Reflecting its continued commitment to provide customers with added-value offerings that improve the way they work, SAi has announced the launch of Sign Design Elements, a comprehensive stock libra...

February 21 2019

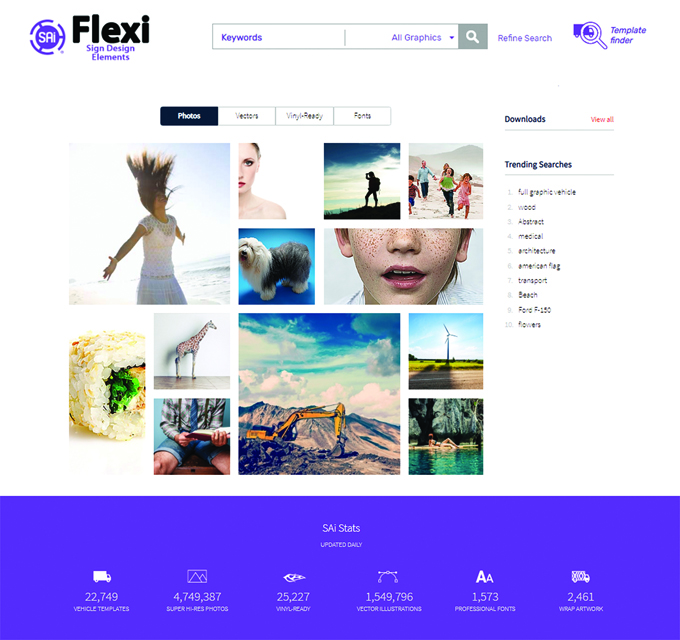

Reflecting its continued commitment to provide customers with added-value offerings that improve the way they work, SAi has announced the launch of Sign Design Elements, a comprehensive stock library of over six-and-a-half million downloadable assets for the sign industry.

Available to customers accessing SAi software on subscription, Sign Design Elements comprises an ever-expanding collection of high-resolution images, logos, fonts, cut-ready vector illustrations, vehicle outlines and wraps, and metallic-ready files. With nearly 23,000 templates alone for global car and truck makes and models, the new portal is expected to prove particularly beneficial to those for whom vehicle wraps is a key application area.

SAi Flexi software subscribers benefit from five free-of-charge downloads each month, with the opportunity to obtain a hundred more images or templates for just $15 (€15 / £10) per month via simple subscription add-on. The service is available to those on both annual and monthly plans and is easily accessible from the user’s SAi Cloud window.

“Sign Design Elements responds to the specific needs of sign businesses that increasingly require high-quality images and graphic elements,” says Annette Plummer, Vice President, SAi. “This offering makes it easy for such users to quickly locate and download exactly what they need from one location directly from their SAi software, saving precious time and maintaining throughput.”

To register for Sign Design Elements, SAi subscription customers can visit here.

Kernow Coatings, the global leader in the development of digitally printable synthetic substrates, announced today the launch of KernowPrint Lucid clear polyester synthetic sheets – a new mat...

February 18 2019

Kernow Coatings, the global leader in the development of digitally printable synthetic substrates, announced today the launch of KernowPrint Lucid clear polyester synthetic sheets – a new material built using the company's proprietary Cobalt Coating Technology for HP Indigo.

KernowPrint Lucid for HP Indigo expands the range of materials offered by Kernow and provides users with an ultra-clear printable film for commercial printing special effects, industrial nameplates, and button panel applications.

KernowPrint Lucid for HP Indigo is a new product that expands the existing KernowPrint for HP Indigo synthetic materials range from Kernow Coatings. The polyester based film delivers high optical clarity and is well suited for applications requiring high transparency, windows, and specialty print needs. To aid in feeding, the KernowPrint Lucid for HP Indigo features an opaque paper backing that can be easily removed after printing. In addition, the material takes advantage of the Kernow Cobalt Coating Technology for HP Indigo to create an optimal surface for ink adhesion and colour vibrancy, while fully controlling static during printing and post-processing. Users can deliver high-durability prints that repel liquids, greases, and oils, including harsh industrial chemicals. Based on a polyester core, KernowPrint Lucid for HP Indigo can handle repeated folding and handling, including strenuous use in applications such as machine button panels and membrane switches.

The KernowPrint Lucid clear synthetic material for HP Indigo is available in a range of sheet sizes for any HP Indigo press and comes in 105, 130 and 180 micron thick sheets.

The newly released material joins the growing range of synthetic products for HP Indigo driven by Kernow's Cobalt Coating Technology. The combination of high optical clarity, extreme durability and easy handling has led customers to early successes in markets, such as industrial manufacturing, promotional piece embellishment, and greeting card special effects.

“The success of our Cobalt Coating Technology with customers has been above and beyond anything we expected”, states Dan Lawellin, HP Indigo Materials Product Manager for Kernow Coatings. “As customers have come to trust Cobalt, optically clear materials have been one of the top requested products by our closest partners. KernowPrint Lucid for HP Indigo gives us a way to answer those needs with a material that is tough, durable, and easy to use. The HP Indigo press is perfectly suited for short run and variable needs of markets such as membrane switches. By providing customers with a new high clarity material, they can take advantage of the digital print technology and further transition business from traditional screen and offset prints to the more lucrative digital presses. Outside of industrial print, we're seeing designers really jump on this product for layered special effects that add excellent depth to promotion pieces and greeting cards.”

KernowPrint Lucid Clear Polyester for HP Indigo is launching worldwide through distributors in Europe, North America, South America, and Asia.

Drytac, a leading international manufacturer of self-adhesive materials for the print, label and industrial markets, has announced the global availability of two new exciting additions to its WipeE...

February 18 2019

Drytac, a leading international manufacturer of self-adhesive materials for the print, label and industrial markets, has announced the global availability of two new exciting additions to its WipeErase range of films.

Drytac ReTac WipeErase and WipeErase White are both designed to be written on with standard dry-erase markers to create a whiteboard anywhere - an ideal practical solution for environments including schools, universities, offices, hospitals, retail stores and more. In addition, their anti-graffiti properties allow for easy removal of permanent markers, while they can both be branded or decorated using UV printing technology.

Drytac's ReTac WipeErase is a 6 mil (150 micron) white dry-erase film, coated with a scratch- and stain-resistant lacquer that is guaranteed for up to ten years. The film is easy to handle, can be applied to a smooth surface and can be taken down and repositioned with no loss of adhesion and leaving no residue, thanks to its integrated ReTac Permanently Peelable Adhesive. Unlike a whiteboard, it won't suffer from ink staining or ghosting.

Shaun Holdom, Global Product Manager at Drytac, comments: "ReTac WipeErase is ideal as a replacement for whiteboards and flip charts, where sheets can be moved around to help with visualising and planning, and then taken away for future use. It essentially provides an 'A-frame whiteboard in a tube'. This product is also hugely beneficial in a retail environment where messages need to be moved around the store relevant to specific product ranges."

These innovative attributes have already won fans in the graphics industry: ReTac WipeErase topped the Laminates, Adhesives, Films, Coatings category in the SGIA Product of the Year awards in 2018. These prestigious awards were announced ahead of the SGIA Expo 2018 in Las Vegas in October 2018 and recognised the most exciting products to be showcased at the event, selected by knowledgeable industry professionals.

Drytac's second new product, WipeErase White, has a permanent adhesive for locations where the signage will not need to be moved, such as wall coverings, restaurant menus and whiteboards. It is a 6 mil (150 micron) film with excellent durability and scratch resistance.

"The WipeErase White film incorporates Drytac's adhesive expertise to deliver a product that is very easy to apply, yet remains firmly intact for many years," explains Shaun Holdom. "When it is time to remove or replace the film, it will leave no residue and the area can have new media applied to it immediately."

As well as offering 'a whiteboard in a roll', both Drytac ReTac WipeErase and WipeErase White can be used to resurface existing whiteboards to give them a new lease of life.

Holdom explains: "Whiteboards often suffer from 'ghosting', making them look grey and shaded. In time, the pens used on these boards scratch the surface and when rubbed off leave a very faint impression of previous writing. Once this has happened, there is no way of repairing the whiteboard itself and so the ghosting needs to be put up with, or the board replaced. A sheet of one of our WipeErase products applied to a whiteboard essentially makes it as good as new and is considerably cheaper than replacing it. Do this across a whole organisation and the savings could be huge."

Supporting an ideology of "New technology for creating the next generation of digital printing," MIMAKI ENGINEERING promotes "Surfac...

January 29 2019

Supporting an ideology of "New technology for creating the next generation of digital printing," MIMAKI ENGINEERING promotes "Surface Imaging", which is a premium added-value printing technology that pushes the known boundaries of graphic expression beyond that of ordinary UV inkjet printers. Metallic expression that uses glitters and foils is a special technique that provides a luxurious and exclusive effect to the printed product. However, it imposes an extra workload on the operators since the metallic process must be handled manually after printing.

By mixing a special bright pigment into the ink, the newly developed UV-curable metallic ink "MUH-100-Si" is able to place UV metallic ink directly on the product without the need for a separate glitter or foil transfer process. Another plus is that applying the in-house printing technology created by the "Surface Imaging" makes available decorative options such as printing both gloss and matte tones, texture expression with embossing effect, and colour metallic expression by printing colour ink overlaid on metallic ink. These provide higher added value to the customer's printed product.

This new ink can be used in a wide range of applications since it is possible to print with UV metallic directly on items such as paper containers and films in addition to a very small lot of novelty items, miscellaneous goods and other formed products.

Main characteristics

1. MMC (Mimaki Metallic Control) printing technology to print both gloss and matte tones

MMC (Mimaki Metallic Control) that prints both gloss and matte tones with one type of metallic ink was created by expanding on the clear ink selective printing technology developed in-house by MCC (Mimaki Clear Control). The range of expression can be expanded according to the application by selecting the beautiful gloss tone print with a shiny mirror finish or a matte tone print that gives a glistening effect by irregular light reflection while limiting the shiny glitter tone.

2. Texture expression with embossing effect

Texture expression is easily printed by changing the ink jet concentration since the ink is instantly cured by UV light when applied to the printing object. The texture expression whose appearance changes according to the light reflection provides a vastly higher level of performance appeal.

3. Full-colour metallic expression

Colour metallic expression is possible by printing with coloured ink on top of metallic ink. The range of expression can be expanded to a nearly unlimited degree by combining the application of metallic, colour and colour metallic according to the design.

4. Printable on wide range of materials using UV-curing inkjet

The most outstanding feature of the UV-curing inkjet printer is that it is printable on widely diverse materials since it cures ink by instantly exposing the ink to UV light when the ink is applied to the object for printing. Conventional analog printing had issues such as being printable only on specific materials such as paper and film. Moreover, the unit cost is high when the lot quantity is less than a certain amount. MUH-100-Si will give a high added value to novelty goods and ordered goods, and drastically widen the scope of customer business since it is printable on a wide range of materials and there is no change in unit cost even in very small production lot.

“This new release LED UV-curable metallic ink, named MUH-100-Si, will be available February 2019," said Brad Creoghton, National Marketing Manager, Mimaki Australia. "The new ink strengthens Mimaki’s product offering and pushes the boundaries of graphic expression beyond that of ordinary UV flatbed inkjet printers. The ink is compatible with Mimaki’s UJF-7151plus printer, which produces high-quality print for an impressive range of industries, from gifts, novelty items and industrial type printing applications. The new ink demonstrates how digital print enables creative ideas to be realised highly efficiently in the product manufacturing process. Whilst metallic effects can generally require further processing, Mimaki’s new technology can be used to produce impactful prints without cost or time restraints.”

www.mimakiaus.com.au

EFI revealed its latest digital front end (DFE) technology for advanced, high-end digital print production. New EFI Fiery FS350 Pro software will give graphic arts professionals more power, product...

January 29 2019

EFI revealed its latest digital front end (DFE) technology for advanced, high-end digital print production. New EFI Fiery FS350 Pro software will give graphic arts professionals more power, productivity and versatility in digital printing. The new Fiery offering – which EFI showed for the first time this week at its annual Connect users conference in Las Vegas – will be available starting this quarter in high-end production DFEs for EFI partners’ new, advanced digital printers and presses.

“With this new platform release, we are continuing to stay ahead of market requirements, ensuring that customers can be as productive and versatile as possible,” said John Henze, vice president of Fiery marketing and sales, EFI. “Fiery FS350 Pro delivers unrivalled productivity from prepress to finishing across a wide range of digital printing engines, plus it provides even better colour results for high-value print products.”

This versatile DFE software offers new features in the key areas that print customers care about: colour and imaging, productivity, management tools and connectivity. New DFEs based on EFI Fiery FS350 Pro software will drive digital printers and presses from several leading manufacturers, across sheetfed, high-speed continuous feed, B1 folding carton, and corrugated digital production systems, including both toner and inkjet technologies. Canon will be the first to launch a new DFE featuring Fiery FS350 Pro in the near future.

The new release also will help customers better manage their print production, using the industry’s most intuitive and integrated DFE offerings, including the ability to establish automated, bi-directional communication and integration with EFI’s market-leading MIS/ERP and web-to-print products. Users also can unify production operations for all Fiery Driven printers – including wide-format and superwide-format inkjet printers – from a single EFI Fiery Command WorkStation interface.

Leading-edge technology for advanced digital print efficiency

FS350 Pro, Fiery Command WorkStation and additional Fiery workflow products for the new DFE software offer a range of production enhancements and advantages including:

Digital Ink Sciences Announces New Dye Sublimation Ink for Wide-Format Textile Printers Digital Ink Sciences announced two new ink formulations designed to solve the common yet vexing ...

January 22 2019

Digital Ink Sciences Announces New Dye Sublimation Ink for Wide-Format Textile Printers

Digital Ink Sciences announced two new ink formulations designed to solve the common yet vexing problem of nozzle dry-out within the aqueous dye sublimation market. The new ink formulations allow the printhead to remain off the capping station dramatically longer than traditional inks.

The DIS1000 and DIS3000 series inks are breakthrough formulations, available in both a mid-viscosity and high-viscosity variety. Their unique technology and chemistry boasts the longest decap time in the industry.

Digital Ink Sciences has a reputation for developing water-based textile inks that create vibrant colours with short cure times while also saving on maintenance costs. The newest ink formulations are specifically well suited for wide-format dye-sublimation printers.

The DIS1000 Series is a Mid-Viscosity ink designed for Epson and Mimaki printheads.

Epson:

DX5, DX6, DX7, 5110, 77, 79, 97

SC-S70680, 50680, 30680, F5080, F7080, F718

SureColor F6200, F7200, F9200

Mimaki:

JV2, JV22, JV3, JV4, JV5

The DIS3000 Series is a High-Viscosity ink designed for:

SEIKO, RICOH, KYOCERA, STARFIRE, KONICA

Grant French, Business Development Manager for Digital Ink Sciences, said: "The 1000 and 3000 series ink sets are surpassing our highest expectations for dye-sub transfers. We're getting beautiful vibrant colours, deeper blacks, and excellent jettability with no clogging or misdirected nozzles.

French says the DIS1000 and DIS3000 inks can even reduce head travel time and save ink costs on wide format runs. "The extremely long decap time means you don't have to print those end of line full-colour bars on wide prints," he said.

The ink sets require fewer head cleanings and flushes, which means operators can keep the machines running longer.

Additional Benefits:

Ink Stability

Better "Jetability"

Maintains Nozzle Integrity

Lower Maintenance

Faster Cure Times

Incredible Blacks

Wide Colour Gamut

Improved Wash-ability

Print Durability

Flexibility

Both inks feature faster cure times. Reduced cure times increase bottom line profits on every print.

Jet Technologies offers new laminating films Jet Technologies has launched a new textured matte film, Rough Touch, featuring a unique rough, gritty feel. Released this yea...

January 22 2019

Jet Technologies offers new laminating films

Jet Technologies has launched a new textured matte film, Rough Touch, featuring a unique rough, gritty feel.

Released this year, Rough Touch thermal matte film provides a new touch and feel that meets consumer demands for luxury looks and sensations in products.

‘The new sandy film is the biggest variation in film to hit the market since the hugely popular Soft Touch film, which offers an ultra-matte silky feel laminate,’ said Jack Malki, director, Jet Technologies. ‘We expect that the Rough Touch film will follow in the footsteps of Soft Touch and prove highly popular amongst our customers who specialise in luxury printing and packaging. We see Rough Touch being a really good fit for curious industries looking for a gritty feel - anything from building and beach to coffee and culture.’

It provides a high-quality matte finish with enhanced color and is applied in the same way as any other conventional film. It offers extra protection for printed jobs through avoiding scuffing and curling.

The film is also compatible with a range of finishes such as spot UV or hot stamping and is able to be glued and printed on by traditional offset with oxidative inks (specifically for non-porous materials), offset UV and screen printing.

CHROMALUXE EXTERIOR NOW AVAILABLE FROM GJS GJS today announced the availability of new, high-definition ChromaLuxe aluminium dye sublimation products that are suitable for exterior use...

January 15 2019

CHROMALUXE EXTERIOR NOW AVAILABLE FROM GJS

GJS today announced the availability of new, high-definition ChromaLuxe aluminium dye sublimation products that are suitable for exterior use. These new products give digital decorators and creators the ability to produce dye sublimation designs and products that can be used outdoors and in direct sunlight for the first time.

The new UV-resistant gloss finish provides the same dynamic image quality as traditional ChromaLuxe panels, is equally easy to clean and resistant to graffiti, scratches and chemicals.

“A previous limitation of dye sublimation was the inability to create and use designs outside and especially in direct sunlight,” said Greg Stone, Managing Director, GJS. “These new panels and products from ChromaLuxe solve this problem and have the potential to open up entire new markets for the dye sublimation market.

While photo reproduction is a favourite application, ChromaLuxe exterior products can also be used for branded logo work, directional and informational signage, wayfinding signs, menu boards, cabinetry, wall coverings and many more applications including:

Hotels

Printers can now create vibrant wall décor for hotels that is multi-functional, serving as an outdoor option or indoors into direct sunlight. Perfect for open lobbies and entryways, or outdoor restaurants and gathering spaces.

Corporate settings

ChromaLuxe exterior is perfect for corporate branding, works of art or inspiring photography inside and outside the office setting. Completely customisable, add logos to vibrant imagery or simply display high-quality wall décor anywhere in the office.

High-end retail

With a sleek and modern look, create stunning branded environments that can be displayed either outdoors or directly in windows and that match a brand’s luxury and exclusivity.

Directional/wayfinding

Thanks to its extreme durability, ChromaLuxe exterior products can be used for directional signage that will hold up to wind, weather and other elements. Thoroughly tested for fade, abrasion and impact resistance, the print surface stands up to the most exacting environmental conditions.

Display/POP

In addition to exceptional image quality, ChromaLuxe exterior is also a perfect fit for point-of-purchase and display messaging including outdoor restaurants, cafes and other businesses.

“We’ve already seen some incredible examples of the versatility of this product around the globe, so we’re excited to see what our customers will create with it,” Greg added.

ChromaLuxe exterior products are available now from GJS in a variety of sizes to serve the signage, display and outdoor photography markets.

Heidelberg Assistant celebrates first anniversary with over 700 users One year from its launch, the Heidelberg Assistant customer portal is now in operation at over 400 print shops wit...

January 15 2019

Heidelberg Assistant celebrates first anniversary with over 700 users

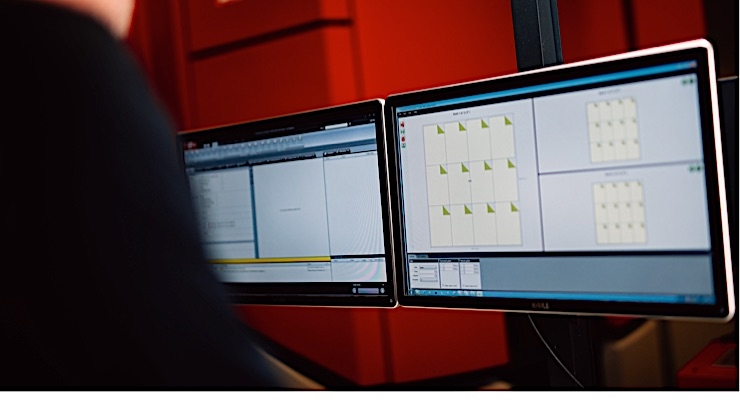

One year from its launch, the Heidelberg Assistant customer portal is now in operation at over 400 print shops with over 700 users – and has just won the 2019 Digital Edge 50 Award in the United States. The platform is currently being rolled out in Japan, Poland and Austria. The OEM’s new digital customer communication platform was launched as a pilot in Canada, the United States, Germany and Switzerland in January of 2018.

The Heidelberg Assistant digitisation solution paves the way for creating and ensuring the smooth operation of a company’s new digital business models. Customers benefit from a transparent process workflow together with smart and efficient print-shop operation. Each user has personal access to the customer portal and obtains an overview of his or her print shop’s service and maintenance status – including helpful data-driven ‘failure predictions.’ Users also benefit from “access to the sector’s largest knowledge database.” In addition, they can access big-data performance analyses that can also boosting productivity. Heidelberg is currently using the technology for further market scaling of its existing big-data applications, such as Predictive Monitoring and Performance Consulting.

“Digitisation is becoming increasingly important at a great many print shops, and our customers appreciate the digital service portfolio we offer them 24/7 with Heidelberg Assistant,” said Professor Ulrich Hermann, Member of the Management Board and Chief Digital Officer at Heidelberg. “Designed as an open digital platform, it’s used by customers of all sizes and from all segments with their own personal Heidelberg ID.” User feedback is equally positive. Jeff Taylor, Senior Vice President of Manufacturing at Hemlock Printers in Vancouver added: “This is exactly the data and information we need to manage production efficiently.”

To coincide with the first anniversary of its market launch, Heidelberg Assistant has won a 2019 Digital Edge 50 Award from the U.S.-based International Data Group (IDG), a world-leading supplier of technology media and data/marketing services. The award is a sought-after accolade that goes to 50 organisations each year for digital innovations that improve business success, modernise operations and enhance the customer experience. “Winning a 2019 Digital Edge 50 Award underlines that we have our finger on the pulse with the Heidelberg Assistant, and have assumed a leading industry role in digitising customer communications,” Hermann added.

INX International Ink Co. has developed a solution for brand owners and food packaging providers looking for safe and sustainable alternatives with natural-based inks. INXhrc offers a number of adv...

January 07 2019

INX International Ink Co. has developed a solution for brand owners and food packaging providers looking for safe and sustainable alternatives with natural-based inks. INXhrc offers a number of advantages that reduce regulatory risk for brand owners and printers and improves production efficiencies for printers and converters.

INXhrc natural-based water, solvent and conventional offset inks have had a far-reaching impact on the food packaging marketplace since they use fewer chemicals compared to traditional inks. INXhrc contains no allergens, nanomaterials, flurochemicals, fanal pigments, heavy metals, latex or PTFE. By utilising clean, bio-renewable and sustainable ingredients, they have reduced CO2 emissions and annually replaced over two million pounds of petro-chemically derived resins, waxes and additives.

“INX International’s commitment to providing safe and sustainable product solutions can help printers and brand owners achieve sustainability goals, and consumers feel confident in their product choices,” says John Hrdlick, president of INX International. “We are keenly aware of the impact we can have on consumer safety, brand marketability and the environment throughout a product’s lifecycle. Our INXhrc inks provide a path to measurable, reportable CO2 savings and ultimately help brands tell a richer sustainability story.”

In addition to the sustainability advantages, the performance improvements of INXhrc has encouraged the adoption of this new technology in numerous pressrooms globally. When combined with high strength colour concentrates, INXhrc provides strong finished inks with excellent resolubility and transfer properties. Printers are seeing increased ink mileage and better production efficiency, leading to reduced resource consumption and waste generation.

HAVI presented an opportunity to align on the mutual recognition of the many benefits that could be derived from natural-based inks. Working together with INX, the company developed the right formula for the market with more sustainable packaging. Acknowledging a 25-to-30% lower CO2 footprint than conventional inks and reduced regulatory risk for brand owners and printers, the global, privately-owned company’s endorsement with INXhrc represents another aspect of the clean food movement and the principle of simplifying materials and chemistries for safer, more environmentally-friendly packaging.

“As a pioneer of clean packaging, HAVI is committed to not only improving the sustainability of food service packaging, but helping food service providers anticipate and stay ahead of consumer concerns about health and safety,” says Shane Bertsch, HAVI’s vice president, innovation. “Working with INX to bring natural-based inks to market has been a meaningful and insightful collaboration. Their expertise in ink formulation and printing have been critical to bringing this new product range to market. We look forward to further driving market innovation through our continued partnership.”

Onyx Graphics, Inc., announced the global availability of ONYX 18.5 software, the latest version release of the company’s wide- and grand-format RIP software. ONYX 18.5 software ...

January 07 2019

Onyx Graphics, Inc., announced the global availability of ONYX 18.5 software, the latest version release of the company’s wide- and grand-format RIP software.

ONYX 18.5 software builds upon the award-winning ONYX 18 version, taking print production to the next level with the distinction of being the first wide-format RIP solution with Adobe PDF Print Engine 5.1 (APPE 5.1). With APPE 5.1, users benefit from the latest technological advancements for complete design-to-print workflows including high impact colour rendering, smoother edges for graphics, enhanced Unicode support; plus support for PDF 2.0 features such as black-point compensation, half-tone origin, special data for spot colours, and page-level output intent.

“ONYX 18.5 continues to lead the wide-format print industry with technological advancements that future-proof print service providers needing to differentiate themselves from their competition,” said Bryan Manwaring, Director of Product Marketing at Onyx Graphics.

“Helping our customers stay ahead of the curve as well as enabling them to take advantage of unrivalled RIP and production speeds are achievements that can greatly benefit their operations for years to come.”

ONYX 18.5 also introduces new Quick Set application library management for improved automation, enhanced iccMAX compatibility with support for third-party files and new spot colour tools for greater colour accuracy and vibrancy. Coupled with new ColorCheck reports,

ONYX 18.5 delivers industry-leading output that can literally be validated to print buyers.

Highlights of ONYX 18.5 include:

• APPE 5.1, the latest Adobe PDF Print Engine

• PDF 2.0 features including black-point compensation

• Unrivalled performance gains with 2X faster RIP speeds and 5X faster production speeds

• Added spot colour vibrancy with Relative Gamut Mapping chroma preservation

• QuickSet application library management to manage multiple QuickSets at the click of a button for securing data and getting to sellable prints faster

Availability

ONYX 18.5 software – covering the entire product portfolio of ONYX solutions including ONYX Thrive print workflow; and ONYX ProductionHouse, ONYX PosterShop, and ONYX RIPCentre RIP software – is now available to all ONYX Advantage customers by requesting a key update and to all other customers through a license purchase.

The ONYX Advantage subscription program gives ONYX software users a quick and easy way to keep their software current and secure their investment. Customers that are not ONYX Advantage subscribers should contact their local Authorised ONYX Reseller or visit onyxgfx.com for more information.

Classic metal effect films by ASLAN ASLAN, the German developer and manufacturer, renowned as a specialist in self-adhesive films, expands its portfolio of special effect films with th...

December 07 2018

Classic metal effect films by ASLAN

ASLAN, the German developer and manufacturer, renowned as a specialist in self-adhesive films, expands its portfolio of special effect films with the introduction of the MetalLux ASLAN SE 50 in Champagne and Platinum. These classic shades impress by their elegant appearance, are both trendy and timeless at the same time.

When applied to a smooth, compatible surface the silky matt shades come into full effect. While Champagne creates a warm ambience, Platinum brings a touch of cool elegance to every single interior space. These self-adhesive films can be used to cover complete surfaces or plotter cut to produce spectacular highlights to any graphic design or logo.

Due to their 50 μm thickness, both Champagne and Platinum are particularly easy to handle and to apply. ASLAN recommends a dry application but wet application is possible as well – as this reduces static charges and makes repositioning even easier. It is important to press the water out completely and carefully with the use of a squeegee. Any slight visible marks that may appear while using a squeegee, are easily removed with a microfiber cloth.

Both Champagne and Platinum are perfectly suited for shop fitting, exhibition stand design, visual merchandising and interior design. These self-adhesive metal effect films are specifically designed for the decoration of smooth surfaces. This makes them ideal for application to flat areas on furniture, ceilings and walls – whether applied to large areas for a complete surface design, or as an individually set highlight. Surfaces should always be cleaned thoroughly, to achieve that trendy and yet timeless classic effect.

MetalLux ASLAN SE 50 Champagne and Platinum have an outdoor durability of 2 years and are available in the dimensions 25 m x 1.25 m.

FASTSIGNS® of Maple Shade relies on SAi Flexi for flexibility and smooth production integration In more than 30 years as a signmaker, Jeffrey Chudoff, owner of FASTSIGNS® of Ma...

November 16 2018

FASTSIGNS® of Maple Shade relies on SAi Flexi for flexibility and smooth production integration

In more than 30 years as a signmaker, Jeffrey Chudoff, owner of FASTSIGNS® of Maple Shade, New Jersey, has witnessed the transformation of vehicle graphics printing. Indeed, he has been one of those who helped drive the evolution, and SAi Flexi was one of the enablers.

With a background in business, brand management and marketing, Chudoff began tinting glass for a range of vehicles from muscle cars to pick-up trucks. Responding to requests for names on windshields, in 1985 he began supplying and installing cut vinyl lettering. Initially this was out-sourced, but in 1986 he bought his first tangential cutter to bring the process – and control – in house.

“That was the beginning of it all,” Chudoff says. “As large format printing for vehicle wraps developed in the early 1990s, I’d put designs on CDs and mail them to Kansas for printing electrostatically. The breakthrough came in 1995 when I bought my first Roland large format inkjet printer at the USSC show.”

Adding the large format printer enabled Chudoff to cut production times, increase margins and accelerate the development of his business. He outgrew the 400 sq. ft. garage where he had been operating and moved to his current 3,200 sq. ft. location – which also has the benefit of being on a highway with 350,000 vehicles passing weekly. The company currently has two Roland printers, an XR-640 and an RF-640.

“While the quality of our work was always high, the software tools for design and workflow could be tricky to use and not especially suitable for vehicle wraps and graphics,” he explains. “We began using SAi Flexi in about 2000, and the tools it has for handling different file formats, colour matching and efficient management of jobs is great.”

FASTSIGNS® of Maple Shade has two subscriptions for Flexi software. “We can afford two because of the price difference for the options. We use one just for designs while the full version is connected to the printers,” he says, adding, “And they’re both always up to date.”

The right tools for the job

“Flexi has lots of clever features. For example, if you are processing a large number of similar pieces, there are short-cut keys that mean you don’t have to go through drop-down menu options again and again,” he says. “Incorporating photographs and artwork from different sources is easy and ensures that we get what we design. I like to say that Flexi plays well in the graphics playground!”

Chudoff also likes the way Flexi’s clean-up tool can be used to separate a logo from a background to prepare graphics suitable for vehicle wraps. “Sometimes people don’t have logo files,” he explains. “We have to scan a letterhead and work from that. The clean-up tool simplifies the process and means that we can get a result that the customer loves.”

Additionally, he uses Flexi to produce other signage and photographic wall murals with logos and special effects incorporated. This enables him to exercise creativity, recognise opportunities, and find the best way to produce what the customer wants.

Chudoff is not wedded to any particular process. He will use the techniques necessary to realise the concept, and his numerous awards from industry magazines attest to his success. At one time he discovered that automatic photo-processing kiosks, like those found in shopping centres, were capable of printing business cards. He was able to use artwork being prepared for a vehicle wrap to print them, giving his customers a more complete and consistent branding package.

For the record – the importance of vinyl

Cut vinyl still accounts for about 40 percent of Chudoff’s jobs. As in many states, New Jersey requires owner information on commercial vehicles and many customers are small one-man operations that don’t want or need a wrap, so the cut vinyl solution is enough.

The state requires the owner’s name and the name of the municipality where his principal place of business is located, and this must be in letters not less than three inches high. Other customers, explains Chudoff, see vehicle wraps as an important tool for their marketing and brand identity.

On this subject, Chudoff is passionate about the role of the signmaker. “Vehicle wraps have a particular job to do,” he says. “Viewers have about six seconds to take in the information on a moving car or truck. That information should help the process of remembering them. That can be a logo, a graphic, a photograph, or a typeface. The right combination of a photograph with words can mean that it’s 87 percent more likely to be remembered.”

According to Chudoff, setting out these elements and achieving the right colour is facilitated by Flexi and makes achieving the desired effect much easier. “It takes people who know about vehicles to do this properly,” he says. “Following corporate guidelines written by people without the right understanding of vehicles and their variations can result in key elements being placed in difficult-to-read positions and failing to communicate the message.”

Chudoff also believes that the right vehicle wrap shop can give advice on the best approach, too. For example, in some circumstances, a partial wrap might be just as effective as a full one and save the customer money. As a result, he might then be prepared to buy some other signage.

Building family relationships

Chudoff operated as an independent sign shop until 2016 when he became part of the FASTSIGNS® family (#2115). “I was amazed at the difference it has made,” he says. “We receive calls and opportunities that we’d never had before. People like the consistency of the experience and if they have had good results from one FASTSIGNS® shop, they will recommend the brand to colleagues and friends elsewhere.”

Chudoff also believes that the industry has come a long way in the last 30 years. In his eyes, colour quality and durability, print speeds, substrates, photographic reproduction, and of course, software and workflow development, have contributed to what is a whole new market segment.

Despite the developments, he also thinks that the industry needs to keep up the levels of training to ensure that younger people learn the techniques of creating quality wraps and installing them properly. “There is now a sophistication in this market that didn’t exist when I began, and it requires a much more professional approach – and it is important to keep the bar high,” he explains.

Having the right tools is part of that picture. “Flexi is a versatile software that can integrate input and output software and devices in a way that is intuitive and meets the needs of busy sign shops,” Chudoff concludes. “That’s one of the reasons I really like it: you can tell that Flexi wasn’t designed by boffins in a lab but by people who are signmakers and who fully understand how we work and what we need.”

Roland DG Announces New VersaWorks 6 RIP Software for Enhanced Efficiency and Performance Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and 3D devices wo...

October 21 2018

Roland DG Announces New VersaWorks 6 RIP Software for Enhanced Efficiency and Performance

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and 3D devices worldwide, today announced the release of VersaWorks 6 RIP and print management software for inkjet printers and printer cutters.

VersaWorks includes a broad range of functions to streamline the entire printing process by generating high-quality print data that optimises the features of the printer, ink and media being used. “Our new VersaWorks 6 comes with an extensive range of features that makes the printing process more accurate and reliable for users, while also building upon the superb core functionality and ease of use of the previous popular VersaWorks software,” explains Yohei Shinomura, manager of Digital Printing Product Management.

VersaWorks 6 provides 64-bit native support to maximise performance from the latest 64-bit operating systems and to improve the processing capability of complicated data including complex vectors and multiple layers with ease and precision. It also provides support for processing PDF files natively to render transparencies, drop shadows and other special effects the way they are intended to look in the design, eliminating the hassle of reworking data.

Shinomura said the user interface has been redesigned consistent with the latest design trends for a high level of visibility, with more intuitive visual icons to enhance usability. An easy-to-use colour matching function ensures consistent colour between multiple printers of the same model, providing accurate colour control when using more than one printer for volume production or jobs involving large, combined graphics. Users now have up to five separate queues with unlimited saved settings available for each queue to suit specific customer requirements and media, as well as to immediately reload past job settings for recurring jobs.

VersaWorks 6 will be bundled with the following Roland DG inkjet printer and printer cutter models beginning in November 2018 and is also available immediately on the website below as a free upgrade for users with the following models.

Eco-Solvent Printers and Printer Cutters

BN-20

EJ-640

RF-640

SG-540/300

SP-540i/300i

VG-640/540

VS-640i/540i/300i

XR-640

UV Printers and Printer Cutters

LEC-540/330

LEF-12/12i

LEF-300/200/20

LEJ-640

Dye Sublimation Printer

RT-640*

* Please note: Those using ErgoSoft Roland Edition are excluded from the upgrade.

Website: www.rolanddg.com.au/products/software/versaworks-6

Mactac Develops PUREapply Adhesive Mactac Performance Adhesives Group has announced the launch of PUREapply, a pressure sensitive adhesive designed to deliver a combination of high ini...

October 05 2018

Mactac Develops PUREapply Adhesive

Mactac Performance Adhesives Group has announced the launch of PUREapply, a pressure sensitive adhesive designed to deliver a combination of high initial adhesion with clean initial removability.

Ideal for semi-rigid or rigid container substrates like high-density polyethylene (HDPE), polypropylene and glass, it forms a strong bond when applied, yet at the same time, provides clean removability.

“PUREapply was designed to help customers cleanly and easily remove labels that may have been misapplied initially to quickly replace old labels with new labels,” says Kim Hensley, marketing manager, Mactac Performance Adhesives. “It is uniquely formulated to provide extended open time for clean removal, allowing the product container to be re-labeled while continuing to offer excellent tack for long-lasting shelf appeal.”

PUREapply performs well on low-surface energy substrates and is suitable for cold, damp labeling applications. It can be used across a broad range of applications, including beverage, cosmetics, toiletries, household goods and food packaging labeling.

PUREapply exhibits:

High-Tack

Excellent Initial Removability

Ultimate Adhesion

Exceptional Clarity

Xeikon announces newest X-800 DFE Xeikon has announced the newest version of its X-800 digital front-end (DFE). It is designed to deliver maximum automation to enable the most powerful...

October 05 2018

Xeikon announces newest X-800 DFE

Xeikon has announced the newest version of its X-800 digital front-end (DFE). It is designed to deliver maximum automation to enable the most powerful workflow on the market.

The X-800 6.0 combines consistent print with enhanced productivity to enable digital printers to process their print jobs, no matter how complex, in the fastest, most flexible and secure way. It is upgradable to all press-models from the Panther UV inkjet presses – the PX3000 and PX2000 to the Xeikon 3000 series to the Cheetah series for labels and the Xeikon 8000 and 9000 series for the graphic arts markets.

The product enables print service providers to reduce job preparation time, automate converting and serve new businesses that can only be enabled through digital print, such as variable data.

“We are constantly innovating our press portfolio and, as a result our, software solutions that support them, so our customers can maximize their production possibilities,” comments Filip Weymans, vice president of marketing at Xeikon. “The Xeikon X-800 6.0 DFE builds on our highly successful and established dedicated Xeikon press software platform that works with open standards and delivers scalable functionality.”

Weymans continues, “It will allow all our customers to add value no matter their specialty area. From label and packaging converters to operations with high-volume data throughput requirements, the latest version will help them streamline their workflow, reduce job preparation time for even the most complex work and become more responsive and efficient.

“Our X-800 DFE is designed from a digital printing perspective to outperform any other DFE in the market when it comes to the level of automation possible. X-800 6.0 strongly focuses on enhancing operational capabilities, one of which is automated impositioning," Weymans explains. “Streamlining this process can easily help operations save hundreds of prepress and job preparation hours per year. This alone delivers a clear and measurable value.”

To demonstrate the possible business gains for individual operations Xeikon has launched a new initiative called “Workflow Challenge”. Customers can request an online review by simply mailing info@xeikon.com comparing the X-800 6.0 to other workflows.

Adds Weymans, “Simply seeing the impact a software solution has on other similar operations does not always make it easy to understand how it will help your business’s performance. With our Workflow Challenge, a much more direct comparison can be made helping define specific goals that will achieve tangible results. We will highlight how job automation reduces job preparation, enables variable data management and supports web to print with laser diecutting.”

INX International launches new inks From a new electron beam low migration ink solution and a preview of the NW340 UV digital label printer, to an overflow of various tag and label ink...

October 02 2018

INX International launches new inks

From a new electron beam low migration ink solution and a preview of the NW340 UV digital label printer, to an overflow of various tag and label ink and coating solutions, eco-friendly INXhrc inks, and a small batch ink dispenser that ideally suits the tag and label market, the INX booth has plenty of options for consideration.

“The Labelexpo crowd is always looking for a product with that something extra so they can separate themselves from the competition. I think it best describes the products we are exhibiting this year,” says Jim Lambert, INX International’s vice president of digital sales – Ink and Hardware. “We have an ink solution for nearly every occasion and Prodigy EBGA, the new low migration ink we are introducing, was just named SGIA’s 2018 Product of the Year for its category. I’m also excited about previewing the NW340 printer at our hometown show.”

The single-pass NW340 printer is a UV digital label press that gives label converters, packaging, in-house and commercial printers the opportunity to seamlessly transition to digital inkjet technology. The complete solution includes high quality inks and expandable modules to help printers meet the increasing demand for high quality, short-run digital printing.

The NW340 represents third generation label technology that Lambert says is an important and natural progression.

“It seems like only yesterday when we previewed the NW140 printer at Labelexpo,” remarks Lambert about its 2010 pre-launch debut. “A few years later we followed with the NW210. Both of those printers offered resolutions of 360-by-360 dpi and produced labels at speeds up to 80 fpm. The main difference was the printing width of 140mm and later, 210mm.

“The NW340 is a whole different ballgame. We’ve elevated the resolution to 1200-by-600 or 1200-by-1200 dpi, improved the width range to 340mm, and have increased the speed up to 300 fpm to satisfy market demand. Printers want faster equipment and higher resolution so they can more favorably compete with offset presses. This machine does that and more.”

Prodigy EBGA is the new EB low migration solution from the popular line of industrial and packaging application inks. SGIA’s 2018 Product of the Year for Digital Inks - Industrial and Packaging -, the premium inkjet ink cures by electron beam using Uteco’s GAIA printer. It is the first inkjet machine offering electron beam technology, eliminating the need for photoinitiators, the company says.

EBGA inks provide strong adhesion to a range of traditional label material and film, with high chemical and scratch resistance. Available in CMYK, they can create custom spot color in addition to orange, green and violet.

A complete assortment of AquaTech water-based tag and label inks and coating solutions, including the new AquaTech ION-X series, are on display. Known for their strong performance and excellent print stability, these inks are formulated to provide premium strength for today’s higher line anilox rolls and excellent cure rates at high press speeds. Whether it is AquaTech or a solution for sheetfed or web offset, flexographic, UV hybrid, HUV and LED or electron beam printing, INX has those inks and coatings at Labelexpo Americas.

INXhrc water-based inks have replaced over two million pounds annually of petro-chemically derived resins, waxes and additives. The eco-friendly, fast drying ink offers clean, renewable and sustainable ingredients that are free of allergens, nanomaterials, flurochemicals, fanal pigments, heavy metals, latex and PTFE. When used in tandem with INXPlus dispersions, INXhrc provides for the strongest finished inks available with excellent resolubility and transfer properties and other benefits.

The HMJ-200 small batch ink dispenser offers many advantages, especially for the tag and label market. It provides a single point dispense into jugs with small openings, and a quick adjust scale base accommodates multiple dispense containers from jugs to pails. The HMJ-200 is also fast, dispensing four ingredients in a one-gallon jug in 90 seconds. Available for water-based or UV curable inks, the small footprint machine has an automated valve cleaning system.

Xitron introduces Navigator Flexo Suite Xitron, an independent developer of RIP and workflow products for commercial, digital, flexo, and high-speed inkjet printing has introduced Navi...

September 26 2018

Xitron introduces Navigator Flexo Suite

Xitron, an independent developer of RIP and workflow products for commercial, digital, flexo, and high-speed inkjet printing has introduced Navigator Flexo Suite at Labelexpo. Comprised of several productivity tools designed specifically for flexo imaging, the modular workflow is fully compatible with any flexo CTP engine that accepts one-bit TIFF files, such as Amsky, Cron, Xeikon, and others.

Conceptualized in meetings with several flexo CTP vendors at last year’s Labelexpo in Brussels, the package was developed, tested, and sent to beta accounts around the world in the span of nine months. “We had a very specific list of requirements with which to work,” said Karen Crews, president of Xitron. “Besides our meetings with Flexo CTP manufacturers, we also worked with distributors and dealers before building the product roadmap. This gave us a short list of ‘must-have’s’ in terms of functionality. All of our CTP partners wanted a competitive price point, productivity beyond existing systems on the market, and the option of high fidelity screening for applications that require it,” she continued.

Navigator Flexo Suite starts with the ubiquitous Navigator RIP platform, of which more than 35,000 have been sold in commercial, in-plant, digital, screen printing, inkjet, and flexo markets around the world. Notably, Navigator Flexo Suite makes its debut being PDF 2.0 compliant right out of the box, as Xitron began shipping Navigator 12 on September 24th.

It’s coupled with the Client-Server properties of the Navigator workflow, which gives all prepress operators and artists independent submission, modification, pixel-level preview, and throughput control of jobs from their own workstations. This allows them to work independently and without interruption from anywhere on the network. Finally, all the color separated job plates are collected by Navigator Plate Controller, which helps the operator assemble the final flexo plate for output with as little material waste as possible.

The optional high-fidelity screening engine gives users the ability to specify FM to AM crossover points between highlights/shadows and mid-tones while also letting them determine minimum dot size through nine levels of sustainable “smart dots.” Users are able to customize the screening based on platesetter exposure accuracy and the print results of each individual press. Those customized setups are retained as screening templates for repeated use.

“From day one, our goal was to develop a product that could hit the market at a price point under $15,000 to stay in line with the decreasing cost of flexo CTP engines,” said Crews. “It was an intense development and testing cycle, but we brought it to the finish line without compromising the original requirements list.”

From the end user’s perspective, one thing that rated high on the list was annual maintenance costs; something they see as out of control in software and not always accounted for when considering a purchase. “We addressed the maintenance issue head on,” said Crews. Annual support for Navigator Flexo Suite is an affordable $1,495 per year, and that includes minor upgrades.”

Mitsubishi Imaging (MPM) Inc. Introduces SWORDiJET 5.5 High Gloss Mitsubishi Imaging (MPM) Inc. announces the addition of the SWORDiJET 5.5 High Gloss to Mitsubishi Paper Mill’s ...

September 20 2018

Mitsubishi Imaging (MPM) Inc. Introduces SWORDiJET 5.5 High Gloss

Mitsubishi Imaging (MPM) Inc. announces the addition of the SWORDiJET 5.5 High Gloss to Mitsubishi Paper Mill’s (MPM) portfolio of high-speed production inkjet coated papers. “We are excited to bring to market one of the highest gloss levels available for high speed printing”, says Chris Hung, Vice President of Sales and Product Planning. “An 80% gloss level opens up a range of possibilities for Publishers”, he continues. Mitsubishi specifically engineered SWORD iJET 5.5 High Gloss to target the high-end Magazine, Catalog, Book and Scientific Journal market which are seeing growth from the benefits of personalized content and print on demand capabilities that are now possible with high speed production printing.

Mitsubishi partnered with HP to license SWORDiJET 5.5 High Gloss with the HP ColorPro technology. “We’re proud to have worked with one of the most successful and trusted OEM’s in the High Speed Print market. The stringent print, color excellence and performance standards developed by HP ensure successful implementation. Together, we’re delighted to offer a seamless solution for high quality, efficient output for Printers and Publishers” says Mitsubishi Imaging (MPM), Inc. CEO and President Hide Tsukada.

HP and Mitsubishi are committed to the value of print and Production Inkjet technology. HP’s press advancements and technical support program combined with Mitsubishi Paper Mills coating technology offer high value opportunities for Print Service Providers (PSP) to expand existing business or create new markets to serve. PSP’s will see immediate cost savings in efficiencies, Mitsubishi’s coating technology maximizes press performance with increased speeds, reduced ink loading and unprecedented dry times. Additionally, high volume accounts can benefit from cost advantages in direct container paper shipments.

SWORDiJET 5.5 High Gloss is available in 90 gsm/24lb basis weight, with heavier grades to follow including a 7 and 9pt to serve Direct Mail applications. In addition to the Mitsubishi SWORDiJET 5.5 High Gloss, SWORDiJET 4.3 Gloss and Matte and Premier IJ Book and Form have also been licensed with HP ColorPro technology and will be available through established distribution partners. These grades are all produced at Mitsubishi Paper Mill’s fully integrated Hachinhoe Paper Mill in Japan. For additional information, please visit www.mitsubishiimaging.com/production-inkjet.html

Antalis introduces MetaliK films for luxury detailing Antalis, the leading European distributor of paper, packaging and visual communication solutions, has introduced large format inkj...

September 06 2018

Antalis introduces MetaliK films for luxury detailing

Antalis, the leading European distributor of paper, packaging and visual communication solutions, has introduced large format inkjet metallic films to its portfolio to enable customers to combine print and cut applications for creative display.

The KernowJet MetaliK range delivers high quality metallic films for use within luxury retail settings, window displays and point of sale (POS), Christmas or seasonal campaigns and countless other applications. The films, which are available in gold, silver and rose gold finishes, provide an extremely smooth finish, giving any application a near-mirror effect.

The new offering includes KernowJet MetaliK Cut&Print; a removable metallic film ideal for double-sided displays. It is particularly suited for bright reflective lettering, logos and designs for shop windows and glass, as well as general retail settings, perfumeries, luxury boutiques and campaigns. The removable adhesive makes it specifically useful for evolving point of sale promotions. Along with being inkjet printable with Solvent, Latex and UV, the film can be easily plotted out for eye-catching lettering and decals. Kernow MetaliK Cut&Print is suitable for wet-application allowing easy application and is the same colour on both sides making it ideal for double sided window display.

Mike Collins, Product Manager for Visual Communications at Antalis UK, comments: "We are delighted to be offering a new extended offering of the brilliant KernowJet MetaliK portfolio here at Antalis. MetaliK is truly eye-catching, and the Cut&Print films in particular provide great options for many retailers and consumer-oriented companies who are looking for a smooth finish to their displays, with the luxury metallic effect providing stand-out visual aesthetics.”