we provide unique solutions, for visual graphic displays & merchandising, in addition to general commercial printing, assisting small & large businesses, offering exciting solutions to increase ‘Brand Awareness’! With over 60 years of experience in the retail sector we have the capabilities and knowledge to meet the most demanding of applications and time restraints.

When we first started to investigate a new solution our main driver was machine availability, as we needed to fulfil a large order. However, quality, service & backup also was a major influence, indeed so too the cost of spare parts, added to the criteria. After a few weeks of investigation and bearing in mind the need to print in excess of 3000m2 in a short period of time, we decided to move forward with the latest offering from Agfa.

John Fisher Printing have purchased multiple platforms, but this was our first acquisition from Agfa. From the outset, Agfa’s support from on-the job training, through to return training have been important factors. Responsiveness to queries & assistance for relatively new or inexperienced operators have also been helpful. I was also impressed with the Anapurna’s ability to print saleable images in ‘Express mode’ which enabled us to meet our Clients demanding timescales”.

The latest edition to the Agfa family of printers, the Anapurna H1650i LED device is a 6 Colour Hybrid Printing Platform. Speeds up to 63m2 per hour and able to deliver Photorealistic images. Being able to switch swiftly from board to roll and by utilising the latest LED curing technology enables the operator to print Corflute, Composite Panel, Acrylics, Foam PVC, Banner, Paper, SAV and heat sensitive stock.

Tony continues – “Overall, we are equipped to run retail campaigns matching both traditional offset & wide format digital inkjet printed projects. Our technology allow us to offer custom design solutions for short run packaging & point of sale with all in-house facilities. We also provide additional fulfilment facilities, consolidation of promotional materials, packaged for retail distribution in standard or specialty made shippers”.

Michael Culver, Inkjet Manager Oceania said – “When you are not the incumbent supplier it is always going to be a challenge. Tony and his Team are well rehearsed and understand the market they play in. Agfa look forward to growing this new partnership and will endeavour to expand our product assortment at John Fisher Printing”.

Please feel free to visit John Fisher Printing operations

http://www.youtube.com/watch?v=NJC3OvioV1c

Less than twelve months ago Queensland based Spot Productions invested in an Anapurna H2500i and Agfa Acorta cutting table. Due to their ever increasing work load, the need for another platform was...

September 24 2019

Less than twelve months ago Queensland based Spot Productions invested in an Anapurna H2500i and Agfa Acorta cutting table. Due to their ever increasing work load, the need for another platform was evident and so the latest Agfa H1650 was purchased.

Simon Carmody Managing Director of Spot Productions said – “I have seen our new Wide Format Division grow at an amazing rate due to the continued support of our loyal Client base, so it was decided that more capacity was needed. Once this decision had been made we started our investigations to find a new platform that would compliment our existing range, but more importantly assist with our growth.

After a number of weeks researching possible solutions, Spots Management Team and I decided to move forward with Agfa again. The Quality from our first Anapurna LED platform was of such a high standard, we needed something that could match the output, so we decided to purchase the latest H1650 Six Colour LED Hybrid printer”.

The latest edition to the Agfa family of printers, the Anapurna H1650i LED device is a 6 Colour Hybrid Printing Platform. Speeds up to 63m2 per hour and able to deliver photorealistic images. Being able to switch swiftly from board to roll and by utilising the latest LED curing technology enables the operator to print Coreflute, Composite Panel, Acrylics, Foam PVC, Banner, Paper, SAV and heat sensitive stock.

Simon continues – “Also in our thought process was the need to keep a high level of support which Agfa have in abundance. Having experienced Sales and Engineering staff on call to react to our needs makes a massive difference, especially as a number of potential Suppliers continue to shed heads.

Wide Format started out as a hobby shop for us to add value to our existing Client base. Now it is a very important productive part of our Business as it adds tremendous value, especially on cross media campaigns, utilising Offset, Cut Sheet Digital and Sign and Display items”.

Michael Culver, Inkjet Manager Oceania said – “It is a pleasure working with Simon and his Team. Being asked to supply another machine was a great success story for all involved. When you gain multiple orders you must be doing something right. Spot are a loyal and dynamic Customer and we are excited about their continued expansion”.

A team of 15 talented young Australian ‘Skillaroos’ has placed 8th in the world after competing in their chosen skills with teams from 65 other countries at the recent 45th WorldSkills ...

September 11 2019

A team of 15 talented young Australian ‘Skillaroos’ has placed 8th in the world after competing in their chosen skills with teams from 65 other countries at the recent 45th WorldSkills International Championships in Kazan, Russia.

Four of this year’s Skillaroos - Patrick Brennan, Maxine Colligan, Clinton Larkings and Patrick Keating - medalled in their categories with others including Indy Griffiths – supported by her employer, Mona Vale print and sign business Style Communications and sponsored by Visual Connections – achieving a Medallion of Excellence.

Indy, who competed in the Graphic Design Technology Category, is the first graphic designer to be sponsored by Visual Connections, with CEO Peter Harper explaining that the organisation usually sponsors print, sign and display apprentices.

“We are strong supporters of vocational education and training, and are committed to helping young people gain the skills, knowledge and experience they need to build successful careers in our sector,” says Peter Harper, CEO of Visual Connections.

“We often sponsor young print or sign apprentices to participate in WorldSkills Championships but there’s nothing more fundamental to our industry than design. Indy is already proving an asset to our industry and we’ve been delighted to sponsor her. We’re so proud of her achievements, and those of her fellow Skillaroos.”

After a farewell from friends, family and supporters, the team participated in a resilience-building workshop before their departure, which saw them travel to Kazan via Moscow, where a short stopover saw the team meet Australian Ambassador to Russia, Graeme Meehan.

An inspiring opening ceremony in Kazan the night before competition commenced at the Kazan Expo International Exhibition Centre set the stage for the intense, three-day competition, where our Skillaroos rose to the occasion and displayed great acts of comradery and sportsmanship.

A monumental effort was presented by the entire team, which included a large volunteer workforce from across Australia, culminating in the outstanding achievement of an overall 8th placing.

Brigitte Collins WorldSkills Australia General Manager shared from Kazan, “We are all very impressed with the performance of the team, they showcased the power of excellence and demonstrated the strength of vocational education and training in Australia.

“Our internationally recognised experts and volunteers demonstrated once again, their capability and dedication. The Skillaroos, Team Australia and the volunteer workforce should all feel very proud of what they accomplished here in Kazan, Russia.”

Visual Connections adds their congratulations, not only to Indy but to the entire team, for their dedication to their chosen craft, their commitment to the achievement of excellence, and for their outstanding representation of Australia on the international stage.

Follow WorldSkills Australia @WorldSkillsAU. Images Supplied by: TAFE NSW & WorldSkills International

DIC Corporation has entered into a definitive agreement to acquire BASF’s global pigments business, known as BASF Colours & Effects (BCE). The acquisition will broaden DIC&rs...

September 03 2019

DIC Corporation has entered into a definitive agreement to acquire BASF’s global pigments business, known as BASF Colours & Effects (BCE).

The acquisition will broaden DIC’s portfolio as a global manufacturer of pigments, including those for electronic displays, cosmetics, coatings, plastics, inks and specialty applications.

‘Our acquisition of BCE brings together complementary resources and expertise of two recognised leaders in innovation, product stewardship, regulatory leadership, application support and manufacturing,’ said Kaoru Ino, president and chief executive officer of DIC. ‘We have outlined a clear growth path for DIC with the target to increase our sales to 1 trillion yen (approximately 8 billion euros) by 2025. In this context, BASF’s pigments portfolio is an important strategic addition in meeting our goals more expeditiously. It will allow us to expand our offering as one of the leading pigment suppliers globally and provide our customers even more versatile solutions.’

‘We have achieved our goal to find an owner who considers pigments a core strategic business,’ said Dr Markus Kamieth, member of the board of executive directors of BASF SE responsible for the Industrial Solutions segment. ‘DIC pursues ambitious growth plans and has announced to further develop the business in the coming years. We are convinced that the pigments business will be able to unfold its full potential within DIC.’

With over 30 pigment production facilities worldwide between DIC and BCE, the company’s pigment portfolio will be able to offer broader product categories related to effect pigments, inorganic pigments, organic pigments, specialty dyes, and pigment preparations.

Yoshinari Akiyama, DIC executive officer and general manager of the Colour Material Products Division, said:‘The acquisition of BCE is extremely ideal within the DIC pigments business, due to the complementary regional footprint and product portfolio. It is a strategic partner for DIC who aims for high growth and high added value by expanding functional pigments into niche applications. By combining the technological capabilities of both companies, we will continue to create new value and provide it to the market as a leading company in the pigment business.’

For Dr Alexander Haunschild, senior vice president and managing director at BASF’s pigment-focused subsidiary BASF Colours & Effects, the agreement is a chance to continue the growth path started in 2016: ‘We see DIC as an owner who is willing to invest, committed to innovations and interested in the longer term success of the business.’

‘As a long-standing business partner of BASF, we value the expertise and engagement of BASF’s employees in the pigments business,’ said Myron Petruch, DIC executive officer and president and CEO of Sun Chemical, a subsidiary of DIC Corporation. ‘The move improves our pigment footprint in Europe and underscores our commitment to delivering solutions tailored to meet the needs of our customers. It also allows us to compete in the global marketplace more effectively going forward.’

In the immediate future, business for customers will remain the same as usual. A transition team will be put in place to ensure a smooth transition for customers and employees by the expected closing date in the fourth quarter of 2020.

The acquisition is subject to the receipt of regulatory approvals.

Huntsman Corporation said it entered into a definitive agreement to sell its chemical intermediates businesses, which includes PO/MTBE, and its surfactants businesses to Indorama Ventures in a tran...

September 03 2019

Huntsman Corporation said it entered into a definitive agreement to sell its chemical intermediates businesses, which includes PO/MTBE, and its surfactants businesses to Indorama Ventures in a transaction valued at $2.076 billion, comprising a cash purchase price of $2 billion, plus the transfer of up to approximately $76 million in net underfunded pension and other post-employment benefit liabilities.

The $2.076 billion transaction value represents an LTM adjusted EBITDA multiple of approximately 8 times, which includes retained SG&A costs of about $30 million, a portion of which Huntsman expects to eliminate overtime. Under the terms of the agreement, Indorama Ventures would acquire Huntsman’s manufacturing facilities located in Port Neches, Texas; Dayton, Texas; Chocolate Bayou, Texas; Ankleshwar, India; and Botany, Australia. The transaction is subject to regulatory approvals and other customary closing conditions and is expected to close near year-end.

“This transaction further transforms Huntsman’s balance sheet and future. It accelerates our ability to expand more in areas both downstream and complementary to our portfolio," said Peter Huntsman, Chairman, president and CEO. "This is another milestone in our stated strategy to focus more on our downstream and specialty businesses where we will generate more stable margins and consistent, strong free cash flow. We are committed to retaining our strong investment-grade balance sheet, repurchasing our shares, investing in organic research and select capacity expansions and acquiring strategic assets that are accretive to our earnings and create shareholder value.

“Indorama Ventures will be acquiring a strong EO/PO derivatives business with a very experienced workforce and management team."

“Huntsman intends to accelerate share repurchases under its existing $1 billion multi-year authorisation after the close of this transaction.”

According to a new report published by Allied Market Research, "UV-Curable Resin Market by Type and Application: Global Opportunity Analysis and Industry Forecast, 2019-2026," the global UV curable...

September 03 2019

According to a new report published by Allied Market Research, "UV-Curable Resin Market by Type and Application: Global Opportunity Analysis and Industry Forecast, 2019-2026," the global UV curable resin market was valued at $4,745.6 million in 2018 and is estimated to reach $9,769.7 million by 2026, growing at a CAGR of 9.4% from 2019 to 2026.

The use of UV curable resins has grown significantly, as they have several advantages over conventionally cured resins in terms of less energy consumption, reduced waste, zero-emission of volatile organic compound (VOCs), and higher productivity (fast curing).

UV curable resins do not contain any organic solvents, which could have adverse environmental effects. However, the light penetration depth, which depends on the wavelength and spectral distribution, does not exceed a few millimetres. Thus, the application of UV-curable resins is restricted to inks, coatings, and adhesives.

The UV curable resin market is segmented based on resin type, application, and region. Based on resin type, the global UV curable resin market is fragmented into acrylated epoxies acrylated polyesters, acrylated urethanes, acrylated silicones, and others. The acrylated epoxies UV-curable resin segment is expected to dominate the market, owing to its fast cure rates and good adhesion performance because of the presence of polar hydroxyl and ether groups in the epoxy backbone structure. However, the acrylated urethane UV curable resin segment is expected to grow at the highest CAGR during the forecast period.

Based on application, the market is categorised into coating, packaging, printing, adhesives & sealants, and others. The coating application is expected to dominate the market and printing application is expected to grow with the highest CAGR in the market.

Region-wise, the market is analysed across North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific dominates the market owing to the growth in paints and coating industry which is the primary consumer of UV curable resins. Asia-Pacific is further expected to maintain its dominant position in the near future.

"UV-LED curing technology has undergone significant advancements in the past few years. This technology serves as an environmentally friendly solution, as UV-curable resins ensure zero VOC emission, thereby significantly fuelling their demand across the globe," said Eswara Prasad, manager, Material and Chemical at Allied Market Research.

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, today announced the VersaUV LEF2-300 benchtop UV flatbed printer will be rolled out worldwide. The ...

September 02 2019

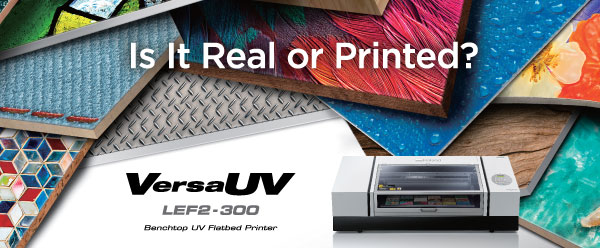

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, today announced the VersaUV LEF2-300 benchtop UV flatbed printer will be rolled out worldwide. The LEF2-300 is the newest model in the LEF2 series, delivering 1.5-times the print area and print speed of the recently released LEF2-200. It also comes with a range of new functions that make it even easier and more efficient to use.

The LEF2-300 uses UV-LED lamps to instantly cure ink on the surface of materials with UV light, so that photos, graphics and fine text can be printed onto PVC, plastics, canvas, wood, leather, fabric, and other materials with unmatched print quality. Using Clear (transparent) ink produces premium gloss and matte finishes that can be applied in multiple layers for a simulated embossing look and textures that seem amazingly lifelike. UV ink is designed for flexibility and can be used on soft materials such as leather and fabric. The 770 (W) x 330 (D) x100 (H) mm print area of the LEF2-300, combined with its four print heads and two UV lamps, ensures enhanced productivity.

According to Kohei Tanabe, President of Roland DG's Digital Printing Business Division, new features make printing easier and quicker. “A Multiple Print Function prints the same data again by simply pressing a button on the control panel and a Printer Status Monitor checks the operating status of multiple printers in real-time to promote efficient performance when printing large volumes.”

“As lifestyles and preferences become increasingly varied, the demand for making one-of-a-kind items or high-mix, small-batch runs, continues to grow,” Kohei said. “The LEF2 series is designed to meet such demand. The devices are capable of on-demand printing quickly onto a diverse range of materials. The addition of the LEF2-300 to the series lineup gives even more customers the ability to print amazing graphics and lifelike textures. We aim to develop more products that encourage customer creativity in order to boost business growth.”

The LEF2-300 comes with a range of new functions that make it even easier and more efficient to use:

- Print stunning, premium-quality photos, graphics and fine text onto PVC, plastics, canvas, wood, leather, fabric, and other materials with unmatched print quality.

- In addition to CMYK, clear ink produces premium gloss and matte finishes for unique textured effects, and white ink is available to ensure colours pop on dark or clear substrates.

- Optional on-board primer increases efficiency by prepping the surface of materials like acrylic and plastic for full-colour customisation.

- A 770 (W) x 330 (D) x100 (H) mm print area, combined with four print heads and two UV lamps, ensures enhanced productivity.

- A height tolerance of 2mm allows printing onto curved and irregular shapes, and an optional rotary axis jig is available for printing onto bottles and other cylindrical objects.

- An automatic media height system for detecting the thickness of the substrate.

- A Head Refresh Feature removes any ink remaining on the print heads and cleans the print head surface to maintain the health of the printer.

- Should a print head clog, a new Nozzle Mask function allows printing to continue while using the remaining part of the print head.

- A Multiple Print function allows users to perform the next print just by pressing the start button on the machine, without returning to the software.

- A Start Timer function lets users set a time to automatically complete the set-up procedures so the machine is ready to load materials and print straight away.

- “Roland DG Printer Status Monitor" allows users to instantly check the operation status of multiple printers, including printing, waiting, and emergency stop errors on a monitor.

- A built-in vacuum table efficiently and accurately secures thin materials and delicate media.

- Bundled Roland VersaWorks 6 RIP software includes Special Colour Layer Generation for quick and easy printing operation.

To find out more, go to: www.rolanddg.com.au/lef2series

Durst, manufacturer of advanced digital production technologies, has announced the opening of Durst Oceania after the successful launch of its P5 technology and innovation platform for large-format...

August 30 2019

Durst, manufacturer of advanced digital production technologies, has announced the opening of Durst Oceania after the successful launch of its P5 technology and innovation platform for large-format specialists at Printex in Sydney. This new branch marks another watershed moment in the proud history of family-owned Durst, which opened its new global headquarters in Brixen, Italy, earlier this year, as it continues to cement its transformation into a highly integrated process service provider.

Durst Oceania covers Australia, New Zealand, Tazmania and other outreach markets in the Pacific Ocean. Its headquarters will be close to Melbourne’s international airport and central business district in Tullamarine. The official launch follows the successful conclusion of negotiations to acquire the business interests of Durst distributor Photo Electronic Services – known as PES – based in the north-east of the Australian city.

Durst Oceania Managing Director is long-serving employee Matt Ashman who hails from the UK but has taken up Australian residency. He has been associated with Durst for more than 25 years, first as a customer and then within Durst UK and Ireland’s sales and marketing operation until relocating from England in 2015.

“I am delighted to be at the helm of a new era of what I am sure will be sustained growth for Durst in the region,” he said. “The market potential is huge. Durst Oceania is a strong economic region with a young entrepreneurial vibe. Its diverse population represents many different cultures from around the world. Customers in the region have really embraced our innovative technology – particularly the new P5 platform shown at Printex for the first time in August – and software solutions such as Durst Workflow, Dust Analytics and Durst Smart Shop.”

Durst Group CEO and joint owner Christoph Gamper, who has led the company’s transition and introduced a new management structure, said: “We are extremely grateful to the work dedication of PES, and would like to put on record our sincere thanks for their support and cooperation as a long-standing Durst distributor. But now we move forward and welcome Durst Oceania to our growing family. Matt and his team epitomise our new business philosophy: a passion for technologies and markets, with innovation as the driver, and provides active collaboration and participation in every area. Durst Oceania is an important strategic step as we continue to shape the future and grow our business. Driven by the mantra of innovation, Durst offers complete solutions from pixel to output.”

Durst is a global leader in high-performance printing systems – from image data processing and printing to final product finishing – all from a single source. It employs more than 700 people across the world. At FESPA this year it launched new P5 printing systems with integrated modular software solutions, analytics software and optional expansion with prepress and webshop solutions under the motto "Pixel to Output". The P5 platform setting new standards in print quality comprises the P5 250 HS launched in 2018, new family members the 350/210 hybrid solutions equipped with LED technology, and the P5 250HS and P5 200 HS featuring MEMS printhead technology.

If life teaches you anything, it’s that no matter what plans you make, fate sometimes has other things in store. For James Sultana, owner of NSW-based sign and display company Grand Print Ser...

August 27 2019

If life teaches you anything, it’s that no matter what plans you make, fate sometimes has other things in store. For James Sultana, owner of NSW-based sign and display company Grand Print Services, plans for a relaxing life on the coast morphed into a busy new business that now supplies customers around Australia.

There were no grand career aspirations behind James Sultana’s decision to move to the NSW South Coast from Sydney. Rather, he and his wife saw it as an opportunity to spend extra time with their young family in a more relaxed environment.

But the best laid plans are apt to go astray, as they say – and four years later, James is instead working hard to take his business, Grand Print, to the next stage, with a new factory in Gerringong and a double investment in equipment from Océ Australia.

The move – which will see the company install a top-of-the-range Arizona 1380XT flatbed printer and a ProCut 3200L digital cutting system – is a significant leap for Grand Print, which started with a chance encounter soon after the family’s move.

“I was looking for work and a connection here offered me some signage installation management work” James explains. “With my background in the sign and display industry, project managing installations and expos, it seemed like good work to pick up while I looked for something more permanent.”

Pretty soon, that ‘stop gap’ became almost a full-time occupation, and his clients started to ask for a full ‘turn key solution’

“I had no plans to get back into production, and starting a business was the furthest thing from my mind…but eventually I found a niche in the market to provide a very high level of service for the entire production process, as opposed to just supplying print or just managing the install,” he explains.

For a while, outsourcing the print sufficed, but by late last year, it became apparent that the convenience and control of his own manufacturing facilities would make life easier.

An initial investment in a roll-to-roll machine helped somewhat, but there was still an enormous amount of work that had to be sent out – or, alternatively, assembled manually in-house, like corflute signage, which involved a time-consuming process of printing decals, then mounting on the rollover table and manually trimming.

After doing some research – prioritising flexibility and reliability – he found the solution in the printer and cutter duo from Océ Australia.

“We had talked to our Océ BDM, Chris Bowden, about their solutions, and we ended up taking a trip to Melbourne to the company’s new Customer Experience Centre, where we were able to see both machines in action,” James explains.

“Chris worked with us to really understand our business requirements and recommend a solution which would answer those needs – and the new workflow from Océ makes the whole solution seamless.”

As a key innovation centre for Canon, a global leader in consumer and professional imaging, Océ invests heavily in R&D. The new Arizona 1300 range draws on more than a decade of flatbed development to provide the sign and display market with a printer which is not only more versatile than competitors, but also more productive.

As well as handling an impressively wide range of media, the high-quality printer’s application versatility is enhanced with innovations like Touchstone software which enables ‘2.5D’ print for raised and textured surfaces, and LED curing – which not only speeds make ready, but also enables the use of Greenguard-certified LED-UV ink – while Arizona Xpert job preparation software turbo-charges productivity.

“The flatbed capacity will be a game-changer for us, hugely expanding the range of work we can handle and increasing options for our clients, and I’m really excited about the range of products and print finishes it will allow us to produce,” James says.

The ProCut 3200L – from the Océ range of digital cutters, can cut, mill, polish and engrave on media up to 60mm in depth. The ProCut pairs with the Arizona for seamless large format workflow – from prepress to finishing. Providing automation and ease of use, making it the perfect finishing companion for this flexible printer.

“The ProCut will be an amazing addition, increasing our accuracy and capacity to trim and finish both rigid and flexible products in-house and improving our productivity and profitability,” he adds. “And it’s so easy – we can just print directly onto whatever substrate we’re using, scan the barcode into the digital cutter, and we’re done!”

As well as giving James control over production by bringing a high percentage of jobs in-house, the dual investment also provides capacity for future growth and, together with the planned addition of some new staff resources, sets the stage to give him some much-needed time to reflect on his future business strategy and planning.

“I was talking to someone the other day about how busy I was at work, and they asked me if I really wanted to be spending long hours at the factory every day for the rest of my life. And of course, I don’t – having more time with my family was the reason we moved here in the first place,” he says.

“This new technology from Océ, backed by their technical expertise and local service support, will put me back in control of my future – and that’s a great feeling.”

Imagination Graphics, a professional printing company based in Marrickville in Sydney’s inner west and Konica Minolta National Specialised Print Awards 2018 winner, is the first NSW customer ...

August 27 2019

Imagination Graphics, a professional printing company based in Marrickville in Sydney’s inner west and Konica Minolta National Specialised Print Awards 2018 winner, is the first NSW customer to invest in the AccurioJet KM-1 from Konica Minolta.

Imagination Graphics provides graphic design, print, and pre-press services to help customers maximise the value of their promotional material. Imagination Graphics focuses on delivering high quality outcomes for a reasonable price. The company was on a solid growth path and had gone from strength-to-strength over the past three years. This made it the right time to invest in new technology to support that growth, and future growth.

The AccurioJet KM-1 is a B2+ sheet-fed UV inkjet press that delivers all the quality and versatility of offset printing with the convenience and flexibility of digital printing on any type of stock for projects such as bound books, presentation folders, and packaging.

Emmanuel Buhagiar, director, Imagination Graphics, said, “This investment was a big step for Imagination Graphics, however, it was the right one. We did our due diligence and had faith that the KM-1 and Konica Minolta, as a trusted partner for more than 10 years, would deliver.

“Imagination Graphics chose the KM-1 due to its ability to print on a wide variety of stocks, which gives us great versatility in the types of work we can take on, as well as the colour and quality reproduction and ability to match Pantone colours.

“The KM-1 will open up a whole new market and client base for Imagination Graphics. It will also give us more speed, faster turnaround, the ability to bring work in-house that we have previously had to outsource, and the opportunity to take on short-run projects, which will make us more competitive. For example, using the KM-1, we can print up to 3,000 A2 posters in an hour, all with different designs, which would be far more costly and time-consuming on an offset press. As a customer-focused business, the ability to deliver on time with quality is critical to our success.”

Adam Todd, industrial print solutions consultant, Konica Minolta, said, “Konica Minolta is excited that Imagination Graphics is the first NSW installation of the game-changing KM-1, and the third in Australia. The KM-1 will open up new markets for Imagination Graphics and let it produce a much wider variety of high-value applications for its customers. We are proud that Imagination Graphics has selected Konica Minolta as its strategic partner for this venture.”

Emmanuel Buhagiar said, “Imagination Graphics has worked with Konica Minolta for more than 10 years, and every time we have upgraded our equipment we have seen business growth right up to our last investment, which was the AccurioPress C6100 and C1085. We expect the KM-1 to bring the same benefit.”

This is the first NSW install for the KM-1, the third in Australia, and the 100th globally since its introduction to the market just over two years ago.