Direct Color Systems is happy to introduce a new line of printers to its current portfolio. The new product line, named VIBRAHUE, is a collaboration between Direct Color Systems an...

January 30 2024

Direct Color Systems is happy to introduce a new line of printers to its current portfolio. The new product line, named VIBRAHUE, is a collaboration between Direct Color Systems and Team EPS. Direct Color Systems, well known for its innovative products for Braille and Textured printing, is adding the VIBRAHUE product line to meet the needs of traditional UV printing. Team EPS is a 30-year-old service company to the printing industry and is very well known for providing exceptional technical service and support.

The VIBRAHUE line of UV printers are a fast, reliable, and competitively priced lineup of printers with Flatbed, Roll-to-Roll, and Hybrid formats. They are available in a variety of sizes and a choice of printheads. Direct Color Systems will be handling the Sales and Marketing for the product line, while Team EPS will be managing the Installation, Training, Technical Support and Service.

The VIBRAHUE series of printers is a testament to the synergy between Direct Color Systems’ innovative spirit and TeamEPS’ commitment to high quality service. Steve Mills, Global VP of Sales and Marketing at Direct Color Systems, comments on the strategic integration of VIBRAHUE with their existing product line, “The VIBRAHUE product line compliments our Direct Jet line of printers. We are not just expanding our product range; we’re enhancing the capabilities of our clients. Customers involved in traditional Point of Purchase printing can now enjoy a more comprehensive offering, right alongside our Direct Jet products.”

The TeamEPS and Direct Color Systems collaboration is more than a partnership; It is a fusion of expertise and excellence. This cooperation allows the two partners to make the most of their expertise in service and utilize an established sales and marketing network.

This strategic move is part of Direct Color Systems’ broader vision to strengthen its market presence while bringing new product possibilities to its customer base. Tom Kaplinski, Direct Color Systems, President elaborates, “The launch of VIBRAHUE aligns perfectly with our strategy to continuously evolve and provide superior technical products. It is not just about adding new printers; it is about new possibilities like roll-to-roll printing, an area we are excited to explore. Our collaboration with TeamEPS and their world-class service organization marks a new chapter in our journey.”

directcolorsystems.com

Canon is proud to announce that Keypoint intelligence has awarded Canon the Buyers Lab (BLI) 2024-2025 Pacesetter award in Wide Format Sustainability: Product Innovation. This pres...

January 23 2024

Canon is proud to announce that Keypoint intelligence has awarded Canon the Buyers Lab (BLI) 2024-2025 Pacesetter award in Wide Format Sustainability: Product Innovation. This prestigious accolade acknowledges Canon as the leading company supporting environmental improvements and initiatives in the wide format printing systems market through product innovation, across its complete portfolio.

In its extensive research of the global wide format printing systems market, Keypoint Intelligence identified Canon's outstanding commitment to sustainability through innovative features across its wide format print devices.

As part of the assessment, Keypoint Intelligence invited all leading document imaging companies to complete an exhaustive questionnaire detailing their environmental efforts and programs in a range of sustainability areas, including business operations, products, recycling, and goal tracking. Participating companies were also asked to make key personnel available for in-depth interviews with the Keypoint Intelligence analyst team to give a complete picture of their sustainability strategies. After gathering this data, analysts used a proprietary rating scale to determine the Pacesetter Award winners.

Canon's commitment to innovation in sustainable wide format printing technology is evident not only in its extensive portfolio, featuring the Colorado, Arizona, PlotWave and ColorWave lines of printers, but also in its award-winning CrystalPoint and UVgel ink technology.

Through innovation, Canon actively strives to minimize the overall impact of its products throughout the complete product lifecycle. This starts with R&D and development – being engineered into the design and use – and continues all the way to end of life and the reuse, refurbishment and remanufacturing of products and parts.

Furthermore, Canon is consistently adopting energy-efficient LED curing technologies throughout its portfolio and with Canon’s award-winning, proprietary UVgel ink technology, customers can benefit from up to 40% less ink consumption compared with competitive technologies. UVgel technology also operates and produces output with zero volatile organic compounds (VOC) emissions or hazardous air pollutants.

Canon designs its products with the circular economy in mind to contribute to a waste-less society. By innovatively designing its printers and products to be modular and for greater longevity, they are upgradable, enabling them to stay operational for longer, rather than being seen as disposable devices with a limited lifetime.

Martijn van Hoorn, Senior Vice President Research & Development at Canon Production Printing, comments: “Being awarded the Wide Format Sustainability Award for Product Innovation by Keypoint Intelligence acknowledges the innovative developments we’ve made in designing our wide format printing systems portfolio to be a sustainable solution our customers can rely on. At Canon, we operate according to the philosophy of Kyosei – a Japanese word that means ‘living and working together for the common good’. This philosophy is deeply ingrained in the way we design and develop our products. Product innovation is key in any R&D centre around the world, and we have actively defined sustainability and environmental impact as a key requirement for our future portfolio. This has led to numerous small and significant innovations that you see in every new product we release, most recently with the launch of our Colorado M-series with its modular design and in-field upgradability.

“We passionately believe this long-term strategy will change the way large format graphics and other applications are being produced for the better, and will benefit our customers and the wider society.”

Eric Zimmerman, Principal Analyst and Director Wide Format Printing at Keypoint Intelligence, emphasizes the significance of partnering with environmentally conscious manufacturers like Canon Production Printing, "Businesses have seen the results of becoming more eco-friendly, and by partnering with manufacturers like Canon, which are dedicated to environmental friendliness and place that central in their innovation, you are that much closer to achieving better sustainability."

For more information about Canon's sustainability initiatives and its wide format printing portfolio, please visit https://global.canon/en/csr/ and https://graphiplaza.cpp.canon/sustainability-2/

Since Epson signed their landmark technology and sustainability agreement to support First Nations Fashion + Design (FNFD), each of the designers who participated in the inaugural...

January 23 2024

Since Epson signed their landmark technology and sustainability agreement to support First Nations Fashion + Design (FNFD), each of the designers who participated in the inaugural FNFD x THE ICONIC Incubator training program have now completed the unique course. Throughout and now at the end of the Incubator program, the designers had their unique designs digitised and printed by Epson via Epson digital printing solutions.

Epson’s applications and training specialist Derek Mobbs working with The Incubator program participants to help digitise and print their designs

FNFD founder and chairperson, Grace Lillian Lee, explained, “We were so lucky to have Epson’s Derek Mobbs come out and scan the artists’ paintings and digitise the files. This was done on the Epson Expression 11000XL A3 scanner, a high-resolution A3 scanner designed to meet the most demanding graphic arts applications, that Derek bought to our hub at the Powerhouse Museum. Derek then spent time knitting the images together to make a repeat print that could be printed at length on the amazing Epson ML-8000 textile printer. There was a lot of care taken by the team at Epson to respectfully adjust the prints in order for them to become textile designs, with Derek consulting with each designer to make sure that he wasn't changing the story of their artworks. First Nations artists and designers use their works as a form of storytelling and the integrity of these stories were very important to Derek and his process.”

The Epson Monna Lisa ML-8000 direct-to-fabric printer

Epson Australia MD, Craig Heckenberg said, “It is very exciting to see the work and dreams of these amazing First Nations designers become reality. We at Epson are delighted to be able to help tell their unique stories by using Epson digital printing technologies.”

FNFD x THE ICONIC Incubator Program participants watching the Epson ML-8000 print out their designs at the Epson Experience Centre in Yennora

Clearly the team at FNFD are very grateful for all the support and time provided by Epson to the winning designers who took part in The Incubator program.

FNFD’s founder and chairperson, Grace Lillian Lee and Epson Australia MD, Craig Heckenberg

Lee added, “There has been so much respect and care taken by the Epson team to make sure that the fabric is the correct format, sizing and configuration. The gifted fabric allowed the designers to play with scale and placement of their prints without price being a barrier. It also enabled them access to a large quantity of great quality fabrics for the sampling of their ranges so that they could meet quicker than usual deadlines for production and photoshoots.”

With Epson’s help the designers were able to skip the toile stage of their sampling - usually done on a plain calico to save money - to doing it immediately, in the moment and with the fabric they eventually intended to use in final production.

Grace Lee concluded, “Epson’s help, support and printing expertise has been truly invaluable. The designers were so happy with their fabrics that they ordered bigger quantities for their manufacturing component of the program. Selected pieces and designs will be stocked on THE ICONIC website from 31 January and will be showcased at the upcoming FNFD X THE ICONIC event at the China Heights Gallery in Surry Hills on the same date.”

For more on the Epson ML-8000 digital textile printer go to: www.epson.com.au/Products/IndustrialProducts/DisplayMain.asp?id=ML-8000&groupid=180

For more on FNFD go to: https://firstnationsfashiondesign.com

Computer-to-plate might be a mature market but it is far from a ‘sunset’ one. Market leader SCREEN continues to upgrade its PlateRite range of 4pp, 8pp and VLF devices and h...

January 23 2024

Computer-to-plate might be a mature market but it is far from a ‘sunset’ one. Market leader SCREEN continues to upgrade its PlateRite range of 4pp, 8pp and VLF devices and has recently passed the 20,000-mark in CtP units shipped worldwide, which includes OEM models.

Sydney January 10th 2024 - Screen GP Australia Managing Director Peter Scott notes: “The tail-end of 2023 saw a marked upsurge in our PlateRite CtP sales and requests for replacements in 2024. These were mostly via our plate-supplier partners Fujifilm and Ferag Australia. CtP today is mostly a replacement market and printers are looking for reliable, well service-backed platesetters – something we at Screen Australia pride ourselves in.”

Peter Scott: Managing Director of Screen GP Australia

Computer-to-Plate turned 30 years old in 2023 and today is virtually all-thermal since the exit of major plate manufacturers from UV violet plates – apart from newspaper CtP and a few legacy devices.

“Processless and chemistry-free plates are now the norm in the commercial CtP sector,” says Scott, “the shift to sustainable, low-emission platemaking is almost complete.”

Supporting offset printers’ platemaking since 1995

Since releasing its first CtP setter – the PlateRite 1080 in 1995 – Screen built on its fine reputation for reliable film imagesetters and replicated this with 4, 8, 16 and larger page devices. Several plate suppliers, notably Fujifilm and Agfa, turned to Screen for OEM versions of its Kyoto, Japan-made devices. In passing the 20,000 total CtP units shipped, Screen has also announced upgrades to its 4 and 8-page PlateRite machines.

The upgraded Screen PlateRite HD 8900N II uses much less power

Scott says: “ Litho offset is still the strongest print method and presses have become phenomenally automated. Packaging offset is streaking ahead for folding carton work, as printers balance the decline in commercial offset with the increase in packaged goods. This means more plate changes, more multi-colour work, more short runs. The importance of reliable, well-backed, automated and precise CtP has become all the more important – CtP becomes the heartbeat of busy offset print shops. With this in mind, Screen has upgraded its PlateRite range once again.”

The 8-page (B1) PlateRite HD 8900N series is now known as the HD 8900N II and is available in ‘E, S and Z’ versions for delivering 36, 48 or 70 plates per hour respectively. All models use GLV (Grating Light Valve) optics for uniform light distribution and ultra-high quality dot placement. Leveraging Screen’s market-leading position in photolithography for silicon wafer production, a high-precision autofocus mechanism enables the use of precision screenings such as Screen’s proprietary Spekta-2 and Randot-X FM methods.

Automatic plate loading and unloading adds to efficiency, especially in multi-press environments, with Screen’s AT-M8100N units capable of discharging plates in up to 5 directions for fully automated platemaking and delivery.

Sustainability applies in CtP too

In line with its ‘Innovation for a sustainable World’ philosophy, Screen has also managed to greatly reduce energy consumption on the new PlateRite HD 8900N II series. Taking the ‘Z’ model as an example, power consumption is reduced by 43% in operation and a massive 93% while the system is idle.

Scott adds: “Screen is totally committed to CtP and workflow, which is far from a ‘sunset’ market. We continue to invest in R&D and work with our plate partners to refine and automate plate production to an extent that it can even become a ‘hands-free’ prepress operation when auto-loaded with up to 600 B1 plates. As always, we back this up with factory-trained technicians, some with 28 years of experience, right here in the Australia-New Zealand and Pacific Islands region.

“As the new year dawns, we have experienced an unprecedented demand for CtP across all formats: four, eight and VLF page sizes up to 48-pages. New Zealand is particularly strong through our partnership with Fujifilm. Of course, Screen also has a leading position in digital printing, particularly in labels and soon to be in flexible packaging too but Offset is still the dominant print technology by both value and volume, according to a report from the Smithers group.

“This is gratifying, as Screen’s origins were in Lithography and we progressed into Offset Litho when it emerged in the early 1900s. A modern, automated offset shop is unrecognisable to those early ones and CtP production is the heartbeat of the workflow as jobs progress from design to completion. Screen GP Australia is proud to be an important part of this progress.”

After careful consideration, the owner families have decided to merge the Hunkeler Group with the Müller Martini Group. Mül...

December 12 2023

After careful consideration, the owner families have decided to merge the Hunkeler Group with the Müller Martini Group. Müller Martini Holding AG has acquired all of the shares of the Hunkeler Group. With this transaction, the Hunkeler family and Crédit Mutuel Equity have sold off all of their shares to Müller Martini. The parties have agreed not to disclose the purchase price.

Hunkeler AG and Müller Martini AG are both global market leaders with innovative solutions for post-print paper processing. Both companies focus a significant part of their innovative strength on the economical production of individualised print products within an automated smart factory.

Hunkeler and Müller Martini have been very close for many years. The long and successful history began during the 2nd World War, when Hans Müller worked for Hunkeler as a mechanical engineer before setting up his own business in 1946 by establishing the company Hans Müller / Grapha. These good relations have been maintained for decades. The local proximity in the Zofingen region of Switzerland and the already existing and successful partnership in the machine and component business form an ideal starting point for even closer cooperation in the future.By joining forces, both companies see great opportunities to bundle their innovation activities and to serve our global customer base even better in the future through joint sales and service activities. The two owner families have therefore decided on this strategic transaction that led to the acquisition of Hunkeler AG by Müller Martini AG.Bruno Müller: "The graphic arts industry is constantly changing and regularly calls for new innovations.

By combining the key components of the two companies, such as personnel, expertise and technology, we will be able to serve our global clientele even better with innovative solutions in the future." Stefan and Michel Hunkeler: "There is a long-standing partnership between Hunkeler and Müller Martini and a regular exchange. The opportunity for the merger is currently greatly beneficial for both partners and our joint customers, as it will result in considerable advantages in a combined enterprise. This is also a strong commitment for the Zofingen region."The following key points are intended to answer the most important questions and serve as a guide for day-to-day business in the coming weeks.

We are firmly convinced that print products have a promising future. Our expanded solutions portfolio as well as our even greater consultancy expertise resulting from the merger of these two great companies will better position us to address the opportunities and benefits of the ongoing digital transformation in the market. As a result, we are an even stronger partner for end-to-end finishing solutions, particularly in the growth segment of short run book production.

Leading printhead and inkjet technologies manufacturer Xaar, has announced a strategic partnership with Codpad, an inkjet coding and marking machine specialist based in Guangdong, ...

December 12 2023

Leading printhead and inkjet technologies manufacturer Xaar, has announced a strategic partnership with Codpad, an inkjet coding and marking machine specialist based in Guangdong, China.

The collaboration was formally announced at 2023 SWOP Packaging World Expo in Shanghai, where Codpad showcased its latest high-resolution UV inkjet coding machine, incorporating the Xaar Irix printhead.

The new machine is designed for a wide range of coding applications including printing on metal, plastic, cartons, wood, aluminium foil, and films and supports different subdrop volumes for extra versatility by using both the Xaar Irix 40 picolitre and 80 picolitre variants. Offering simple and effective installation and maintenance, the machine’s built-in recirculation and ink supply temperature control, enable consistent performance in dynamic environments. In addition, the machine offers multi-level UV curing for superior adhesion on products with more challenging print requirements.

The print quality, user-friendliness, and reliability of the Xaar Irix printhead made it the ideal choice for Codpad. Individually lasered nozzles and Xaar’s AcuDrp Technology ensure uniform print quality even at long print distances. In addition, its highly accurate drop placement and enhanced factory calibration provides consistent printing even during extended print runs. These advantages, together with its compact design, makes the Xaar Irix a cost-effective, highly reliable printhead for coding and marking applications.

As a subsidiary of the Docod Precision Group, Codpad boasts over two decades of expertise in the coding and marking industry. Specialising in providing comprehensive solutions for food, electronics, pharmaceuticals, plastics, construction materials and hardware, Codpad is widely recognised for its commitment to excellence.

The launch of its latest machine, with Xaar’s printhead technology, perfectly positions Codpad to become a leading provider of robust printers in the industrial coding and marking sector.

Mr. Xie Ruzhou, General Manager of Codpad, expressed enthusiasm about the collaboration, stating, “We are happy to partner with Xaar and this partnership enables us to open new possibilities in the market.

“The integration of the Xaar Irix into our high-resolution UV inkjet coding machines will elevate our product performance and market competitiveness and we are very confident that our latest product launch will offer our customers the superior coding solutions required to meet their evolving needs.”

Samuel Tam, General Manager of Xaar Asia, added, 'We are extremely excited about our collaboration with Codpad. The Xaar Irix is a leading printhead in the coding and marking industry and delivers exceptional print performance and reliability for our customers. We look forward to working together to jointly explore new market opportunities and provide end-users with the latest in high-quality coding and marking solutions.”

The team at Kissel + Wolf are thrilled to announce a major development in the printing and packaging industry, as industry veteran Bruce Caldwell has officially joined Kissel + Wol...

December 05 2023

The team at Kissel + Wolf are thrilled to announce a major development in the printing and packaging industry, as industry veteran Bruce Caldwell has officially joined Kissel + Wolf Australia as the new Sales Manager ANZ for corrugated packaging – sign and display. This strategic appointment comes as part of our ongoing commitment to innovation and growth in the dynamic world of Print & Packaging.

Bruce brings a wealth of experience and expertise to his new Kissel + Wolf Australia role. With an illustrious career spanning over 20 years, Bruce has established himself as a visionary leader in the industry. He is known for his strategic insights and unparalleled dedication to helping customers in their digital transformation.

In his new capacity, Bruce will spearhead the development of our cutting-edge digital inkjet solutions, with a primary focus on the Corrugated Packaging and the Sign and Display market across Australia and New Zealand. His profound understanding of market trends, coupled with his ability to forge strong relationships, positions Kissel + Wolf Australia to reach new heights in the industrial printing landscape.

Bruce's appointment is starting on 1. January 2024, and we welcome you to connect with him to explore and discuss the exciting possibilities that lie ahead. He can be reached at 0402 121 043 or bruce.caldwell@kiwo.com.au

"Bruce and I have worked together in the past and we have known each other for years. I am thrilled to welcome Bruce to the Kissel + Wolf family. Together, we will drive change in the corrugated packaging segment with innovative digital solutions." – Jamie Weller, Managing Director, Kissel + Wolf Australia.

Jon Field, Executive Director of Sales & Service – Digital, Kissel + Wolf Australia said, "There is no substitute for experience, knowledge and a strong customer focus. Bruce has these attributes in spades. I am personally delighted to welcome Bruce to the sales team, and I look forward to working closely with him to offer our customers a strategic competitive advantage in the sustainable, short-run, corrugated packaging market".

Mark Andy, the world’s leading manufacturer of narrow- and mid-web printing and finishing equipment with a specialty in the narrow web label industry, today announced Duane Pekar a...

December 05 2023

Mark Andy, the world’s leading manufacturer of narrow- and mid-web printing and finishing equipment with a specialty in the narrow web label industry, today announced Duane Pekar as the company's new Chief Executive Officer.

Pekar brings more than two decades of C-suite leadership experience and success across various industries, facilitating companies' growth and evolution by architecting innovative strategic plans and leadership initiatives driving bottom-line impact.

Pekar's latest role was as President and CEO of Trajus Building Products, where he steered the parent company – and its three subsidiaries, including multi-family interiors leader Republic Elite – through significant operational enhancements, resulting in a doubling of Trajus’ revenue. He held additional key leadership roles at Midstate Berkshire, FRAM Group, Honeywell, Carrier, and General Motors.

Jason Desai, the outgoing CEO of Mark Andy, expressed his gratitude for serving as CEO with an exceptional team and building relationships with valued customers. “The Board has laid out a leadership succession plan that best serves Mark Andy and our customers’ interests now and into the future. We are fully confident that Duane brings the vision and decades of experience needed to propel our company forward.” Desai will continue his involvement in Mark Andy as a member of the Board of Directors.

"Mark Andy is a true graphic and printing pioneer, and I’m thrilled to help steer this organization into the future,” says Pekar. “With its legacy in the flexographic and digital printing industry and a reputation for strong technical knowledge and customer-centric service, Mark Andy plays a leadership role in the converting industry, and I am eager to build on this legacy, spearheading innovations that will catalyze growth for our customers and business partners."

Desai adds that bringing Pekar on board signifies Mark Andy's pledge to pioneer innovation while fostering customer success. “Under Duane’s expert leadership, our company is poised to enter a new chapter of growth.”

Frame Today was founded by Michael and Lucy Tarrant in 2005 with a vision to help its customers capture the important moments in their lives. Since then, the company has helped thousands of peop...

November 22 2023

Frame Today was founded by Michael and Lucy Tarrant in 2005 with a vision to help its customers capture the important moments in their lives. Since then, the company has helped thousands of people produce stunning wall decor through inspirational picture framing design and quality workmanship. After a comprehensive evaluation process, they decided their main photo printer of choice would be the Epson SureColor P5070.

Epson SureColor P5070 photo printer in use at Frame Today

Lucy Tarrant explained, “We have fourteen stores across NSW and QLD, each with qualified picture framing consultants and each with an Epson SureColor P5070 photo printer. All work is done in-store with staff providing the expertise to guide your framing choice that enhances your valued photo, artwork, or object. Our framers undertake our framing training program and are also members of the Picture Framers Association. Thus, with these standards the photo printer we use is absolutely critical to our success and levels of service and quality.”

Epson SureColor P5070 photo printer in use at Frame Today

With one of the largest ranges of picture frame finishes, colours and timber materials to choose from, Frame Today’s professional picture framers are trained to help customers select the best framing option to suit their work and hanging location.

Tarrant continued, “At Frame Today we have strived to be the number one choice for custom framing. As a customer forward business we are always looking for ways to innovate and be a complete solution for our customers. We were on the lookout for a printer than can deliver the quality and output of the best large format printers but be compact enough that we could have them in every store. Ease of use was a must as we wanted all our staff for be able to use the printers without any issues. After considering all available options, our choice had to be the Epson SureColor P5070 photo printer.”

Epson SureColor P5070 photo printer in use at Frame Today

Frame Today are so confident in their quality of service, materials and craftsmanship that they provide every customer with a lifetime guarantee.

Tarrant continued, “The Epson SureColor P5070 photo printer has fulfilled all our requirements allowing us to print on various media, fine art and photo paper so we can offer our customers a range of options. We’re able to print up to a decent size and due to the performance of the Epson, we can offer this service to our customers with a very quick turnaround.”

According to Tarrant, Frame Today’s staff and customers are often giving them positive feedback about the results achieved with the Epson printers.

She added, “Ease of use and the high quality of prints have been the most reported feedback, even during the rollout phase. Our staff picked up the operation very quickly as you don’t need to be tech savvy to operate these printers and we still get the amazing quality output you would want from a large format high performance printer.”

Epson SureColor P5070 photo printer

Frame Today use their Epson SureColor P5070 photo printers daily in all of their stores. As a further development, with the launch of their own Print Studio brand they also successfully created a one stop shop for printing and framing in house.

Tarrant said, “We offer high quality photo and fine art printing paper finishes ensuring only the best quality prints for our customers. This way there is no need to go anywhere else as, with Print Studio and Frame Today, you can have it all, print and frame all under one roof with exceptional results guaranteed.”Customers can come in person or email a copy of their images with the size requirements to their chosen Frame Today store. A staff member sets the images up and makes them print ready, then the Epson SureColor P5070 photo printer and paper are checked, and the image is then sent to print. If the image is bring framed it will undergo an additional curing process and then it will be custom framed.

Lucy Tarrant concluded, “We are still relatively new to the printing game, but so far, we have been very impressed with the ease of use of and quality of output from the Epson SureColor P5070 photo printers and these clever printers now allow us to set the standard for the print and frame industry. We aspired to the be industry leaders and having professional high-quality printing in every store has given us a competitive edge. When you enter any of our stores you know that the person serving you is the same person trained in printing your photo or artwork and the one custom framing it. We deliver on every expectation because your cherished memories are not changing through multiple hands. We take our jobs very seriously and the Epson SureColor P5070 photo printers are a critical part of our service and success.”

Melbourne’s Tiger Corp needed to improve competitiveness and production – particularly for Braille and wayfinding signage – they turned to Total Image Supplies who had previously i...

November 22 2023

Melbourne’s Tiger Corp needed to improve competitiveness and production – particularly for Braille and wayfinding signage – they turned to Total Image Supplies who had previously installed there smaller Mutoh XpertJet 661UF UV-LED Flatbed device. Upon the release of Mutoh’s new XpertJet 1462UF UV-LED Flatbed Printer, the company could see it would be perfect for its growth plans, and ordered it immediately, becoming Australia’s first user of the technology.

Located in the tiger territory of Richmond, Tiger Corp is a provider of a broad array of retail, business, building, construction & architectural signage solutions. With over 130-year history in Melbourne, Australia Tiger Corp have always been ahead of the curve and innovation by investing in the latest and best technology available.

We live in a digital world, custom signage with a quick turnaround a main growth area. Flatbed UV with high media printability is the best way to achieve this, printing objects, braille signage and more with inks that cure hard and are durable. Tiger Corp invested in Mutoh XpertJet 661UF A2 UV-LED Flatbed Printer from Total Image Supplies a few years ago to focus on small format Braille tactile signs. The experience with this device was only positive and demand for higher productivity meant either considering a second machine or looking for a larger format more versatile solution.

When Mutoh announced the XpertJet 1462UF at FESPA Global Print Expo, Munich in May 2023, it immediately caught Tiger Corp’s attention. Here was a unique UV-LED production printer based off already successful technology capable of printing at double the speed and up to 150mm in height on an extended print area of 1420mm x 700mm. Additionally, it featured white & varnish ink for printing specialty finishes and full blockout on coloured and clear media.

Larry Sbisa, Tiger Corp Director says: “As per the smaller Mutoh printer, we were attracted to the quality of its output but also the ease of operation. Also, the ability to print raised text was vital for our Braille Tactile sign production.”

When Total Image Supplies were able to deliver the new XpertJet 1462UF in September, Tiger Corp placed an order immediately and became the first such installation in Australia – and indeed the Southern hemisphere. “We had operated other machines for many years before discovering Mutoh and it has proven to be an excellent choice. We have found Total Image Supplies and Mutoh Australia excellent to deal with, both are very responsive and knowledgeable,” says Sbisa, adding: “We are gradually moving into other markets such as retail, medical etc. Without the new Mutoh 1462UF, we have been uncompetitive for quick-short-run retail signs and expect to be able to secure more work in that space now that it is up and running, producing beautiful work.

“Based on our experience to date, we would definitely recommend these Mutoh printers and the services we get from Total Image Supplies.”

Tyson Buechler, Director Total Image Supplies comments, the Mutoh 1462UF came to market at the perfect time with many existing clients needing faster production speeds, larger bed size, all with the same reliability and unique features the Mutoh 661UF offered.

With the 1462UF now featuring dual print heads, a larger bed, and the ability to print up to 150mm thickness in CMYK plus white & varnish. We have found the Mutoh 1462UF to be a hot-ticket item and very in-demand printer for various markets such as braille and tactile signage, bespoke & niche signage, promotional print, homeware & display.”

Buechler adds: “We have already seen further sales of the device and are very excited about bringing this unique award-winning printer to the wider Australian print markets.

About the award-winning Mutoh XpertJet 1462UF

Immediately after being released the Mutoh XpertJet 1462UF UV-LED Flatbed Printer won the USA Pinnacle Product award in the UV / Latex Flatbed (under USD$70K category).

Based on the extraordinary success of the smaller format XpertJet 461UF (A3+) and 661UF(A2+) printers, the new 1462UF is a B1++ printer with extra width to enable more ‘n-up’ printing of media and objects. It features:

The Mutoh XpertJet 1462UF UV-LED Flatbed Printer is available through Total Image Supplies.

www.tigercorp.com.au

www.totalimagesupplies.com.au

November 14 2023

In the ever-evolving landscape of print and packaging, integration partnerships are key in driving efficiency and ensuring quality. With the recent launch of our Premium Integration Partnership program, we emphasize the importance of an integrated workflow when striving for productivity and processing more orders faster and better. We are delighted to award Esko, our long-lasting partner and industry-leader in prepress workflow software, the CERM Premium Integration Partner quality label. Understanding the CERM Premium Integration Partnership The CERM Premium Integration quality label represents the essence of an ideal partnership, and it challenges us to work in tandem with all our integration partners towards shared goals and top-level quality. Forging stronger ties with our industry counterparts. Welcoming Esko as premium partner isn't just adding another name to a list, but rather a joint commitment to operational excellence with an industry reference for prepress workflow software. Seamless Workflow: From Product Creation to Approval The CERM-Esko integration automates the complete process from product creation in the CERM MIS Software to the approval of the soft proof by the print buyer. This collaboration aims at eliminating tedious and time-consuming manual interventions and paving the way for a more streamlined and efficient process. One of the most significant advantages of automation, especially in a sector where precision is crucial, is the reduction of potential errors. No longer do companies have to grapple with human-induced inconsistencies. Moreover, by automating repetitive tasks, it allows prepress operators to channel their expertise where it matters most, ensuring a consistent approach in file management, naming, and storage. A Partnership Defined by Quality While each partner integration carries its unique essence and context, the CERM-Esko partnership was thoroughly analyzed in all its facets. We recognized the depth and quality of this automated workflow solution, and therefore we – quite logically - named Esko as our next Premium Integration Partner. It signifies that when two industry leaders collaborate, they produce results that are high in quality, reliable, and trustworthy. With a shared vision and a commitment to excellence, both Esko and CERM are set to redefine integration standards, ensuring that the end-users get the best of both worlds. without declaring any undue advantage or bias within the industry. It's a mark of assurance, a quality promise, and commitment to drive our industry forward. CERM has recently launched its Premium Integration Partnership program and we’re delighted to welcome Esko as our next Premium Integration Partner. The CERM Premium Integration quality label represents what could be an ideal partnership and it challenges us to work towards a common goal with all our industry partners. With Esko, we add one of our Industry leaders in prepress workflow software to our Premium Integration Partnership program. The CERM-Esko prepress integration is intended to automate the complete process from product creation in the CERM MIS Software to the approval of the soft proof by the print buyer. Automating repetitive tasks saves time and reduces errors. It also allows your prepress operators to focus on added value operations – their real expertise – with operator independent consistency in file handling, naming and storage. As each CERM partner integration has a context of its own, we have carefully reviewed the CERM-Esko partner integration in all its dimensions, and we recognize the depth and quality of this automated workflow solution. And therefore, awarding it the CERM quality label. The CERM Premium Integration Partner label serves as a badge of assurance, signifying that both parties deliver high-quality results through a proven and trusted solution – naturally - without creating any unfair advantage or bias within the industry. | ||

Kodak is proud to announce Mercury Print Productions as its first customer for the KODAK PROSPER 7000 Turbo Press. Mercury, based in Rochester, NY, USA, has chosen the fastest inkj...

November 14 2023

Kodak is proud to announce Mercury Print Productions as its first customer for the KODAK PROSPER 7000 Turbo Press. Mercury, based in Rochester, NY, USA, has chosen the fastest inkjet web press currently available on the market to significantly expand its high-volume digital printing capacity.

Mercury has been a user of KODAK PROSPER Technology Solutions since 2011, printing up to 10 million pages per day. The renowned print service provider will use the new PROSPER 7000 Turbo Press for a wide range of print jobs, including educational, trade and children’s books, personalised direct mail, marketing collateral, transactional documents as well as short to medium-run packaging requiring variable print.

A future-proof investment for the benefit of Mercury’s customersCommenting on the company’s decision to add the PROSPER 7000 Turbo Press, John Place, CEO of Mercury Print Productions, explained: “Our primary goal with this investment is to enhance our production capabilities, improve efficiency, and offer our customers a broader range of printing options. We aim to provide faster turnaround times, greater substrate flexibility and capabilities, and consistent print quality across various substrates. We needed another press as we have experienced a significant increase in demand for digitally printed products as our customers continue to look for solutions that offer offset quality while allowing for the flexibility that inkjet provides. It enables our customers to order what they need, when they need it.”

“Our experience with Kodak's technology has been highly satisfactory. Kodak has a reputation for delivering reliable and innovative printing solutions, and we have a strong working relationship with their service & support teams,” said Christian Schamberger, President, explaining Mercury’s renewed decision in favor of Kodak. “The PROSPER 7000 Turbo Press stood out for its exceptional speed, high-resolution capabilities, and versatile substrate compatibility. It aligns perfectly with our commitment to providing our customers with the best possible print quality and options. What’s more, Kodak's commitment to continuous improvement and investment in inkjet technology aligns with our long-term growth strategy.”

Utilising KODAK Stream Inkjet Technology and KODAK EKTACOLOR Inks, the PROSPER 7000 Turbo Press takes high-speed inkjet printing to a whole new level. Designed for monthly print volumes of up to 239 million A4 pages, the press offers unmatched printing speeds of up to 410 mpm (1,345 fpm) and a throughput of up to 5,523 A4 or U.S. letter pages per minute. The PROSPER 7000 Turbo Press has three optimized print modes – Quality, Performance and Turbo – which allow easy adjustment of print speed and quality to the requirements of each job, always ensuring maximum production efficiency.

A major boost to Mercury’s inkjet firepowerWith its exceptional speed and productivity, the PROSPER 7000 Turbo Press will increase Mercury’s inkjet capacity by approximately 40-50%.

“We thank our long-standing customer Mercury Print Productions for their continued confidence in Kodak's technology and our commitment to innovation. With this latest investment, Mercury takes a major leap forward in digital capacity, production versatility and business opportunities,” said Jim Continenza, Executive Chairman and Chief Executive Officer, Kodak. “The PROSPER 7000 Turbo Press, with its unmatched speed and incredible application range, enables users in wide areas of the commercial and publishing printing markets to print a wide variety of jobs more productively and profitably than ever before.”

Empowering photographers to produce the finest exhibition quality prints, Epson today launched the new 17-inch SureColorP5360 professional printer designed to meet the demanding needs of pr...

November 07 2023

Empowering photographers to produce the finest exhibition quality prints, Epson today launched the new 17-inch SureColorP5360 professional printer designed to meet the demanding needs of professional and production photographic markets.

The new Epson 17-inch SureColor P5360 professional printer

Incorporating technological breakthroughs and enhanced reliability to produce prints as the artist intended, the new printer has an improved printhead, new ink set with an extended colour gamut in dark blue hues, plus an advanced print engine for productivity boasting a higher resolution of up to 5760 x 1440 dpi and including sheet and roll capability.

Boasting a refined design, the SureColor P5360 combines an improved advanced Micro Piezo printhead with Epson’s Variable Sized Droplet Technology (VSDT). This pairing ensures the consistent production of prints with smooth tonal transitions, allowing it to reproduce intricate details captured by today’s modern high-resolution cameras.

Featuring a new 10-colour UltraChrome PRO10 ink set in high-capacity 200 ml cartridges (costing just RRP AUD$169 and NZ$189 including tax), including Violet Ink, the printer delivers an extended range of blue hues. With dedicated channels for photo and matte black inks, there’s no ink switching, helping to save time and reduce ink waste.

The printer’s built-in Carbon Black Mode increases Dmax, allowing for rich blacks and exceptional contrast on glossy paper.

Offering flexibility and increased productivity, the printer includes a built-in roll feeder, auto cutter and a high-capacity cassette that accommodates up to 100 cut sheets ranging from 8" x 10" (203 x 254 mm) to A2+ (432 x 610 mm) sheets.

In addition, to further support today’s workflows that leverage both Epson and third-party media, the SureColor P5360 includes Epson Media Installer, a software application designed to help control parameters for successful printing with a variety of media, including thick fine art papers.

By listening to market needs and incorporating customer feedback, Epson has integrated the latest printhead and ink technologies that are optimised for photography into this new printer so professional photographers can maximise productivity, reliability and consistently produce the finest exhibition-quality prints.

Designed to meet demanding needs, the SureColor P5360 is an evolution to the hugely popular SureColor P5070, adding improved reliability, deeper black density and wider colour gamut in blue hues.

Additional SureColor P5360 features include:

• Intuitive operation – a new large 4.3-inch colour LCD touchscreen and interface allows for easy setup, control and maintenance

• Expanded connectivity – Ethernet, USB and now included, Wi-Fi connectivity

• Advanced software support for enhanced productivity – includes Epson Cloud Solution PORT1 for fleet management and Epson Print Layout software for simple print production

AvailabilityThe Epson SureColor P5360 is expected to start shipping in Australia in December 2023, with a price tag of $3,495.00 (including tax) in Australia and $3,895 (including tax) in New Zealand maintaining the same price point as its predecessor, the SureColor P5070.

We are delighted to announce the appointment of Steven Badger as Canon Production Printing new Head of Sales & Professional Services across both the Large Format Graphics and Techn...

November 07 2023

We are delighted to announce the appointment of Steven Badger as Canon Production Printing new Head of Sales & Professional Services across both the Large Format Graphics and Technical Document Systems Sector within Oceania, effective Monday 30th October. Steven takes on this position after spending 7 years overseas in various positions within the Canon Production Printing Group.

As the international Product Manager, Steven spent the first half of his assignment supporting the launch of the newly developed Colorado UVgel technology, based at Canon Production Printing’s HQ in Venlo, the Netherlands. In his final years abroad, Steven was appointed Business Development Director of Large Format Graphics, for the APAC region based in Singapore.

Steven returns to Australia with over 30 years of international and local printing industry experience within the Large Format Digital printing sector, having started his career in Product Marketing, moving to Pre and Post-sales support before heading off on his International assignment. I am confident that Steven will have a positive impact on the Oceania Print industry while supporting Canon’s growth strategy.

Craig Nethercott

Managing Director | Canon Production Printing Oceania

At Kala, we know that finishing is an essential step in graphics’ production and a way to generate more profit for the shop owners. Teaching and training is crucial in a more and m...

October 31 2023

At Kala, we know that finishing is an essential step in graphics’ production and a way to generate more profit for the shop owners. Teaching and training is crucial in a more and more competitive environment.

"We are proud to have entered into this partnership with HP, as we are convinced that our large-format laminator is a valuable asset for any wrap shops and all distributors. Mistral 1650 is compatible with this latest range of printers, enabling latex to be laminated straight off the press. This means no bubbles, orange peel effect or blisters. At room temperature and with no lag time, the result is optimal," says Patrick Marillier, Managing Director of Kala

A concept shared by Johan Spies, Product Manager, Mid Volume Printing, at HP EMEA, who says: “ In the HP Graphics Experience Centre in Barcelona, we strive to bring the best out of our HP Latex printers and combining it with the best finishing solutions. We are very pleased to have the Kala Mistral 1650 laminator next to our HP Latex printers to be able to show and demonstrate the total solution to our customers. By showcasing possible workflows in our HP Graphics Experience Centre, we are now able to advise them the best possible solutions for their applications.”

A promising commercial development for Kala's "waste free laminator". A guarantee of quality and functionality, the French brand's flagship product has made all the difference. Johan Spies says: “The reason for choosing the Kala Mistral 1650 for our HP Graphics Experience Centre, is due to the ease of operation and the short time needed to set it up. This adds perfectly to the way we work and design our HP Latex products. On top, it has a small footprint, consistence quality and versatility of laminating rigid and flexible materials for a large range of applications. Overall, we are very pleased of having the great addition of the Kala Mistral 1650 laminator for our HP Latex printers in our HP Graphics Experience Centre in Barcelona.

For the short term we have multiple demos per week where customers come to Barcelona to see and work with the wide range of technologies, we have available. On the medium term we are scheduling seminars and events where we also show the laminating process with the Kala Mistral 1650 as being part of one of the many workflow solutions we are covering today in our HP Graphics Experience Centre in Barcelona.”

In Australia, Celmac sell the Kala range of finishing equipment including laminators, XY cutters, and mounting tables.

When Dayne Nankervis, CEO of leading trade printer CMYKhub, surveys the new Horizon binding line at his company’s West Heidelberg premises, it’s not only with a sense of profession...

October 31 2023

When Dayne Nankervis, CEO of leading trade printer CMYKhub, surveys the new Horizon binding line at his company’s West Heidelberg premises, it’s not only with a sense of professional excitement at its potential but also the feeling that it is symbolic of a ‘full circle’ moment.

Dayne, his siblings and cousins, spent many childhood hours sorting and collating book sections in the bindery at Impact Printing, a pioneering Melbourne print shop owned and run by Dayne’s father, Garry, and Garry’s brothers Greg and Ray.

“In particular, when school yearbooks started to come in around October each year, it was all hands on deck,” Dayne recalls.

Fast forward to November 2022, and Dayne – together with family members and most of his executive team – found themselves once again in the bindery hand collating yearbooks, “and not doing it very efficiently,” he says wryly.

“When a job comes in over a Web2Print service like ours, it’s difficult to say no, but the truth is that we were not really geared up to do book work efficiently or profitably.

“Occasionally, we would turn down a job at quoting stage because it simply wasn’t feasible, or we’d outsource the finishing – but that added time and cost to the job. More often, we would say yes, then find ourselves on the factory floor at nights and on weekend to meet the commitment.”

It’s the kind of dilemma, ironically, that CMYKhub exists to solve.

“Print is a very diverse sector, but not every print business is equipped to produce every printed product,” Dayne points out. “That’s where CMYKhub comes in – we invest so our resellers can offer the widest possible range of solutions to their customers.”

This ethos had seen CMYKhub grow into a diverse operation which offers everything from business cards and flyers, to commercial digital and offset jobs, wide-format sign and display solutions, and most recently labels. As a trade supplier, all must be supplied to the highest standards, in the shortest deadlines and at the best possible price to allow print service providers to add their own margin.

“We are continually monitoring trends to identify new ways for our resellers to grow their markets,” Dayne says. “We have grown and diversified organically over the years in response to their evolving needs, and we’ll continue to invest to support their success.”

Earlier this year, CMYKhub introduced a now-growing range of label products. Now, their sights have turned to book production, driven by a significant resurgence in demand for conventional books.

“It may seem strange in the era of the iPad and Kindle, but while there are always ebbs and flows in the annual publishing cycle we are absolutely seeing an increase in demand, particularly for short run books,” Dayne says, attributing this to the growth of self-publishing and the trend for larger publishers to print local runs of even global best-sellers on demand.

“Consumers today better understand the inherent sustainability of paper products today and appreciate that the experience of reading a physical book has real benefits. There has also been a huge resurgence of book-like products including notepads and diaries during COVID – the pandemic reminded people that print has the ability to make a powerful physical connection with absent staff and customers,” he says. “We see no sign of demand slowing.”

While CMYKhub has always technically been able to produce digital or offset books, the margins – as with most print – were tight and what little profit there may have been was quickly eaten up by the need for manual processing.

“If there’s one thing I hate, it’s inefficiency,” Dayne says grimly. “Going down to the bindery to see people hand-collating frustrated me no end.”

Eventually, with the busy end-of-year school book season looming, the company decided it was time to ‘gear up, or get out’. That’s when supplier Currie Group came up with an option too good to refuse – a hybrid Horizon binding line straight out of the showroom in Japan.

Installed in September by Currie Group engineers supported by Horizon technical specialists flown in from Japan, the new Horizon CABS4000 binding line comprises a 12-station gatherer which can handle A1 or A2 folded offset sections and a digital inserting station for pre-collated book blocks.

Once collated, sections are conveyed to a nine-clamp perfect binder which can handle both PUR and EVA glues, although CMYKhub opts for the stronger PUR finish as a default for customers. The binder can process books individually, or accumulate multiple products up to 60mm in height, before moving on to a HT-1000 variable three-knife trimming station.

Integrated weighing stations sit between sections to check for discrepancies in the collation, and a sophisticated optical inspection system with ‘auto-stop’ error detection ensures the right cover goes on the right book. In short, the system is designed to guarantee only ‘perfectly-bound books with perfectly-matched covers’ ever reach the in-built conveyor-stacker at the end of the line.

A high speed of 4000 units per hour makes this line a productive workhorse, however it’s the computer-aided binding (CAB) features which really make the difference for short-run book batches, with barcode-driven automated programming of all stations optimising set-up and job changeover times.

The new line is currently operating from a former storage area in one of the company’s West Heidelberg factories. Next year, it will be relocated with two offset presses to a brand-new factory currently under construction, forming a book production hub to service the company’s national customer base.

To ensure print capacity keeps pace with the new system, CMYKhub has lifted offset and digital production to 24 hours a day, six days a week. The intention is to streamline the system further by batch producing ‘like’ products.

“The Horizon is incredibly versatile, giving us the flexibility to choose the most efficient and profitable production method for each book project without being hampered by binding constraints,” Dayne points out.

“It will allow our resellers to support the growth of small brands and also look after larger customers by offering print-on-demand efficiencies. While the sweet spot will probably be runs between 2 – 4,000 copies, we anticipate being able to handle much shorter and much longer run lengths. Basically, we’d consider doing a single book if we can do it profitably and keep the price reasonable for our resellers.”

With the new line now in full flight producing the first of the 2023 School Yearbooks, Dayne says the company couldn’t be happier

“The addition of the Horizon binding line was very much a case of the right opportunity, at the right time, and from the right people,” says Dayne, who rates the company’s partnership with Currie Group as pivotal to their success.

“Like us, Currie Group are problem-solvers. Just as we try to support our customers success, they are always looking for ways to help us grow and diversify. Up until now, we’ve really been hampered in growing book printing, but the new Horizon from Currie Group has taken the brakes off…and given us our weekends back this summer.

“Books are back, and we are going full steam ahead!”

Scodix, the leading provider of digital print solutions for the graphic arts industry, is pleased to announce that Ricoh USA, Inc., a digital information services provider and majo...

October 31 2023

Scodix, the leading provider of digital print solutions for the graphic arts industry, is pleased to announce that Ricoh USA, Inc., a digital information services provider and major print industry player, has become a distributor for Scodix in the United States. This strategic partnership will strengthen and support Scodix in its goal of expanding market presence and providing economic and sustainable embellishment solutions to a larger network of print providers.

“This partnership is a deliberate step forward in providing maximum value to our customers, empowering them to increase the worth of their printed products,” says Gavin Jordan-Smith, Senior Vice President and General Manager, Head of Global Sales Strategy Division & RICOH Graphic Communications North America Sales, RICOH Graphic Communications. “Including Scodix embellishment solutions within our portfolio supports our competitive approach, delivering applications to the market that can catapult printers in their quest for competitive differentiation and heightened brand awareness.”

Scodix offers a variety of tools that enable brands to achieve a high level of luxury and customization in their print products and packaging. With an extensive range of top-tier embellishment options, including Smart High Definition (SHD) quality, and independently verified sustainability practices, Scodix has the capability to enhance the consumer experience, while also providing measurable economic and environmental benefits.

“Ricoh has a stellar reputation of understanding market needs in the graphic communications space, making them a perfect partner for Scodix,” said Mark Nixon, EVP Global Sales & Marketing at Scodix. “This collaboration allows us to work together to meet customer needs and create a portfolio that stands out with the goal of increasing profits through embellishment. Scodix has an easy go-to-market solution that supports the graphic arts community in providing printed products that effectively engage their audiences. With the wide range of embellishment effects achieved on a single Scodix press, we are able to offer businesses an opportunity for embellishment that was once considered too expensive. With Scodix, production costs and waste are minimized through the most sustainable methodology in the market.”

With an impressive 90%[1] of commercial printers anticipating that embellishment will play a vital role in their digital print growth strategies, Scodix' Ultra series of digital presses presents an opportunity for both in-plant and commercial print operations including book publishers, direct mail printers, prototypers, trade finishers, packaging, and folding carton printers.

The Scodix range of digital enhancement solutions seamlessly aligns with Ricoh's award-winning sheet-fed digital press portfolio. This ensures that adding Scodix to a Ricoh digital press delivers top-quality embellishments for high-end luxury prints designed to captivate attention, bolster commercial print profits, and rival both the economics and quality of conventional methods.

A global leader in pressure sensitive adhesive films, Avery Dennison Graphics Solutions, is partnering with Siser®, a leader in the world of personalisation and customisation through their premi...

October 24 2023

A global leader in pressure sensitive adhesive films, Avery Dennison Graphics Solutions, is partnering with Siser®, a leader in the world of personalisation and customisation through their premium heat-transfer products, to empower crafters across Australia and New Zealand with cutting-edge pressure-sensitive film products designed to expand crafting possibilities.

“The partnership between Avery Dennison and Siser is an exciting collaboration,” said Jordan Leach, Business Director, Graphics Solutions, Australia and New Zealand and ASEAN, Avery Dennison. “The combination of Siser’s consumer-focused expertise and our leadership in innovation and material science has created a new set of best-in-class products for the vibrant crafting community. We are proud to see Siser introduce these innovative, high-quality and industry-leading products to creative professionals and crafters across ANZ for the first time.”

This partnership is Avery Dennison's inaugural foray into the crafting industry. The Australia and New Zealand region is the first in Asia Pacific to offer the new Siser® by Avery Dennison brand, which leverages Avery Dennison’s technology leadership in pressure sensitive vinyl (PSV) and Siser's expertise in consumer crafting and heat-transfer vinyl. Crafters can harness its potential to create unique gifts and execute DIY projects suitable for indoor and outdoor environments.

Product lines under the Siser® by Avery Dennison brand include the remarkable EasyPSV® Starling™ range and the dazzling EasyPSV® Glitter collection. Crafted with precision, the EasyPSV® Starling™ range features 57 solid colours in both gloss and matte finishes, while the EasyPSV® Glitter range boasts 17 stunning glitter colours. These offerings give crafters and creative professionals an expansive pallet to manifest their artistic visions.

Some of the remarkable features that set EasyPSV® apart are its ease of use, versatility and durability. The range offers industry-leading ease of weeding1 and precise conversion on plotters. It will adhere strongly to a wide range of materials, as well as being dishwasher safe for up to 80 washes2. This sets an industry standard for resilience even in the face of frequent use.

Crafting professionals can learn where to procure these groundbreaking crafting solutions by visiting the following website: https://siseranz.com/

The new exhibition area offers customers and visitors close-up view of SCREEN’s innovative inkjet printing technology for label, commercial and packaging markets. Local MD Peter Sc...

October 17 2023

The new exhibition area offers customers and visitors close-up view of SCREEN’s innovative inkjet printing technology for label, commercial and packaging markets. Local MD Peter Scott visited the centre during Labelexpo, describing it as 'amazing.'

SCREEN Europe unveiled its new Inkjet Innovation Center (IIC) in Aalsmeer, the Netherlands, with a ‘Grand Opening’ exhibit late last month. For the first time, the leading manufacturer of inkjet digital printing equipment showcases all its series of innovative presses for label, packaging, commercial and CtP printing in one room. More than 100 customers, sales agents, partners and local community representatives attended the celebratory event at Screen Europe’s new headquarters.

SCREEN Grand opening of the IIC/HQ Sept 2023

“Establishing the IIC reflects our confidence in the status of the printing industry and Screen’s position as a leading player in the market for inkjet digital printing equipment,” said Mr. Eiji Kakiuchi, chairman Screen Holdings. He adds: “We overgrew our previous building due to our solid and steady growth in existing inkjet and CTP markets and also needed more space for the next wave of industrial inkjet digital innovations for both existing markets, such as label and commercial, as well as new markets such as flexible packaging.”

Chiyoda President Hiroyoshi Sato (L) and SCREEN GA President Yukiyoshi Tanaka confirm the PAC 830F deal.

In the 2,000m² showroom and demonstration center, visitors can explore Screen's inkjet digital printing solutions across three distinct product lines: Truepress JET for Commercial Printing and Direct Mail, Truepress LABEL for label printing, and the new Truepress PAC range for Flexible Packaging. The new IIC also showcases Screen's well-established CtP product range.

“In addition to showcasing our expanding range of digital printers, the Inkjet Innovation Center will serve as a hub for innovations in digital printing. Collaborating closely with our software and finishing partners, our aim is to provide customers with end-to-end printing solutions, offering a glimpse into the future of the printing industry,” said Osamu Yamagata, President Screen Europe.

Screen Europe was honoured to host distinguished guests, including Mr. AJ Kakiuchi, Chairman of Screen Holdings, Mr. Yukiyoshi Tanaka, President Screen Graphic Solutions, and Mr. Takanori Kakita, Advisor of Screen Graphic Solutions.

Also present was the esteemed Mayor of Aalsmeer, Mr. Gido Oude Kotte, for a momentous ribbon-cutting ceremony at the official Grand Opening event. Japanese drummers marked the occasion with a thrilling performance of traditional Taiko drums.

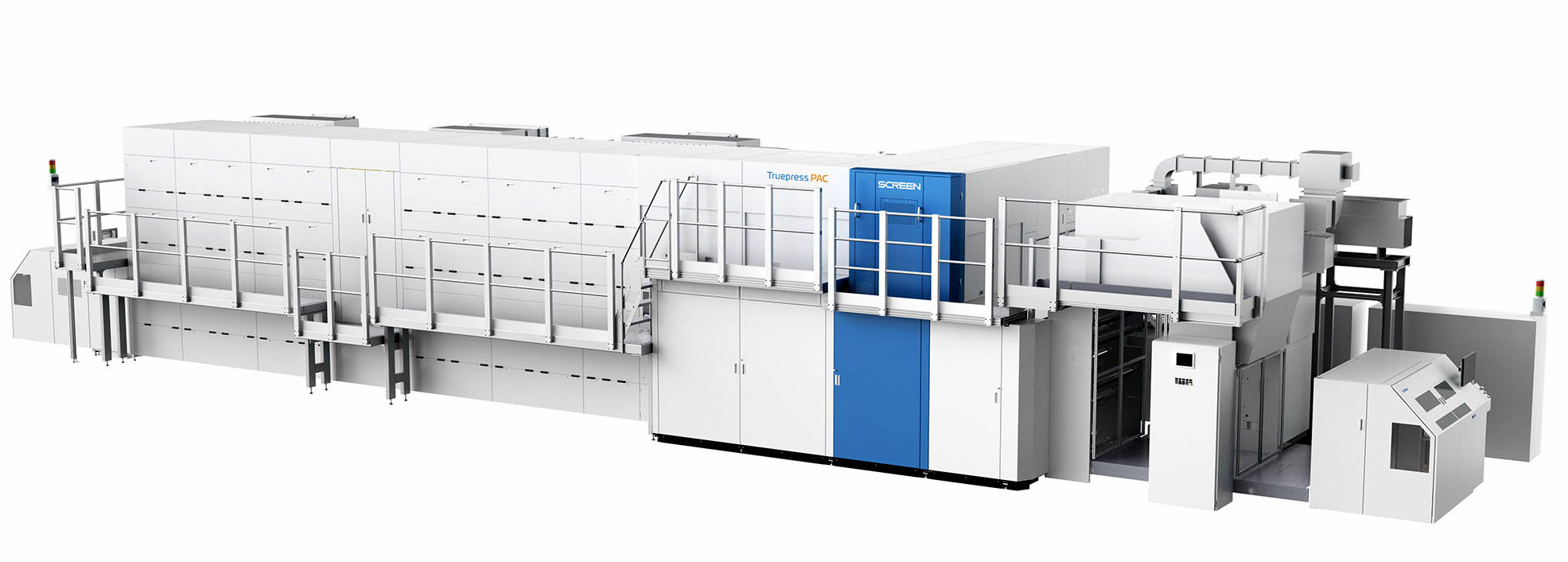

First PAC 830F flexible packaging press installed

The Screen Truepress PAC 830F, now entering the market

In other Screen news, Screen Japan and Chiyoda Gravure Printing have reached an agreement that will see them work together to drive the use of digital printing for flexible packaging materials. The initiative will use Screen's Truepress PAC 830F, a new water-based digital inkjet system that is capable of full-scale production of small to medium lot jobs, first announced in developement in 2020.

Countries worldwide have increasingly moved to create a sustainable society and the packaging industry has also seen a growing need for more environmentally - conscious production methods and greater responsibility in its supply chain. At the same time, maturing consumer preferences have also created a trend toward diversified small lot production using flexible packaging.

Pouches for pooches? Typical flexible packaging work printed inkjet on the PAC 830F - Pet food pouches

Solving the short-run issue

While gravure, and some Flexo printing has been the standard across the industry until recently, this method is best suited to large print runs. When it is used for small to medium lot work, a number of problems arise, including low productivity, significant strain on operators and considerable losses due to the discarding of unused products. Naturally, these issues have led affected companies to search for potential solutions.

Against this backdrop, Chiyoda and Screen GA have recently worked together to install the Truepress PAC 830F at Chiyoda’s facility. Screen has specifically developed this water-based digital inkjet press to enable full-scale mass production of small to medium lot jobs. Both companies have agreed to jointly drive the increased use of digital printing for flexible packaging, with the shared aims of expanding target applications for the Truepress PAC 830F as a production system, constructing an improved digital workflow, and identifying and resolving various issues that occur in small to medium lot production processes.

The two companies intend to pursue this initiative based on Chiyoda’s corporate philosophy of: “Trust, continuous growth and human resource development” as well as the Screen Group’s corporate purpose of “Innovation for a Sustainable World.” In addition to making a social contribution, they hope to upgrade the working environment at production sites for flexible packaging and deliver print quality that will make the world an evermore colorful place. The two companies cooperate closely in order to achieve the necessary technological innovations.

It is expected that a PAC 830F will be installed in the new IIC in The Netherlands, and may be exhibited at drupa 2024, late May-June in Düsseldorf, Germany.

Sales in Australia will be through Screen’s label press partner Jet Technologies

www.jet-ap.com

ENDS

Furthering its commitment to the environment and sustainability, Epson Australia has entered a new partnership with Botanic Gardens of Sydney to help address critical environmental challeng...

October 03 2023

Furthering its commitment to the environment and sustainability, Epson Australia has entered a new partnership with Botanic Gardens of Sydney to help address critical environmental challenges, with a specific focus on saving Australia’s vulnerable rainforest species.

Vulnerable rainforest species Sloanea woollsii. Photo credit: Botanic Gardens of Sydney

Epson Australia MD Craig Heckenberg explained, “Our partnership with Botanic Gardens of Sydney is deeply committed to playing a role in preventing the rapid loss of plants and the impending extinction of species impacted by the harmful myrtle rust fungal disease. This partnership aligns closely with Epson’s dedication to achieving sustainability and enriching communities. By emphasising the importance of progressing toward a nature-positive and climate-resilient nation, this further highlights Epson’s commitment to making a meaningful difference in both the environment and the communities we serve.”

Epson Australia MD Craig Heckenberg explained, “Our partnership with Botanic Gardens of Sydney is deeply committed to playing a role in preventing the rapid loss of plants and the impending extinction of species impacted by the harmful myrtle rust fungal disease. This partnership aligns closely with Epson’s dedication to achieving sustainability and enriching communities. By emphasising the importance of progressing toward a nature-positive and climate-resilient nation, this further highlights Epson’s commitment to making a meaningful difference in both the environment and the communities we serve.”

The Epson Australia team inside the award-winning Australian PlantBank conservation and research facility at the Australian Botanic Garden Mount Annan, with Dr Cathy Offord, Head of Australian PlantBank Research

Australian rainforest plant species face numerous threats, including habitat fragmentation, invasive species, diseases and the impacts of climate change. At present, there are at least 16 rainforest species that are likely to become extinct within one generation, and there are over 350 other species that are also affected by myrtle rust - a significant proportion of our unique Australian flora.

Through the partnership, Epson will be supporting the Botanic Gardens of Sydney’s research and conservation efforts, with a primary focus on the Rainforest Seed Conservation Program. This program propels innovative conservation methods for storing seeds and plant material of rainforest species, many of which cannot be conserved by traditional seedbank storage methods, making them more vulnerable to the risk of becoming threatened or extinct.

Epson’s partnership with the Botanic Gardens of Sydney will support the team at the Australian PlantBank to continue advancing the development of alternative conservation techniques, including tissue culture, cryogenic storage and living plant collections. This crucial ‘protective custody’ provides an ongoing source of material for research and enables plants to be returned to the wild as part of rewilding or restoration programs.

Amanda Rollason, Botanic Gardens of Sydney's Technical Officer, prepares plant specimens for storage in sterile tissue culture at the Australian PlantBank, an alternative to traditional seed banking. Picture credit: Botanic Gardens of Sydney.

Botanic Gardens of Sydney Chief Executive, Denise Ora, said Botanic Gardens of Sydney is a purpose driven organisation that relies on support from partners such as Epson to help achieve positive environmental outcomes through shared values in sustainability and conservation.

Epson volunteer planting session at the Australian Botanic Garden Mount Annan.

“Native Guava is a critically endangered rainforest species and with Epson’s support, our scientists will conduct critical work in developing a genetically diverse collection in tissue culture at the Australian PlantBank. This will help to secure this species in our living collections and enable a range of research outcomes aimed at eventually restoring this species in the wild to help build more resilient ecosystems for generations to come,” Ms Ora said.

Epson Australia Environment & Sustainability Manager, Fatida Un, added, “This partnership not only underscores the importance of conservation and biodiversity but also aligns seamlessly with the United Nation’s Sustainable Development Goals by promoting community education and advancing climate action.”

To celebrate the partnership, Epson employees recently joined the Botanic Gardens of Sydney’s horticulture team to help restore habitats with understorey plant species such as shrubs and grasses, which play a vital role in the natural landscape by protecting the soil and providing food and shelter for insects and animals.

Craig Heckenberg concluded, “As we collaborate with the Botanic Gardens of Sydney, we are inspired by the diverse range of initiatives they advocate for as their iconic botanic gardens, cutting-edge research facilities, powerful community engagement programs and youth education initiatives open doors for our partnership to thrive. Our new partnership will truly help Epson and the Botanic Gardens of Sydney to co-create meaningful value within our local communities.”

More about The Rainforest Seed Conservation Program

The Rainforest Seed Conservation Program aims to increase the Australian and global capacity to conserve rainforest species by improving our understanding of their biology, developing best-practice methods of conservation, and working with other conservation agencies to prevent future loss of plant species in the wild.

Follow Epson on social media:LinkedIn: @Epson-AustraliaFacebook: @EpsonAustraliaFacebook: @Epson New ZealandTwitter: @EpsonAustYouTube: @EpsonAustraliaInstagram: @EpsonAust